A&E Systems 5000 Guide

1

PopRivetTool

AdjustableWrench

1/8" Drill Bit

SmallFile

Screwdriver

Electric Drill

StepLadder

3/16" Pop Rivets

Vise Grips®

SocketWrenchSet

3/16" Drill Bit

1/8" Pop Rivets

ToolsRequired:ToolsRequired:

ToolsRequired:ToolsRequired:

ToolsRequired:

TOP CASTING

AWNING

FABRIC

COTTER

PIN

MOVE LEVER POSITION TO

ROLL DOWN POSITION

RIGHT-HANDSIDE

(VIEWED FROM FRONT)

FIG. 2

Form No. 3103699.033 11/93

(Replaces 3103699.025 10/92)

©The Dometic Corp., LaGrange, IN 46761

FabricFabric

FabricFabric

Fabric RollerRoller

RollerRoller

Roller TT

TT

Tubeube

ubeube

ube

For Models 5000, 7000, 7500, 8000, 8500, 9000, 9500For Models 5000, 7000, 7500, 8000, 8500, 9000, 9500

For Models 5000, 7000, 7500, 8000, 8500, 9000, 9500For Models 5000, 7000, 7500, 8000, 8500, 9000, 9500

For Models 5000, 7000, 7500, 8000, 8500, 9000, 9500

& Grande Pavilion& Grande Pavilion

& Grande Pavilion& Grande Pavilion

& Grande Pavilion

TT

TT

Toror

oror

orsion Assembsion Assemb

sion Assembsion Assemb

sion Assembll

ll

lyy

yy

y

REPLAREPLA

REPLAREPLA

REPLACEMENT INSTRCEMENT INSTR

CEMENT INSTRCEMENT INSTR

CEMENT INSTRUCTIONS FOR AUCTIONS FOR A

UCTIONS FOR AUCTIONS FOR A

UCTIONS FOR AWNINGWNING

WNINGWNING

WNING

A. GENERAL INSTRUCTIONSA. GENERAL INSTRUCTIONS

A. GENERAL INSTRUCTIONSA. GENERAL INSTRUCTIONS

A. GENERAL INSTRUCTIONS

The Fabric Roller Tube Assembly (FRTA) consists of a

fabric, a roller tube and torsion assemblies.

For proper awning operation, the roller is under spring

tension from the torsion assemblies. Improper release ofImproper release of

Improper release ofImproper release of

Improper release of

this spring tension can result in damage to the aw-this spring tension can result in damage to the aw-

this spring tension can result in damage to the aw-this spring tension can result in damage to the aw-

this spring tension can result in damage to the aw-

ning, severe personal injury, or both.ning, severe personal injury, or both.

ning, severe personal injury, or both.ning, severe personal injury, or both.

ning, severe personal injury, or both.

Service to the FRTA should be performedService to the FRTA should be performed

Service to the FRTA should be performedService to the FRTA should be performed

Service to the FRTA should be performed

ONLYONLY

ONLYONLY

ONLY

by aby a

by aby a

by a

qualified service person.qualified service person.

qualified service person.qualified service person.

qualified service person.

Read and understand the instructions before starting the

replacementofafabric,arollertubeoratorsionassembly.

B.B.

B.B.

B. REMOREMO

REMOREMO

REMOVV

VV

VAL OFAL OF

AL OFAL OF

AL OF THE ATHE A

THE ATHE A

THE AWNING FRWNING FR

WNING FRWNING FR

WNING FROMOM

OMOM

OM THE COTHE CO

THE COTHE CO

THE COAA

AA

ACHCH

CHCH

CH

NOTE:NOTE:

NOTE:NOTE:

NOTE: Awning removal from the coach is NOT neces-

sary when replacing a torsion assembly. Proceed to

Section C, Steps 1 & 2, Sections D, Steps 1-3, and

Section L, Steps 1-3.

4. Remove both of the patio feet from their mounting

brackets and extend the adjustable arms until each

patio foot rests on the ground and lock button locks in

hole.

5. Slidetheawningfabricorrollercover outoftheawning

rail.

a. To keep the 7500, 8000, 8500, 9000, 9500 and

Grande Pavilion Model Awnings from unwinding

duringthisstep,besurethecamlockleverisinthe

rolldownposition.A1/8"cotterpincanbeinserted

ineachtorsionassembly forpositivelockingofthe

roller tube. See FIG. 2.

