Inter-Connection Diagram

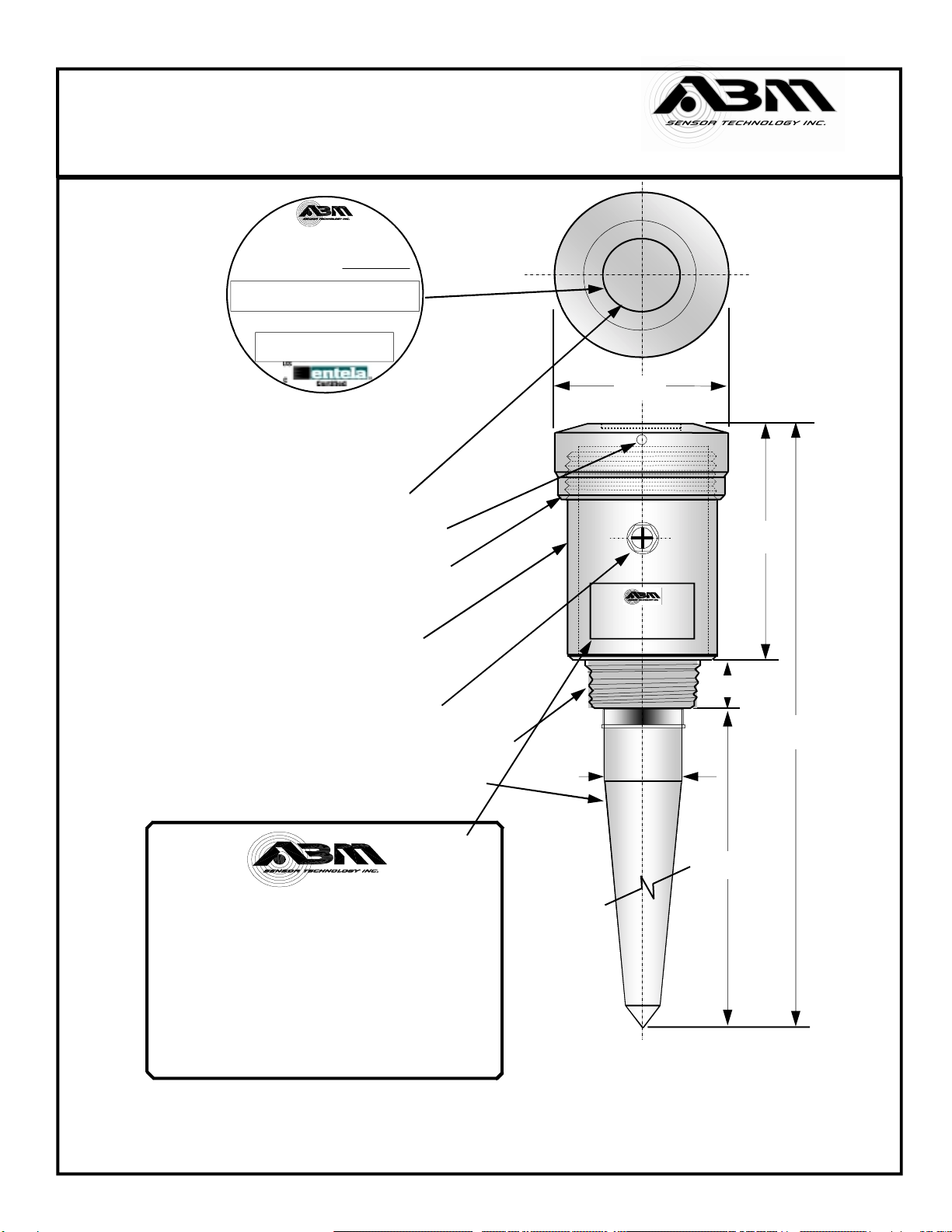

Top View of Sensor (Access Cover Removed)

FCC INFORMATION TO RADAR USERS

NOTE: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provided reasonable pro-

tection against harmful interference when the equipment is oper-

ated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interfer-

ence in which case the user will be required to correct the interfer-

ence at his own expense.

WARNING-Changes or Modifications not expressly approved by

ABM Sensor Technology Inc. could void the user’s

authority to operate the equipment.

Wiring Information

- Ground shield at one end only.

- All terminal block wiring must be rated for 250V.

- Power input wiring must be protected by a 15A double pole cir-

cuit breaker .

- Terminal is for use only with equipment which has no live parts

which are accessible .

- Terminal is for use with equipment which maintains basic insula-

tion from hazardous voltage under normal and single fault condi-

tions .

- Connection used at the remote end of external circuit .

