is-69PTKH_06/09/17

INSTRUCTION SHEET

PEX Crimp Tool

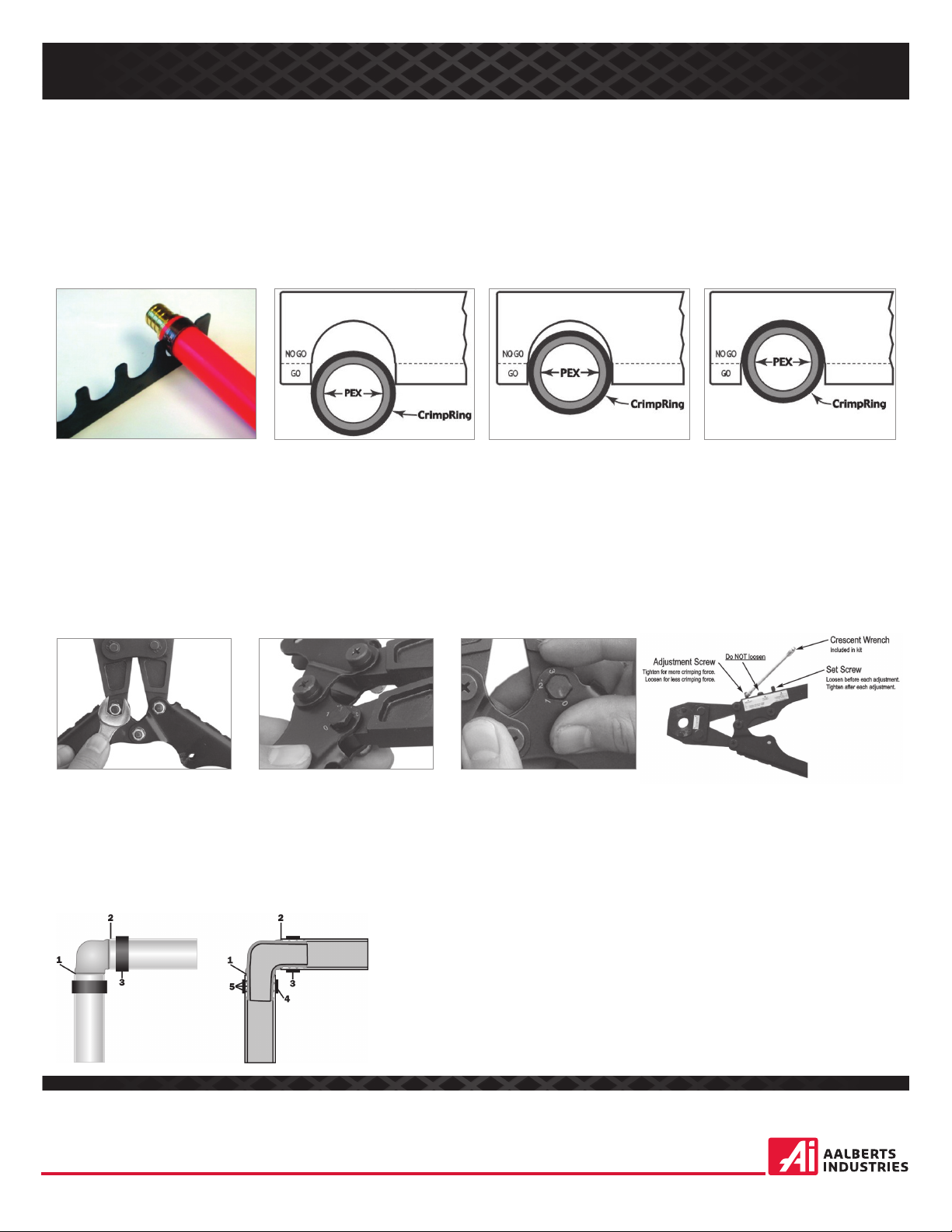

Go/No-Go Gauge

PEX

1. Slide the correct slot on the

gauge around the crimped ring.

2. If the ring does not fit into

the slot at all, then the crimp

is a“No-Go”. Adjust the

crimping force on the tool and

re-crimp the ring.

3. If the ring slides into the slot

and stops in the“Go”range at

least at one point, then the

crimp is good.The ring will

not fit the go range all the way

around it.

4. If the ring slides all the way

into the slot, then the crimp

ring is compressed too small

and is a“No-Go”. Remove the

ring and adjust the crimping

force on the tool.

