A&E Systems WeatherPro Oasis Elite User manual

1

DIAGNOSTIC

SERVICE MANUAL

Form No. 3308058.001 11/02

©2002Dometic Corporation

LaGrange, IN 46761

2

Contents PAGE NO.

WeatherPro & Oasis Elite Symptom/Cause ........................................... 3

SECTION 1- Wiring ..................................................................................4-5

1.1 12VDC Supply Wire ................................................................. 4

1.2 Wire From Control Box To Awning ................................................... 4

1.3 Wire Inside Hardware Channel (WeatherPro Only)......................... 4

1.4 Motor Connection & Motor............................................................... 4

1.5 Wire To Remote Switch ................................................................... 5

1.6 Wind Sensor Cable.......................................................................... 5

1.7 Ignition Interlock wire....................................................................... 5

SECTION 2- WeatherPro Wind Sensor ................................................... 6

2.1 Wind Sensor.................................................................................... 6

SECTION 3- Control Box.........................................................................6-7

3.1 Circuit Board ...................................................................................6-7

3.2 Control Box Rocker Switch .............................................................. 7

3.3 Wind Sensor Toggle Switch ............................................................. 7

3.4 Wiring Diagram ...............................................................................6-7

SECTION 4- Remote Switch .................................................................... 7

4.1 Remote Switch ................................................................................ 7

SECTION 5- Remote Key FOB ................................................................. 7

5.1 Remote Key FOB............................................................................. 7

5.2 FOB Programming ........................................................................... 8

SECTION 6- WeatherPro Auxiliary Cable ............................................... 8

