AccuTemp XLR8 Administrator Guide

SP8144-2011

AccuTemp Products INC

8415 N. Clinton Park Dr, Fort Wayne IN 46825

www.accutemp.net

XLR8 UPPER HEATED PLATEN

INSTALLATION & OPERATOR MANUAL

Serial Number:

Model:

SP8144-2011 XLR8 Installation & Operation Manual 1

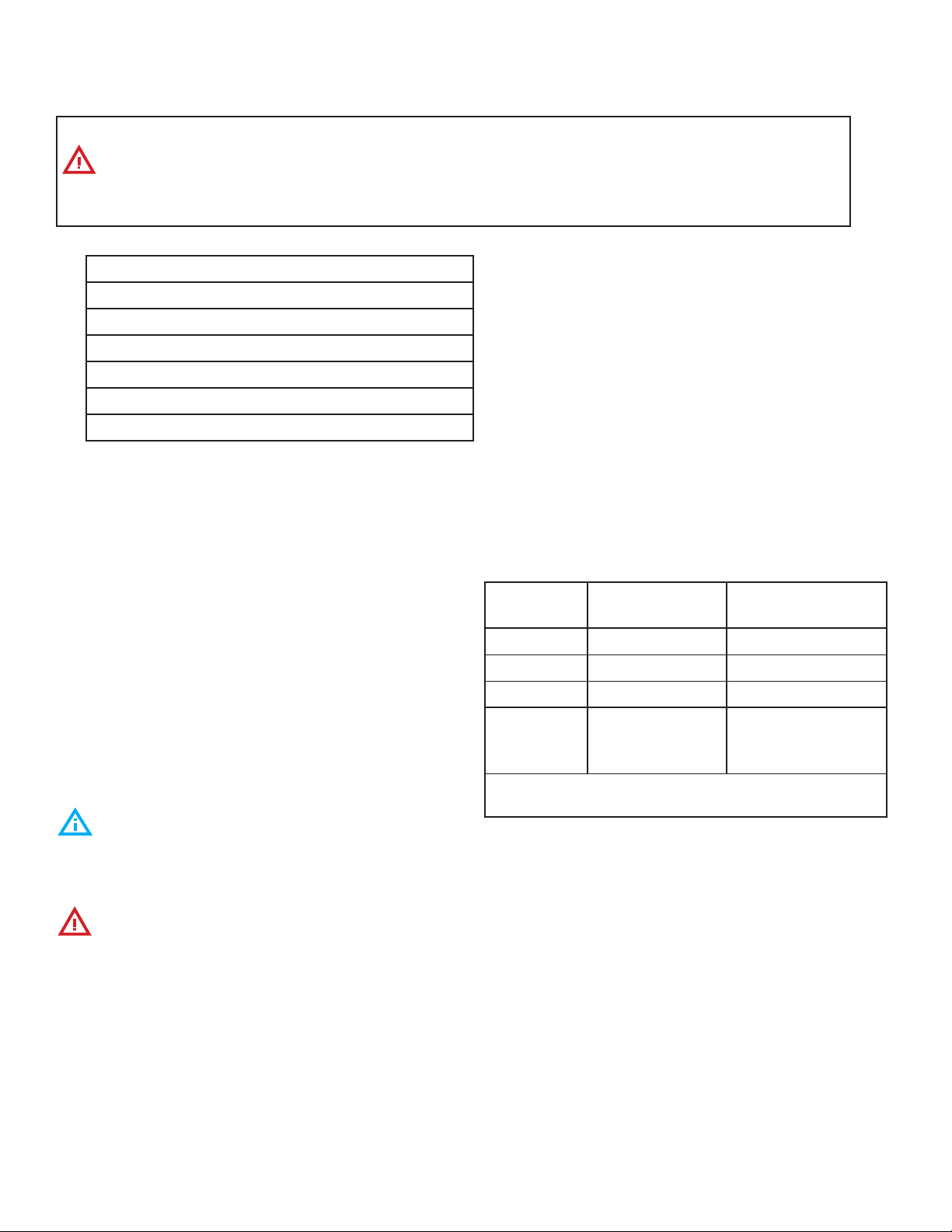

DESCRIPTION PAGE

Table of Contents / Document History 1

Safety Warnings 2-5

General Info 6-7

Start up Form 8-10

Installation 11-13

Operation 14-24

Planned Maintenance 25

Service & Troubleshooting 26-27

Warranty Information 28-30

TABLE OF CONTENTS

DOCUMENT HISTORY

Current Revision Date Prior Revision Date Revision

SP8144-2011 XLR8 Installation & Operation Manual 2

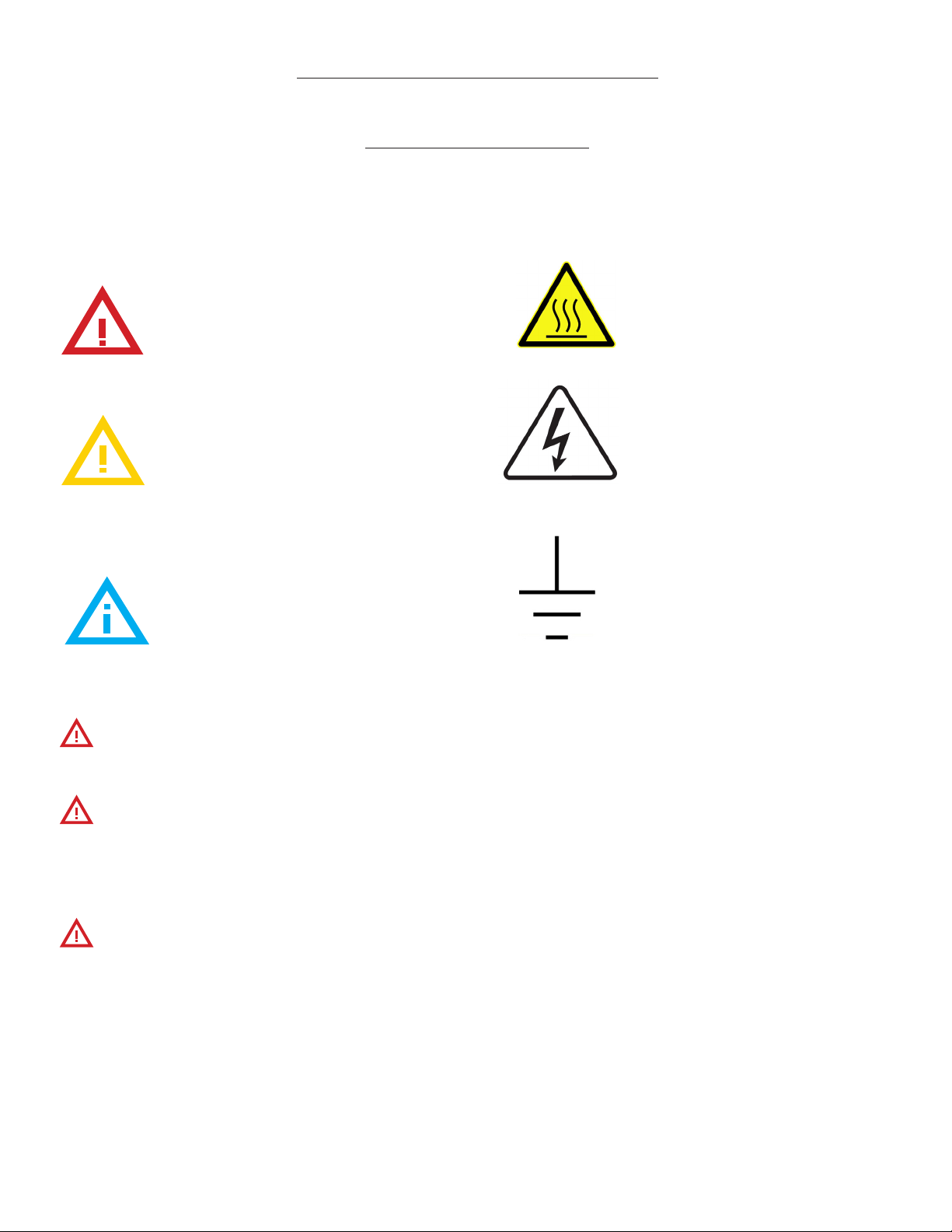

1. WARNING SYMBOL DEFINITIONS

SYMBOL DEFINITIONS

Symbols are used to attract your attention to possible dangers. They are only

eective if the operator uses proper accident prevention measures. Some of the

symbols are boxed text; while others maybe just picture icons. Please give this

information the respect they deserve for safe operation.

CAUTION -

HOT SURFACE

DANGEROUS

VOLTAGE

EARTH GROUND

DANGER

Indicates an imminently hazardous

situation; which, if unchanged, will

result in death or serious injury.

CAUTION

Indicates a potentially hazardous

situation; which, if unchanged, will

result in minor or moderate injury.

NOTE

Advises the reader of information

or instructions, vital to the

operation or maintenance of the

equipment.

In the event of a power failure, do not attempt to operate this equipment.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

Only qualified service technicians/electricians should install this equipment to ensure that

all electrical and safety requirements are met and that all wiring is installed in accordance

with all national, state and local electrical codes.

WARNING

WARNING

WARNING

SP8144-2011 XLR8 Installation & Operation Manual 3

2. General Information

2.1 Unit Specifications

MM5261-2009

AccuTemp Products, Inc.

