Installation instructions

Before you start

The Ecoexitblade is intended for recessed mounting in a ceiling. The mains connection is via a standard

Australian flex and plug. A standard 10A single surface socket outlet plug base or equivalent is required in

the celling cavity close to the intended location of the fitting. A surface mount kit (part number

Blade configuration

1. Identify the location for the fitting and determine the type of exit display required - exit left, exit

right or straight-ahead. Note that the Blade assembly is supplied configured for straight ahead –

double sided.

2.

unwanted pictogram out the top of the assembly and insert the required pictograms and diffusers.

3. Make sure the edge of the diffuser inserts with the notched corners goes in with the notches

downward. The top of the pictograms and inserts should be flush with the top of the Blade

assembly. A fingernail slid along the bottom of the Blade assembly will help the inserts slide fully

into the bottom edge of the frame.

Power up

1. After installation switch on the mains power to the unit and test. Once powered up the fitting will

light up and the red LED indicator should be on – indicating the battery is connected and charging.

2. Press the test button located on the fitting near the red LED. Hold the test button in for a few

seconds and observe the red LED go off while the main light remains on. The transition of the

mains light from mains to emergency is seamless and is only indicated by the red LED.

3. Carry out a commissioning test as per AS/NZS 2293.2.

Battery Replacement (and product removal)

1. Turn off the mains supply to the fitting. If the fitting is functioning correctly the lamp will remain lit

but the red LED should now be off.

2. Insert a large flat head screwdriver under the edge of the Base plate and lever the plate away from

the ceiling far enough to insert your fingers in the gap. Pull the fitting down from the ceiling. Take

care to avoid having your fingers near the mounting springs as they will snap back to the plastic

with some force.

3. Unplug the fitting from the mains socket.

4.

battery and replace with part 03-01325.

5.

6.

battery before it will be capable of a full length discharge again.

7. Carry out a commissioning test as per AS/NZS 2293.2.

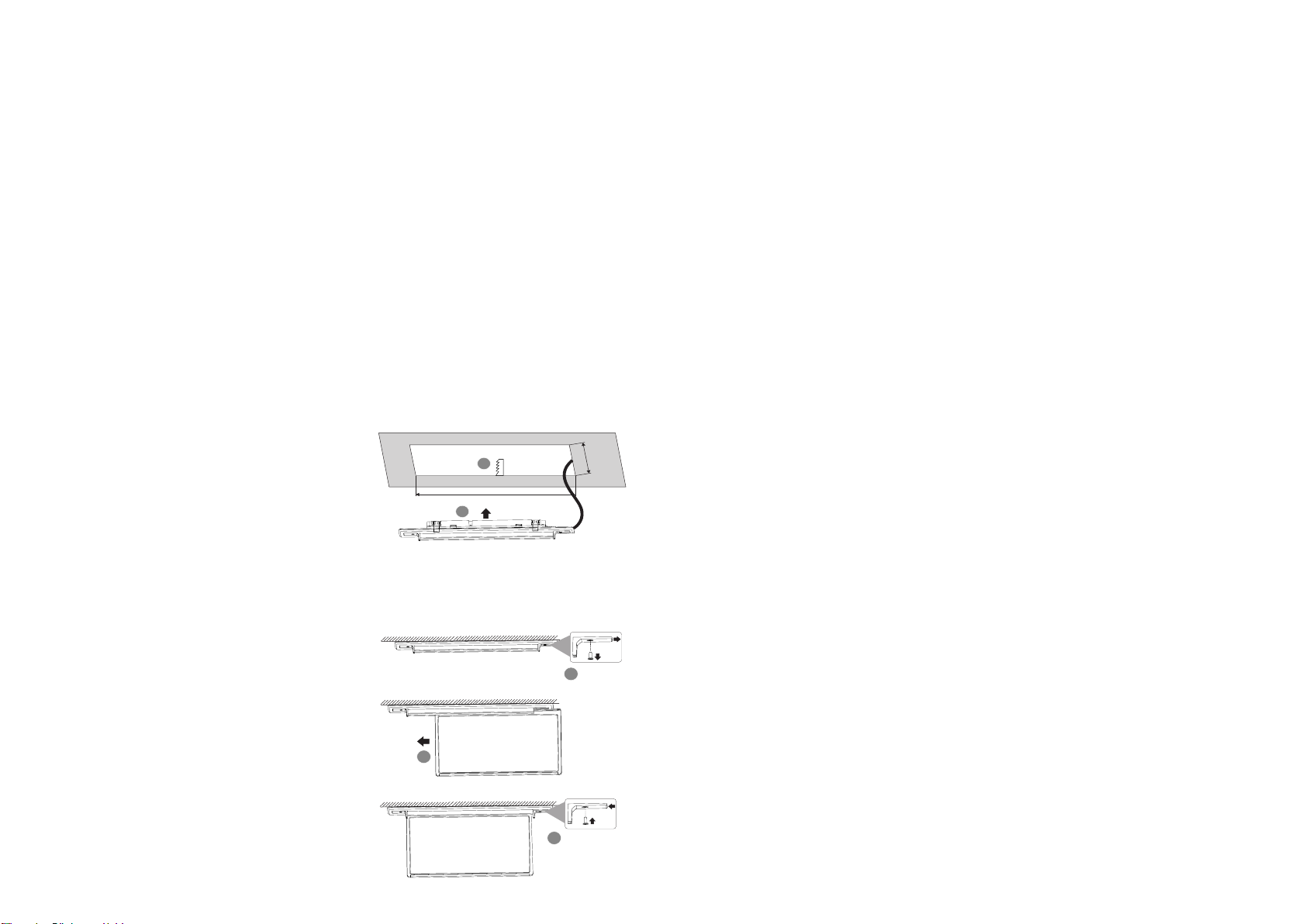

Base installation

1. Ceiling cut-out is 370 x 90 mm. Cut the opening

in the ceiling and mark the centre of the long

side of the cutout to aid in centering the

assembly.

