Page 6

©2005 Accent Signage Systems, Inc. All rights reserved.

TM

Raster Method of Braille

Working with Other Materials

Plastic and metal are not the only choices for sign substrates using the

Raster

Also bear in mind that any time you use clear Rasters

Wood: Most woods can use the friction-fit Raster

™ method. We have experimented extensively with different materials.

Use the information here as a starting point, but always test an unknown

material before using it for a job.

™, the material

underneath will be visible through the Braille dots. If the material under the

surface is a different color, you may want to consider using one of the

opaque colors of Rasters™.

™ method, but avoid

softer woods. Any wood softer than pine isn't likely to be dense or strong

enough to support the Rasters™. Plywood and manufactured wood products

like MDF will work well.

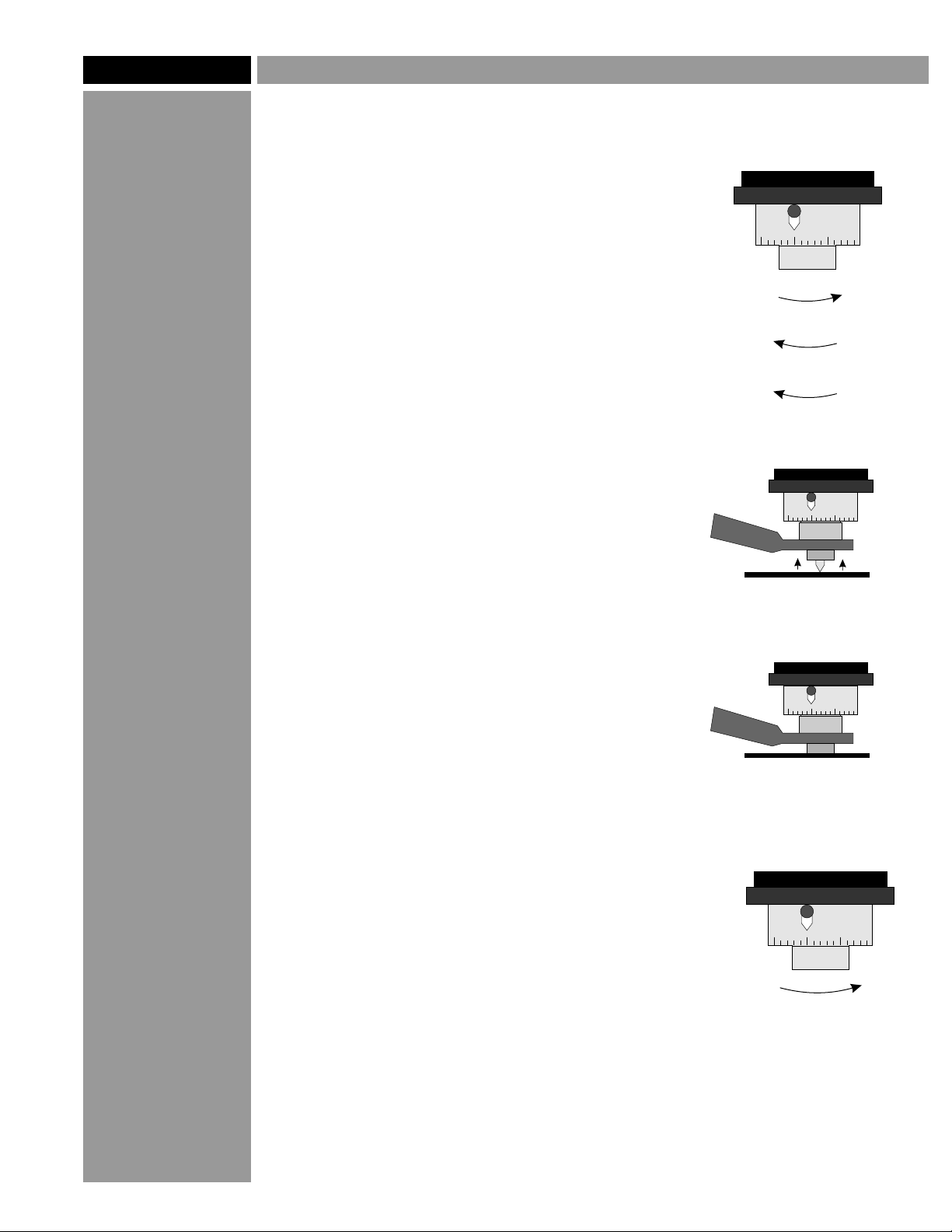

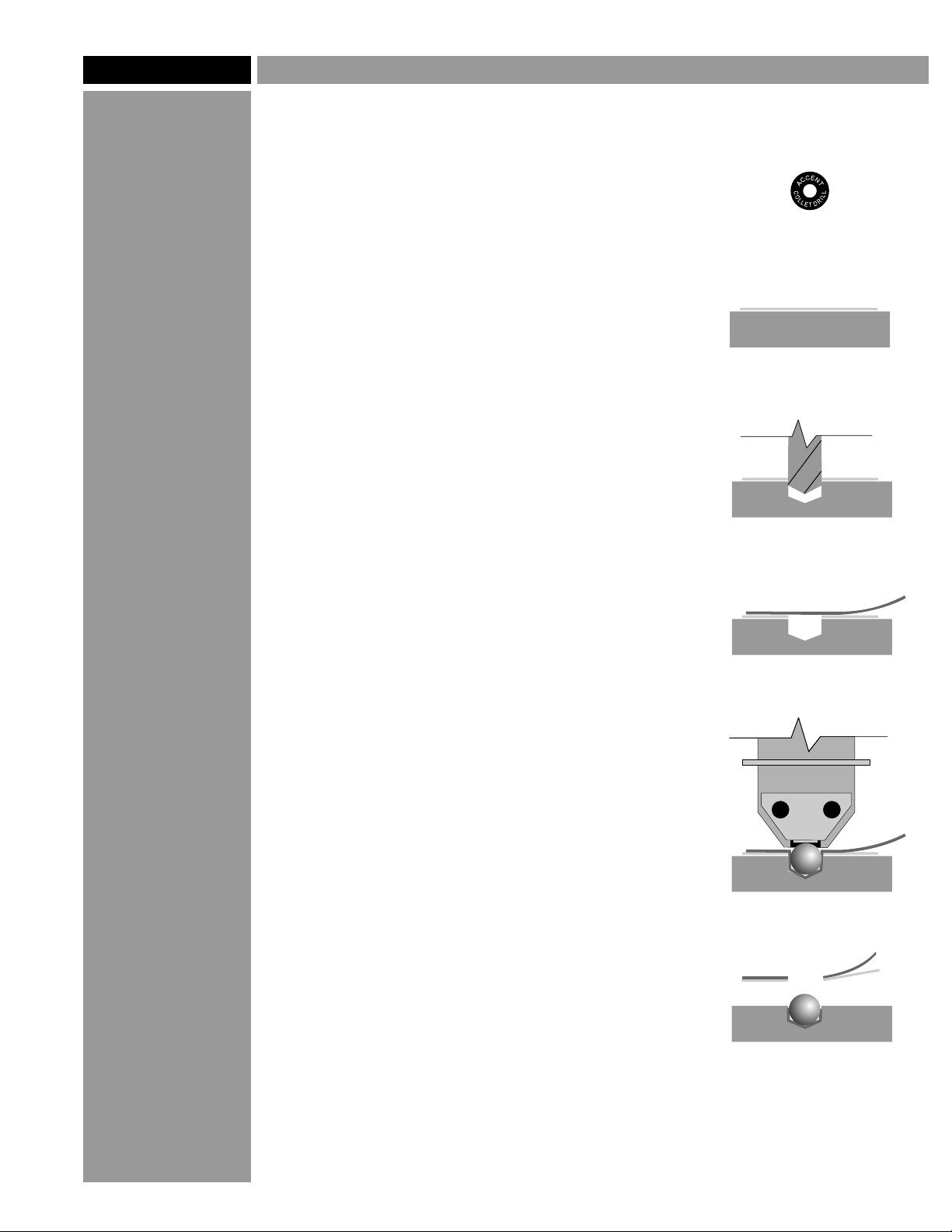

High-pressure laminates: Laminated materials such as Formica® generally

shoud use the adhesive-assist method. In some cases, a hybrid of the two

methods will work best; drill the holes using the collet assembly, but insert

the Rasters™ dry (no adhesive).

Phenolic or fiber-reinforced plastic: Use the adhesive-assist method with

these materials. Be aware that these materials are abrasive and will wear out

tools faster than other plastics.