8415 North Clinton Park • Fort Wayne, IN 46825 • 800-210-5907 • 260-493-0415 • Fax 260-493-0318 • accutemp.net

XLR8 Upper Heated Platen (Replace *** with voltage)

Model # XLR8***1B-00

208/1 Amp/ kW 10 A / 2.1 kW

240/1 Amp / kW 11.3 A / 2.7 kW

Breaker Size 15A

Unit Width (1 arm) 11.50

NEMA Plug (208/240) L6-30P

Notes:

1. Each XLR8™ Arm comes with 6’ power cord, separate receptacle

needed for each unit.

2. For use on individual branch circuits only.

®

AccuTemp product may be covered by one or more US Patents. See www.accutempip.net

XLR8™ UPPER HEATED PLATEN

Electric Upper Heated Platen Arm

24 3

8"

(COOKING DEPTH)

20"

4 11

16 "

"

4

UNIT WIDTH

UNIT DEPTH

16

39 1"

24 1

23 7

8"

(COOKING WIDTH)

4

3"22 15

"

5

16

4 8"

3"

16

10

(COOKING HEIGHT)

"

4

3

24

13

31 1

2"

44 13

16 "

Drawing shown with (2) XLR8 Upper Heated Arms

Mounting bracket illustrated and required.

Available in 2’, 3’ or 4’.

MM5261-2009

AccuTemp Products, Inc.

8415 North Clinton Park • Fort Wayne, IN 46825 • 800-210-5907 • 260-493-0415 • Fax 260-493-0318 • accutemp.net

XLR8 Upper Heated Platen (Replace *** with voltage)

Model # XLR8***1B-00

208/1 Amp/ kW 10 A / 2.1 kW

240/1 Amp / kW 11.3 A / 2.7 kW

Breaker Size 15A

Unit Width (1 arm) 11.50

NEMA Plug (208/240) L6-30P

Notes:

1. Each XLR8™ Arm comes with 6’ power cord, separate receptacle

needed for each unit.

2. For use on individual branch circuits only.

®

AccuTemp product may be covered by one or more US Patents. See www.accutempip.net

XLR8™ UPPER HEATED PLATEN

Electric Upper Heated Platen Arm

24 3

8"

(COOKING DEPTH)

20"

4 11

16 "

"

4

UNIT WIDTH

UNIT DEPTH

16

39 1"

24 1

23 7

8"

(COOKING WIDTH)

4

3"22 15

"

5

16

4 8"

3"

16

10

(COOKING HEIGHT)

"

4

3

24

13

31 1

2"

44 13

16 "

Drawing shown with (2) XLR8 Upper Heated Arms

Mounting bracket illustrated and required.

Available in 2’, 3’ or 4’.

SP8144-2011 XLR8 Installation & Operation Manual 4

3. INSTALLATION

TOOLS REQUIRED:

Spirit Level

Phillips Screw Driver

Small Blade Straight Screw Driver

Digital Clamp Ammeter

Multimeter

Weighted Temperature Probe

Digital Temperature Meter

3.1 INSTALLATION NOTICE

Only qualified service technicians/electricians should perform the installation to ensure

that all electrical and safety requirements are met and that all wiring installations are

performed in accordance with all national, state and local codes.

Location Combustible

Construction

Non-Combustible

Construction

Back 2 Inches 0 inches

Right Side 1 Inch 0 inches

Left Side 1 inch 0 inches

Above

Arms

26 inches

(+height of

griddle)

26 inches (+height

of griddle)

SUITABLE FOR ALL INSTALLATION ON COMBUSTIBLE

FLOORS.

3.2 UNPACKING

This equipment was carefully inspected before

shipment from the factory. The transportation

company assumes full responsibility for safe

delivery to the customer until customer

acceptance of the package. Careful inspection

of the packaging and the equipment should

be completed before acceptance from the

transportation company.

3.3 XLR8 LIFTING

The equipment is heavy enough to require

additional manpower or powered assistance

when installing or moving.

When moving the equipment manually

make sure there are enough people for the task

as the equipment is heavy.

Make sure the equipment is not dropped

during moving. People doing the carrying

could be seriously injured and/or the

equipment damaged. The manufacturer does

not accept any responsibility for damage

resulted from such actions.

3.4 LOCATION AND PLACEMENT

The XLR8 electric equipment has been designed

to be mounted on an AccuTemp AccuSteam

griddle.

The operating temperature ranges from 200°-

400°F (93°- 204°C). Since these temperatures

can also be found on surfaces around the

perimeter of this commercial equipment, care

should be given not to install next to or against,

objects or surfaces with a low melting or flash

point.

3.5 CLEARANCES

3.6 LEVELING

The equipment must be installed in a level

condition. An out-of-level condition will result in

an uneven compression of product and uneven

cooking.

