EmbeddedBlue 500 3

Copyright ©2003 A7 Engineering, Inc.

Table of Contents

Introduction .......................................................................................................................................... 7

Manual Conventions .......................................................................................................................... 7

eb500 Basics ........................................................................................................................................ 8

Command Mode ................................................................................................................................ 8

Data Mode ......................................................................................................................................... 8

I/O Lines............................................................................................................................................. 9

Resetting the eb500 to the Factory Default Settings......................................................................... 9

Switching between Data Mode and Command Mode ....................................................................... 9

BASIC Stamp Application Debugging ............................................................................................. 13

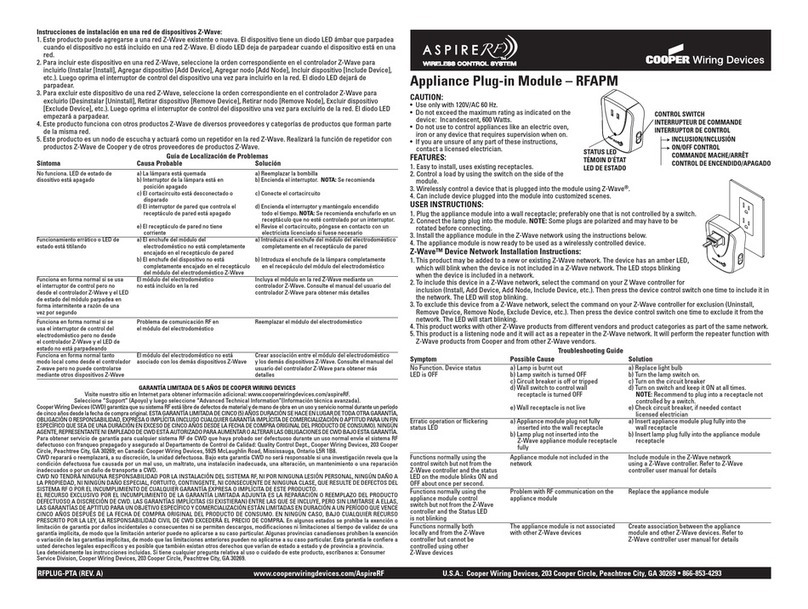

Hardware Connections ...................................................................................................................... 14

Board Of Education ......................................................................................................................... 15

Basic Stamp Activity Board.............................................................................................................. 16

BS2P40 Demo Board ...................................................................................................................... 17

Javelin Stamp Demo Board............................................................................................................. 18

SumoBoard...................................................................................................................................... 19

Super Carrier Board......................................................................................................................... 20

Establishing a Connection ................................................................................................................ 21

Connecting two eb500 Modules ...................................................................................................... 21

Connecting a PC with an eb600 to a Board of Education ............................................................... 25

Connecting a PC with a DBT-120 to a BOE.................................................................................... 28

Connecting a BOE to a PC with a DBT-120 .................................................................................... 32

Connecting an iPAQ h1940 to a Board of Education ...................................................................... 35

Connecting a Board of Education to an iPAQ h1940 ...................................................................... 37

Communications ................................................................................................................................ 40

Communicating between Two eb500 Modules................................................................................ 40

Communicating between a PC with an eb600 and a BOE.............................................................. 46

Communicating between a PC with a DBT-120 and a BOE ........................................................... 51

Communicating between an iPAQ h1940 an a BOE....................................................................... 57

eb500 Commands .............................................................................................................................. 63

Command Basics............................................................................................................................. 63

BASIC Stamp Application eb500 Command Error Handling........................................................... 64

Connect............................................................................................................................................ 65

Disconnect ....................................................................................................................................... 66

Get Address..................................................................................................................................... 67

Get Connectable Mode.................................................................................................................... 68

Get Discoverable Mode ................................................................................................................... 69

Get Escape Character ..................................................................................................................... 70

Get Flow Control.............................................................................................................................. 71

Get Link Timeout ............................................................................................................................. 72

Help.................................................................................................................................................. 73

List ................................................................................................................................................... 74

Return to Data Mode ....................................................................................................................... 75

Set Baud Rate ................................................................................................................................. 76

Set Connectable Mode .................................................................................................................... 77

Set Discoverable Mode.................................................................................................................... 78