2. Locate the mains socket and plug in the Base

assembly. Identify which side the test switch

and LED should sit then insert the Base

centrally into the cutout by engaging the

mounting springs on one side. With your

thumbs fold back the other two mounting

springs sufficient to engage the cutout then let

the Base snap into position.

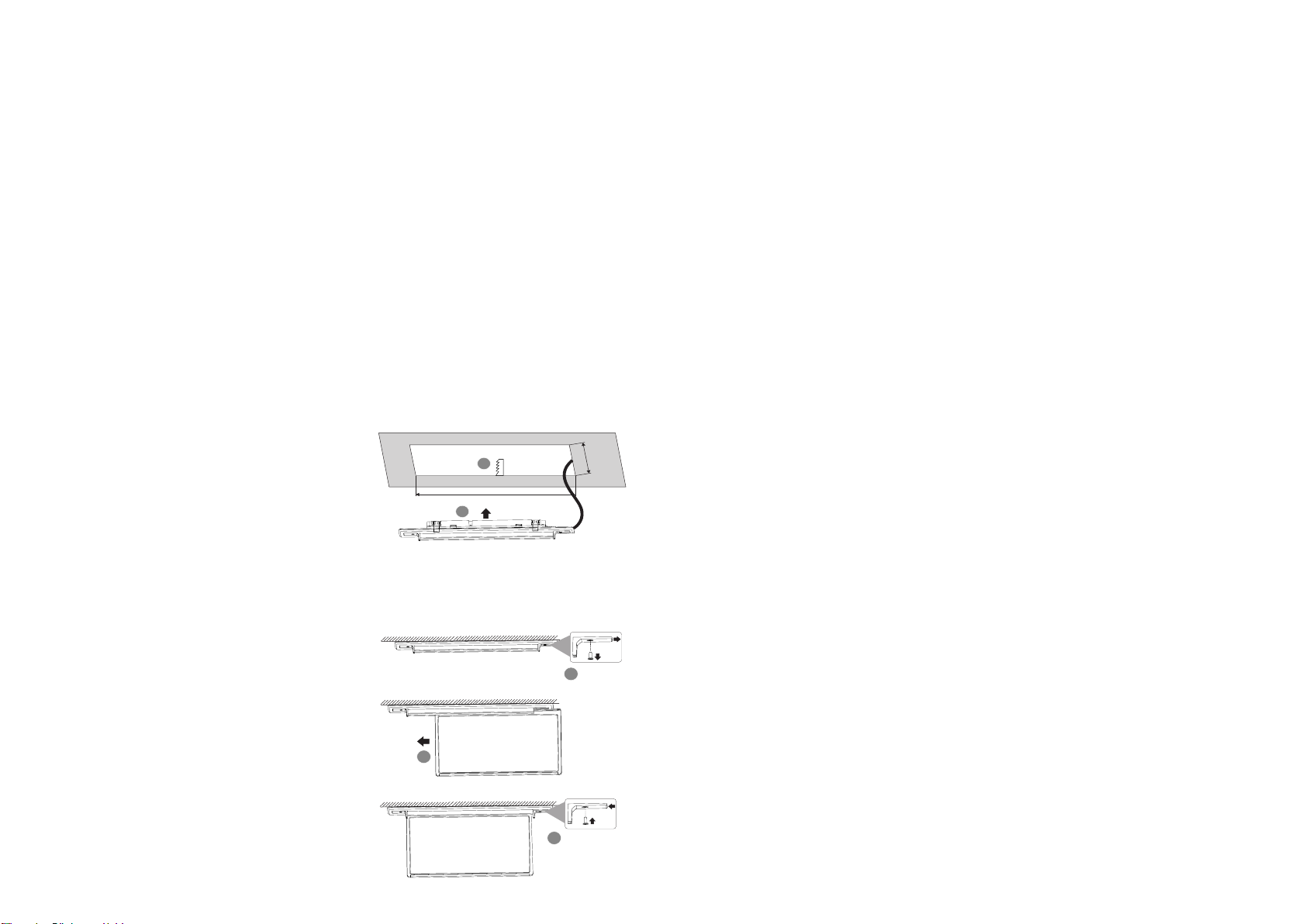

Blade installation

1.

Base by removing the retaining screw.

2. Slide the Blade assembly into the extrusion.

3.

24 hours battery charge is recommended to allow the fitting battery to reach full capacity, ie: prior

to a discharge test. As the installer, it is your responsibility to conduct the initial discharge testing

of the installed fitting. Refer to AS/NZS 2293.2.

Testing precautions

Once the fitting is permanently connected to the mains supply, a commissioning discharge test as

required in AS/NZS 2293.2 must be carried out.

Allow 24 hours for the battery to fully charge prior to conducting this test, presently (at the time of

hours for their commissioning test and for not less than 90 minutes thereafter (it is required that 6

and enter them into the building emergency services logbook or via other recording methods as

allowed by AS/NZS 2293.2.

Construction sites

Continuously switching off the mains power supply that is connected to emergency light fittings

during the construction phase of an installation will cause these fittings to discharge and charge their

batteries many times over a short period; this can shorten life of the battery. ABB does not

recommend such practices and may not honour the warranty on batteries when they are subjected to

such harsh operating conditions. Emergency light fittings are designed to be discharge tested once

every 6 months as per AS/NZS 2293.2, subjecting the product to repeated discharge or charge cycles

is regarded as an abuse of the fittings.