SP8144-2011 XLR8 Installation & Operation Manual 5

3.7 ELECTRICAL CONNECTIONS

3.7.1 ELECTRICAL SUPPLY

The electrical voltage requirement is

listed on the data plate that is located on the

lower left side panel.

Make sure the voltage is within 10% of

the voltage listed on the steamer data plate.

Connection to any other voltage not

identified on the data plate will cause damage

to the components and is not covered under

warranty.

Grounding provides a path for electric

current to reduce risk of shock.

If provided with one, the plug must be

plugged into a receptacle that is properly

installed and grounded in accordance with all

National, State and local electrical codes or in

the absence of local electrical codes with the

National Electric Code, ANSI/NFPA 70, or the

Canadian Code, CSA C22.2 as applicable.

Under no circumstances shall the plugs

grounding prong be cut or bent to fit a

receptacle other than the one specified.

Do not use any adapters.

Any in-field modification made that

bypass the safety features of this equipment

will result in serious injury or death.

Any in-field modifications made without

written authorization from AccuTemp

Products, Inc. will void all written and oral

warranties.

This commercial equipment must

be properly grounded in accordance of

all current National, state and local codes.

Never remove the ground prong of the plug.

The XLR8 has been designed, manufactured

and tested to meet or exceed the demanding

standards of safety set forth by ANSI/NFPA

70.To to ensure that this high level of

safety is maintained in your installation, it is

important that you read and understand the

following information before attempting to

use the equipment.

3.7.2 ELECTRICAL REQUIREMENTS

Electrical requirements are listed on the

data plate located on the front right of the

control panel. All standard XLR8 are wired to

an internal power supply terminal and draw

power from the griddle.

If supplied with a 6ft (1.83m) cord and the

appropriate UL listed plug, the equipment

must be connected to the correct voltage

specified on the units data tag. Depending on

the rating listed on the data plate. Make sure

that the voltage at your supply receptacle

is within ± 10 % of the voltage listed on the

griddle data plate. Connection to any other

voltage may cause damage to components in

the commercial equipment. The equipment

plug must be used with the appropriate

receptacle.

3.7.3 GROUNDING INSTRUCTIONS

Grounding provides a path for electric

current to reduce the risk of shock. This

product is equipped with a power cord

having a grounding conductor and a

grounding plug. The plug must be plugged

into a grounded receptacle that is installed

and grounded in accordance with local

codes, or in the absence of local codes,

with the National Electric Code, NFPA 70, or

the Canadian Electrical Code, CSA22.2, as

applicable

SP8144-2011 XLR8 Installation & Operation Manual 6

3.8 START UP PROCEDURE

1. Ensure both arms are square with

the griddle. Use the griddle sides as a

reference.

2. If adjustment is needed, loosen the nuts

that hold the lift assembly to the base lift

bracket.

3. Resecure the nuts once the arm assembly

has been squared.

3.8.1 INSTALL TEFLON SHEET

1. Raise the two teflon retaining handles o

the arm.

2. Secure one side of the teflon sheet using

one handle, keeping the handle at the

central point of the arm (“Figure 11”).

3. Stretch the teflon across the underside

of the platen and secure with the other

retaining handle.

TEST INSTALL

1. Plug in lift power cord to correct NEMA

receptacle.

2. Power the XLR8 on using control buttons

located on top of the arm.

3. Keep arm elevated an allow to heat to

temperature displayed on control digital

display.

4. Monitor temperature using a fluke wand

meter.

5. Once unit has reached temperature allow

15 minutes for it to stabilize, then take

three temperature readings from the

front, middle and back of the arm cooking

surface.

6. The temperatures should be with 5+/-F of

the temperature displayed.

SP8144-2011 XLR8 Installation & Operation Manual 7

4. OPERATION

RISKS RESULTING FROM CONTACT WITH VERY HOT OBJECT:

HOT

Hot areas may form during the cooking process. Use protective gloves whenever handling hot

objects.

During the cooking process, do not handle cookware containing liquids or liquid foodstus

located above eye level. Danger of burns.

Be sure all operators read, understand and follow the information contained in this manual

including caution warnings, operating instructions and safety instructions.

Never use wet or damp gloves as moisture can conduct heat quickly.

Keep the floor in front of the equipment clean and dry. If spills occur, clean immediately to

avoid potential injuries.

Do not use abrasive (or steel) materials, such as wire brushes, metal scouring pads to clean

the teflon sheet surface.

