8

The covering material used on the Thermalaire EP is

a heat shrink polyester material. Because of this, it is

possible with heat and humidity changes that the cov-

ering on your airplane may wrinkle or sag. This trait

is inherent in all types of heat shrink material. To

removethe wrinklesyouwill needto purchase,or bor-

row from a fellow modeler, a heat iron. If you need to

purchase one, the Global Sealing Iron # 360900 is

recommended.

Follow these simple steps to remove the wrinkles:

❑1) Plug in and turn on the sealing iron to the

medium temperature setting. Allow the iron to heat

up for approximately 5 - 7 minutes.

❑2) After the iron has reached temperature,

lightly apply the iron to the wrinkled section of

the covering. Move the iron slowly over the

wrinkled section until the covering tightens and the

wrinkles disappear. You will notice that the color

of the covering will darken when it is heated. When

the covering cools back down, it will return to its

normal color.

☛If the color layer smears from any of the seams

the temperature of the iron is too hot. Turn the tem-

perature dial down and wait about 5 minutes for the

iron to adjust to the lower temperature. You can re-

move any excess color streaks using a paper towel

soaked with a small quantity of Acetone.

A NOTE ABOUT COVERING

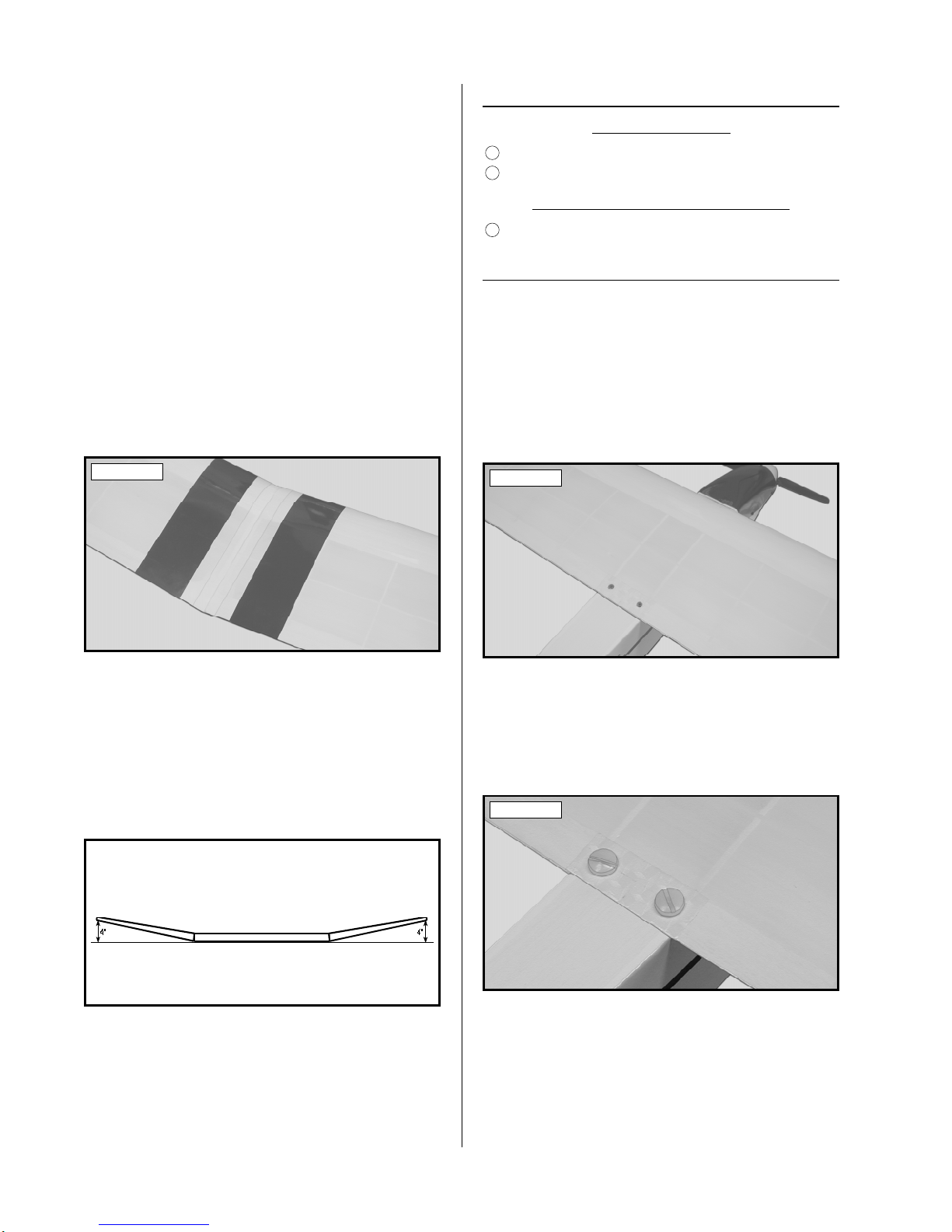

❑8) Set the motor between the handles of a pair

of needle nose pliers and secure the motor to the

handles using three rubber bands. This will keep

the motor secure enough for the break-in procedure.

