A111 Pulsed Coherent Radar (PCR)

Datasheet, v1.8

Page 3 of 34 2019-06-12 © 2019 Copyright by Acconeer

Table of Contents

1Revision History........................................................................................................................................... 4

2Description.................................................................................................................................................... 5

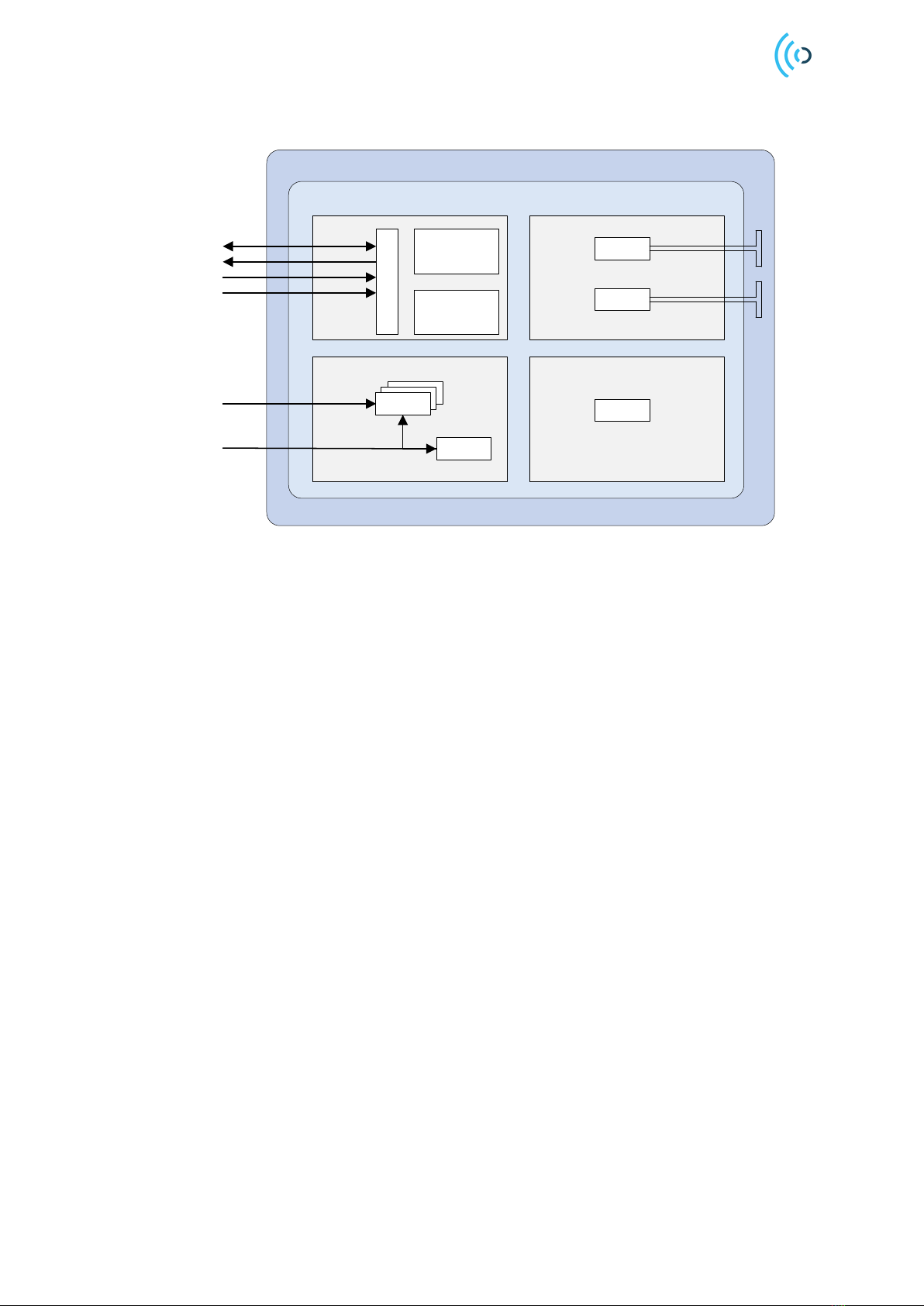

2.1 Functional Block Diagram.................................................................................................................. 6

3Pin Configuration and Functions............................................................................................................... 7

4Specifications............................................................................................................................................... 9

4.1 Absolute Maximum Ratings............................................................................................................... 9

4.2 Environmental Sensitivity................................................................................................................... 9

4.3 Recommended Operating Conditions............................................................................................ 10

4.4Electrical Specification ..................................................................................................................... 10

4.5 Power Consumption Summary....................................................................................................... 11

4.6 RF Specification................................................................................................................................ 11

