3.0 SAFETY WARNING

1) Ensure that the tractor PT0 shield and pump PTO guard are in place and the PT0 shaft guard is fitted

properly.

2) PTO guards should be kept well lubricated, refer to the accompanying leaflet for operating and

maintenance instructions on the shaft.

3) Do not operate the manual control on the rear valve or open the rear manhole while the tanker is

pressurised high pressure liquid could cause injury.

4) Operators should be trained and know how to use the tanker controls while standing as far away as

possible from the revolving shaft.

5) Suitable close-fitting clothing should be worn with no loose fabric to catch in the shaft.

6) Take care to match the tractor horsepower to tanker on soft sloping ground to prevent dangerous

uncontrollable situations from occurring.

7) If you have any doubts as to the safety operation of the Slurry Tanker advice should be sought from

your local dealer or direct from the Manufacturer.

8) Caution: Never enter a tanker to clean or inspect it unless it has been thoroughly ventilated. Any

gases that have remained in the tank after working it can be lethal.

9) When opening or inspecting the manual or hydraulic top fill point (if fitted), caution should be taken

to avoid falling from such a height.

10) If a ladder is fitted to the tank it must not be used while the tank is working or pressurised.

11) Do not operate the tank with excessively worn hitch eye. Replace it! The hitch eye should be checked

regularly particularly on tanks used for long periods during the season.

12) Damaged or worn hydraulic hoses should be replaced.

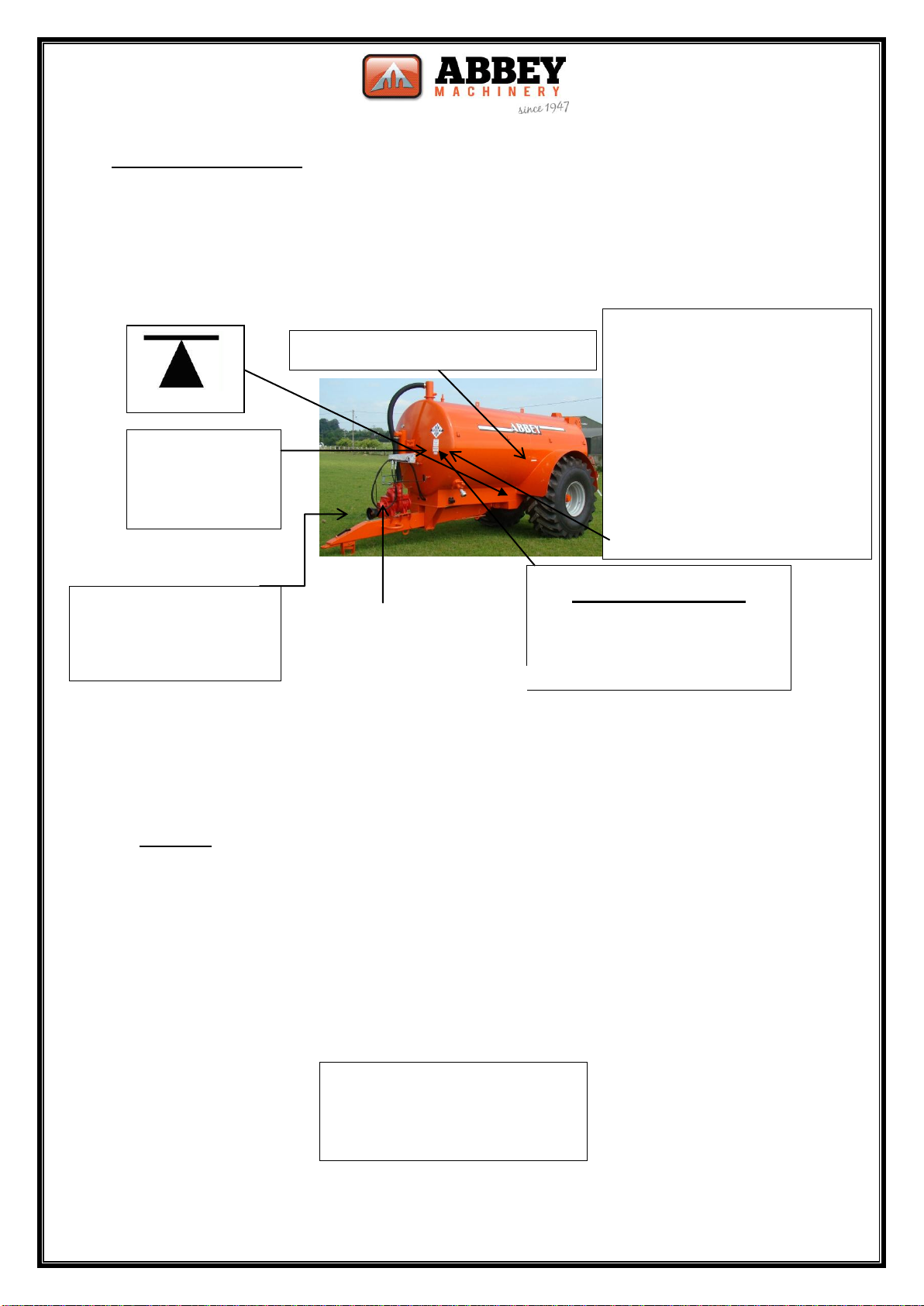

13) Both standard lifting points on the top of the barrel of the tank must be used if the tank is to be lifted

off the ground. Drawing A, page 8 shows the positions of the lifting points.

14) Never operate the tank in an unsafe manner.

15) Warning - Under no circumstances should the pump guard be used as a step.

16) Do not attempt to approach any part of the power shaft while it is working.

17) Caution: The Abbey tank has not been designed to travel at speeds over 40 km/hr and should be used

in line with the road regulations regarding trailed machines in your particular country. If you require

the tank to operate at speeds higher than this contact your Abbey dealer. Purpose built tankers will

be required.

18) The PT0 shaft is to be left on the stand provided, when the machine is not in use to prevent the shaft

guard from being damaged.

19) Caution: Before carrying out maintenance or adjustment on the Abbey tank, stop the tractor, apply

both the tractor and tank parking brakes, and disconnect the PTO shaft.

20) Caution: Always regularly check that the lights are working correctly when using the machine on the

road.

3.1 Slurry Tanker Noise Levels

Continuous A-weighted sound level at workstations. Noise levels exceed 70 db(a)

Peak C-weighted instantaneous sound pressure exceeds 63pa.

Caution: The necessary protective devices should be worn when operating the machine if required.