Chapter 1

Introduction

1-7

The 1391-DES is generally used with computer aided, closed loop

positioning systems such as Allen-Bradley “S” Class or IMC products.

These systems control the position and linear or rotary motion of various

machine members on an automated machine. To enhance system reliability,

the 1391-DES has an encoder output (AQB) that produces four channels of

2048, 1024, 512 or 256 lines and two marker pulses per motor revolution

which feeds position information to the position controller.

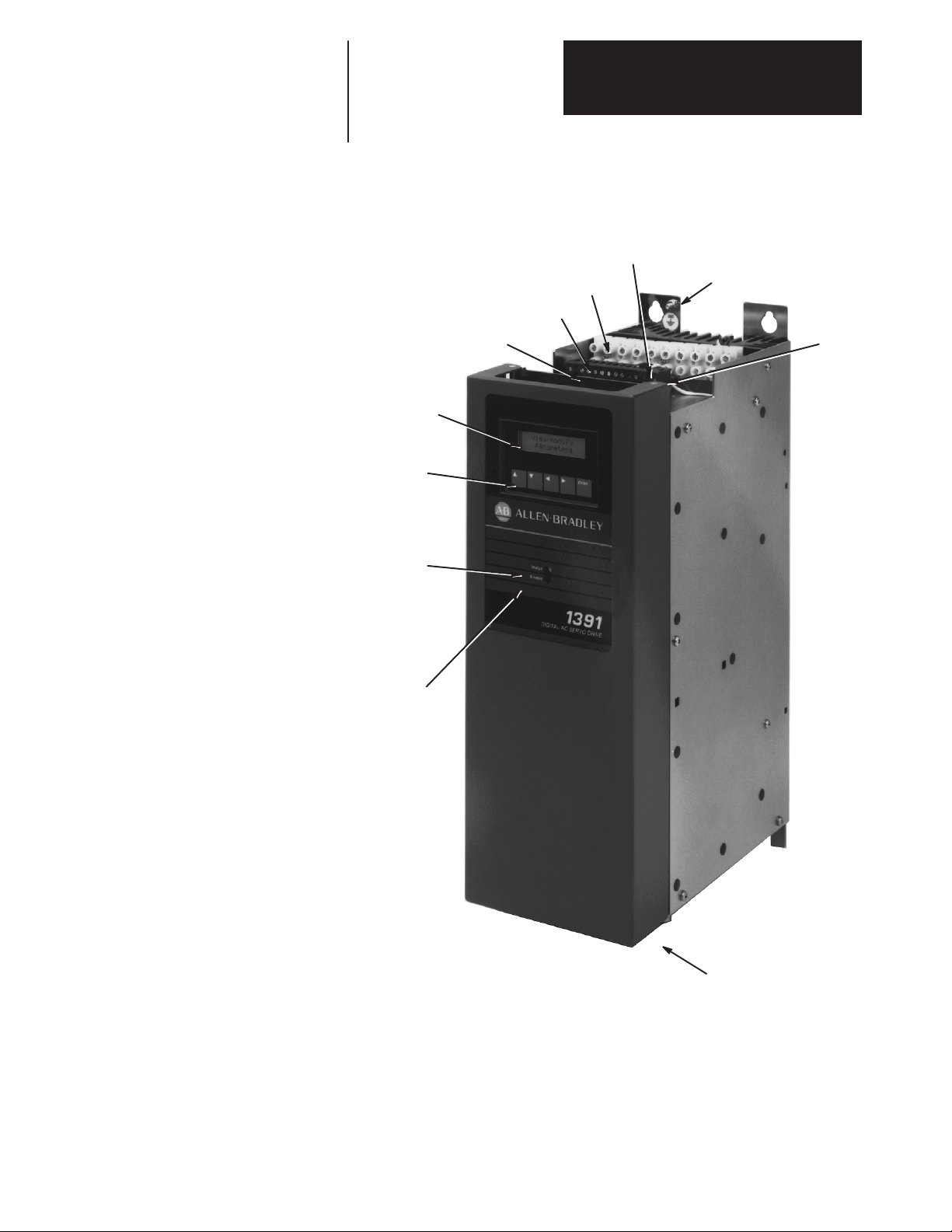

All components are mounted in an open framed package with a slide-on

front cover. The drive is intended to be panel mounted in an enclosure and

ventilated with filtered and/or cooled air. An internal fan is included to

circulate air over the power heat sink.

The 1391-DES converts a three-phase, 50/60 Hz input, to a variable AC

voltage with controlled phase, amplitude and frequency. The output which

is proportional to a user supplied analog command, regulates the speed

and/or current (torque) of a 1326 permanent magnet AC servomotor. The

drive is available in ratings of 15, 22.5 and 45A RMS with all package

sizes being identical. A 1391 Transformer, 1326 AC Servomotor and 1326

Cables complete the servo system.

Standard Features The 1391-DES contains a number of standard features required in a typical

automated machine servo system.

•Input protected against transient voltage.

•A power line/DB contactor which opens the AC line to the drive and

inserts a shunt regulator resistor across the DC bus whenever the

contactor is de-energized.

•An integral circuit breaker which will open all three AC line leads in the

event of a short circuit condition in the power circuitry.

•A standard 300V DC power bus supply that includes an integral shunt

regulator.

•A shunt regulator resistor to dissipate the energy generated by the motor

during regenerative braking.

•Prompted startup procedure to shorten setup time.

•Two line LCD display and programming panel.

•Patented current control implementation.

•Torque feedforward differential input.

•Microprocessor based logic boards that can be quickly removed and

easily interchanged for troubleshooting and diagnostics.

•Three drive ratings that are in the same physical package and have

identical mounting dimensions.

•True vector control.

•Up to 600 feet (183 meters) between drive and motor.