1. In all instances of fabric or roller tube replacement, it

will be necessary to have a large work area to allow

completeunrollingoftheawning.Thisworkareamust

becleanandsmoothsothefabricwillnotbedamaged.

2. RemovetheTEKscrewssecuringtheawningfabricor

roller cover at each end of the awning rail. See FIG. 1.

3. Removebothtopmountingbracketsontheendsofthe

awning rail. See FIG. 1

FIG. 1

1/2" TEK

SCREW

AWNING

RAIL

REMOVE FROM

BOTH SIDES

FABRIC

SECTION TOP

BRACKET

2

NOTENOTE

NOTENOTE

NOTE: Some 5000 and 7000 Model Awning torsion

assembliescannotbepinned.Ifyouhavethistype,the

torsionspringmustbeunwoundbeforetheawningcan

be removed from the coach. Follow the instructions in

Section C, Steps 1 and 2.

b. Tokeepthe5000or7000ModelAwningfromunwind-

ing, it must be pinned. See FIGS. 3 & 3A.

C.C.

C.C.

C. UNWINDING AUNWINDING A

UNWINDING AUNWINDING A

UNWINDING A TT

TT

TORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLY SPRINGY SPRING

Y SPRINGY SPRING

Y SPRING

NOTENOTE

NOTENOTE

NOTE: If the awning is installed on a coach, complete the

following steps on a step ladder, with the awning fabric

unrolled two feet from the awning rail.

1. ClampaViseGrip® tightlyonthetopcasting.Remove

the 1/4-20 hex head machine screw from the top

casting. See FIG. 4.

WW

WW

WARNINGARNING

ARNINGARNING

ARNING

Severeinjuriescanresultfromtherapidspin-offofSevereinjuriescanresultfromtherapidspin-offof

Severeinjuriescanresultfromtherapidspin-offofSevereinjuriescanresultfromtherapidspin-offof

Severeinjuriescanresultfromtherapidspin-offof

thetop casting.Use ViseGripsthetop casting.Use ViseGrips

thetop casting.Use ViseGripsthetop casting.Use ViseGrips

thetop casting.Use ViseGrips®--

--

- NEVERNEVER

NEVERNEVER

NEVER usebareusebare

use bareusebare

use bare

hands - to handle a top casting under springhands - to handle a top casting under spring

hands - to handle a top casting under springhands - to handle a top casting under spring

hands - to handle a top casting under spring

tension.tension.

tension.tension.

tension.

2. Take the top casting carefully out of the main support

arm (see NOTE below). Slowly let the torsion spring

unwindcompletely.RepeatSteps1&2fortheopposite

end.

NOTENOTE

NOTENOTE

NOTE: If the awning's right-hand torsion assembly has

been pinned (5000 & 7000 Models), the cotter pin must be

removed from the torsion assembly before the spring can

beunwound. If theawningisan 8000, 8500,9000,9500or

Grande Pavilion Model, the cam lock lever on the right-

handtorsionassemblymustbeturnedclockwise totheroll

up position, before the spring can be unwound.

MAIN SUPPORT ARM

LOCKING

TAB

FIG. 3A 7000 MODEL AWNING7000 MODEL AWNING

7000 MODEL AWNING7000 MODEL AWNING

7000 MODEL AWNINGFIG. 3 5000 MODEL AWNING5000 MODEL AWNING

5000 MODEL AWNING5000 MODEL AWNING

5000 MODEL AWNING

COTTER PIN MAIN SUPPORT ARM

LOCKING

TAB

COTTER PIN

LOCK

LEVER

TOP

CASTING

MAINSUPPORT

ARMASSEMBLY

VISE-

GRIPS®

1/4-20 X 1/2" HEX

HD. MACH. SET SCREW

FIG. 4

3

DD

DD

D..

..

.HOHO

HOHO

HOWW

WW

W TT

TT

TO REMOO REMO

O REMOO REMO

O REMOVE AVE A

VE AVE A

VE A TT

TT

TORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLYY

YY

Y

1. Make sure the torsion spring has been relieved of its

tension (see Section C.)