Expanded PVC plastic: Lightweight sign materials like Sintra® are not

strong or dense enough to support Rasters™ and are not recommended.

Solid-surface materials: Materials such as Corian® are essentially dense

hard plastic and will work best with the collet assembly. Like laminated

materials, adhesive sometimes isn't necessary with these materials.

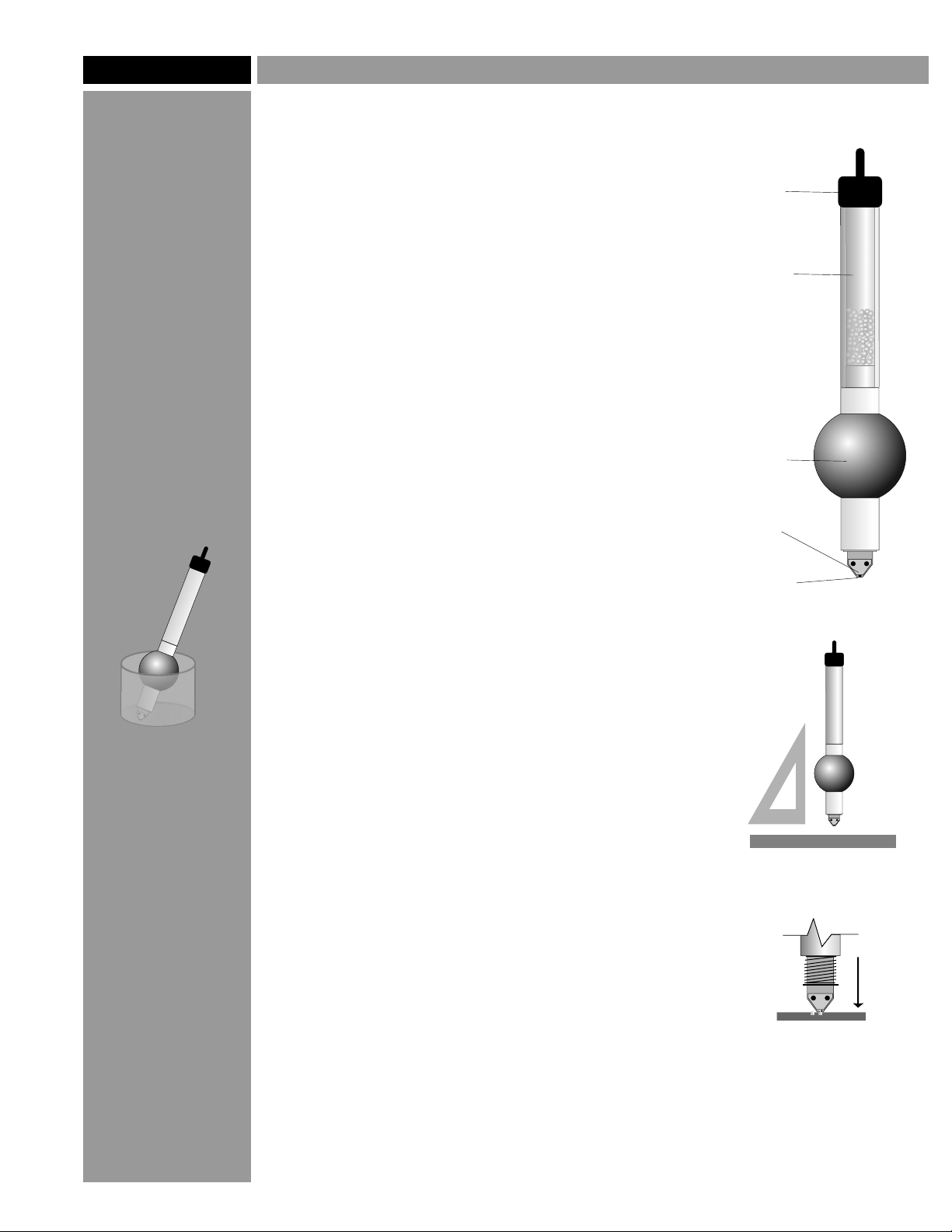

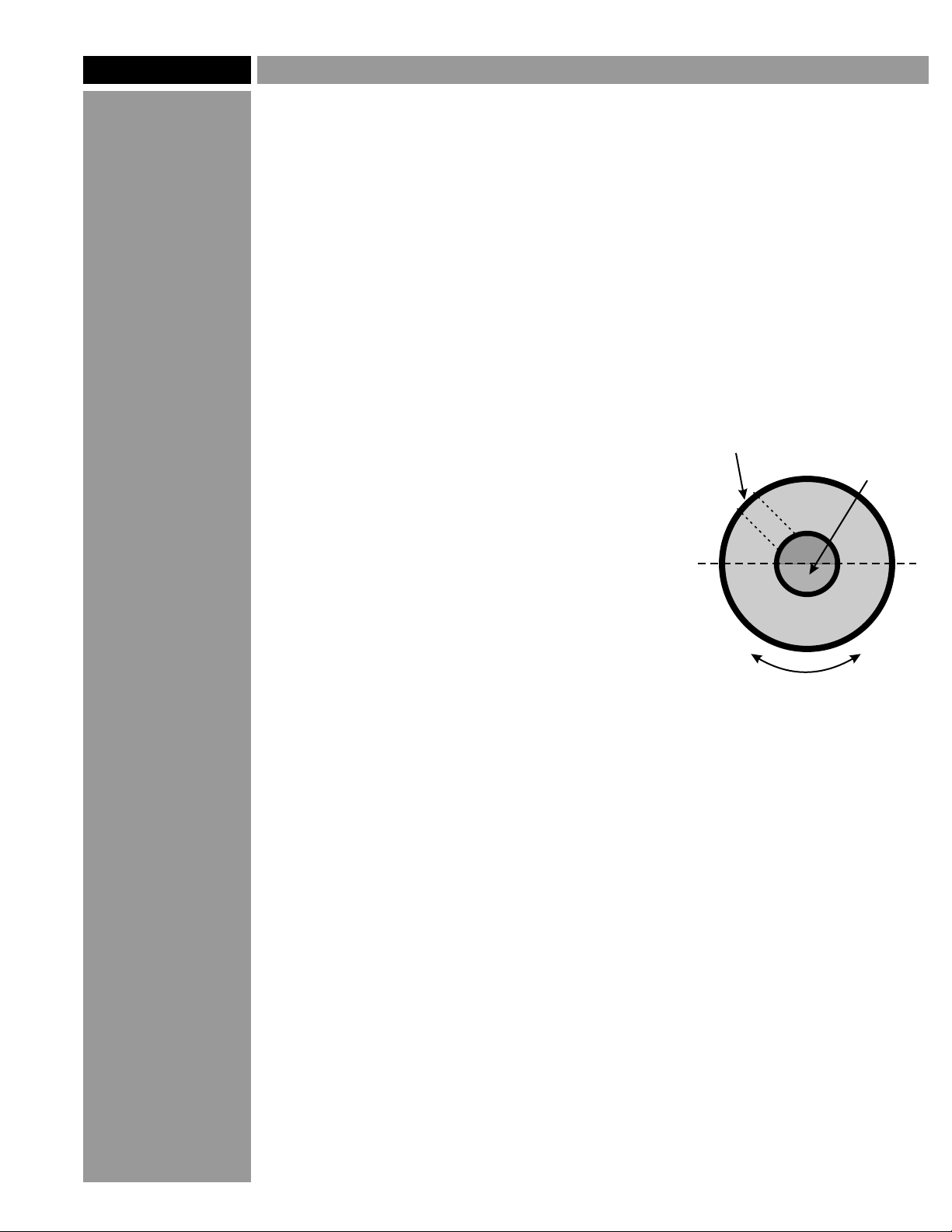

Hard stone (marble/granite): It is difficult to work with these materials

without the proper tools. You can use the carbide drill bit, but it will wear out

quickly. If you have access to proper stoneworking tools, and can drill 1/16"

holes to a precise depth, you can insert Rasters™ using adhesive-assist.

Soft stone (sandstone, etc): Softer stone is easier to drill into, but use

caution when inserting the Rasters™. Use adhesive-assist, and test the

adhesive to make sure it sticks to the stone.

Glass: It is possible to drill holes for Rasters™ into glass, but it is not

practical. The process is very difficult and time-consuming. Working with

glass requires special tools, training, and equipment. We don't recommend

you try drilling into glass unless you have experience. Substitute clear acrylic

or polycarbonate for real glass.