8

Introduction

This document provides instructions on how

the variable speed scroll compressor and

inverter drive are applied to a variable speed

compressor in a safe and reliable manner.

The variable speed scroll compressor will be

referred to throughout this document as the

“variable speed compressor” or the

“compressor”. The inverter drive will be

referred to throughout this document as the

“inverter drive”or simply the “drive”.

Variable Speed Scroll Compressors

Product Description

The variable speed compressor has a speed

range of 900 (refer to operating envelope for

low speed operation) to 5000 revolutions per

minute and is intended for use in

commercial air conditioning, chiller, and

heat pump applications. The variable speed

scrolls utilize three-phase brushless

permanent magnet (BPM) motors. The

compressors have been qualified for use

with drives which have been developed and

qualified for BPM motor-compressors.

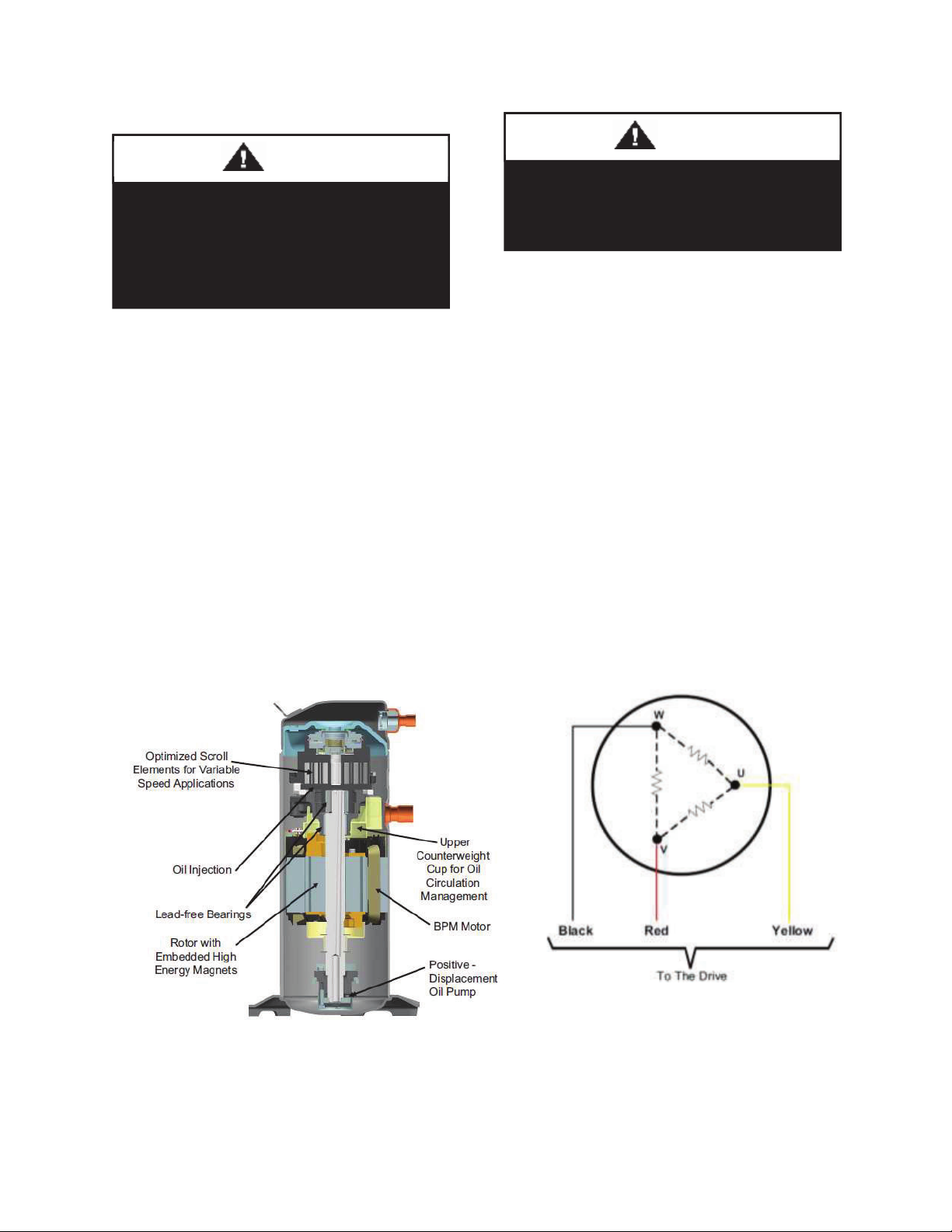

Compressor Motor

The brushless permanent magnet (BPM)

motor in the variable speed scroll consists of

a three-phase stator and a rotor embedded

with high energy permanent magnets. The

input voltage is a series of pulses of varying

frequency at 120 degree intervals between

phases.

Oil Pump

The variable speed scroll is equipped with

an oil pump to ensure an adequate supply of

oil to the bearing system throughout the

operating speed range of 900 to 5000 RPM.

Compressor Temperature Protection

A discharge line thermistor must be used to

protect the compressor. The drive will shut

down the compressor when the thermistor

temperature exceeds 275°F (135°C).

Oil Recovery

An oil recovery cycle is required if

compressor speed is below 1,800 rpm for 2

hours. When this occurs, the unit controls

will increase the compressor speed to 3,600

rpm for five minutes.

Motor Protection

The drive includes motor protection features

for the compressor. The drive sets the

maximum current limit, low voltage fold

back which allows the compressor to ride

through low voltage situations, which helps

keep the compressor running to avoid

nuisance trips.

Starting and Stopping Routine

The drive controls the starting and stopping

routine of the variable speed scroll. This

routine allows soft starting and controlled

stopping, an advantage over traditional on-

off control of fixed capacity units. Please

refer to Table 4 for an exact explanation of

the starting and stopping process.

The variable speed scroll compressor

incorporates a fluid brake design to help

mitigate reverse rotation during shutdown. A

momentary reverse rotation sound may be

heard.