2. Mark or make note of the location of the fabric and the

end cap on the roller tube. This is necessary to

reposition the new torsion, fabric or roller tube exactly

the same when the new part is installed.

3. Remove the two screws holding the torsion assembly

to the roller tube. If secured by pop rivets, drill out the

tworivetsusinga3/16"drillbit.Removeassemblyfrom

roller tube. See FIG. 5.

E.E.

E.E.

E. HOHO

HOHO

HOWW

WW

W TT

TT

TO REMOO REMO

O REMOO REMO

O REMOVE FVE F

VE FVE F

VE FABRIC FRABRIC FR

ABRIC FRABRIC FR

ABRIC FROM ROM R

OM ROM R

OM ROLLEROLLER

OLLEROLLER

OLLER TUBETUBE

TUBETUBE

TUBE

1. Remove both torsions. See Section D, Steps 1-3 for

torsion removal.

2. Roll the awning completely out on a clean smooth

surface.

3. Withtheawninglayingflat,slidetherollertubeoutfrom

fabric.

NOTE: Whenremovingthefabricfrom the 9000 and 9500

Modelawning,itisnecessarytoremovethe1/8" poprivets

from both ends of the roller cover. Once the rivets are

removed,youcanslidethefabricoutofthecover. SeeFIG.

6 & 7.

FF

FF

F..

..

.INSTINST

INSTINST

INSTALLING FALLING F

ALLING FALLING F

ALLING FABRIC ON RABRIC ON R

ABRIC ON RABRIC ON R

ABRIC ON ROLLEROLLER

OLLEROLLER

OLLER TUBETUBE

TUBETUBE

TUBE

1. Unfold the new fabric and lay it on top of the existing

fabric in the exact same positionexact same position

exact same positionexact same position

exact same position. Be sure the new

fabricisthecorrectsizeandcolor.Ifrollertubeisbeing

replaced,makesureitisthecorrectlengthandposition

it the same as the original.

2. Guidetherollertubeoverthepoly-rope(s)ofthefabric.

Be careful not to damage the roller tube or the fabric.

NOTENOTE

NOTENOTE

NOTE: When changing the fabric, it is vital that the same

groove(s) be used. This eliminates the need to redrill any

holes (i.e. center support).

3. Center the fabric on the roller tube and hand-roll the

entire assembly in the same direction as the original

fabric.

G.G.

G.G.

G. FF

FF

FABRIC REPLAABRIC REPLA

ABRIC REPLAABRIC REPLA

ABRIC REPLACEMENT ON 9000CEMENT ON 9000

CEMENT ON 9000CEMENT ON 9000

CEMENT ON 9000 WITH 7 SLAWITH 7 SLA

WITH 7 SLAWITH 7 SLA

WITH 7 SLAT RT R

T RT R

T ROLLER COOLLER CO

OLLER COOLLER CO

OLLER COVERVER

VERVER

VER

RIVETS DRILLED OUT

ROLLER TUBE

FABRICUNROLLED

SLIDE OUT TORSION ASSEMBLY

FIG. 5

Installing a new replacement fabric on a Model 9000Installing a new replacement fabric on a Model 9000

Installing a new replacement fabric on a Model 9000Installing a new replacement fabric on a Model 9000

Installing a new replacement fabric on a Model 9000

roller cover with 7 slats and a vinyl strip. See FIG. 6:roller cover with 7 slats and a vinyl strip. See FIG. 6:

roller cover with 7 slats and a vinyl strip. See FIG. 6:roller cover with 7 slats and a vinyl strip. See FIG. 6:

roller cover with 7 slats and a vinyl strip. See FIG. 6:

1. Remove vinyl strip AA

AA

A(FIG. 11) and hinge slat BB

BB

B(FIG.

10) from top slat CC

CC

C(FIG. 8). Discard both vinyl strip AA

AA

A

and hinge slat BB

BB

B.

2. Remove top slat CC

CC

C(FIG. 8) from roller cover assembly

and keep to be installed later.

3. The new replacement fabric will be installed as shown

in FIG. 77

77

7.

4. Useasmallfiletoroundtheendsofthegrooveinthe

5/16" channel of the main slat DD

DD

D(FIG. 9).

5. Slidethe5/16"channelofthemainslatDD

DD

Dontothepoly-

ropelocatedapproximately12"fromthetopedgeofthe

fabric.