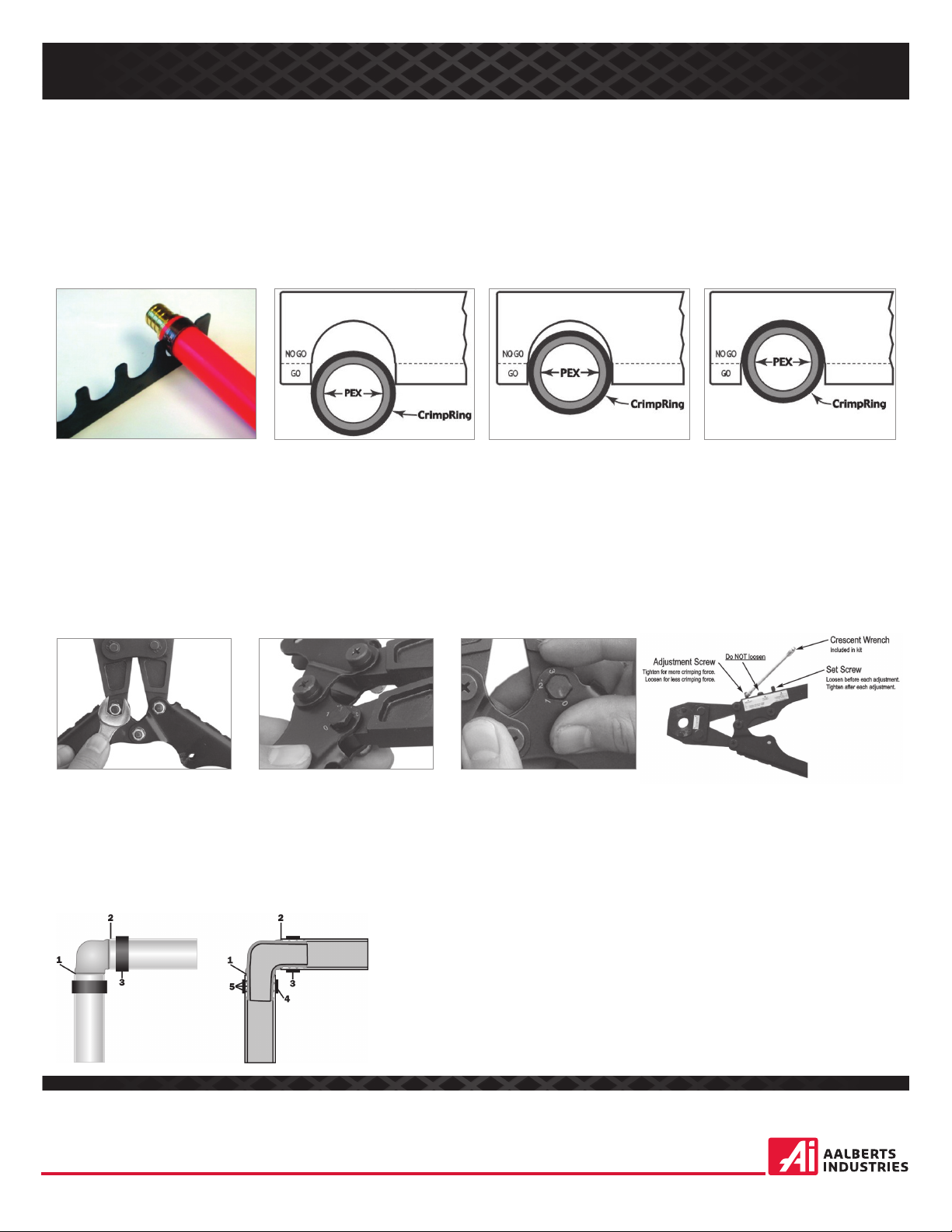

1. Open the handle, then

loosen the nut on the screw

with the numbers

surrounding it.

2. Push and rotate the screw.

Increase the number for

more crimp force. Decrease

the number for less crimp

force.

3. Push the screw back into

place and tighten the nut.

How to adjust the crimp force:

If your crimp tool has screws on the side, to

adjust the crimp force first loosen the set

screw. Next, tighten the adjustment screw

for more force or loosen the screw for less

force. Finally, tighten the set screw after

any adjustments.

Illustration of a good connection:

1. Fitting shoulder location.

2. Pipe is cut square and stops at fitting sholder.

3. Position the CrimpRing 1/8" - 1/4" from the end of the pipe, directly over two end ribs of the fitting.

4. The CrimpRing is evenly compressed over the pipe and shows no evidence of uneven distortion.

5. The PEX material is uniformly compressed between the ribs, resulting in a leak-free, quality joint.