3

For more cool Wattage products visit our website at http://watt-age.globalhobby.com

Thisinstructionmanualisdesigned to guide you through theentire final assemblyprocess of your newairplane in the

least amount of time possible. Along the way you'll learn how to properly assemble your new airplane and also learn

tips that will help you in the future. We have listed some of our recommendations below. Please read through them

before beginning assembly.

●Please read through each step before beginning as-

sembly. Youshould find thelayoutvery complete and

straight forward. Our goal is to guide you through

assembly without any of the headaches and hassles

that you might expect.

●Thereare check boxes nexttoeach step. After you

completea step, checkoffthe box. Thiswill help pre-

vent you from losing your place.

●Cover your work table with brown paper or a soft

cloth, both to protect the table and to protect the parts.

●Keep a couple of small bowls or jars handy to put

the small parts in after you open the accessory bags.

●We're all excited to get a new airplane in the air, but

take your time. This will ensure you build a straight,

strong and great flying airplane.

●If you come across this symbol ☛, it means that

this is an important point or an assembly hint.

●A glossary of Terms begins on page # 32. Refer to

it if you come across any unfamiliar terms.

If you should find a part missing or damaged, or have any questions about assembly, please

contact us at the address below:

Wattage Customer Service

18480 Bandilier Circle

Fountain Valley CA 92728

Phone: (714) 963-0329 Fax: (714) 964-6236 E-mail: service@globalhobby.net

INTRODUCTION

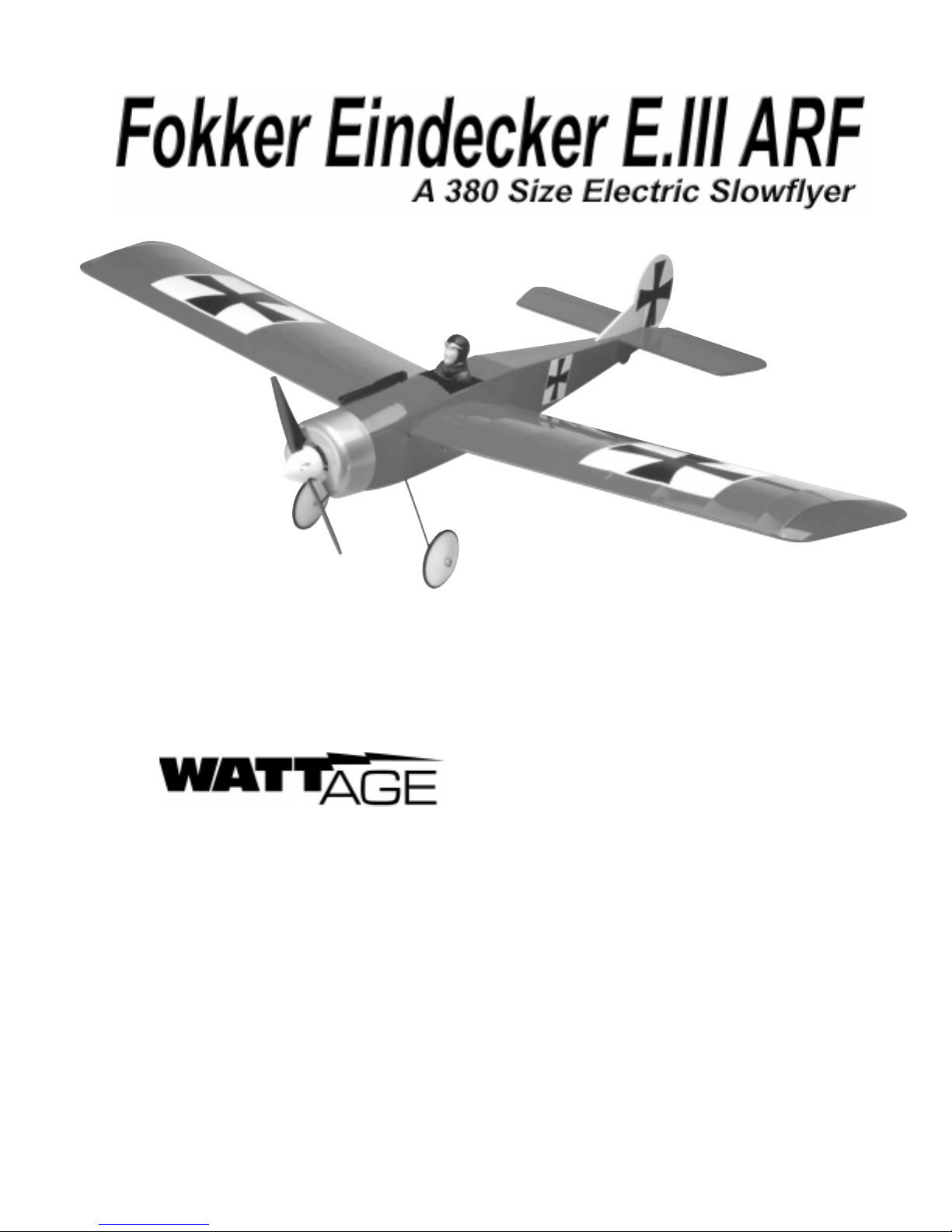

Thank you for purchasing the new Wattage Fokker Eindecker E.III ARF. Before

completing the final assembly of your new airplane, please carefully read through

this instruction manual in its entirety. Doing so will ensure success the first time

around!

The original Fokker Eindecker was the first monoplane of WWI. It was considered the technological wonder of its day.

Itslight wing loadingand stall resistantwing meant itcould turn insideevery opponent outthere. Not only wasit the first

monoplaneofthewar, it was also thefirst tofeature a synchronizedforward firingmachine gun thatcould fire throughthe

arc of the propeller. With this technology, better aim and precision was possible, giving it an even greater advantage.

Max Immelmann scored his first victory flying the Eindecker. Soon after its debut in 1915, it proved its advantage. The

Eindecker E.I was so potent that Allied opponents called themselves Fokker Fodder. Germans were so protective of its

technology that the airplane was never allowed to fly across into enemy territory to prevent giving the Allied forces this

advanced technology, should the airplane be shot down.

Now you can rule the skies with your Fokker Eindecker 400. Wattage's Eindecker handles well at all throttle settings and

performs tight turns with ease. The low wing loading and lifting airfoil give the Eindecker long flights and great perfor-

mance. The Eindecker is expertly built and covered using standard construction techniques. Only high quality balsa,

plywood and real iron-on covering material is used. Assembly is very quick and easy, owing the prefabricated and

painted parts. Experienced modelers will appreciate the craftsmanship of this fun-flying Fokker.