6. Install twopop rivets inthe main slat DD

DD

Donboth ends to

prevent the fabric from shifting in roller cover. If a new

rollercoverassemblyis being installed, a 1/8" hole will

need to be drilled 1-1/2" to 2" from end of the main slat

for the pop rivets. To prevent damage, be sure to

remove any burrs left by the drill.

7. Use a small file to round the ends of the 5/16" grooves

onthetopslatCC

CC

C(FIG.8)topreventtearingofthefabric.

SlidethetopslatCC

CC

Contoboththe1/4"channelofthefifth

main slat DD

DD

Dand the polly-rope 1-1/2" from the edge of

the fabric.

8. Install the screws into the edge of the roller cover

assembly. See FIG. 7.

4

1/4" CHANNEL

TOP SLAT "C"

VIEW RH END

MAIN SLAT "D"

VIEW RH END

HINGE SLAT "B"

INSTALL A 1/8"

POP RIVET

EACH END

D

D

D

D

D

C

INSTALL A 1/8"

POP RIVET

EACH END

D

D

D

D

D

C

VINYL STRIP "A"

E

HINGE SLAT "B"

FIG. 6FIG. 6

FIG. 6FIG. 6

FIG. 6

FIG. 7FIG. 7

FIG. 7FIG. 7

FIG. 7

E

5/16" CHANNEL

INSTALL TOWARD

CANOPY

FIG. 10FIG. 10

FIG. 10FIG. 10

FIG. 10

FIG. 9FIG. 9

FIG. 9FIG. 9

FIG. 9

FIG. 8FIG. 8

FIG. 8FIG. 8

FIG. 8

FIG. 11FIG. 11

FIG. 11FIG. 11

FIG. 11

VINYL STRIP "A"

FOR FIGS. 6—11FOR FIGS. 6—11

FOR FIGS. 6—11FOR FIGS. 6—11

FOR FIGS. 6—11

A - VINYL STRIPA - VINYL STRIP

A - VINYL STRIPA - VINYL STRIP

A - VINYL STRIP

B - HINGE SLAB - HINGE SLA

B - HINGE SLAB - HINGE SLA

B - HINGE SLATT

TT

T

C -C -

C -C -

C - TT

TT

TOP SLAOP SLA

OP SLAOP SLA

OP SLATT

TT

T

D - MAIN SLAD - MAIN SLA

D - MAIN SLAD - MAIN SLA

D - MAIN SLATT

TT

T

E - AE - A

E - AE - A

E - AWNING RAILWNING RAIL

WNING RAILWNING RAIL

WNING RAIL

FIGURES 6FIGURES 6

FIGURES 6FIGURES 6

FIGURES 6 THRTHR

THRTHR

THROUGH 11OUGH 11

OUGH 11OUGH 11

OUGH 11

5/16" CHANNEL

BOTH ENDS

1/4" CHANNEL

INSTALL TOWARD

AWNING RAIL

5/16" ROD IN

AWNING RAIL

3/8" CHANNEL

FOR VINYL

STRIP "A"

5

H.H.

H.H.

H. FF

FF

FABRIC REPLAABRIC REPLA

ABRIC REPLAABRIC REPLA

ABRIC REPLACEMENT ON 9000/9500CEMENT ON 9000/9500

CEMENT ON 9000/9500CEMENT ON 9000/9500

CEMENT ON 9000/9500 WITH 6 SLAWITH 6 SLA

WITH 6 SLAWITH 6 SLA

WITH 6 SLAT RT R

T RT R

T ROLLER COOLLER CO

OLLER COOLLER CO

OLLER COVERVER

VERVER

VER

I.I.

I.I.

I. INSTINST

INSTINST

INSTALLING NEW RALLING NEW R

ALLING NEW RALLING NEW R

ALLING NEW ROLLER COOLLER CO

OLLER COOLLER CO

OLLER COVERVER

VERVER

VER WITH 7 SLAWITH 7 SLA

WITH 7 SLAWITH 7 SLA

WITH 7 SLATS &TS &

TS &TS &

TS & VINYL STRIPVINYL STRIP

VINYL STRIPVINYL STRIP

VINYL STRIP

Installing new roller cover on 9000 model with 7 slatsInstalling new roller cover on 9000 model with 7 slats

Installing new roller cover on 9000 model with 7 slatsInstalling new roller cover on 9000 model with 7 slats

Installing new roller cover on 9000 model with 7 slats

and a vinyl strip. See FIG. 6.and a vinyl strip. See FIG. 6.

and a vinyl strip. See FIG. 6.and a vinyl strip. See FIG. 6.

and a vinyl strip. See FIG. 6.