Recommended Wiring

For AC Sensor —

Power 3 Wire unshielded 22 AWG , 300 V

Current Output 1 Pair shielded 24 AWG , 300 V

Communication 1 Pair shielded 24 AWG , 300 V

For DC Sensor—

Power & Current output 3 Wire shielded 24 AWG , 300 V

Communication 1 Pair shielded 24 AWG , 300 V

Status LED

Terminal Block

+

++

+ 8

12– 30 VDC -- 7

6

DC Power Input

Note - TB #7 is

Connected to TB #4

RS232/485

L1 8

4-20 mA

AC IN

3

STATUS

A/TX 2

B/RX 1

— 4

+ 5

L2/N 7

6

SWITCH

ABM

SENSOR TECH. INC

- F1/8 A 250V

CALIBRATION

FUSE

Control Panel

Fastening Screw !

Calibration Pushbutton

NOTE — Use only 1/2” NPT Conduit

DWG 10A363

Calibration — 4 -20 or 20 - 4 mA Output

For Radar programmable through communication is

recommended.

FULL — Calibrate 20 mA or 4mA (Set Near Target)

1. Calibration mode LED color is Green.

(for Radar Low Dielectric Materials has to be off)

2. Push button and hold until LED turns Yellow (20 mA)

or push button and hold until LED turns Red (4 mA)

3. Release button, observe LED flashes to acknowledge

the calibration.

EMPTY— Calibrate 4 mA or 20 mA (Set Far Target)

1. Calibration mode LED color is Green

(for Radar Low Dielectric Materials has to be off)

2. Push button and hold until LED turns Red (4 mA)

or push button and hold until LED turns Yellow (20 mA)

3. Release button, observe LED flashes to acknowledge

the calibration.

For Radar to turn the Low Dielectric Materials operation mode

ON and OFF (this mode is recommended for materials with

dielectric constant lower than 4 and also to eliminate multiple

reflections in tank.)

1) To turn the Low Dielectric Materials ON. Push button and hold until

LED goes OFF after the sequence of Yellow , Red and turns Off. The Low

Dielectric Material operation is On when the LED’S Green light blinks

constantly.

2) To turn the Low Dielectric Materials OFF. Push button and hold until

LED goes OFF after the sequence of Yellow , Red and

Turns OFF. The Low Dielectric Material operation is OFF when LED is

continuously Green.

3) Use communication software.

Operation

OperationOperation

Operation -

--- An ultrasonic/electromagnetic pulse is transmitted from the

An ultrasonic/electromagnetic pulse is transmitted from theAn ultrasonic/electromagnetic pulse is transmitted from the

An ultrasonic/electromagnetic pulse is transmitted from the

ABM sensor . The pulse travels to the surface being monitored and is

ABM sensor . The pulse travels to the surface being monitored and isABM sensor . The pulse travels to the surface being monitored and is

ABM sensor . The pulse travels to the surface being monitored and is

reflected off this surface back to the sensor . The time of flight is divided

reflected off this surface back to the sensor . The time of flight is dividedreflected off this surface back to the sensor . The time of flight is divided

reflected off this surface back to the sensor . The time of flight is divided

by 2 and converted to an output signal directly proportional to the

by 2 and converted to an output signal directly proportional to theby 2 and converted to an output signal directly proportional to the

by 2 and converted to an output signal directly proportional to the

material level .

material level .material level .

material level .

USER INSTRUCTION MANUAL

For ABM300/4XX (DC/AC) SENSORS

STD. , SANITARY AND RADAR 730 The Kingsway Peterborough , Ont. K9J6W6 Canada

Tel: (705) 740 — 2010 Web: www.abmsensor.com

Typical Installation

1) DIRECT MOUNTING ULTRASONIC SENSOR -SIMPLY THREAD SENSOR

DIRECTLY INTO METAL OR PLASTIC NOZZLE.

2) RADAR UNIT MUST BE INSTALLED INTO METAL FITTING WITH THE ANTENNA

POINTING DOWNWARD. BUT DO NOT MOUNT IN THE CENTER OF A DOMED

TANK.

OPTIONAL Programmable Calibration &

Diagnostics, Data Logging , RS232 or RS485 Com.

Temperature Compensation for the speed of sound

for ultrasonic.

1/2” NPT Conduit

1/2” NPT Conduit1/2” NPT Conduit

1/2” NPT Conduit

Hole

HoleHole

Hole

Process Mtg.

Process Mtg.Process Mtg.

Process Mtg.

1”,1 1/2”,2”,3”NPT

1”,1 1/2”,2”,3”NPT1”,1 1/2”,2”,3”NPT

1”,1 1/2”,2”,3”NPT

Ultrasonic Sensor

Ultrasonic SensorUltrasonic Sensor

Ultrasonic Sensor

Radar Rod

Radar RodRadar Rod

Radar Rod

A

C

C

U

R

R

E

S

O

L

U

T

I

O

N

Per

Chart

Deadzone

+/—0.25%

EMPTY

4 or 20mA

20 or 4 mA

FULL

Level

Material

S

P

LED

Red

Yellow

Process Temperature

Radar ;190°F/90°C

— 40°F/°C

Ultrasonic ;

140° F/60 °C

— 40° F/° C

CALIBRATION PUSHBUTTON

/ Led Indicator For 4 - 20 mA (750 ohm Max.)

output

12 - 30 Vdc

115/ 230 Vac

60/ 50 Hz

˜