Table of Contents Assembly Tools Required

Part Identification

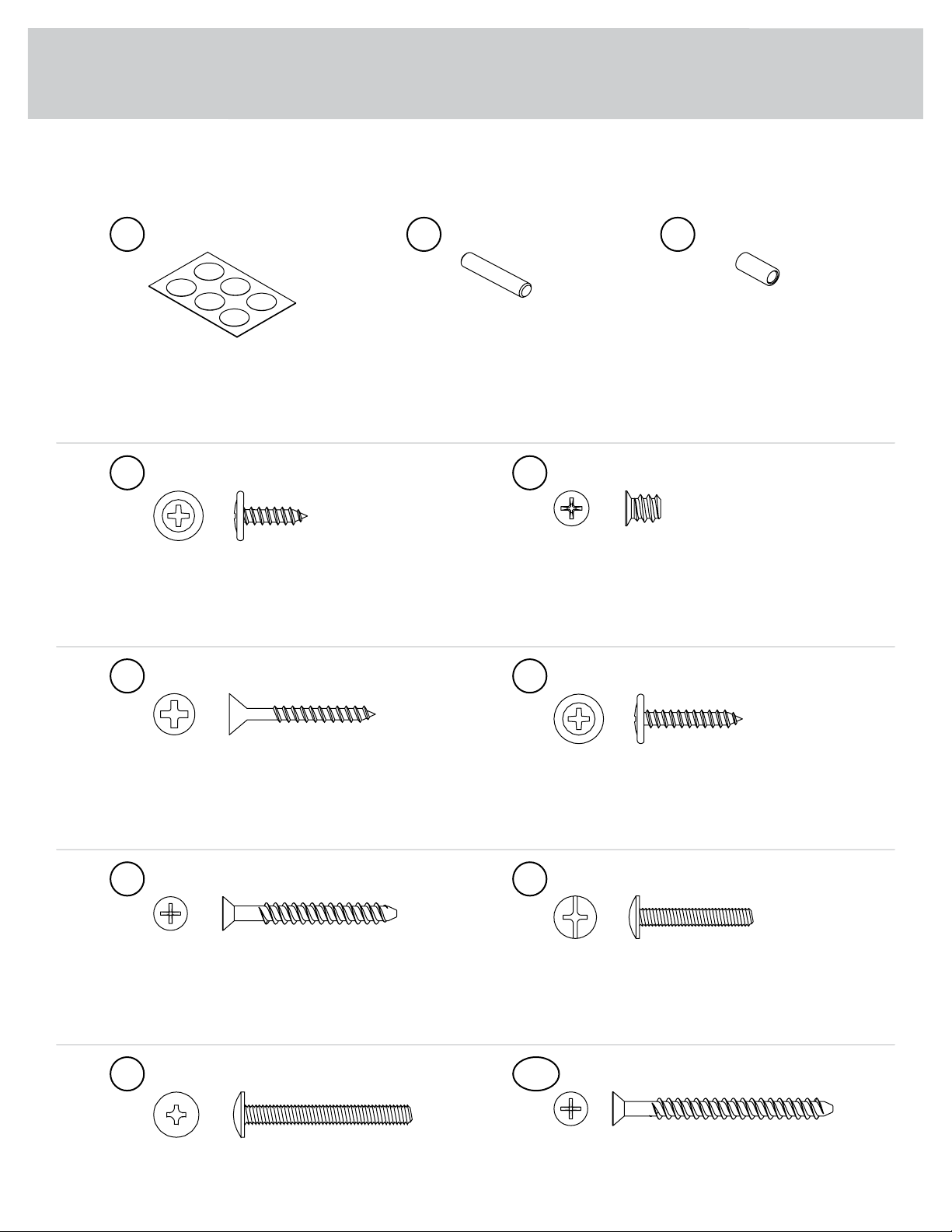

Hardware Identification

Assembly Steps

Français

Español

Safety

Warranty

Hammer

Not actual size

No. 2 Phillips Screwdriver

Tip Shown Actual Size

2-3

4-5

6-51

52-57

58-64

65-66

67

Page 2

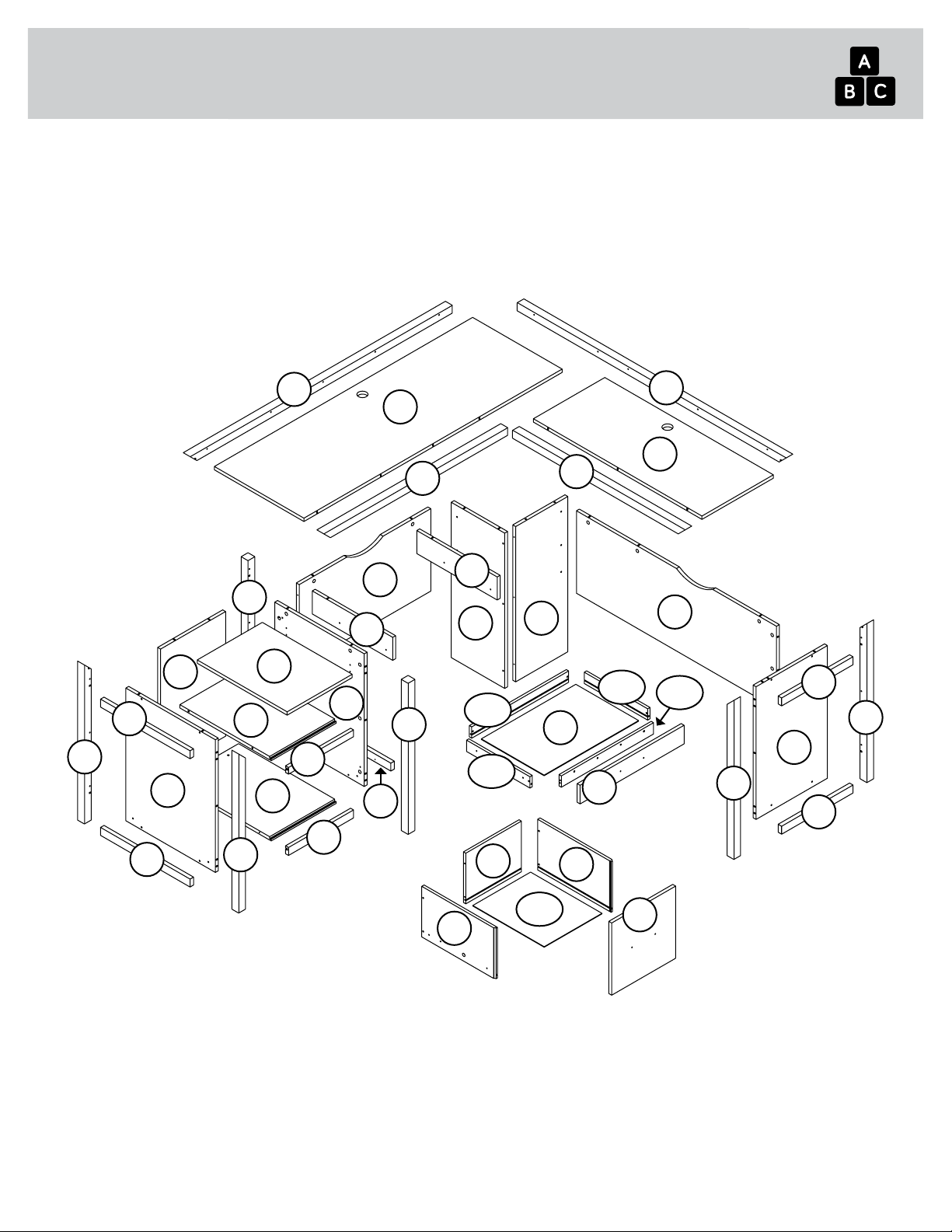

Part Identification

åWhile not all parts are labeled, some of the parts will have a label or an inked letter on the edge

to help distinguish similar parts from each other. Use this part identification to help identify similar parts.

A RIGHT PEDESTAL END (1)

B LEFT PEDESTAL END (1)

B55 PENCIL DRAWER BOTTOM (1)

C DESK TOP (1)

D RETURN TOP (1)

D28 FILE RIGHT DRAWER SIDE (1)

D29 FILE LEFT DRAWER SIDE (1)

D78 FILE DRAWER BACK (1)

