KL II Series User Manual 2

CONTENT

1 PRODUCT INTRODUCTION ...................................................................................................................................................... 6

1.1 Main features ........................................................................................................................................................................... 6

1.2 Product specification ............................................................................................................................................................. 7

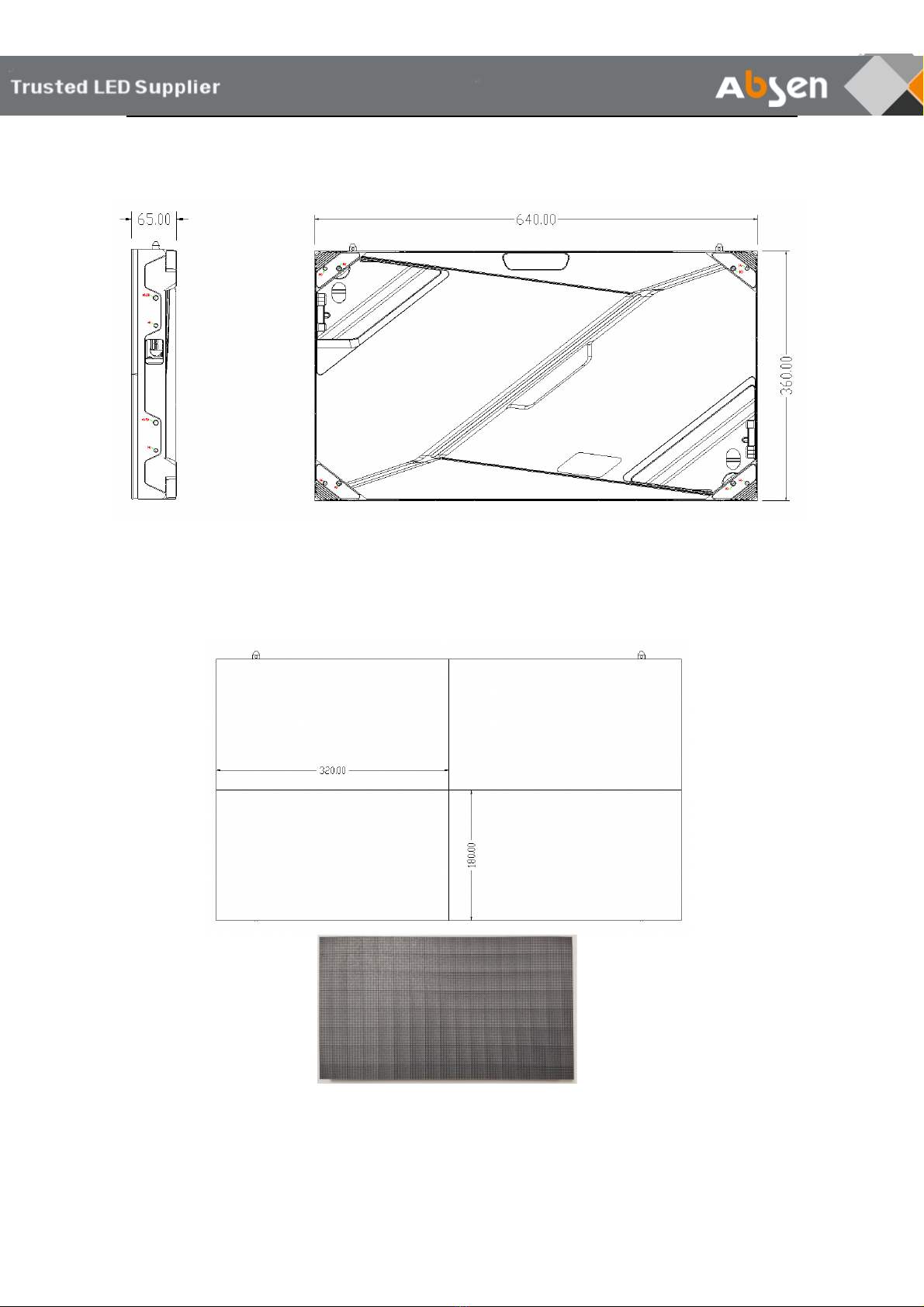

1.3 Panel size .................................................................................................................................................................................. 8

1.4 Module size .............................................................................................................................................................................. 8

2 PRODUCT COMPONENTS ........................................................................................................................................................ 9

2.1 Panel Introduction ................................................................................................................................................................. 9

2.2 Product Accessories ............................................................................................................................................................ 10

3 PREPARATION BEFORE INSTALLATION ............................................................................................................................. 14

3.1 Installation tools ................................................................................................................................................................... 14

3.2 Installation site environmental requirements .............................................................................................................. 15

3.3 Precautions for product installation ............................................................................................................................... 15

4 PRODUCT INSTALLATION ...................................................................................................................................................... 16

4.1 Ground stack installation ................................................................................................................................................... 16

4.2 Wall-mounted installation ................................................................................................................................................ 18

4.3 Rigging installation .............................................................................................................................................................. 20

4.4 Trim pieces installation ....................................................................................................................................................... 21

5 CABLE CONNECTION ............................................................................................................................................................... 23

5.1 LED Panel connection .......................................................................................................................................................... 23

5.2 Power cable connection ..................................................................................................................................................... 24

5.2 Signal cables connection .................................................................................................................................................... 25

5.3 Power cord and signal test ................................................................................................................................................ 26

6 PRODUCT MAINTENANCE ..................................................................................................................................................... 27

6.1 Service tools ........................................................................................................................................................................... 27

6.2 Module maintenance .......................................................................................................................................................... 27

6.3 Receiving card/Hub board/PSU maintenance ............................................................................................................ 28

6.4 Product maintenance precautions .................................................................................................................................. 29

6.5 Troubleshooting ................................................................................................................................................................... 31