See photo # 1 below.

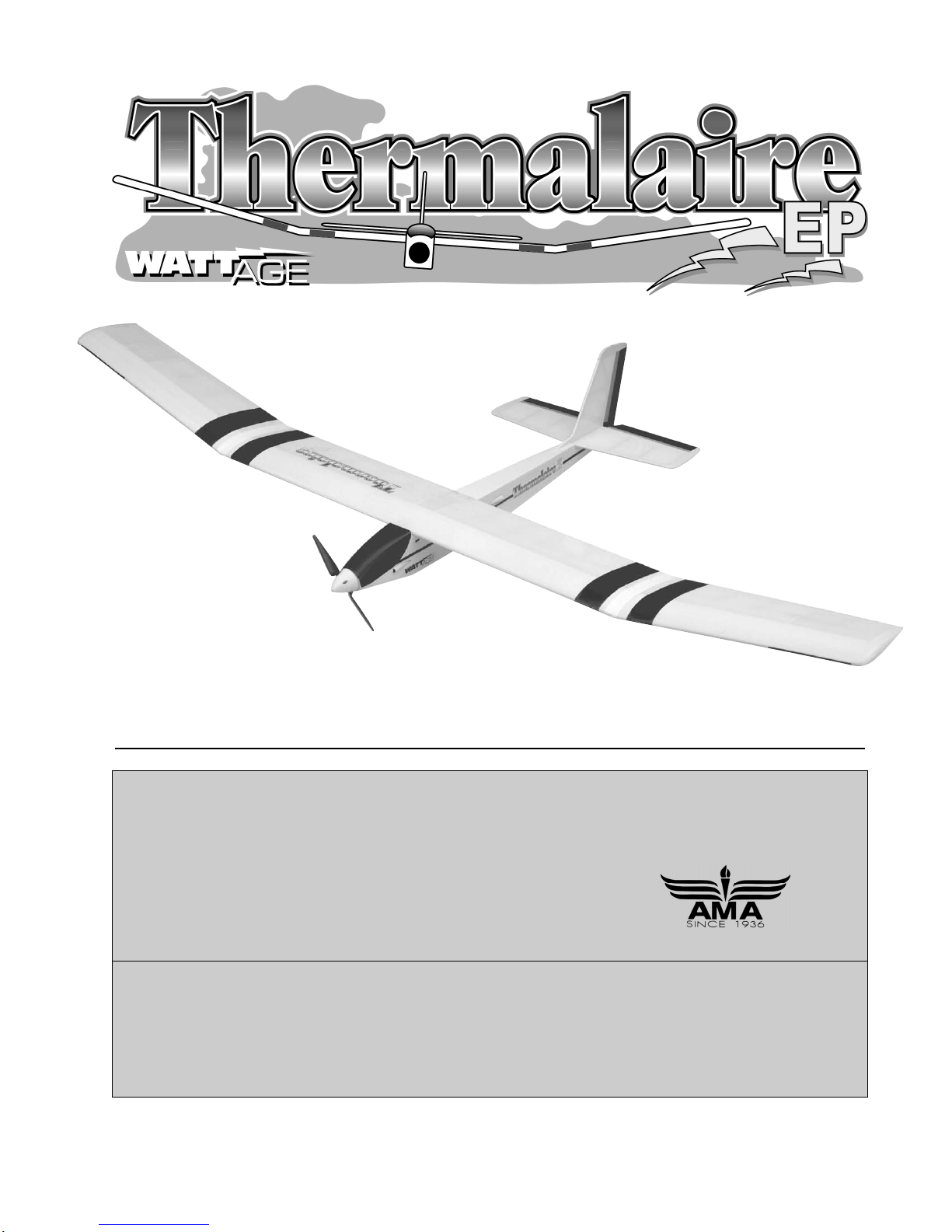

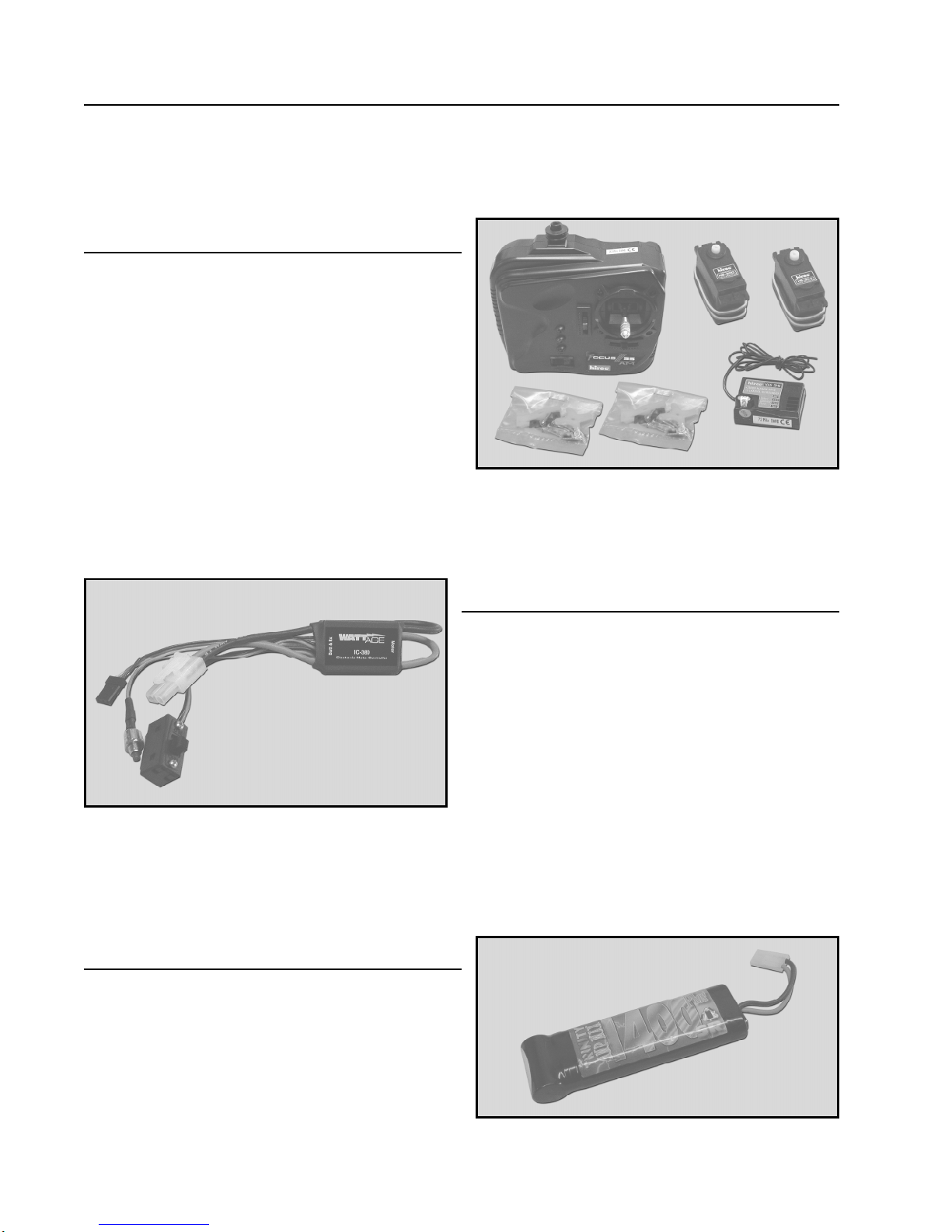

❑9) Turn on the transmitter and plug the flight

battery into the speed control. If the motor turns on

immediately, use the throttle lever on the back of the

transmitter (Focus 3 only) to turn off the motor.

❑10) With the motor turned off, test the opera-

tionof thetwo servos.Both servosshould movewhen

you move the control stick.

❑11) Carefully spray a couple of light sprays of

Performance Plus Motor Spray inside the motor

openings and apply a small drop of Trinity Break-

In Drops onto each of the two motor bushings. See

photo # 2 below.

Photo # 1

Photo # 2

❑12) Using a couple of paper towels, wipe off

the excess motor spray and oil.

❑13) Slowly turn on the motor using the trans-

mitter throttle lever (Focus 3 only). Position the

throttle lever to about 1/3 throttle and let the motor

run. While the motor is running, apply a light spray

of motor spray inside the motor openings once every

minute, followed by a small drop of Break-In Drops

on each of the bushings. Do this until the battery is

fully discharged (i.e., the motor stops).

☛If you have chosen to usean on-off only motor

controller, complete the same process but only run

the motor in two-minute intervals, letting the motor

cool between each.

❑14) After the battery has discharged and the mo-

tor has stopped, spray motor spray through the motor

openings until the fluid runs clear. Apply a couple of

drops of Break-In Drops to the bushings and wipe

away all of the excess using paper towels.

❑15) Reinstall the motor, propeller assembly and

canopy. Reverse the removal steps for installation.