1. Use a file to round the ends of the groove in the 5/16"

channel of the main slat DD

DD

D(FIG. 9).

K.K.

K.K.

K. REPLAREPLA

REPLAREPLA

REPLACINGCING

CINGCING

CING TT

TT

TORSION ASSEMBIESORSION ASSEMBIES

ORSION ASSEMBIESORSION ASSEMBIES

ORSION ASSEMBIES

1. Fold the poly-rope ends into the roller tube. This

preventsthefabricfromshifting.Makesuretheendsof

the poly-rope do not interfere with the cam lock.

2. Reinstall the torsion assembly in the roller tube. Align

thescrew/rivetslotsontheendcapwiththeholesinthe

rollertube-inthe exact same position as in Section D,

Step 2.

NOTENOTE

NOTENOTE

NOTE:Iftherollertubeisnew,therivetholesarenotdrilled.

The torsion assemblies must be positioned as follows:

All Models (except the 5000)All Models (except the 5000)

All Models (except the 5000)All Models (except the 5000)

All Models (except the 5000): The left-hand torsion

assembly position

has the slotted groove in the end

cap aligned with the empty groove of the roller tube.

All Models (except the 5000, 9500 & Grande Pavil-All Models (except the 5000, 9500 & Grande Pavil-

All Models (except the 5000, 9500 & Grande Pavil-All Models (except the 5000, 9500 & Grande Pavil-

All Models (except the 5000, 9500 & Grande Pavil-

ion)ion)

ion)ion)

ion):Theright-hand torsionassemblypositionhasthe

slotted groove in the end cap aligned with the empty

groove in the roller tube.

2. Slidethe5/16"channelofthemainslatDD

DD

Dontothepoly-

rope.

3. Drill a 1/8" hole 1-1/2" to 2" from end of the main slat.

Install a 1/8" pop rivet. Do both ends to secure the

fabric.

JJ

JJ

J..

..

.INSTINST

INSTINST

INSTALLING NEW RALLING NEW R

ALLING NEW RALLING NEW R

ALLING NEW ROLLER COOLLER CO

OLLER COOLLER CO

OLLER COVERVER

VERVER

VER WITH 6 SLAWITH 6 SLA

WITH 6 SLAWITH 6 SLA

WITH 6 SLATSTS

TSTS

TS

Installing new roller cover on model 9000 and 9500Installing new roller cover on model 9000 and 9500

Installing new roller cover on model 9000 and 9500Installing new roller cover on model 9000 and 9500

Installing new roller cover on model 9000 and 9500

with 6 slats. See FIG. 7.with 6 slats. See FIG. 7.

with 6 slats. See FIG. 7.with 6 slats. See FIG. 7.

with 6 slats. See FIG. 7. 1. Follow steps 1-8 in Section G.

Installing a new replacement fabric on 9000 and 9500Installing a new replacement fabric on 9000 and 9500

Installing a new replacement fabric on 9000 and 9500Installing a new replacement fabric on 9000 and 9500

Installing a new replacement fabric on 9000 and 9500

model awning roller cover with 6 slats. See FIG. 7.model awning roller cover with 6 slats. See FIG. 7.

model awning roller cover with 6 slats. See FIG. 7.model awning roller cover with 6 slats. See FIG. 7.

model awning roller cover with 6 slats. See FIG. 7. 1. Follow steps 2-8 in Section G.

EMPTYROLLER

TUBE GROOVE POLY

TUBING

SECTION

FABRIC

VEHICLESIDE VEHICLE SIDE

VIEW

FROM

REAR

VIEW

FROM

FRONT

END

CAP

LUG

FIG. 12

END

CAP

LUG

On the right-hand torsion assembly for the 9500 &On the right-hand torsion assembly for the 9500 &

On the right-hand torsion assembly for the 9500 &On the right-hand torsion assembly for the 9500 &

On the right-hand torsion assembly for the 9500 &

GrandePavilionGrandePavilion

GrandePavilionGrandePavilion

GrandePavilion:Aligntheslot inthe endcapwiththe

next slot counterclockwise (as viewed from the right

end) from the empty slot.

