Accucraft D&RGW C-16 User manual

Other Accucraft Toy manuals

Accucraft

Accucraft 4-6-0 BLACK 5 User manual

Accucraft

Accucraft D&RGW C-19 2-8-0 User manual

Accucraft

Accucraft ACCUCRAFT 7/8 SCALE 7 x 12 INCH BAGNALL User manual

Accucraft

Accucraft FLYING SCOTSMAN User manual

Accucraft

Accucraft Dora User manual

Accucraft

Accucraft WSL #3 heisler User manual

Accucraft

Accucraft SOUTHERN PACIFIC 2-6-0 M-6 ELECTRIC User manual

Accucraft

Accucraft DSP&P 2-8-0 User manual

Accucraft

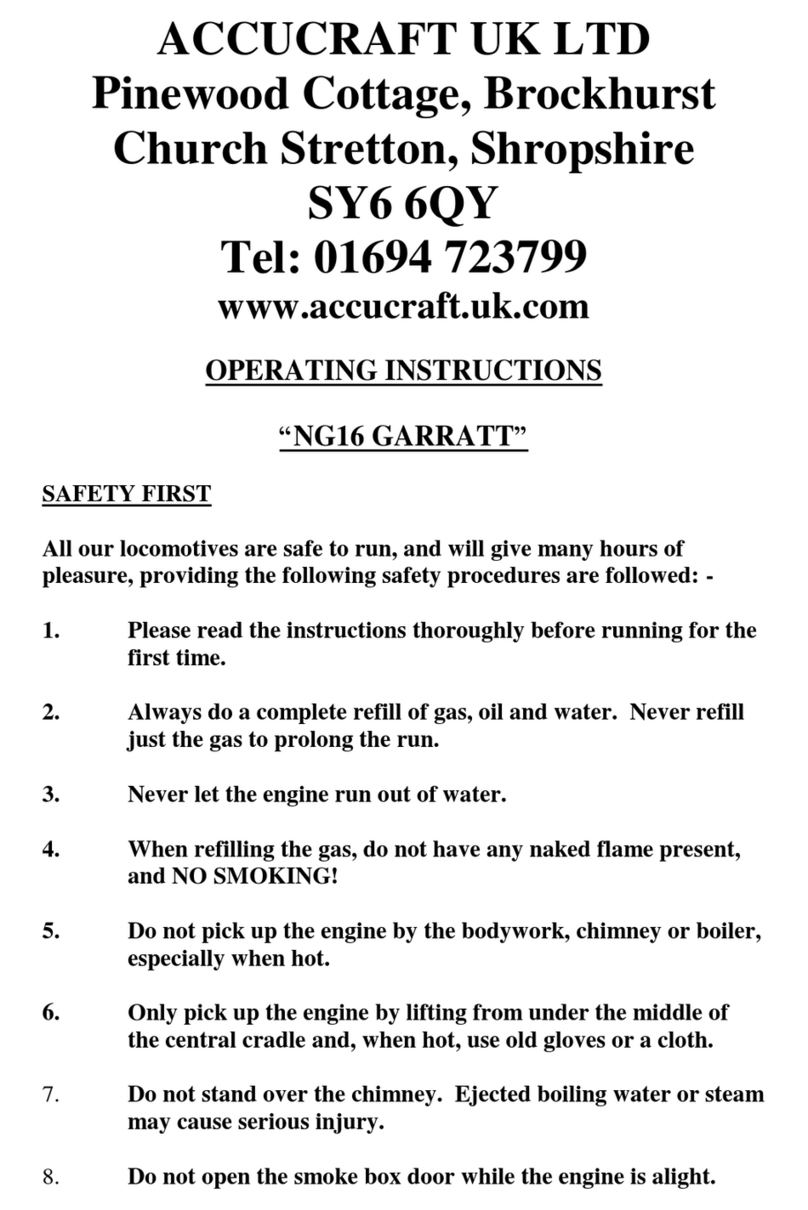

Accucraft NG16 GARRATT User manual

Accucraft

Accucraft KERR STUART WREN 0-4-0ST User manual

Accucraft

Accucraft D&RGW K-37 User manual

Accucraft

Accucraft wsl 15 User manual

Accucraft

Accucraft D&RGW C-16 User manual

Accucraft

Accucraft D&RGW K-27 463 User manual

Accucraft

Accucraft PECKETT 0-4-0ST Assembly instructions

Accucraft

Accucraft GWR 61XX PRAIRIE User manual

Accucraft

Accucraft "W&L Hunslet No. 14" MANUAL CONTROL User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions