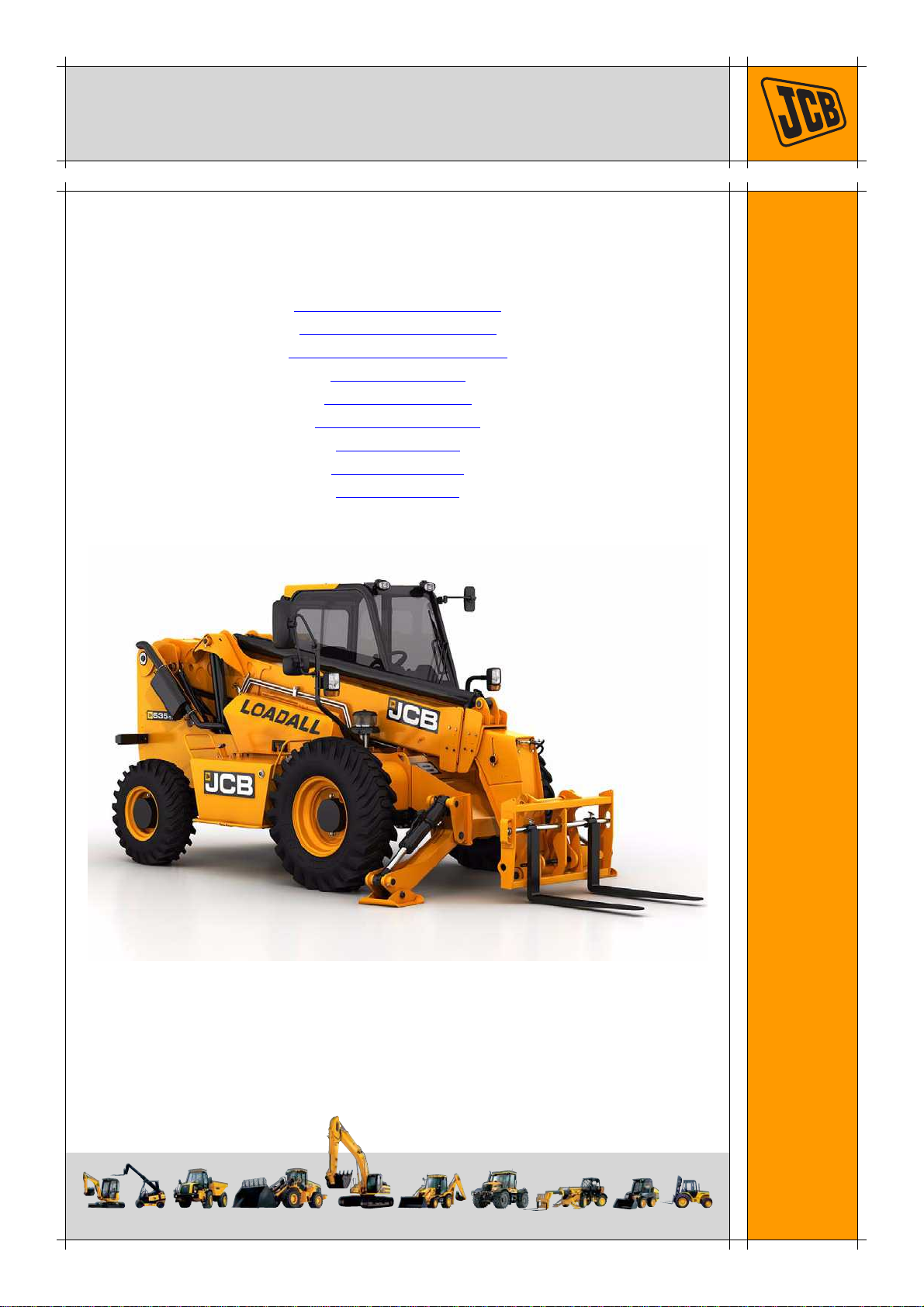

Section 1 - General Information

Contents

1-i 1-i

Page No.Contents

Introduction

Identifying Your Machine ........................................................................... 1-1

Safety

Introduction ................................................................................................ 1-3

Use

Introduction ................................................................................................ 1-5

Scope ........................................................................................................ 1-6

Personnel ..............................................................................................1-6

Newest Data ..........................................................................................1-6

Format ....................................................................................................... 1-7

Left Side, Right Side ..............................................................................1-7

Hydraulic Schematic Codes ...................................................................... 1-8

Colour Codes ........................................................................................1-8

Routine Maintenance

Maintenance Schedules ............................................................................ 1-9

Service Tools

Numerical List .......................................................................................... 1-11

Section B ................................................................................................. 1-14

Section C ................................................................................................. 1-18

Section E ................................................................................................. 1-19

Section F ................................................................................................. 1-27

Section H ................................................................................................. 1-35

Section K ................................................................................................. 1-36

Service Aids

Sealing and Retaining Compounds ......................................................... 1-37

Torque Settings

Zinc Plated Fasteners and Dacromet Fasteners ..................................... 1-39

Introduction ..........................................................................................1-39

Bolts and Screws .................................................................................1-39

Hydraulic Connections ............................................................................. 1-43

'O' Ring Face Seal System ..................................................................1-43

'Torque Stop' Hose System .................................................................1-46

`Quick-Connect' Pilot Hoses .................................................................... 1-47

Disconnecting ......................................................................................1-47

Connecting ..........................................................................................1-47

General Procedures

Introduction .............................................................................................. 1-49

Parking the Machine and Making it Safe ................................................. 1-50

Venting the Hydraulic Pressure ............................................................... 1-51

Connecting/Disconnecting Hydraulic Hoses ............................................ 1-52

Battery Disconnection/Connection .......................................................... 1-53

Removing and Replacing Components ................................................... 1-54

Preparation ..........................................................................................1-54

Original Components ...........................................................................1-54

New Components ................................................................................1-54

Torques and Fixings ............................................................................1-54

Battery Charging System Precautions ..................................................... 1-55

Find manuals at https://best-manuals.com