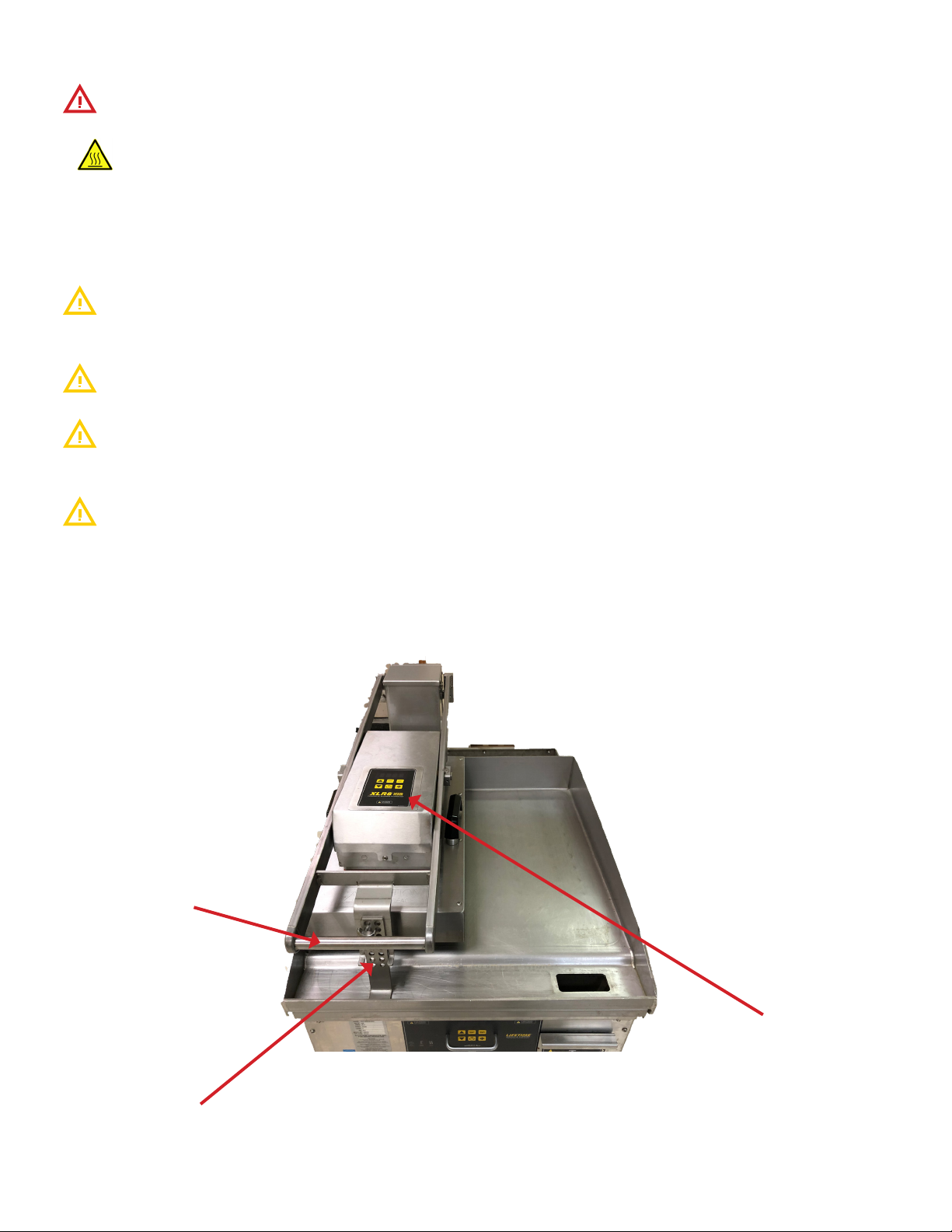

4.1 VISUAL IDENTIFICATION

Fig 4.B

Lift Handle

Height adjustment

knob

Control Panel

SP8144-2011 XLR8 Installation & Operation Manual 8

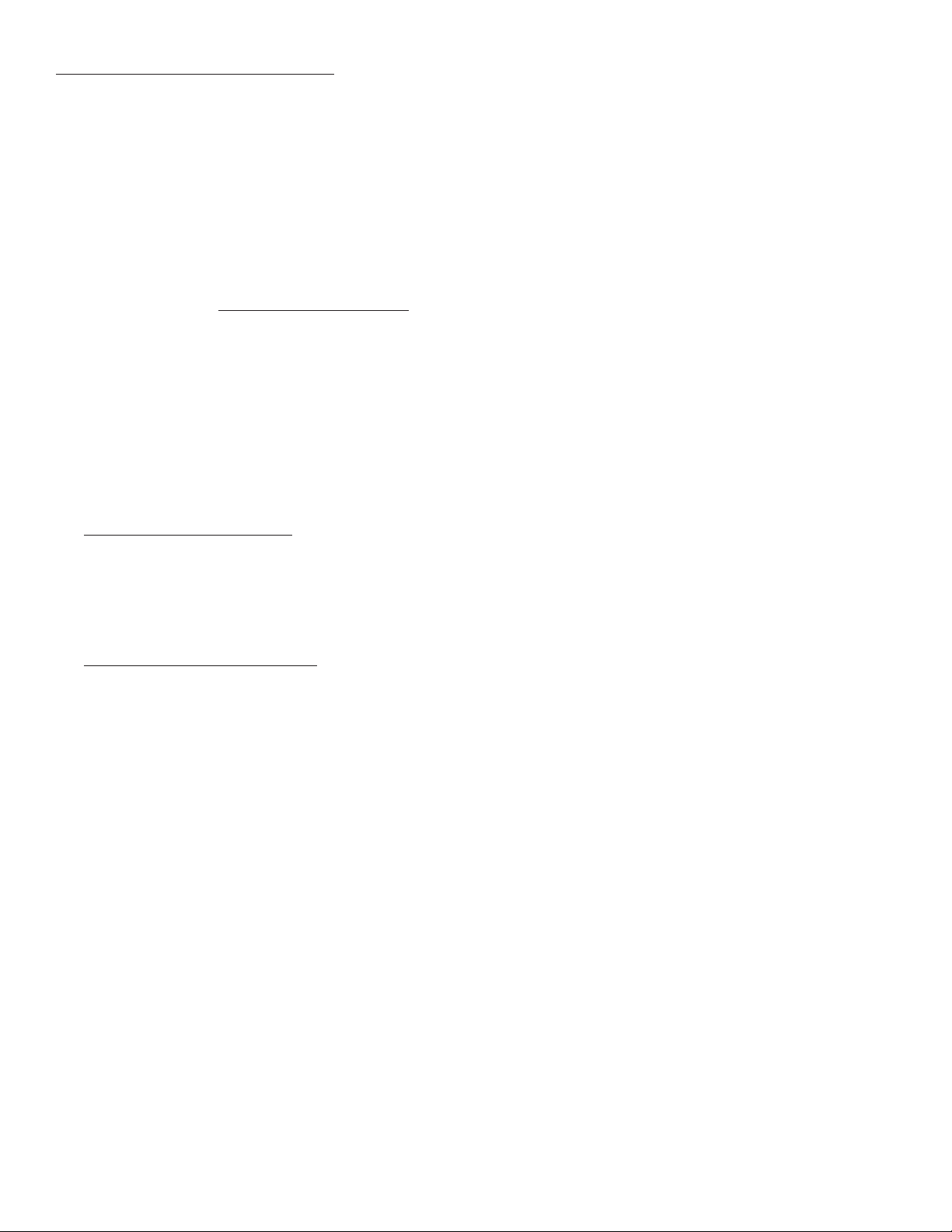

The equipment digital temperature control is easy to operate and requires little customer

interface. OPERATOR DISPLAY AND KEYPAD

ON/OFF

KEY

PROGRAM KEY

DOWN ARROW

LED 1

TIMER RESET KEY

ASTERISK KEY

LED 2

LED 3

PRESET TEMP KEY

PROGRAM KEY

UP ARROW

OPERATOR DISPLAY

4.2 CONTROL OVERVIEW

Fig 4.D

4.2.1 PROGRAM MODE

To enter Manager’s mode, turn the unit OFF by depressing then press and hold the KEY and

hold the key for minimum of 5 seconds. The control is now in Manager Program Mode the icon

will light, LED1 only, will blink, and the keypad will be reconfigured as shown in the following table:

In managers mode, the keypad will operate as follows:

Program # Program Description MIN Setting Max Setting Default

1 ON/OFF KEY ENABLED YES NO YES

2 PRESET TEMP 1 150 400 375

3 PRESET TEMP 2 150 400 350

4 PRESET TEMP 3 150 400 400

5 TIMER DEFAULT VALUE OFF 60:00 MINS 00:30S

Once parameters are set as desired, the control panel can be locked to prevent manipulation

without approval.

Toggle between programs Exit and save Increase displayed item

N/A Cancel will exit without

saving Decrease displayed item

SP8144-2011 XLR8 Installation & Operation Manual 9

4.2.2 GENERAL OPERATION

1. Press the ON/OFF key to turn the unit on. The display will come on and show the current

temperature in the display.

2. To turn the unit o press and hold the ON/OFF key for about 5 seconds.

3. Temperature control features:

4. PRESET TEMPERATURES:

A. To change to a dierent PRESET temperature press the PRESET TEMP key to toggle to the

desired temp setting. (Default values are defined in Manager’s mode, parameters 1, 2 and 3).

The new selection will auto start after 3 seconds if no other key presses are made.

