General Safety Operation Manual Instructions Summary:

ItisessentialtocarefullyreviewandunderstoodthisOperationManual

before operating the equipment. Failing to read and understand this

entire manual may cause injury or death to personnel, or damage to

equipment and the products that are being handled by this equipment if

not properly followed. This safety summary includes general safety

precautions and instructions that must be understoodand applied before,

during, and after operations, as well as maintenance to ensure personnel

safety and protection of equipment. Prior to performing any task, the

contentsincludedinthismanualshouldbereviewedandfullyunderstood.

This manual highlights essential operating or maintenance procedure,

practice, condition, statement, etc. that if not strictly observed, could

result in injury, or death of, personnel or long term hazards; could result

in damage to products being handled, or damage to/destruction of

equipment.

INDEX

Item Pages

I Equipment General Information................................. 1

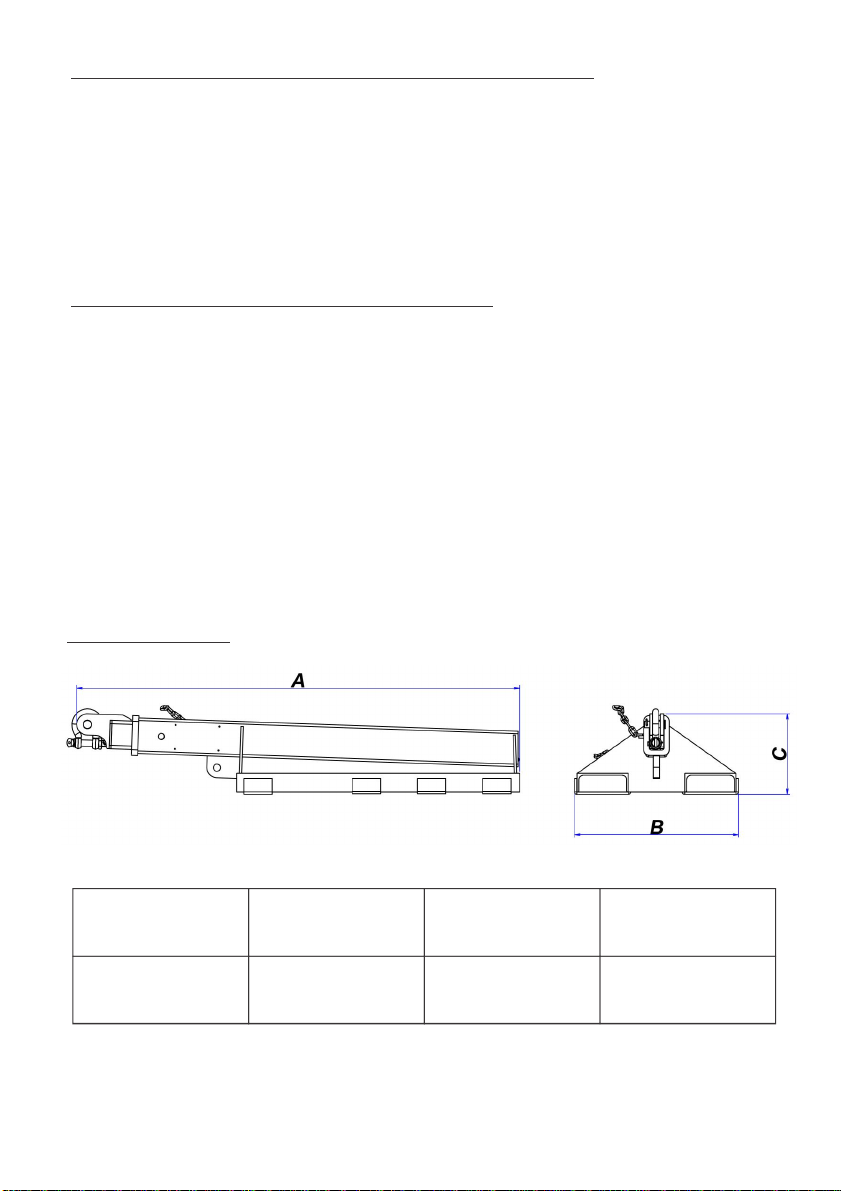

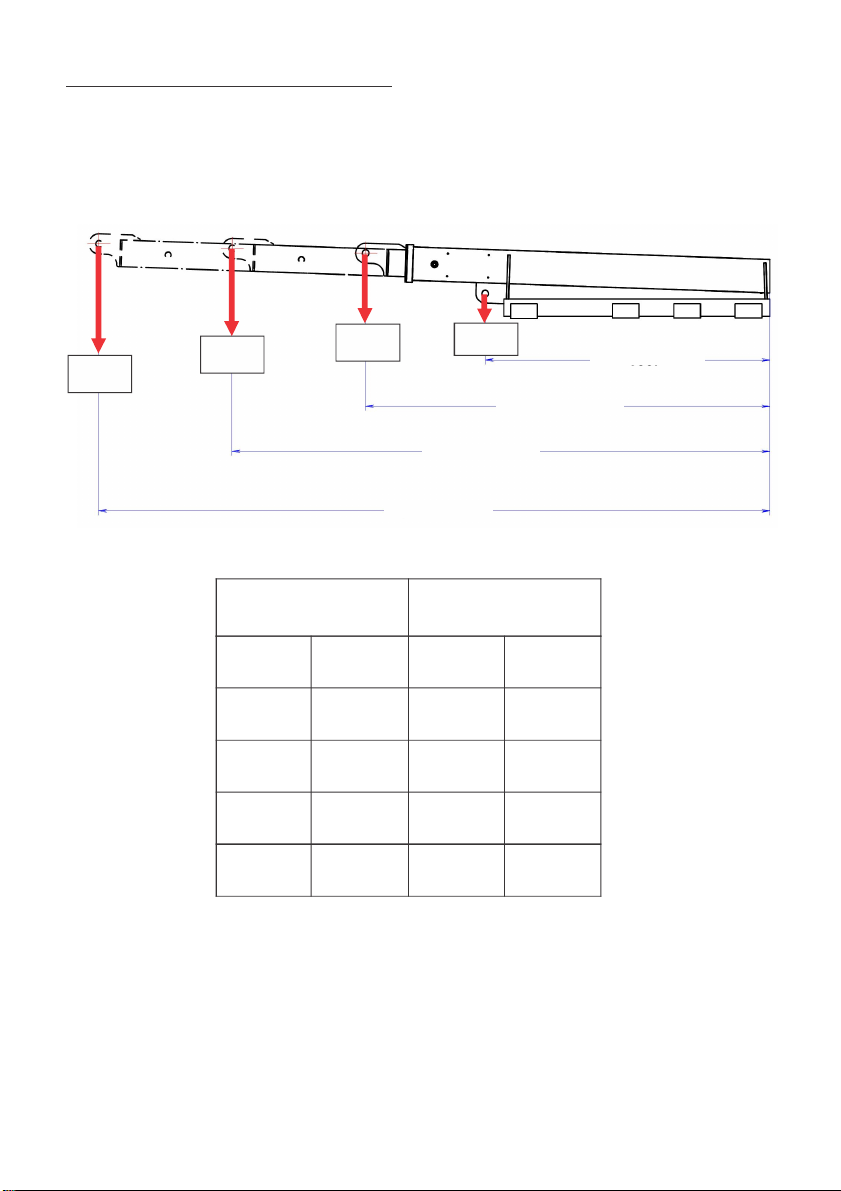

II Technical Specifications............................................ 1

1. Dimensions ........................................................... 1

2. Work Load Limit.................................................... 2

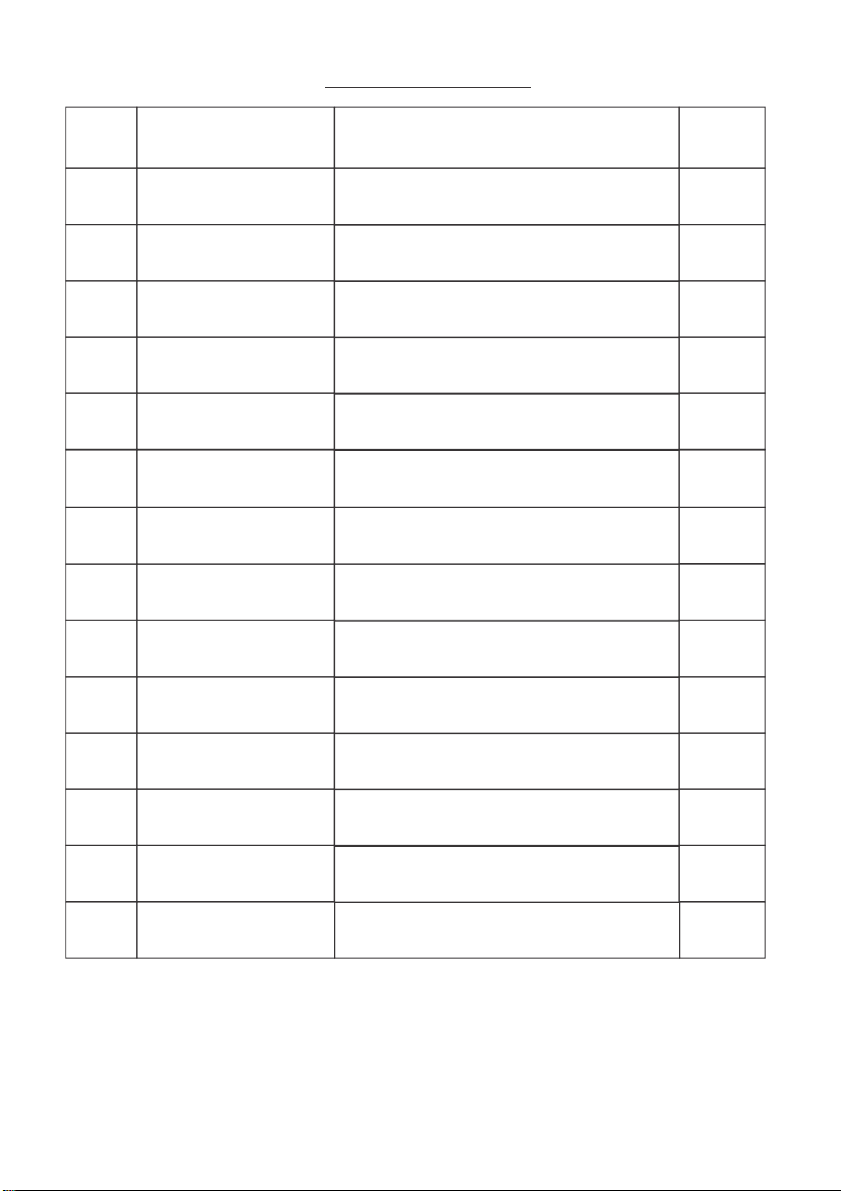

