7

Section 2 – Installation

System Explanation

The Accutron airflow sensors are compact and reliable instruments, especially designed for

measuring airflows in mine environments. The Accutron IS Drift System is for airflow

measurements in mine drifts whereas the Accutron IS Fan System is for measuring the flow

output of large mine fans. Each system consists of an Indicating Transmitter, cabling and two

“ultrasonic sensor” assemblies.

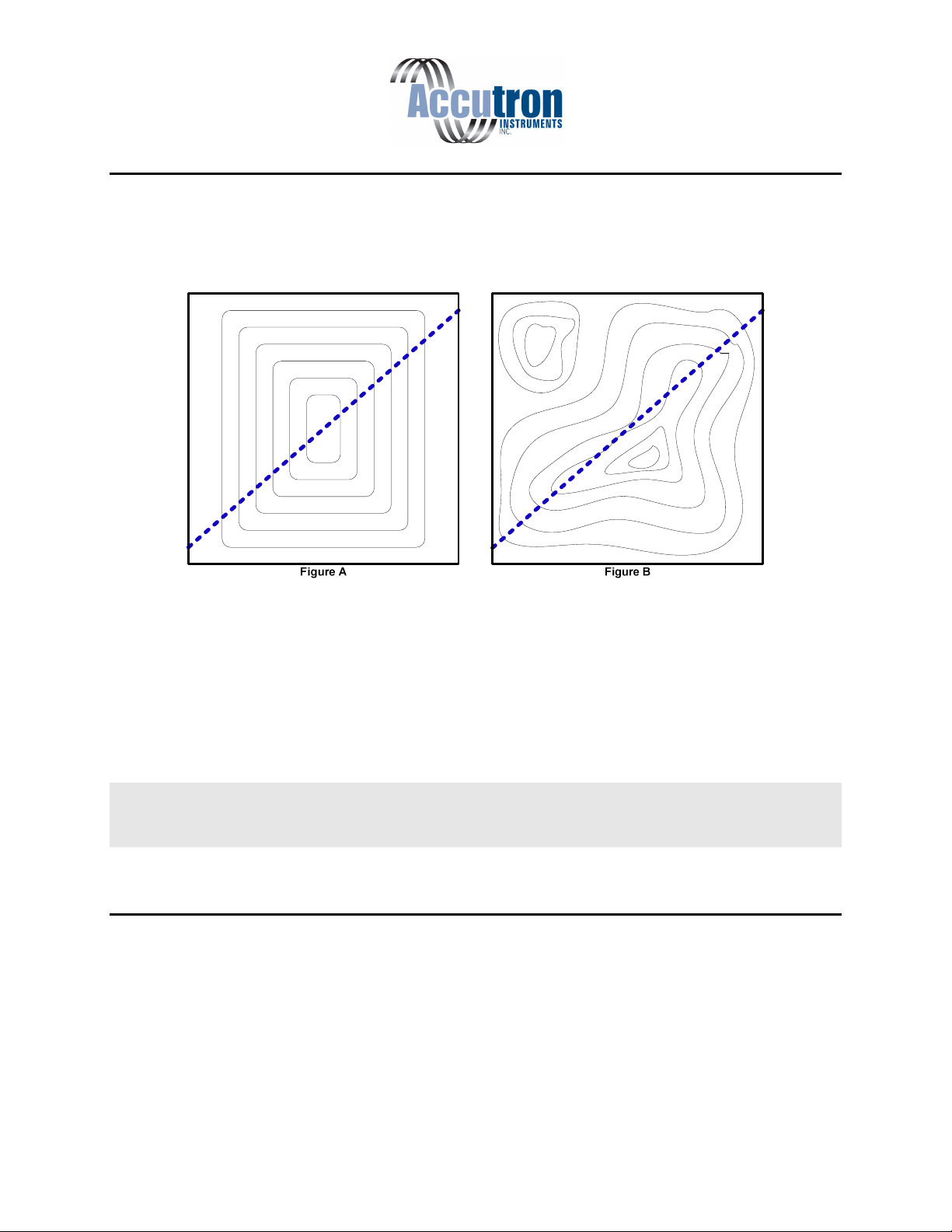

The ultrasonic sensor assemblies are installed in the drift diagonally (one further upstream than

the other) with an “imaginary line” between them intersecting the airflow at a typical angle of

120 degrees.

Ultrasonic pulses are sent back and forth between the transducers across the drift, traveling

through the air current. Let “TA-B” be the time taken for the signal to travel from Transducer Ato

Transducer B, and “TB-A” be the time taken for the pulse to travel from Transducer Bto A. The

control unit accurately measures the time-of-flight for each direction. The difference between

the measured times (TA-B – TB-A) is directly proportional to the airflow. In the case of no moving

air, TA-B equals TB-A and there is no time difference because there is no airflow.

The Accutron IS first internally computes the average velocity of the air in Meters/Sec. In order

to obtain air volumes, the area of the drift is entered into the settings menu (during

programming), along with your selection of measurement units. The system then displays air

volumes in the units selected. Common units used in mining applications are KCFM and

M**3/S, other units may also be displayed to measure the air velocity (Meters/ sec, Feet / Min).

After installation in the drift, measurements are made (area, baseline distance, Face-to-face

distance). Using the navigation buttons, these parameters are entered into the unit.

These parameters are retained in non-volatile Flash memory in the Accutron. Whenever the

Accutron powers up, this information is automatically reloaded.

The system can easily measure air velocities in excess of 1,000,000 cfm with a precision better

than any other conventional methods, as well as low velocity conditions, i.e. 1m/s. In addition,

since the system is able to sample across the entire drift, readings are more representative than

“single point” measurements. The Accutron takes into account the fact that there is a

“distribution profile” for the air in the drift, making it superior to other types of measurement

methods for fixed installations.