On the 5000 AwningOn the 5000 Awning

On the 5000 AwningOn the 5000 Awning

On the 5000 Awning: The lug on the left-hand torsion

assemblyshouldbepositionedat"11:00"andtheright-

handat"1:00"in relationshiptotheemptygroove.See

FIG. 12.

NOTENOTE

NOTENOTE

NOTE: Placing the end caps as suggested usually

positions the lock lever or lugs in the proper position

whenawning is closed. The awningshould be opened

and closed several times, and checked. The models

with the cam lock lever should be at "11:00" and the

lugs of the 5000 and 7000 models should be at the

"12:00"position.Theendcapmayhavetoberemoved

and repositioned if it is not in the proper location. See

FIG. 13.

Models 8500 and 9000 22' - 25' have been manufac-

turedwithbothstandardandheavydutytorsionsprings.

Before reinstalling the torsion, properly identify (Stan-

dardorHeavyDuty)thesprings. Thisisnecessaryfor

properwindingofthetorsion. SeeSpringIdentification

Chart on page 6.

Secure torsion assemblies to roller using 3/16" dia. x 3/8"

long stainless steel pop rivets. NOTENOTE

NOTENOTE

NOTE: DO NOT reuse self-

tapping screws.

3/8"MIN.

EXTENSION

RAFTER

ARM

TOP CASTING

MAIN

SUPP'T.

ARM

TOP MTG.

BRACKET

FIG. 13

!CAUTION

6

L.L.

L.L.

L. REWINDINGREWINDING

REWINDINGREWINDING

REWINDING TT

TT

TORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLORSION ASSEMBL

ORSION ASSEMBLY SPRINGY SPRING

Y SPRINGY SPRING

Y SPRING

2. Rewind the torsion assembly to the number of turns

indicatedby the torsion assembly Torque Chart and in

the direction shown in FIGS. 14 &15.

NOTENOTE

NOTENOTE

NOTE: If the awning is installed on a coach, complete the

following steps on a step ladder with the awning fabric

unrolled two feet from the awning rail.

1. Clamp a Vise Grip® tightly on the thickest side of the

top casting. See FIG. 4.

WW

WW

WARNINGARNING

ARNINGARNING

ARNING

Severe injury can result from the rapid spin-off of theSevere injury can result from the rapid spin-off of the

Severe injury can result from the rapid spin-off of theSevere injury can result from the rapid spin-off of the

Severe injury can result from the rapid spin-off of the

top casting. Use Vise Gripstop casting. Use Vise Grips

top casting. Use Vise Gripstop casting. Use Vise Grips

top casting. Use Vise Grips®- NEVER use bare hands- NEVER use bare hands

- NEVER use bare hands- NEVER use bare hands

- NEVER use bare hands

- to handle a top casting under spring tension.- to handle a top casting under spring tension.

- to handle a top casting under spring tension.- to handle a top casting under spring tension.

- to handle a top casting under spring tension.

3. Place a 1/8" cotter pin through the hole in the end cap

and torsion rod. This will prevent the rapid spin-off of

the top casting during installation of the awning. See

FIGS. 2, 3 & 3A.

NOTENOTE

NOTENOTE

NOTE: If awning is installed on the coach, place the top

casting in the support arm and secure with the 1/4-20 hex

head bolt.

AWNING RAIL AWNING RAIL

WIND TOP

CASTING WIND TOP

CASTING

FIG. 14 FIG. 15

RIGHT-HANDSIDE

(VIEW FROM FRONT) LEFT-HANDSIDE

(VIEW FROM REAR)