3. Spare part list......................................................... 3

Safety Instructions...................................................... 5III

1. General Warnings, Cautions and Notes.................. 5

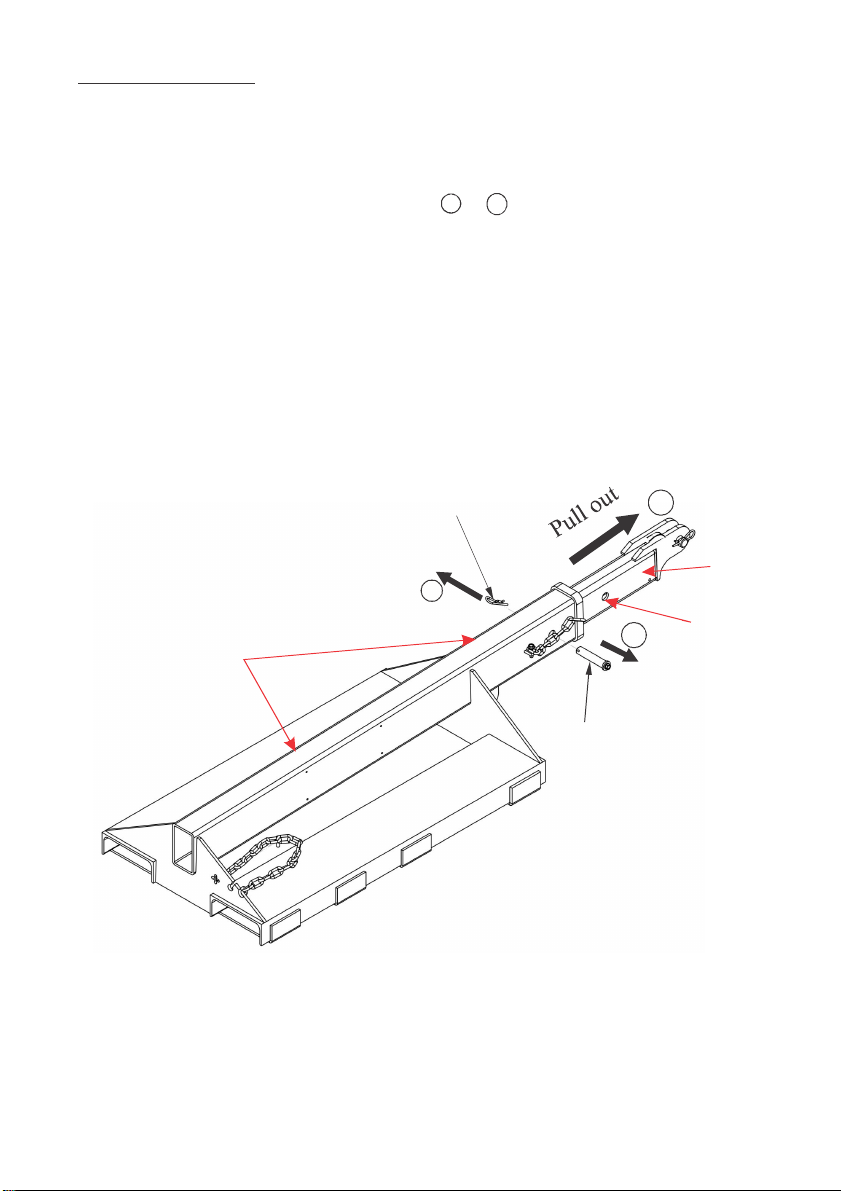

2. Device usage.......................................................... 6

IV Appendix.................................................................... 8

V Technical problems & Solutions................................ 9

VI Inspection & Maintenance.......................................... 9

VII Warranty Policy...........................................................10

Warranty Certificate....................................................11