3

Features SACO 16 D3 is a self-contained microprocessor

based multi channel alarm annunciator unit

16 contact operated on/off alarm or pulse count-

ing channels per unit

16 signal follower relay outputs + two group

alarm outputs or alternatively 16 group alarm

outputs

Relay output for audible alarm and self supervi-

sion

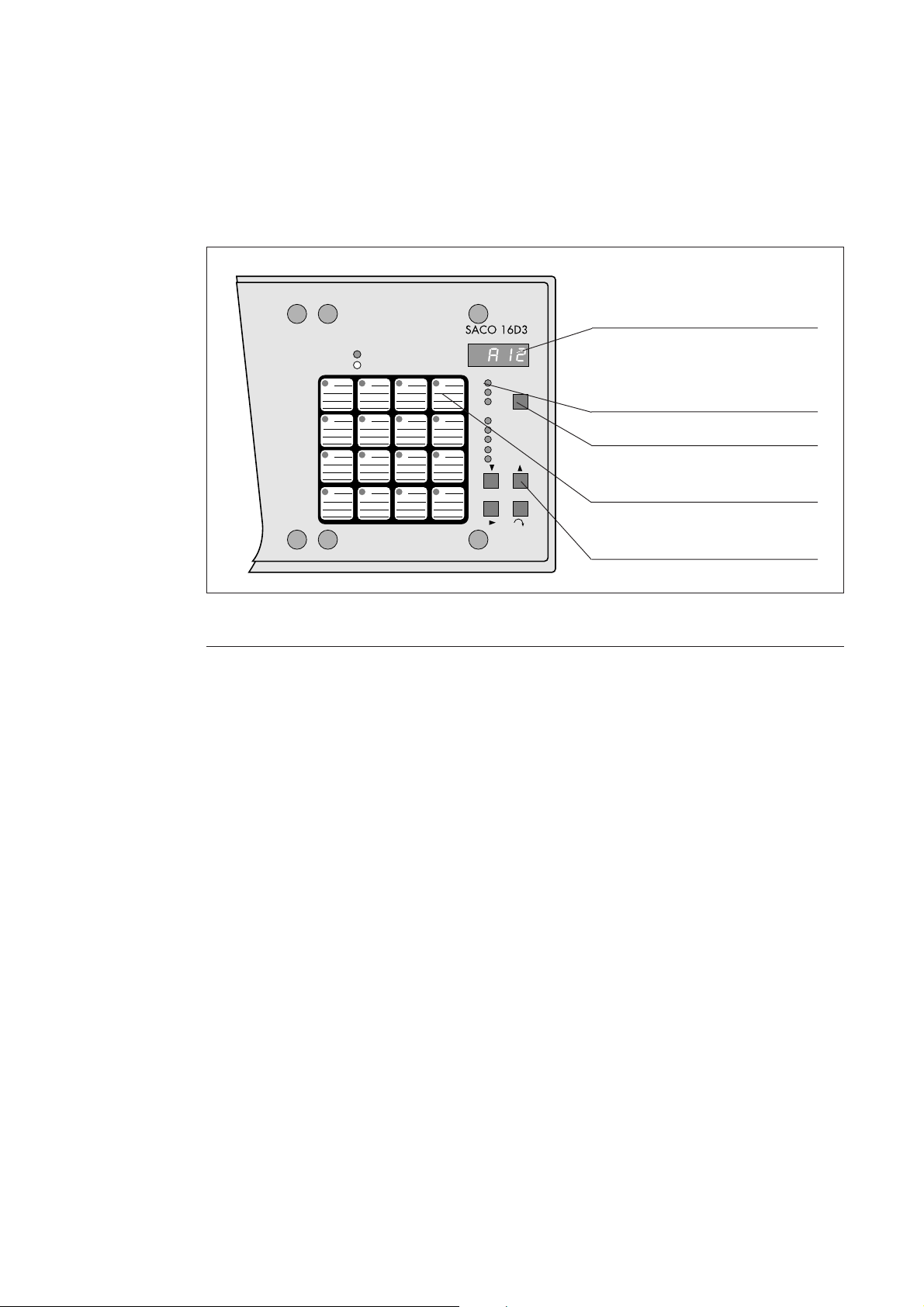

LEDs for visual alarm indication

Fully programmable by means of push-buttons

on the front panel or via the serial communica-

tion interface

Numerical display for first out alarm indication,

event sequence reporting and programming

Event register for the 50 latest events

Serial communication interface for easy con-

nection of the annunciator unit to a monitoring

and/or control system.

Improvedsystemreliability backed upbyasophis-

ticatedself-supervision functioncomprisingboth

hardware and software watchdog functions

High immunity against electrical interference

and an enclosure to IP 54 when panel mounted

General The alarm annunciator unit type SACO 16D3

is a part of the integrated substation secondary

equipment system SPACOM.

The on/off annunciator unit is a fully self-

contained compact microprocessor based de-

vice suitable for use as stand-alone annunciator,

but also as data acquisition, recording or control

unit, either stand-alone or integrated into a

system.

