- 3 -

3

©Copyright 2003 Accuspray Application Technologies, Inc., Cleveland, Ohio USA

800-618-6860 or 440-498-9677 Fax: 440-498-9815

V M X®Owners Manual

Introduction:

VMX®is a high output HVLP spray system

designed to handle a wide variety of coatings. This

system offers many advantages; the ability to spray

large quantities of material, less thinning of material,

greater speed, high transfer rates, low overspray,

and high finish quality. The VMX®system consists

of a 2hp oil-less compressor, a 2.5-gallon pressure

pot, and Accuspray’s model 19c low cfm HVLP

spray gun. Please take a few moments to familiarize

yourself with the operations of the VMX®to ensure

best results. Additional help can be obtained

through our technical service line at (800) 618-6860

ext. 191. Thank you for purchasing Accuspray.

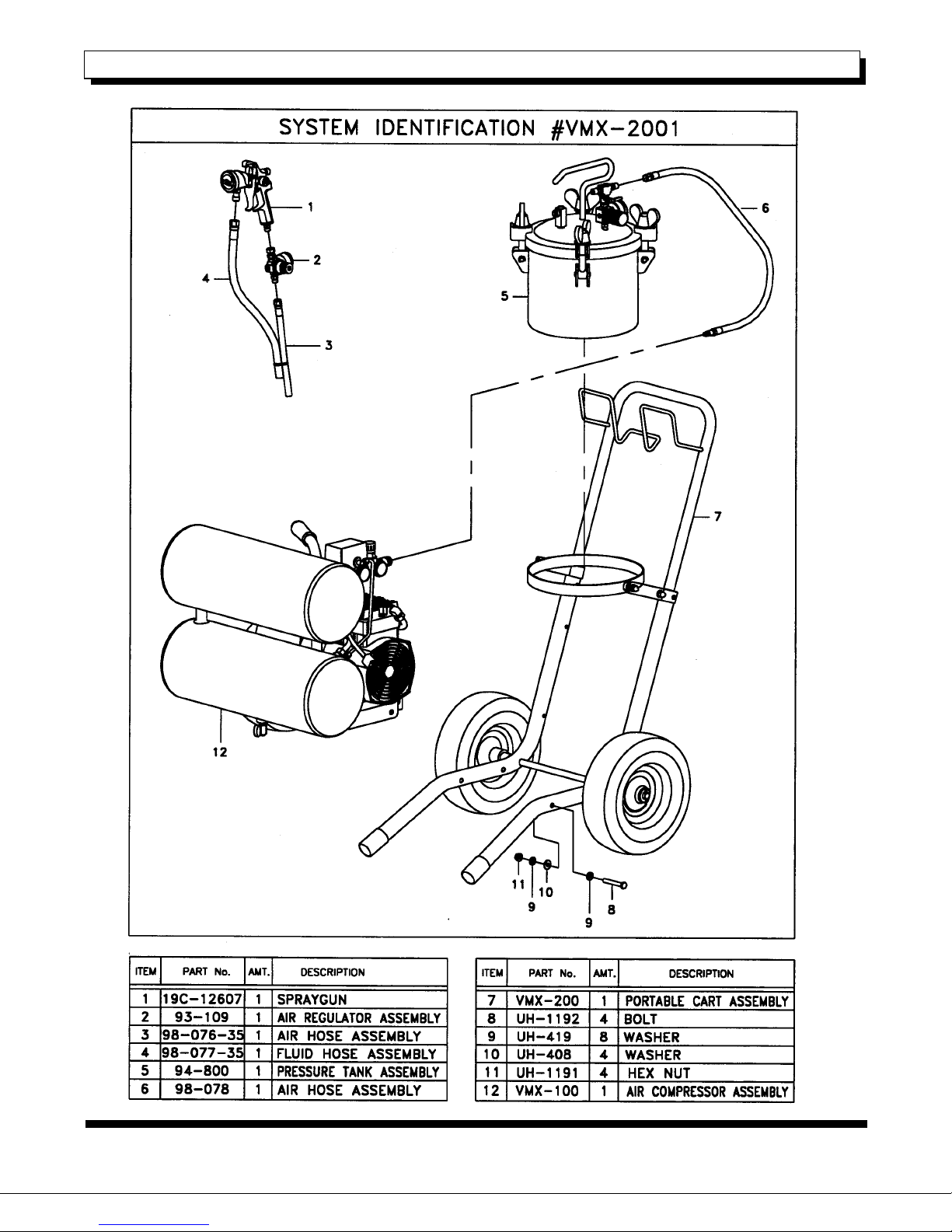

System Contents:

Your VMX system contains:

1- 19c-12607 Low cfm spray gun

1- 93-109 Spray gun air regulator

1- 98-076-35 Fluid hose assembly

1- 98-077-35 Air hose assembly

1- 94-800 2.5-gallon pressure pot with regulator

1- 98-078 Air supply hose

1- VMX-100 Compressor/tank assembly*

1- VMX-200 Cart assembly with pot ring*

*Shipped as a complete unit

See page 4 for a diagram of the system.

Before First Use:

The following tips can help to ensure proper

operation, avoid damage to the system, prevent

personal injury, and extend equipment life.

*Read and follow all safety instructions.

*Read and follow the compressor operations manual

included with this system.

*Always use the proper, grounded extension cord of

appropriate length and gauge (see compressor

manual). Failure to do so voids all warranties,

interferes with compressor operation, and will greatly

shorten the life of the compressor.

* Always fully release all pressure before opening,

cleaning, or servicing any part of this system.

* Always drain compressor air tanks at the end of

the day to avoid corrosion and cut down on moisture

in system air. Conditions may require more frequent

draining depending on environmental factors.

*Keep the air compressor as far away from the spray

area as possible. Extend the air supply line from the

compressor to the pot instead of increasing

extension cord length. Then move the pot closer to

the spray area.

*Always spray at the lowest possible pressure to

correctly atomize your coating. Over-pressurizing

wastes material, increases overspray and works the

unit harder than necessary.