5Timing Requirements.................................................................................................................................12

5.1 Serial Peripheral Interface............................................................................................................... 12

6Typical Characteristics...............................................................................................................................14

6.1 Distance Accuracy............................................................................................................................ 14

6.2 Amplitude Accuracy.......................................................................................................................... 15

6.3 Relative Phase Accuracy................................................................................................................. 15

6.4 Half Power Beamwidth (HPBW)..................................................................................................... 16

7Functional Description ...............................................................................................................................17

7.1 Acconeer Software ........................................................................................................................... 18

7.2 Software Integration ......................................................................................................................... 18

7.3 Power Up Sequence......................................................................................................................... 19

8Layout Recommendations.........................................................................................................................21

8.1 Bill of Material (BoM)........................................................................................................................ 22

8.2 XTAL................................................................................................................................................... 23

8.3 External clock source....................................................................................................................... 24

8.4 Power supply..................................................................................................................................... 25

9Regulatory Approval...................................................................................................................................27

9.1 ETSI.................................................................................................................................................... 27

9.1.1 EU declaration of conformity ..................................................................................................... 27

9.2 FCC Approval.................................................................................................................................... 28

9.2.1 FCC Regulatory Notes................................................................................................................ 28

9.2.2 FCC Grant Authorization............................................................................................................ 29