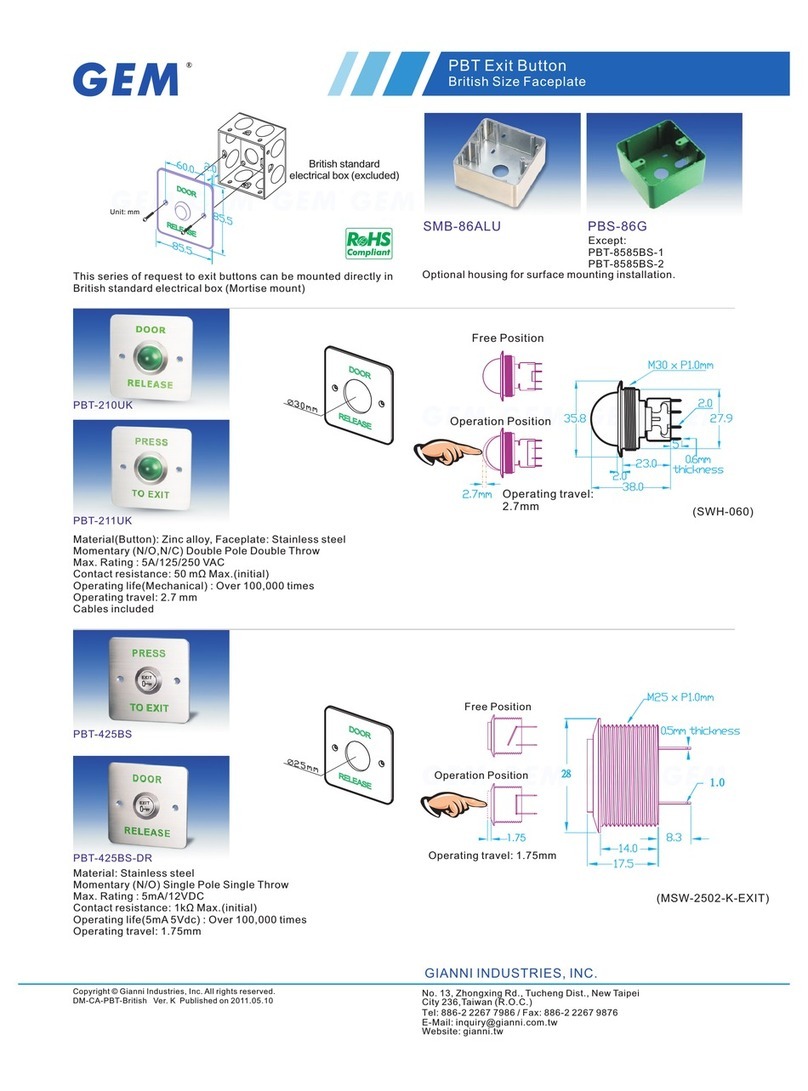

Number of Turns

MODEL NUMBER

5000 7000 7500 9500

Awning Length (Ft.) 8000 GrandePavillion

8500

9000

86-8-

96-8-

10 6 8 8 -

10'8" 6 8 8 -

11 6 8 8 -

12 6 8 8 -

13 7 9 9 -

14 7 9 9 -

15 8 10 10 -

16 8 10 10 6

16'6" - - 12 -

17 10 12 12 6

18 10 12 12 7

19 11 13 13 7

19'6" - - 13 -

20 11 13 13 -

21 11 13 13 8

22 12 - 14 8

23 12 - 14 8

24 12 - 14 9

25 12 - 14 9

TORSION ASSEMBLY TORQUE SPECIFICATIONS

1234567890

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1

23456789

0

1234567890

Paintedredcap

endandno paint

onstabilzierend.

Paintedredcap

endand whiteon

stabilzierend.

Nopaint oneither

end. Paintedwhiteon

cap end and no

paintonstabilizer

end.

Length

22' 14 8

23' 14 8

24' 14 8

25' 14 8

Wire Dia.Wire Dia.

Wire Dia.Wire Dia.

Wire Dia. .120 .140

RHRH

RHRH

RH

LHLH

LHLH

LH

StandardStandard

StandardStandard

Standard Heavy DutyHeavy Duty

Heavy DutyHeavy Duty

Heavy Duty

SPRING IDENTIFICATION CHART

TURNS OF TENSIONTURNS OF TENSION

TURNS OF TENSIONTURNS OF TENSION

TURNS OF TENSION

123456

1

2345

6

1

2345

6

123456

SeeSpring IndentificationChart for No.of Turns

M.M.

M.M.

