3

Table of Contents

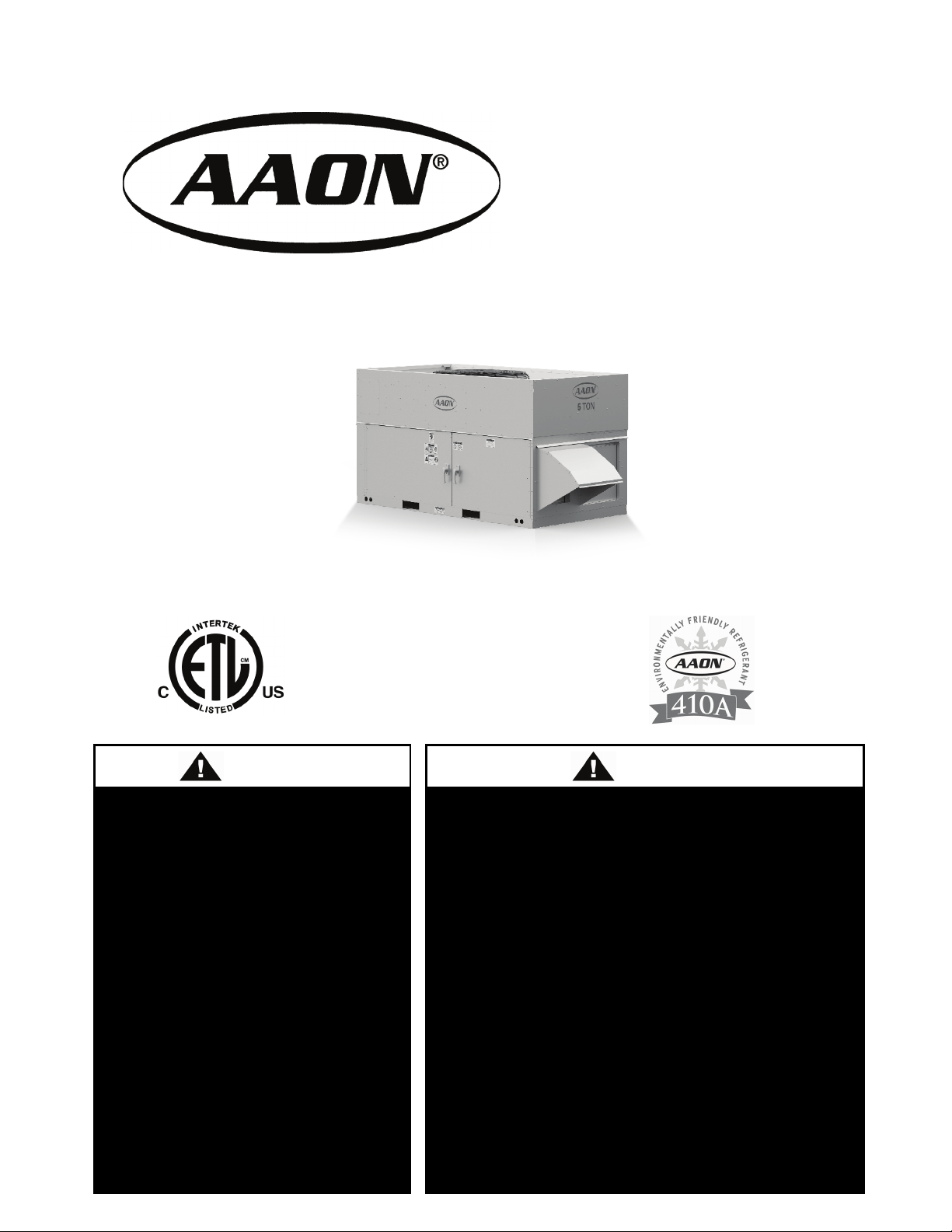

AAON®RQ Series Features and Options Introduction.................................................................. 7

Safety .............................................................................................................................................. 8

RQ Series Unified Feature String Nomenclature .................................................................... 14

General Information...................................................................................................................... 22

Codes and Ordinances .............................................................................................................. 22

Receiving Unit .......................................................................................................................... 23

Storage ...................................................................................................................................... 24

Wiring Diagrams....................................................................................................................... 24

Installation..................................................................................................................................... 24

Unit Location ............................................................................................................................ 24

Setting the Curb ........................................................................................................................ 25

Forklifting the Unit ................................................................................................................... 27

Lifting the Unit ......................................................................................................................... 28

Vertical Duct Connection ......................................................................................................... 29

Seismic Curb Installation.......................................................................................................... 30

Horizontal Duct Connection ..................................................................................................... 32

Outside Air Rain Hood ............................................................................................................. 32

Metal Mesh Filters .................................................................................................................... 33

Electrical ................................................................................................................................... 34

Variable Speed Compressors ................................................................................................ 36

Thermostat Control Wiring................................................................................................... 37

Condensate Drain Piping .......................................................................................................... 37

Draw-Through Coils ................................................................................................................. 38

Non-Compressorized Liquid and Suction Line Piping............................................................. 39

Startup........................................................................................................................................... 41

Filters ........................................................................................................................................ 41

Supply Fan EC Motor Startup .................................................................................................. 42

Adjusting Refrigerant Charge................................................................................................... 43

Checking Liquid Sub-Cooling .............................................................................................. 43

Checking Evaporator Superheat............................................................................................ 44

Adjusting Sub-cooling and Superheat Temperatures............................................................ 45

Freeze Stat Startup .................................................................................................................... 50

Condenser Fan EC Motor Startup............................................................................................. 50

Adjustable Fan Cycling Switch Procedure ............................................................................... 51

Operation....................................................................................................................................... 53

Thermostat Operation ............................................................................................................... 53

Packaged DX Cooling Operation and Control ......................................................................... 53

Gas Heater Operation................................................................................................................ 53

Electric Heating Operation ....................................................................................................... 54

Steam or Hot Water Preheating and Heating Operation........................................................... 54

Modulating Electric Preheat ..................................................................................................... 54

Chilled Water or Non-Compressorized DX Cooling Operation............................................... 54

Maintenance.................................................................................................................................. 54

Supply Fan ................................................................................................................................ 54

DX Cooling............................................................................................................................... 55

Condensate Drain Pans ............................................................................................................. 55