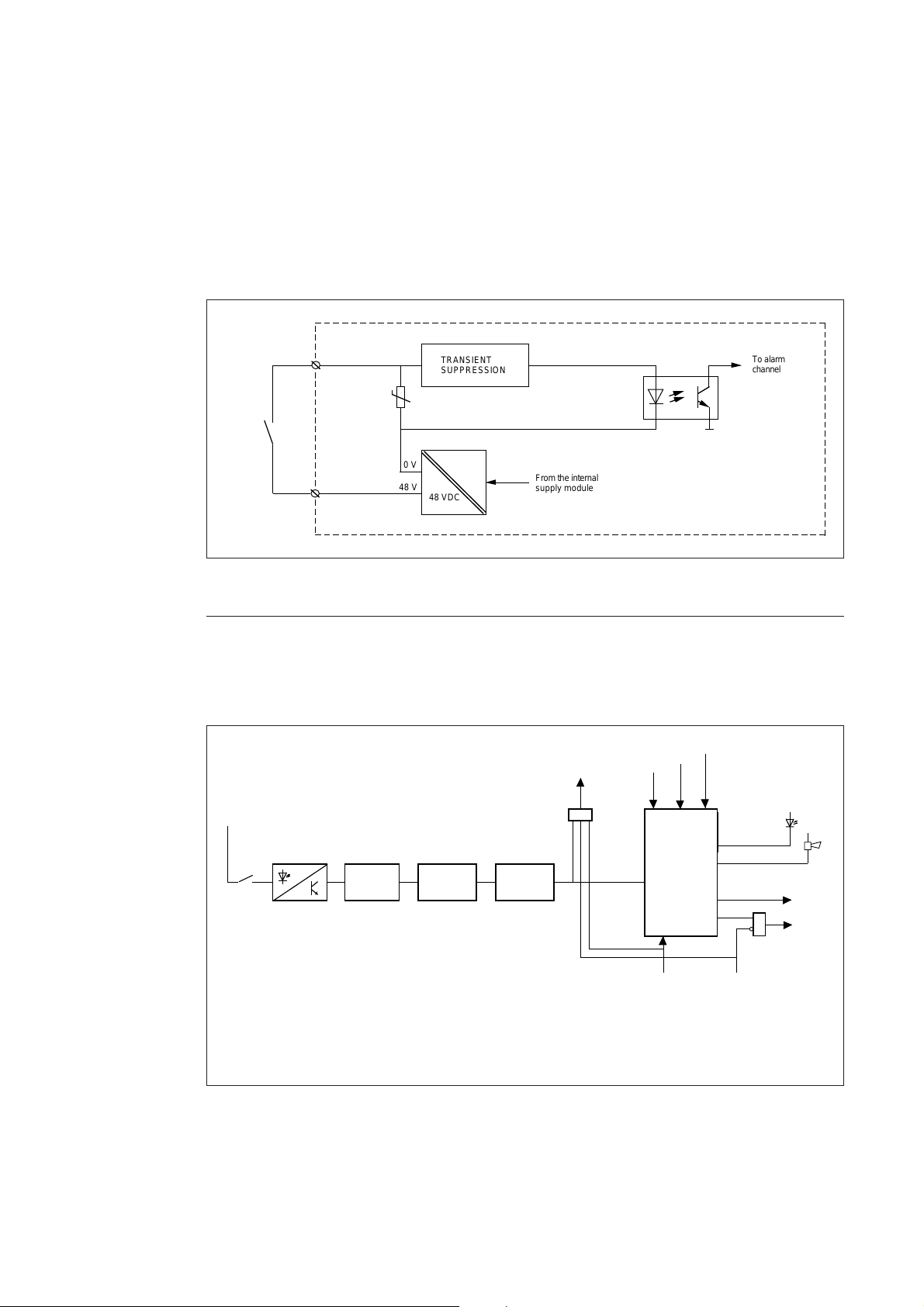

The annunciator unit is provided with 16 chan-

nels for operation from NO or NC field con-

tacts. The unit is furthermore provided with

four auxiliary output relays, one for control of

an audible device (horn, buzzer etc.), one is

controlled by the internal self-supervision sys-

tem and two for general retransmission of indi-

vidual or group alarm signals. The unit is also

provided with two control inputs for external

acknowledge and reset functions. The alarm

annunciator unit is fully self-contained includ-

ing an integral power supply unit generating the

internal supply voltages as well as the external

field contact voltage, which also is used in the

external acknowledge/reset circuits. Thus no

separate power units are needed for the field

contact circuits.

The unit is provided with 20 output relays for

signal transfer. Two of these relays are used as

group alarm outputs, one is to be used for

controlling an audible device and the other for

the internal supervision system. The other 16

output relays can be used either as input signal

following outputs or as group alarm outputs.

The microprocessor module is a standardized

100 mm x 160 mm Euro-card printed circuit

board (PCB) which also functions as the basic

element in large alarm annunciator systems

mechanically designed according to the 19 inch

rack and cabinet system (SACO 64D4).

The modern microprocessor technology used in

the SACO system offers new features which not

only extend the conventional area of application

for alarm annunciator systems but also increase

the reliability of the annunciator systems. The

most significant feature of the new annunciator

system is the outstanding system flexibility. The

annunciator is truly field programmable by

means of push-buttons on the front panel, or

from a PC via the serial communication, for easy

selection of a proper operational scheme and

suitable parameter values in the intended appli-

cation.

Area of

application

The annunciator unit SACO 16D3 has been

developed and manufactured to meet the most

demanding specifications regarding reliability

in operation and immunity against interference

which can be expected from a modern annun-

ciator system for use in:

- electric power plants and substations

- industrial plants and processes

- marine vessels and off-shore installations

- technical installations in buildings

- water treatment plants, etc.

Furthermore the annunciator system can be

used in any conventional application where

there is a demand for a continuous supervision

or monitoring of a number of contacts to pro-

vide an immediate fault recognition, fault iden-

tification and a visual/audible alarm in order to

call attention to an abnormal process condition

or as a pulse counter for change of state of a

process parameter under normal process condi-

tions.