6.1 Auxiliary Cable................................................................................. 8

SECTION 7- WeatherPro Emergency Retract Procedure.....................8-9

7.1 Emergency Retract Procedure .......................................................8-9

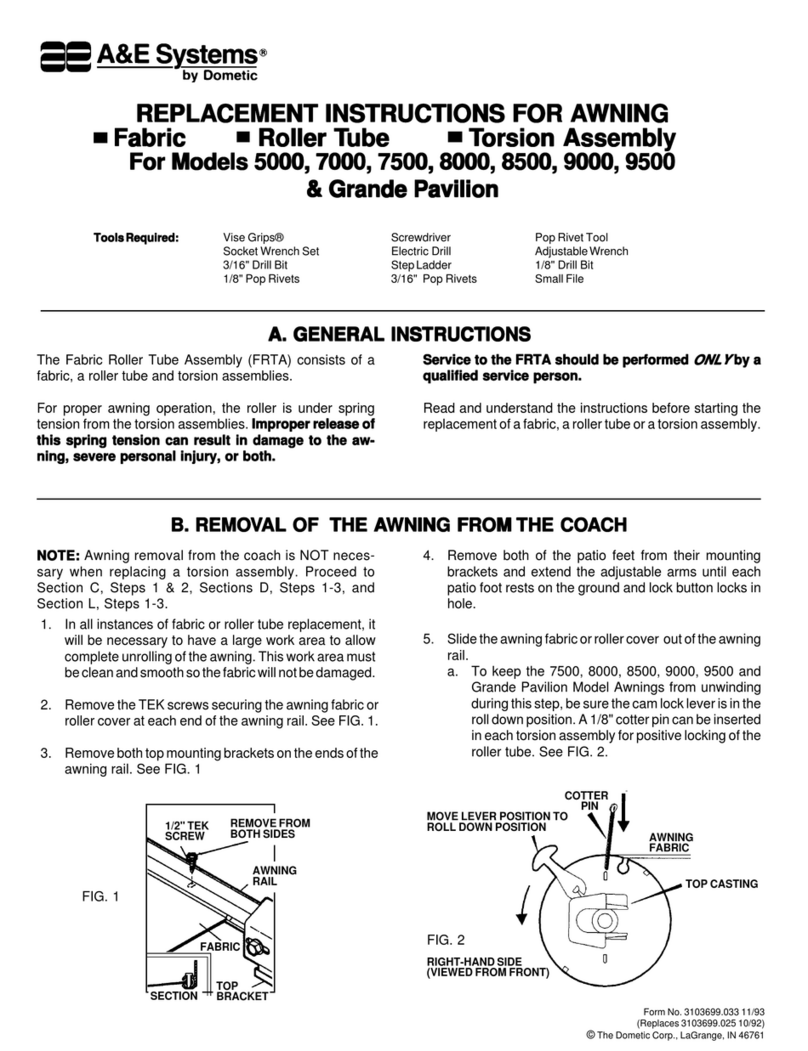

SECTION 8- WeatherPro Fabric, Roller Tube, Torsion Assembly

& Weathershield Replacement ..............................................................9-13

8.1 General Instructions ........................................................................ 9

8.2 Awning Removal............................................................................9-10

8.3 Left Hand Torsion Removal .......................................................... 10-11

8.4 Right Hand Drive Assembly Removal..............................................11

8.5 Fabric Removal From Roller Tube...................................................11

8.6 Weathershield Assembly Removal And Replacement .....................11

8.7 Re-install Fabric On Roller Tube..................................................... 12

8.8 Torsion Assembly Replacement....................................................12-13

8.9 Left Hand Torsion Assembly Winding ............................................. 13

SECTION 9- Wiring Diagram................................................................... 14

9.1 Wiring Diagram .............................................................................. 14

3

SYMPTON CAUSE LOCATION

1. Awning will not open 1. 12VDC Supply Wire Section 1.1

2. Fuse Section 3.1.3

3. Ignition Interlock (WeatherPro) Section 1.7 & 3.1.7

4. Wiring/Connections Section 1.2, 1.3, 1.4.1, 1.5 & 9.1

5. Wind (WeatherPro) Section 2.1 & 3.3

6. Circuit Board Wiring Section 3.1-3.4

7. Motor Section 1.4.2

2. Awning will not close 1. 12VDC Supply Wire Section 1.1

2. Fuse Section 3.1.3

3. Wiring/Connections Section 1.2, 1.3, 1.4, 1.5, & 9.1

4. Circuit Board Wiring Section 3.1-3.4

5. Motor Section 1.4.2

3. Awning works with remote switch 1. Distance Section 5.1

but not key FOB (WeatherPro Only) 2. Key FOB Battery Section 5.1

3. Key FOB Programming Section 5.2

4. Awning works with key FOB but not 1. Circuit Board Wiring Section 3.1.5 & 3.1.6

remote switch (WeatherPro Only) 2. Switch Section 4.1

5. Awning will open when ignition key is in 1. Wiring/Connections Section 1.7

the on position (WeatherPro Only) 2. Circuit Board Section 3.1.7

6. Awning works in opposite direction 1. Wiring/Connections Section 1.5

2. Circuit Board Wiring Section 3.1.5 & 3.1.6

3. Switch Section 4.1 & 3.2

7. WeatherPro awning works when Oasis 1. Wiring/Connections Section 1.2 & 9.1

Elite should or visa versa 2. Circuit Board Wiring Section 3.1.4

8. Awning does not close during high wind 1. Wind Sensor Switch Off Section 3.3

conditions 2. Wind Sensor Wiring Section 1.6 & 3.1.8

3. Wind Sensor Section 2.1

9. Beeping sound coming from control box 1. Wind Sensor Wiring Section 3.1.8

(WeatherPro Only) 2. Wind Sensor Section 2.1

10. Auxiliary Close/Open awning 1. No 12VDC in RV Section 6.1

(WeatherPro Only)

11. Emergency Close Awning 1. No 12VDC Available Section 7.1

(WeatherPro Only) 2. Awning Inoperable Section 7.1

12. Fabric, Roller Tube, Torsion Assembly Section 8.1- 8.9

and Weathershield Replacement

(WeatherPro Only)