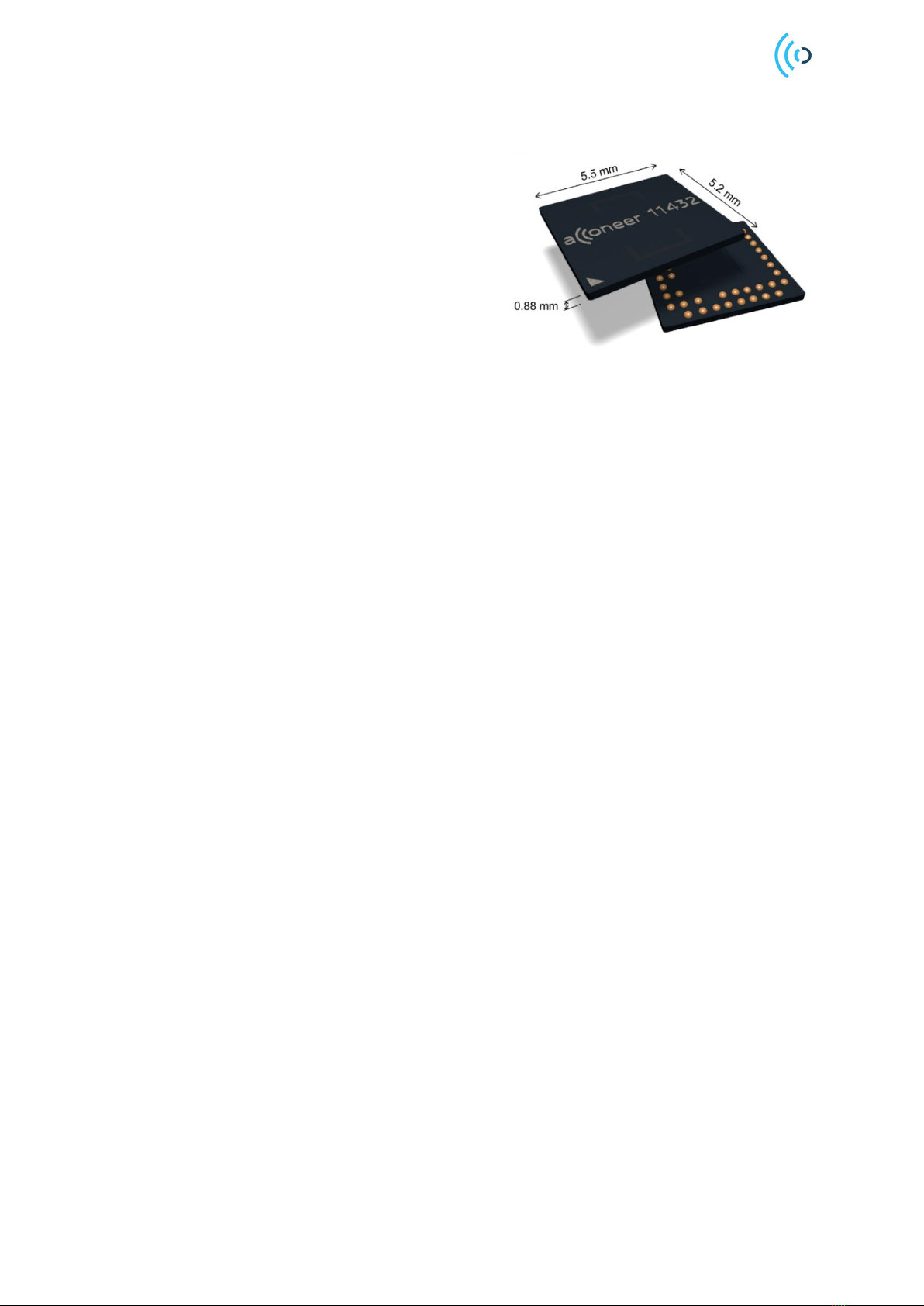

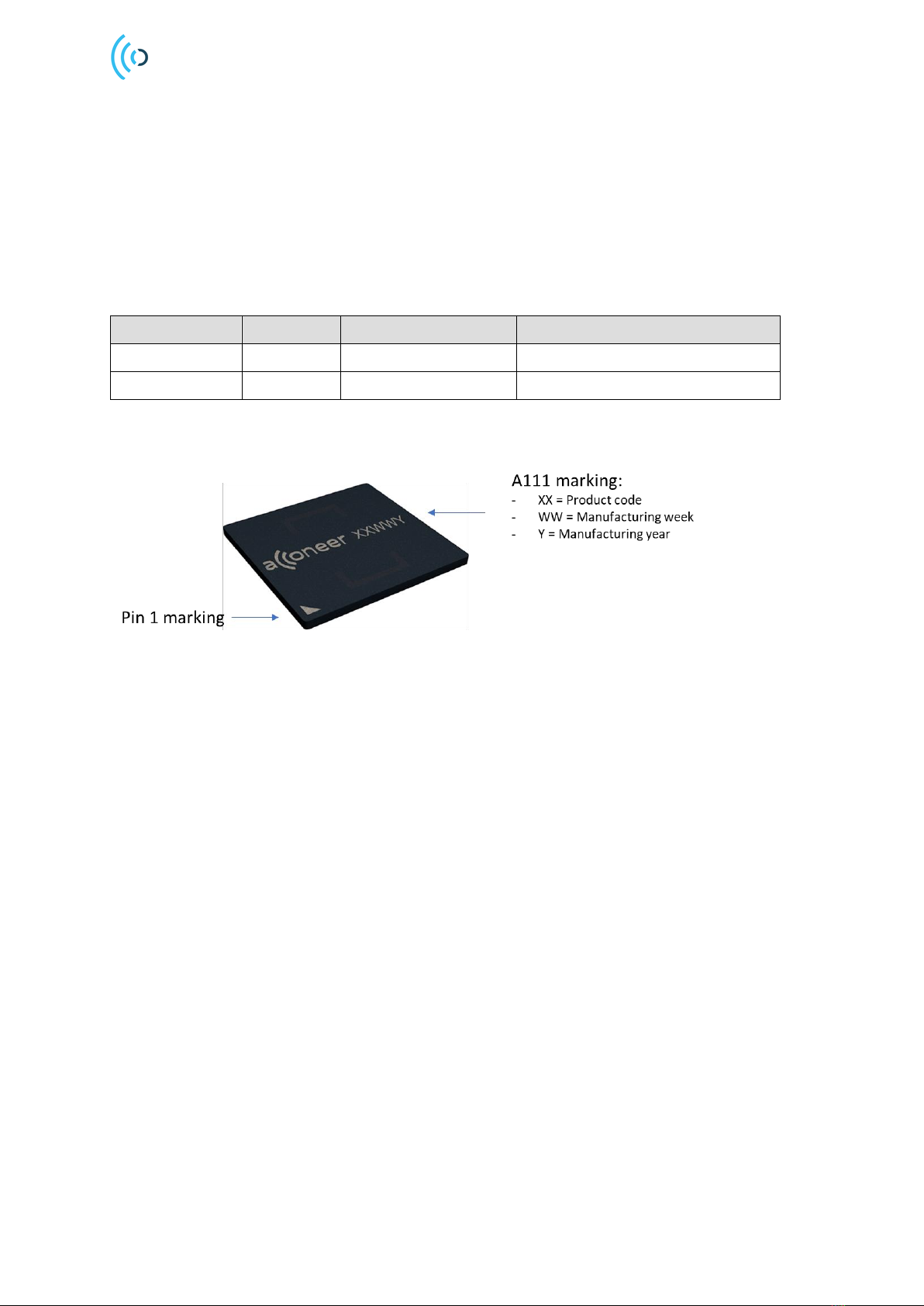

10 Mechanical Data.....................................................................................................................................30

10.1 Recommended Reflow Profile ........................................................................................................ 32

11 Abbreviations..........................................................................................................................................33

Disclaimer.............................................................................................................................................................34