B. To change the temperature on the fly or change a pre-set temp value:

i. Press the PRESET TEMP key to toggle to the desired temp setting. (Default values are defined

in Manager’s mode, parameters 1, 2 and 3. Factory default temps are 375°F, 350°F and 400°F).

ii. Then press and hold the UP or DOWN keys for approximately 3 seconds, the LED indicator for

the selected pre-set will blink. (The LED’s indicate which preset is selected LED1=PRESET 1,

LED2 = PRESET 2, and LED3 = PRESET 3.)

iii. Then press the UP or DOWN KEYS to increase or decrease the cook temperature.

iv. To store the new set temperature into a Preset memory, press and hold the ASTERISK key

before the 3 seconds from the last key press are up.

5. Manual TImer Operation:

A. To start a timer sequence manually press the TIMER RESET key.

B. To stop a timer sequence before it runs out, press and hold the TIMER RESET key for about

three seconds.

C. To silence the timer after it runs out, press the TIMER RESET key or the ASTERISK key.

6. Auto-Start Timer Operation

A. To start a timer sequence lower the handle.

B. To stop a timer sequence before it runs out, press and hold the TIMER RESET key for about

three seconds.

C. To silence the timer after it runs out, lift the handle or press the TIMER RESET key or the

ASTERISK key.

7. To set up user lock out to prevent anyone from changing the temperatures or timer values

press and hold the UP ARROW key and the TIMER RESET key for 5 seconds while the controller

is OFF. This will Toggle USER LOCKOUT parameter between “LOCKED” and “UNLOCKED”.

SP8144-2011 XLR8 Installation & Operation Manual 10

4.3.1 CLEAN AFTER INSTALLATION

It is recommended that you clean your

XLR8 thoroughly before using it for the first

time. To clean the equipment teflon cooking

surface, just simply wash it down with a solution

of mild soap and water, then rinse thoroughly

with clean water and wipe dry with a clean

towel.

4.3.2 PREHEATING

Press the ON/OFF and select the desired preset.

The upper platen should be approximately 40-

50F hotter than the griddle surface to achieve

good caramalization on product.

The equipment will be preheated when the

selected set temperature is displayed and the

corresponding LED goes solid. Please use

caution as temperatures on and around the

cooking surface could cause severe burns.

4.3.3 ADJUSTING THE PLATEN GAP

HEIGHT

The XLR8 arm has gap adjustment every 1/32nd

of an inch. This gives you the control needed to

adjust to any product up to 2” thick. To adjust

the gap remove the adjustment arm in the

front of the Upper Heated Platen. Raise the arm

and place the desired product in the middle

of the platen coverage area. With the griddle

and arm on and preheated, lower the arm until

you start to hear a sizzle from the product.

This means you are applying slight pressure on

the top of the product. At this point, install the

adjustment arm onto the mounting plate. Place

the lock bolt into the hole that lines up with the

mounting plate and tighten.

4.3.4 COOKING

If a recipe is provided for the product you

are preparing, always follow your company

guidelines for preparing product.

If adjusting your own recipe to incorporate the

use of the XLR8 it is recommended to apply the

following steps:

• Divide the total cook time applied to a

product cooking on just the griddle surface

by half. Adjust the time from there until you

are happy with the finished product.

• Once you have the time and temperature

for the product identified, use the

programming instructions to set the timer

and presets accordingly.

• Adding more compression (smaller gap

between platen and griddle surface) will

decrease cook time but may result in a dryer

product.

4.3.5 CLEANING

• Power unit o and allow to cool until it is

safe to touch, approximately 30 minutes.

• Remove teflon sheetand clean using mild

soap and water solution and a towel.

• To clean the arm, once cooled, clean using

mild soap and water solution and a towel.

Rinse when done with clean water and allow

to dry overnight.

Do not Power Spray the griddle or XLR8

Upper Heated Platen. A non-Metallic

cleaning pad can be used to remove large

debris or built up areas.

Please use caution as temperatures

on and around the griddle cooking

surface could cause severe burns.

