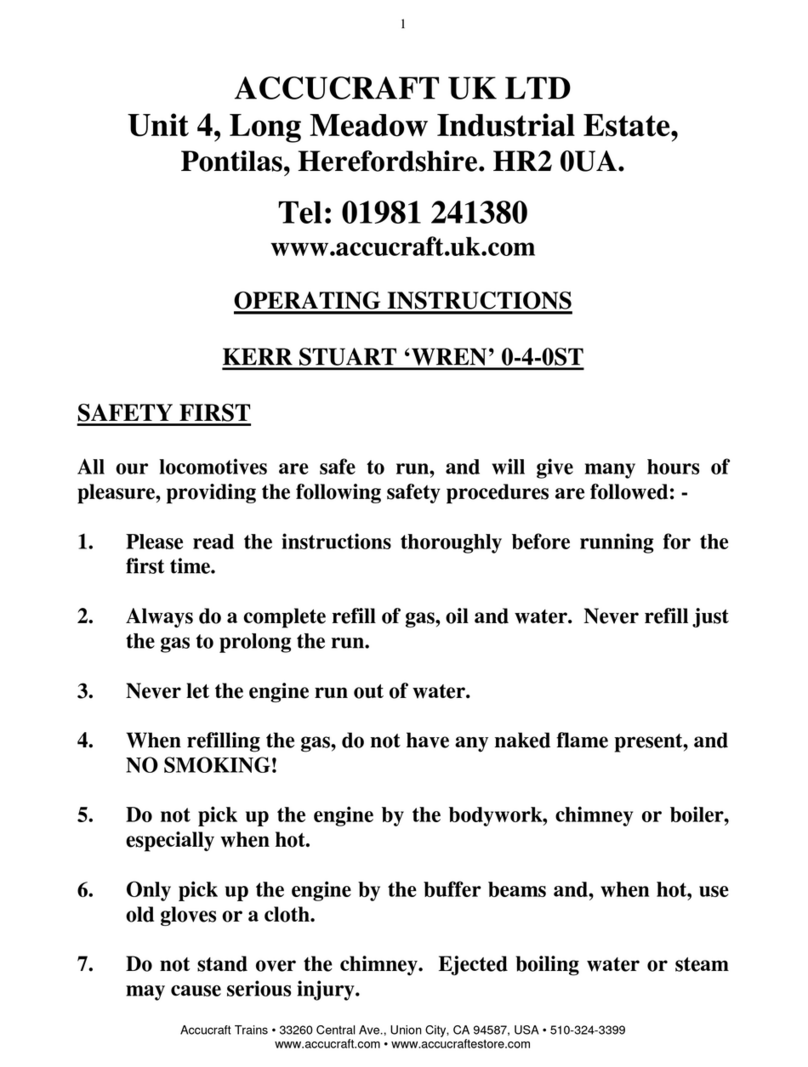

“outside” positions). This will allow water in the cylinders to drain while the cylinders heat up

to working temperature. As steam enters cold cylinders, it condenses, so expect a fair amount

of water to come out at the beginning of each run. Once the cylinders have warmed up, you

can close the drain cocks, if you wish. However, because the holes in the drains are so small,

the engine can be run with them wide open if you like the steam effects. To close them, move

the levers to the “up” position.

Running

Move the reversing lever at the right side of the cab to the forward position. With the engine

on the track, and without a train, open the throttle. The engine may need to be pushed a little

to overcome the steam condensing into water in the cold cylinders, but the open drain cocks

will minimize this. After a few moments, the engine should take off on its own, moving away

smoothly.

Once the engine is running smoothly, a train can be coupled on and the run can proceed.

Since all of the locomotiveʼs functions are controlled from the cab, it can be driven like a full-

size engine, meaning that youʼll have to stay with the engine through the run if you want to

change its speed or direction. If you have a suit-

able track, the engine can be left to run on its own at a steady speed. Keep your eye on the water

glass. When the water level reaches the bottom of the glass, shut the engine down and repeat

the firing up process. With practice and good weather, steady runs of an hour or more are not

uncommon for this engine.

Shutting down

To shut the engine down, simply close the gas valve and allow the engine to run off any

residual steam. At the end of the run, open the blowdown valve and leave it open. This will

relieve the boiler of what little pressure remains and prevent a vacuum from forming inside

that could draw lubricating oil into the boiler if the throttle valve is not fully closed. Because

of the size of this engine, blowing down could take several minutes.

After a dayʼs operation in the garden, youʼll probably find that your engine has a coating

of oil all over it. This is steam-cylinder oil that has been exhausted from the stack. A simple

wipe down with a dry cloth is all thatʼs necessary to restore the engine to pristine condition.

This is best done while the engine is still warm. Wipe any grit and excess oil from the wheels

and running gear.

The boiler can be drained of water, or not, as you wish. Leaving water in the boiler will not

harm it. The lubricator can also be drained and refilled with steam oil in preparation for the next

run.

Cold-weather running

The weather can dramatically affect the performance of your locomotive. Cold and wind

can decrease efficiency to a disappointing level. Butane gas becomes liquid at 32°F and will

not work. As it approaches 32°, its pressure (and effectiveness) diminishes.

The compartment in the tender in which the gas tank resides can be filled with warm water

in cooler weather. This will warm the gas in the tank and keep its pressure up, which will cause

Instruction Manual - D&RGW K-27 Live Steam

Drain cocks open Drain cocks closed

Blowdown valve