ACE BOILER INC.

Page 7

Receiving Your Packaged Storage Water Heater

Check Equipment Received. Inspect the unit for any shipping damage. Make sure you have received

all loose parts, such as listed on the “Bill of Lading”. Larger strainers and valves, usually 2-1/2” and

above, are shipped loose. Note any damages or shortages on the bill of lading prior to signing it. If the

unit is received damaged or missing parts, it is your responsibility to notify the shipping company and file

a freight claim. Ace Boiler cannot send replacement parts for freight damaged or missing equipment as

warranty items. Permission to return goods must be received from the factory prior to shipping. Goods

returned without a Returned Goods Authorization number will not be accepted. Purchased parts are

subject to replacement only under the manufacturer’s warranty. The warranty does not include the cost

for labor, removal, or installation of the warranted part.

General Installation Instruction

NOTE: All electrical and piping installation should only be accomplished by qualified

personnel following all applicable local, and state codes required for their installation.

Code Requirements: It is very important that your installation comply with all

federal, state and local codes as well as meet good industry practices as shown in publications issued by

ASME, AGA, UL, ASHRAE, ABMA, etc.

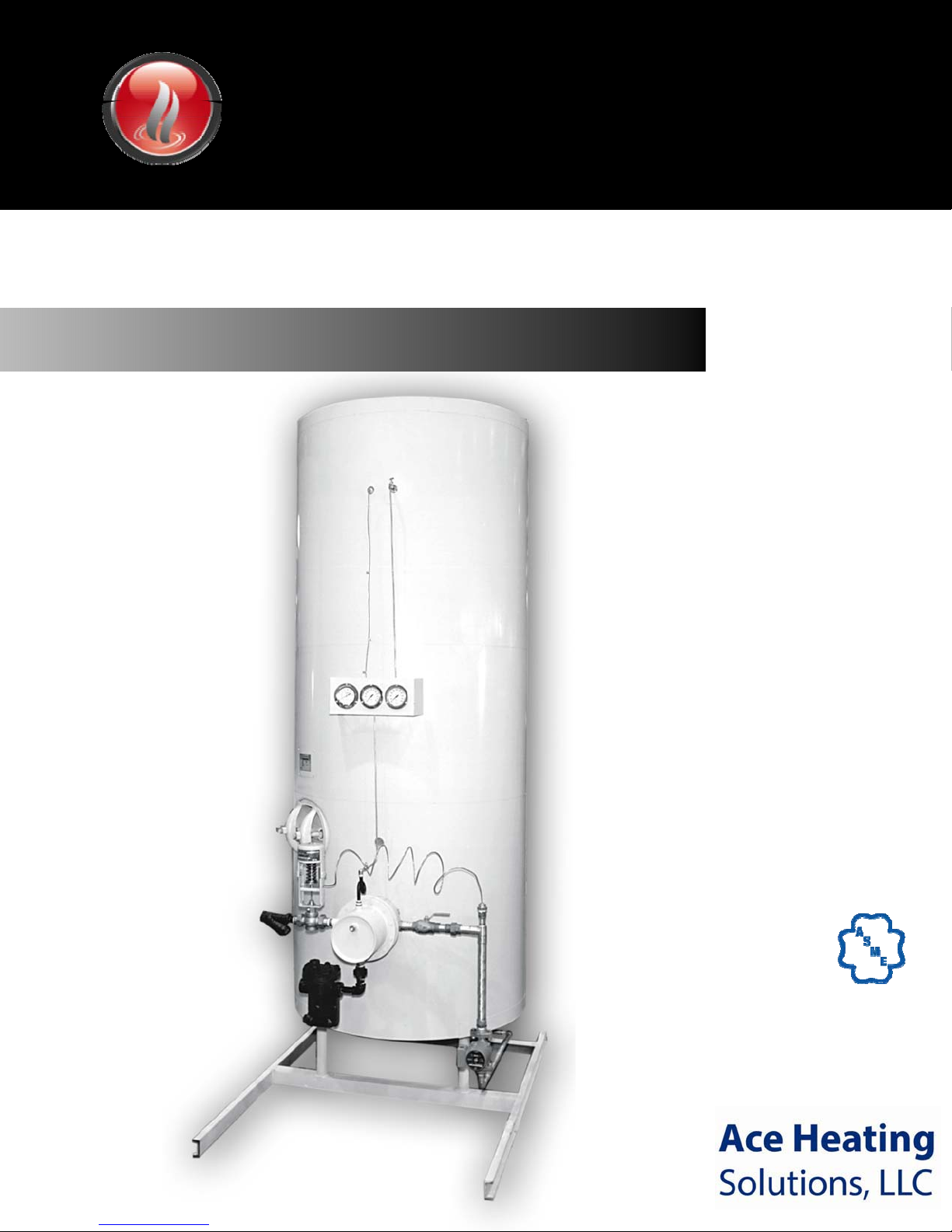

Placement: The storage heater was either fabricated as a vertical or horizontal unit. It should be

installed on a solid foundation, preferably a concrete pad. Provide adequate clearance for normal

inspection and maintenance purposes and allow tube pull clearance to remove the exchanger for

servicing. A minimum clearance of 24” is recommended from all accessories for ease of maintenance.

Make sure the heater is level, from side to side and front to back. Use metal shims if necessary.

Piping: All piping to and from the heater must be provided with adequate supports and expansion

compensation so that pipe stresses are not transmitted to the unit. The relief valve and the double-safety

solenoid valve, if supplied, should be piped to a safe drain.

Stud Nuts: During shipment, the bonnet and shell flange nuts may loosen and should be re-tightened

before start-up. Tighten these nuts to the torques specified later in this manual. After the unit has been

in operation for a few days, check and retighten. Note: Bolting is independent on the bonnet and shell-

side flanges through the use of a threaded tube sheet flange(s). Therefore, stud bolt nuts must be re-

tightened on both sides. See Figure 1.1 for single wall bolting arrangement and Figure 1.2 for double wall

bolting arrangement.