4

SECTION 1 WIRING

1.1 12VDC Supply Wire

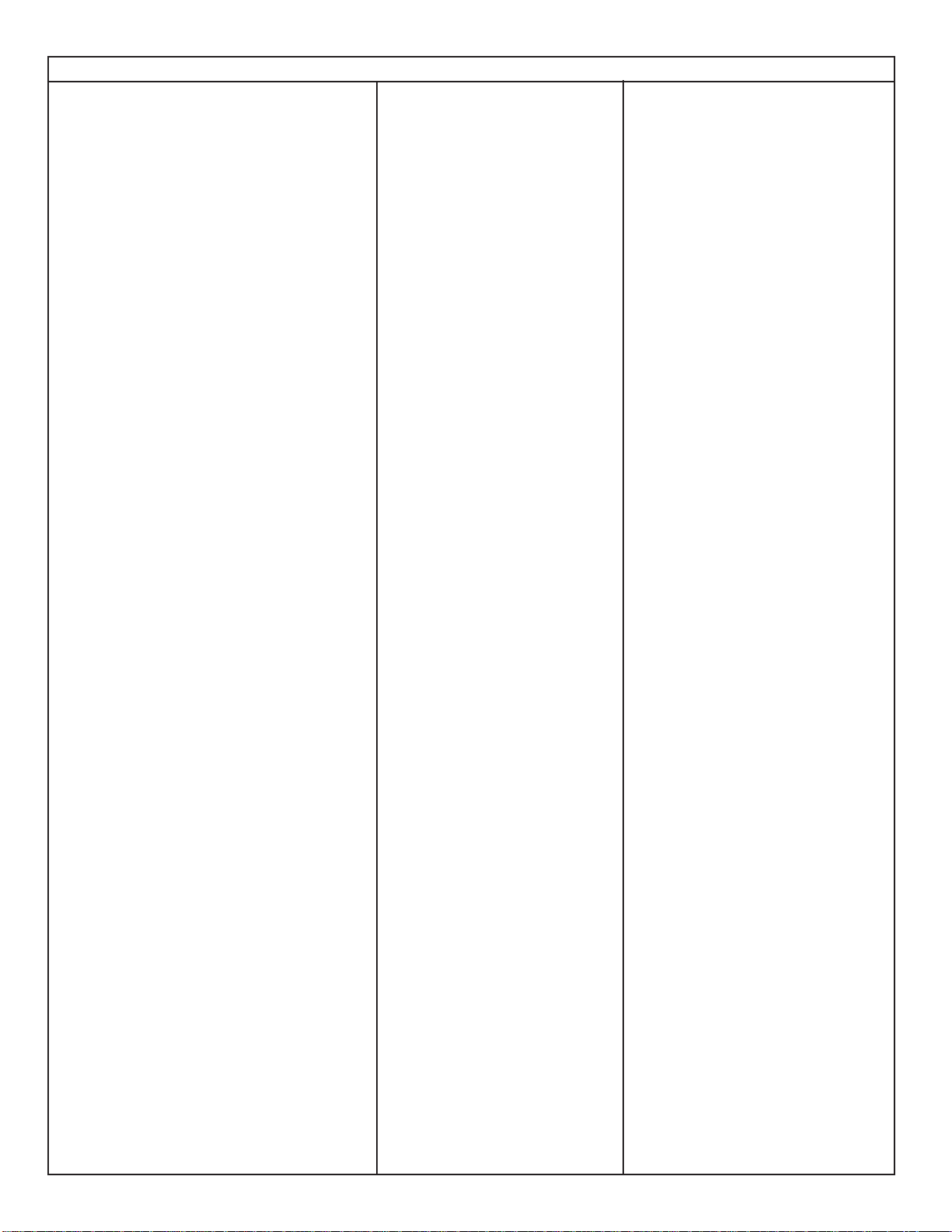

1.1.1 The 12VDC supply wire must be run from

the 12VDC supply source to the Control

Box. It is recommended that these wires

beRED+and Black–12gauge wires.This

needs to be on a separate 15 amp circuit.