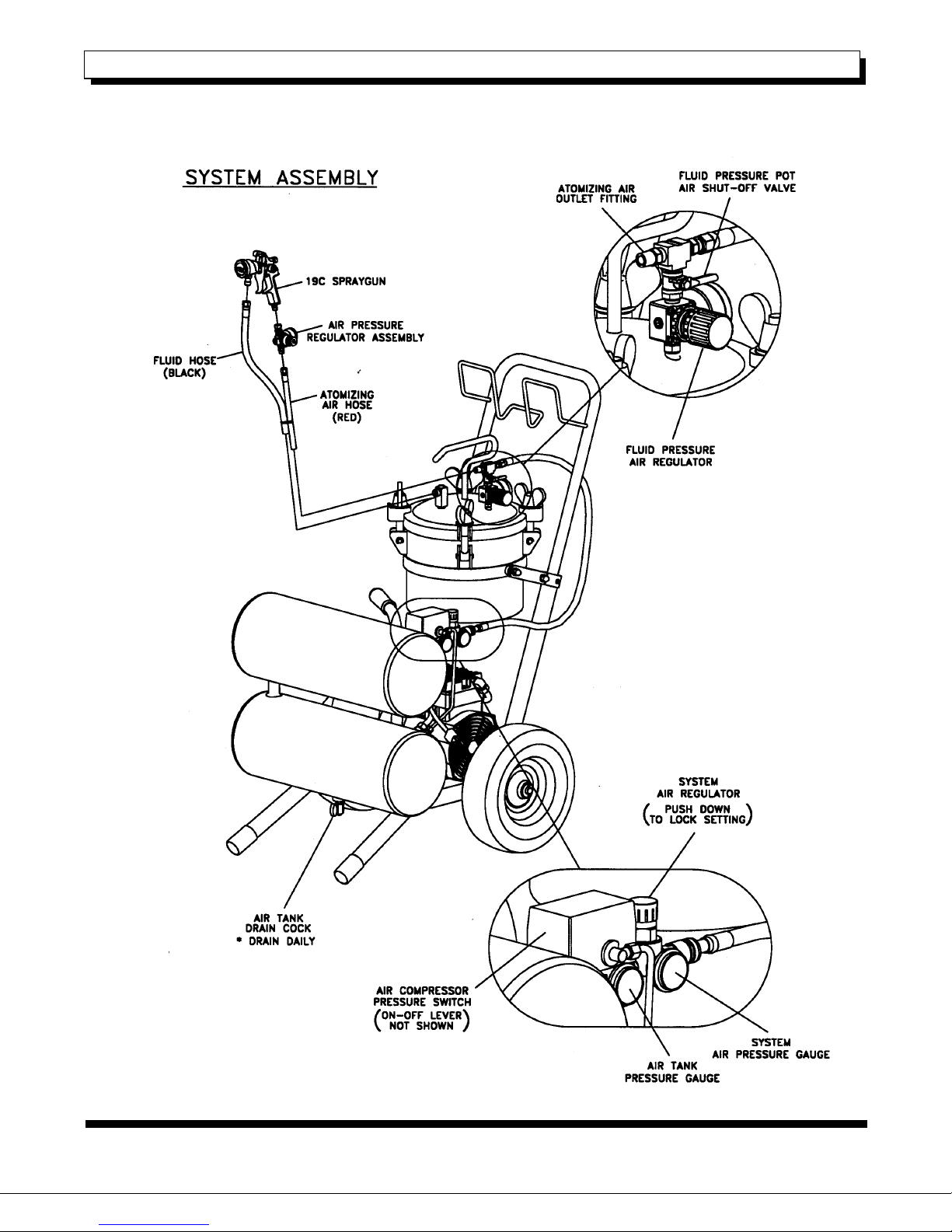

Set Up Instructions:

Diagrams illustrating the following instructions are

located on page 5.

1. Place the pressure pot into the cradle ring on the

cart assembly.

2. Connect the short red air supply hose to the

outlet regulator located on the compressor. This is a

quick coupler connection.

3. Connect the other end of the air supply hose to

the ¼ in. nipple located directly above the gauge on

top of the pressure pot. Fully seat and tighten the

connecting nut. This is a compression fitting and

must be tight to seal. Teflon tape is not necessary.

4. Connect the 35’ red air hose to the nipple just

opposite the connection made at step 3.

5. Attach spray gun regulator to the butt of the spray

gun. Use two wrenches to tighten completely;

failure to do so may damage the air fitting on the butt

of the gun. All connections use compression fittings

and do not require additional Teflon tape.

6. Connect the remaining end of the 35’ air hose to

the bottom of the regulator at the butt of the gun.

7. Connect the black fluid hose to the fluid outlet

fitting located on the top of the pot and connect the

opposite end of this hose to the fitting at the front of

the spray gun. Again, use two wrenches and

completely tighten.

8. Cable ties are supplied to band the fluid and air

hoses together and eliminate line tangle.

9. Check all connections to avoid any leakage.

Start Up/Operating Instructions:

Please refer to the compressor manual for

additional instructions.

1. Plug into appropriate power source.

2. Remove lid from pressure pot, add material to be

sprayed, replace lid and hand tighten until snug.

Always check for a good seal and tighten all bolts

evenly.

3. Turn on the compressor using the on/off switch

located on the pressure switch (see page 5 for

switch location).

4. Compressor will run until air storage tanks are

full. The compressor will stop when air tank

pressure reaches approximately 125 psi. The

pressure can be read at the gauge directly opposite

the on/off switch.

5. Open the pressure pot air supply valve located

on top of the pressure pot directly above the

regulator. When the red handle is up the valve is

open. Close the valve by moving the handle to the

right or left.

6. Slowly turn the dial on the supply air regulator

clockwise until the regulator reads 90 psi. This

regulator is located at the compressor.