4.3 COOKING

SP8144-2011 XLR8 Installation & Operation Manual 11

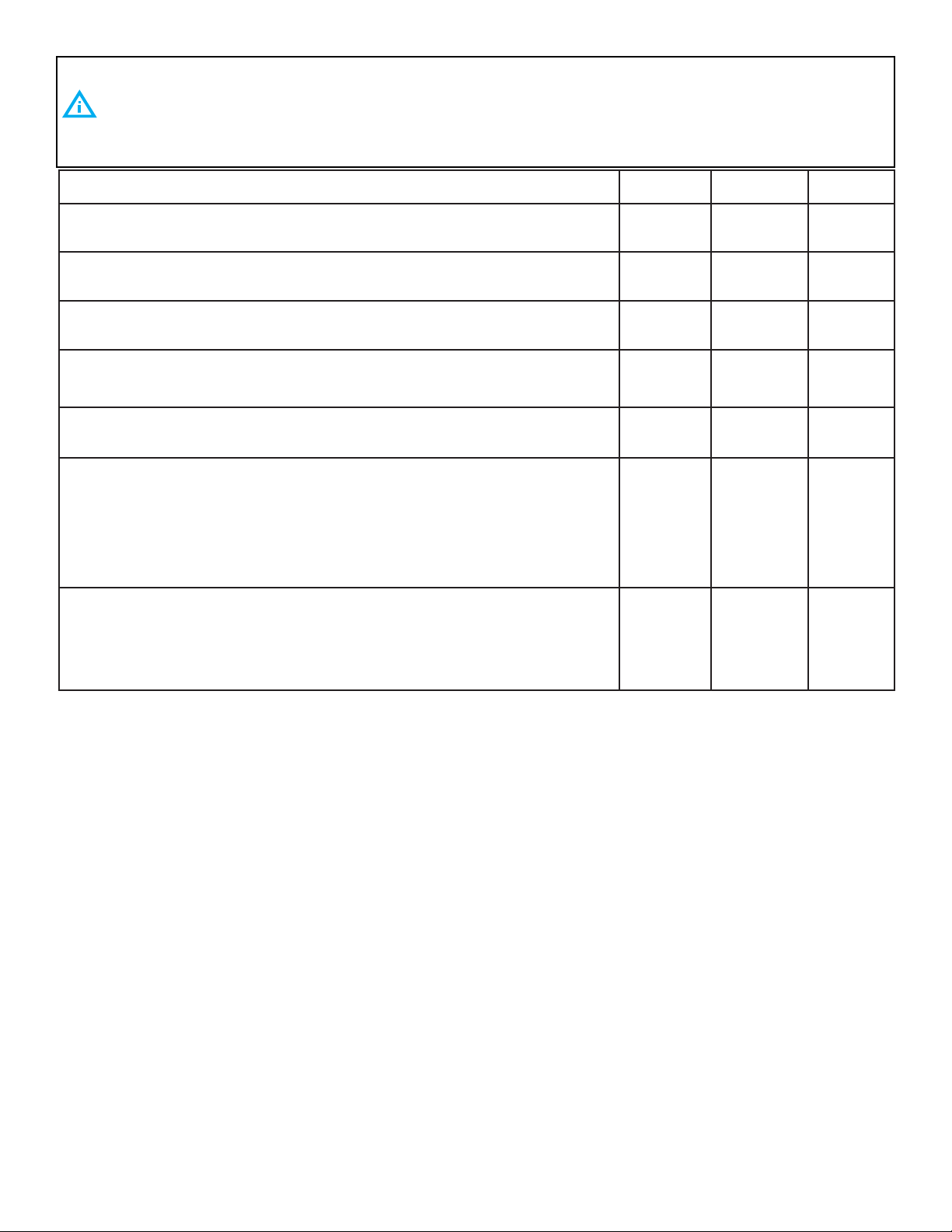

PM TASK DESCRIPTION Daily Biannual Yearly

Verify that the equipment is level and properly located under the

hood. X X

Verify that the temperature controller is working properly and

that there are no rips in the label. X X X

Inspect the control compartment for foreign particulate and any

loose wiring or connections. X X

Check that the power supply cord is not frayed, outer covering

is not degraded or any bare cooper is visible. Replace if required. X X X

Verify amp draw to listed amp requirements on the data tag of

the equipment. X X

Verify mounting fasteners are in place and tight. If not correct. If

the stand has casters check that the wheels are intact and that

they are mounted correctly. If grease covered clean with a mild

detergent and clean water. Dry completely. Apply a food grade

silicone to the locking mechanism.

X X X

After all metallic areas are cool to the touch, clean external

metal surfaces except the cooking surface. With a damp clean

towel saturated with a mild detergent and clean water. Dry with

a clean dry towel.

X X X

5. PLANNED MAINTENANCE CHECKLIST

It is recommended that you contact your AccuTemp authorized service provider to setup a planned

maintenance program to keep your equipment operating in the most ecient manner. AccuTemp

recommends a minimum of a yearly schedule.

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

• Tel: 800.480.0415 or 260.469.3040

• Email - service@accutemp.net

• Web site - www.accutemp.net

Popular Heater manuals by other brands

Smartgen

Smartgen HWP40-3 user manual

HELLER

HELLER HOIL5 instruction manual

Luxel

Luxel Radak Power Controller II Replacement

Vitrulan

Vitrulan V4heat Anti-Mold Kit Operating and assembly instructions

Desa

Desa "A" Models OWNER'S OPERATION AND INSTALLATION MANUAL

Energy Tech Laboratories

Energy Tech Laboratories Modular Direct Fired Heaters Installating and operation manual