See FIG. 1.1.

1.1.2 To ensure proper operation, the control

box must have a minimum of 12.5 VDC at

the control box during operation. Check

voltage output on the Red and Black wire

atthecontrolbox. If voltageisbelow 12.5,

check voltage at supply, If OK it may be

necessary to increase the wire size going

to the control box. See FIG. 1.1.

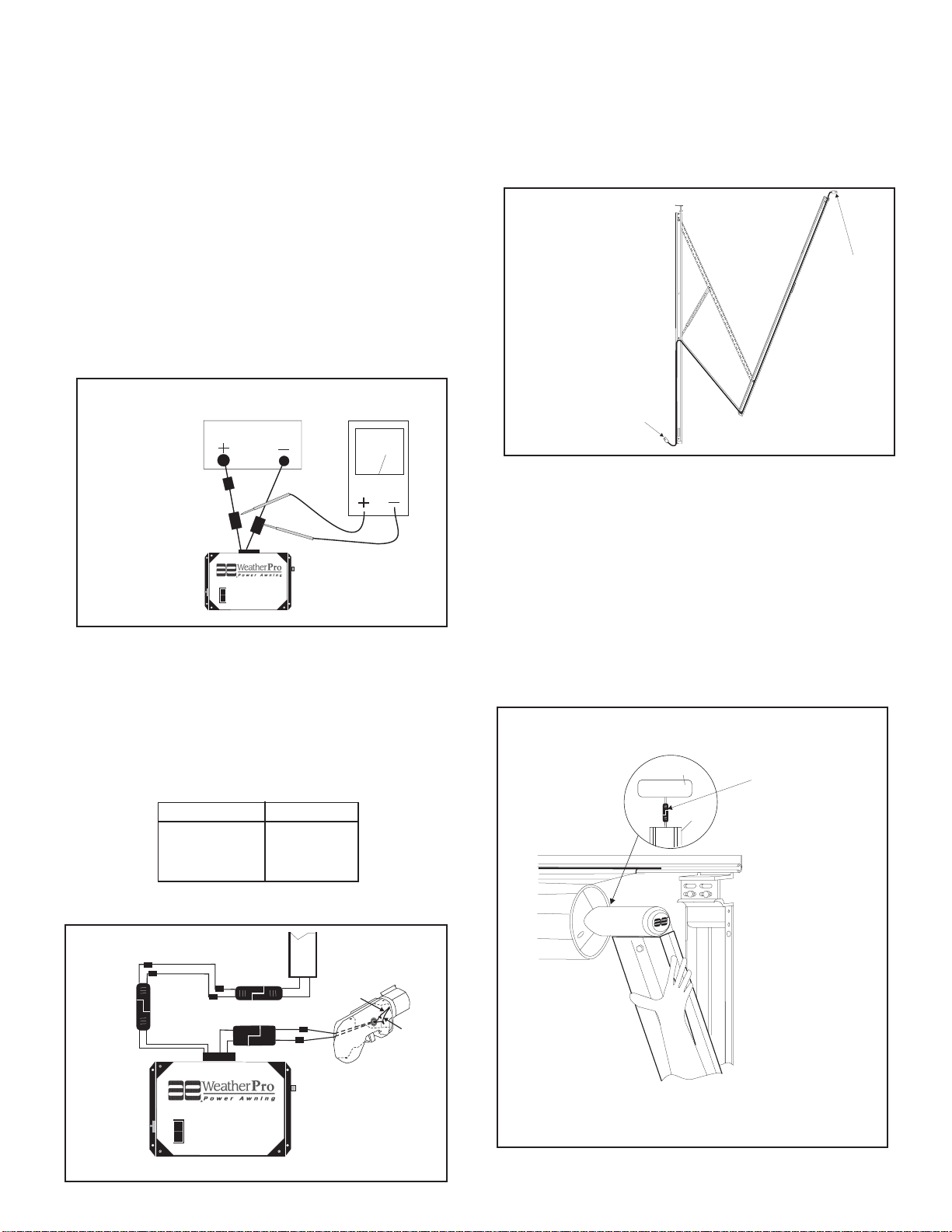

1.2 Wire From Control Box to Awning. Arm As-

sembly (WeatherPro) andAwning Motor (Oa-

sis Elite)

A Red and Black Wire (WeatherPro) Red/White

andBluewire (OasisElite)of adequatesizemust

be run between the control box and the awning.

