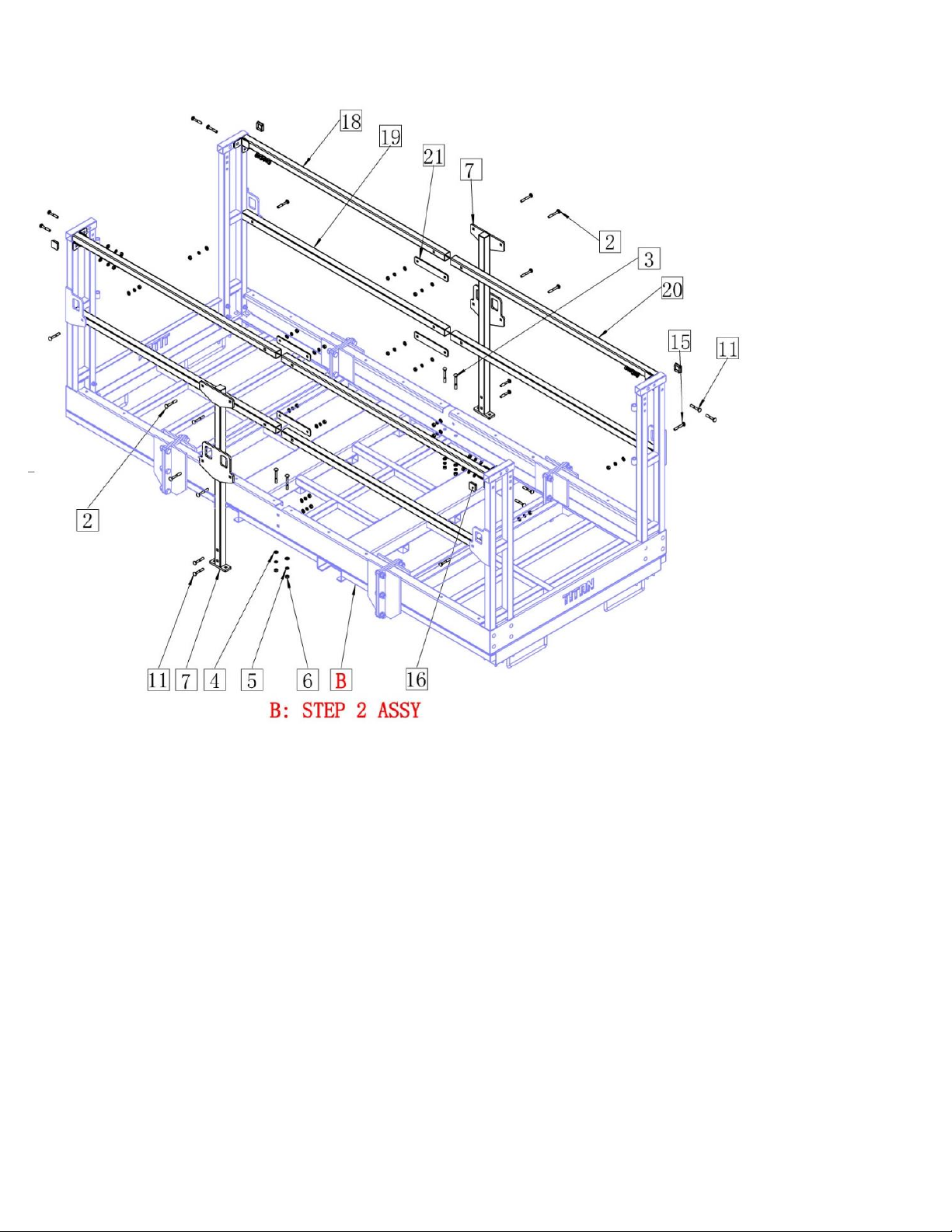

9

5. Repeat the above procedures 1 to 4 to mount the upright post and center guard railing onto

the BACK side of the STEP 2 ASSY.

6. Attach the end of TOP GUARD RAILING-1 (20) to CORNER FRAME-1 (13) on the left side using

CARRIAGE BOLT M10x60 (11), FLAT WASHER M10 (4), SPRING WASHER M10 (5) and HEXA

NUT M10 (6).

Fasten but do not tighten hardware.

7. Attach the other end of TOP GUARD RAILING-1 (20) to the UPRIGHT POST ASSY (7) using

RAILING MOUNT PLATE (21), CARRIAGE BOLT M10x70 (2), FLAT WASHER M10 (4), SPRING

WASHER M10 (5) and HEXA NUT M10 (6). Fasten but do not tighten hardware.

8. Attach the end of TOP GUARD RAILING-2 (18) to CORNER FRAME-2 (9) on the right side using

CARRIAGE BOLT M10x60 (11), FLAT WASHER M10 (4), SPRING WASHER M10 (5) and HEXA

NUT M10 (6).

Fasten but do not tighten hardware.

9. Attach the other end of TOP GUARD RAILING-2 (18) to the UPRIGHT POST ASSY (7) using

RAILING MOUNT PLATE (21), CARRIAGE BOLT M10x70 (2), FLAT WASHER M10 (4), SPRING

WASHER M10 (5) and HEXA NUT M10 (6). Fasten but do not tighten hardware.

10. Perform the above procedure 6 to 9 for both the FRONT and BACK sides of the STEP 2 ASSY.

STEP 4: INSTALLING HARNESS SAFETY BAR