D266 PENCIL RIGHT DRAWER SIDE (1)

D267 PENCIL LEFT DRAWER SIDE (1)

D563 PENCIL DRAWER BOX FRONT (1)

D564 PENCIL DRAWER BACK (1)

D707 FILE DRAWER BOTTOM (1)

E RETURN RIGHT END (1)

F RETURN MODESTY PANEL (1)

G DESK MODESTY PANEL (1)

H FILE DRAWER FRONT (1)

J PEDESTAL BOTTOM (1)

K RETURN SIDE MOLDING (2)

L PEDESTAL END MOLDING (3)

M FRONT BOTTOM MOLDING (1)

N FRONT TOP MOLDING (1)

O

FRONT RETURN MOLDING (1)

P DRAWER MOUNT (2)

Q ADJUSTABLE SHELF (1)

R SHELF (1)

S LARGE SUPPORT PANEL (1)

T SMALL SUPPORT PANEL (1)

U RIGHT FRONT/LEFT REAR LEG (2)

V LEFT FRONT/RIGHT REAR LEG (2)

W RIGHT FRONT PEDESTAL LEG (1)

X RIGHT REAR PEDESTAL LEG (1)

Y BACK (1)

Z PENCIL DRAWER FRONT (1)

AA BACK TOP MOLDING (1)

BB BACK RETURN MOLDING (1)

CC SHELF MOLDING (1)