To avoid voltage drop follow the chart below to

determining the proper size wire to be used.

Wire Length Wire Size

10' & Under 14 Gauge

11' to 30' 12 Gauge

Over 30' 10 Gauge

EXTEND

RETRACT

Awning

Control

FUSE INSIDE

WeatherPro

Main Arm

Right Side

Pig Tail to

Control Box

End

Pig Tail

for Motor

Oasis Elite

Motor

Black

Red

Red

Black

Red/White

Blue

Black

Red Blue

Red

FIG. 1.2

1.3 Wire Inside Hardware Channel (WeatherPro Only)

To make the connection between the wire run in

1.2 and the awning motor there is a cable run in

the hardware from the bottom to the top. Check

this wire for pinches or breaks. If wire is defec-

tive replace with new harness.

1.4 Motor Connection & Motor

1.4.1 The awning motor is connected to the

hardware at the top of the awning hard-

ware front channel. Make sure connec-

tion is tight and corrosion free.

1.4.2 Disconnect the motor from the hardware

connection. See FIG. 1.4. Apply DC volt-

age directly to the motor wire connector.

A minimum of 12.5 VDC is required to op-

erate the motor. If motor does not turn it is

defectiveandthedriveassemblymustbe

replaced.

FIG. 1.4

+12.5

VDC

EXTEND

RETRACT

Awning

Control

FUSE INSIDE

12VDC

Power Supply

15 AMP

Breaker

Red + Black-

FIG. 1.1

FIG. 1.3

Cable

Cable

Motor

Arm

WeatherPro

Motor Con-

nection

5

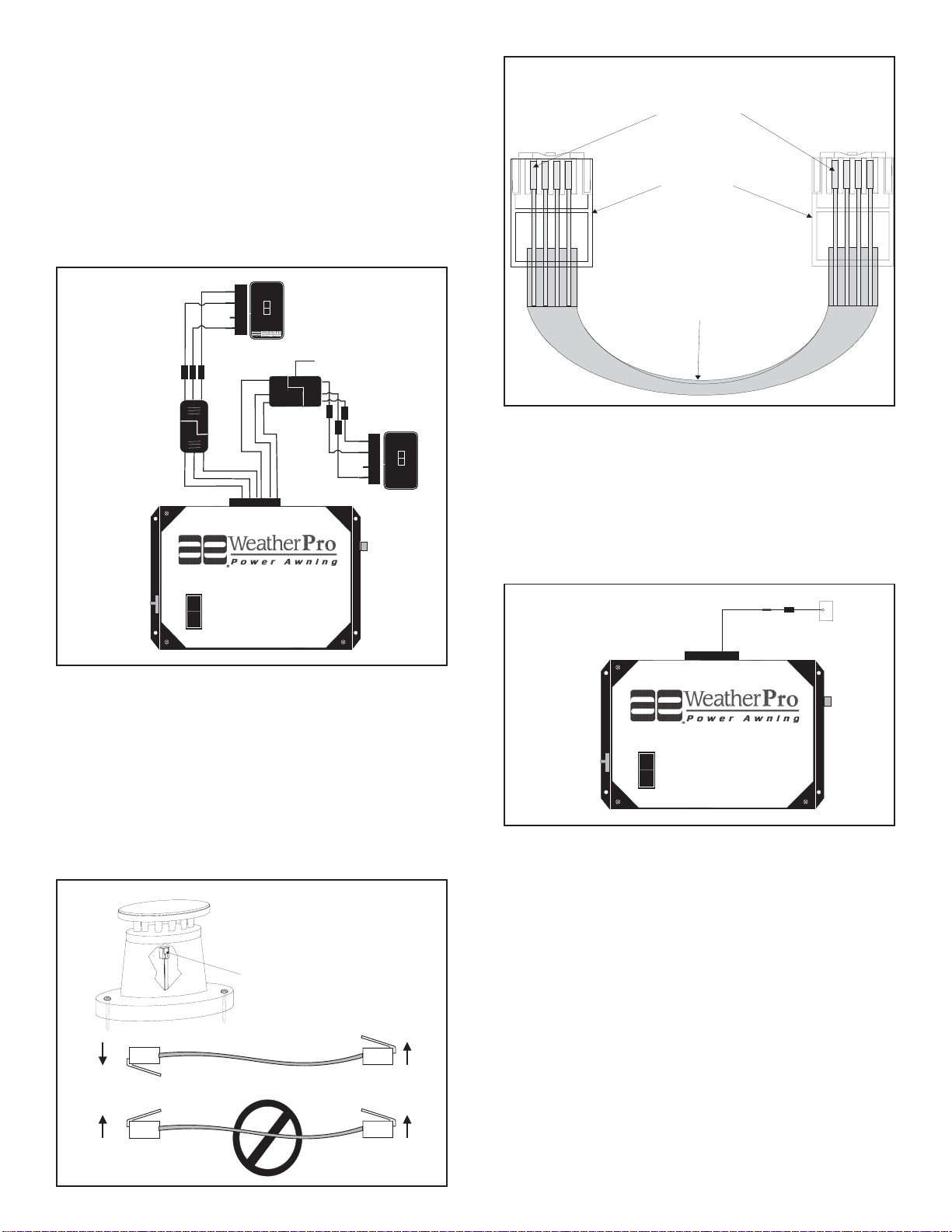

1.7 Ignition Interlock Wire

TheignitionInterlock wirewhencorrectly installed

will prevent the awning from opening when the

ignitionkeyisinthe onposition.This wireisrouted

between the ignition isolator (Pink) wire of the

control box to the ignition isolator of the vehicle.