M. INSTINST

INSTINST

INSTALLING AALLING A

ALLING AALLING A

ALLING AWNING ON COWNING ON CO

WNING ON COWNING ON CO

WNING ON COAA

AA

ACHCH

CHCH

CH

1. Follow installation instructions for the awning when replacing on coach.

This manual suits for next models

7

Table of contents

Other A&E Systems Accessories manuals

Popular Accessories manuals by other brands

Dometic

Dometic CK40D Hybrid operating manual

IFM Electronic

IFM Electronic PY2954 Operating instruction

Emmaljunga

Emmaljunga NXT Curb Lifter instruction manual

Banner

Banner K30 Pro instruction manual

Markilux

Markilux 6000 installation instructions

Zenner

Zenner INDOOR T+H SENSOR LoRa Sz204 868 ID IP40 Assembly and operating instructions

SICK

SICK TiM781 operating instructions

Hytronik

Hytronik HC403VRC-KD/I manual

Crivit

Crivit IAN 109972 instruction manual

Ellia

Ellia IMAGINE ARM-505 instruction manual

Philio Technology Corporation

Philio Technology Corporation PSP05 manual

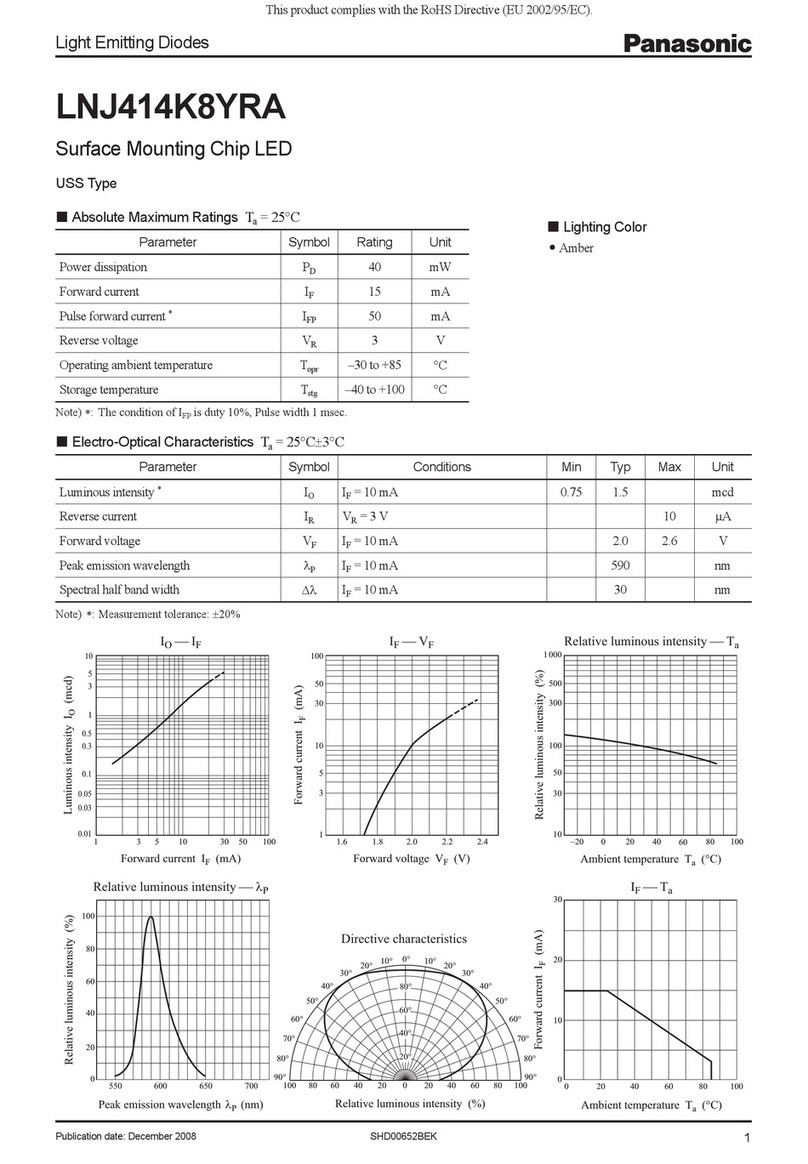

Panasonic

Panasonic Light Emitting Diodes LNJ414K8YRA Specifications