It should be a 16 gauge wire. Make sure wire

connections are tight and corrosion free.

1.5 Wire To Remote Switch

The remote switch is connected to the control

box with three (3) 16 gauge wires. These are

Brown,Yellow,GreenforWeatherProandBrown/

White,Yellow/White,Green/WhiteforOasisElite.

The switch end of the wire will be connected to

the switch by means of 1/4" insulated tab con-

nectors. The control box end has a pig tail to

connectthecontrolbox tothesethreewires. See

switch for correct wiring. Make sure connections

are tight and corrosion free.

1.6 Wind Sensor Cable

The wind sensor is connected to the control box

with a FLAT four (4) conductor cable terminated

on both ends with an RJ-11 telephone connec-

tor. Maximum length is 18'. This cable is polarity

sensitive and must be assembled as shown. A

standard telephone cable will not work. Cable

can be checked with a Dometic 3107127.007

cable tester. If cable is found to be defective re-

place with a cable no longer than 18'

EXTEND

RETRACT

Awning

Control

FUSE INSIDE

WeatherPro

Remote

Switch

EXTEND

RETRACT

Pig Tail to

Remote Switch

Oasis Elite

Remote

Switch

Brown/White

Green/ White

Yellow/White

Green

Yellow

Brown

Green

Yellow

Brown

EXTEND

RETRACT

Brown

White

Green/ White

Yellow/White

Pig Tail to

Remote Switch

FIG. 1.5

FIG. 1.6

Red

4 Conductor

FLAT Cable

Connections

Black

Green

Yellow

Black

Green

Pin 1

RJ-11 Connector

Flat Four Conductor Cable

FIG. 1.6 cont.

Red

Yellow

EXTEND

RETRACT

Awning

Control

FUSE INSIDE

+Ignition

Isolator

Pink

FIG. 1.7

Table of contents

Other A&E Systems Accessories manuals