10

FUSELAGE ASSEMBLY

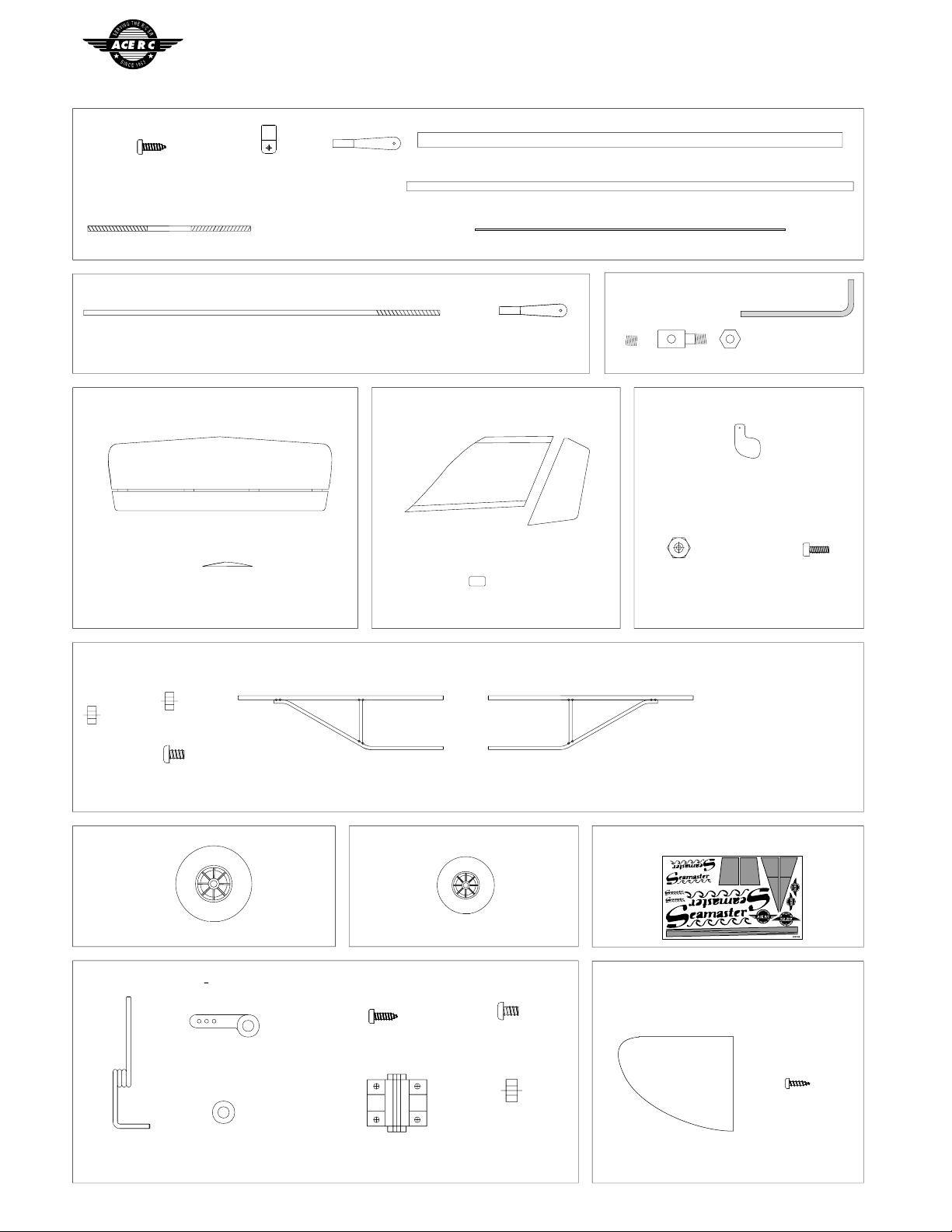

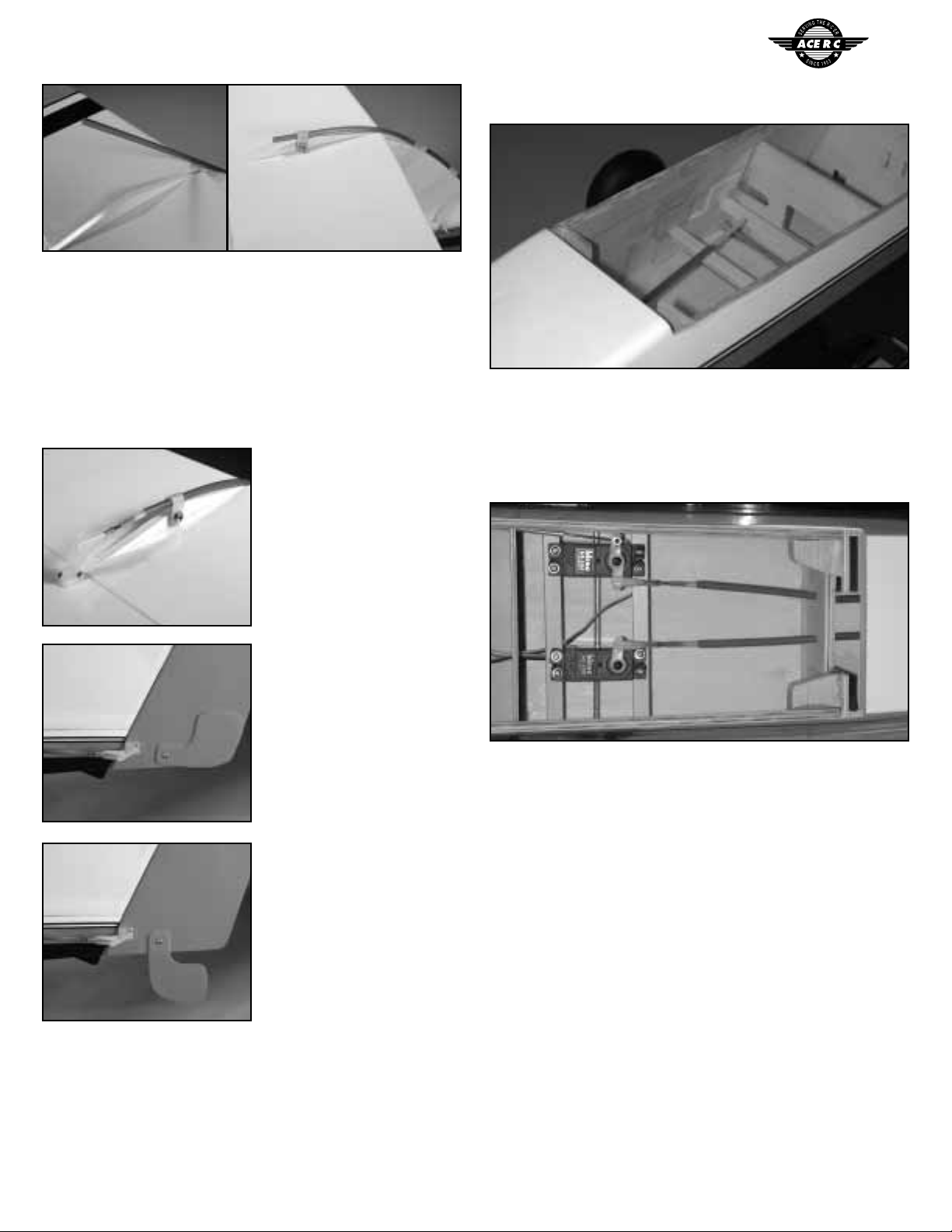

Cut a groove in the top of the leading edge of the stab to accom-

modate the nyrod. Glue the nyrod triangular spacer onto the top of

the stab (cut away a strip of covering material first).

The outer nyrod is secured to the spacer with the nylon clamp

and wood screw furnished. It should also be glued along the leading

edge of the fin. We prefer "Zap-a-dap-a-goo", Shoe-goo", or equivalent

for this operation. CA will not stick well to the nyrod. Use masking

tape to hold while the glue dries. Also glue the outer nyrod where it

exits the fuselage and where it passes through the bulkheads.

When the glue is dry, a white covering material is furnished to

cover the exposed nyrod, if desired.

Hookup on both ends of

the inner nyrod is done via a

threaded stud and nylon clevis.

Thread a clevis onto one of the

studs so some of the threads are

exposed on the inside of the cle-

vis. Then thread this assembly

into one end of the long inner

nyrod. Insert the other end into

the outer nyrod starting at the

stabilizer end. Determine the

proper position for the elevator

control horn and mount it using

the bolts and backplate fur-

nished. Repeat for the rudder.

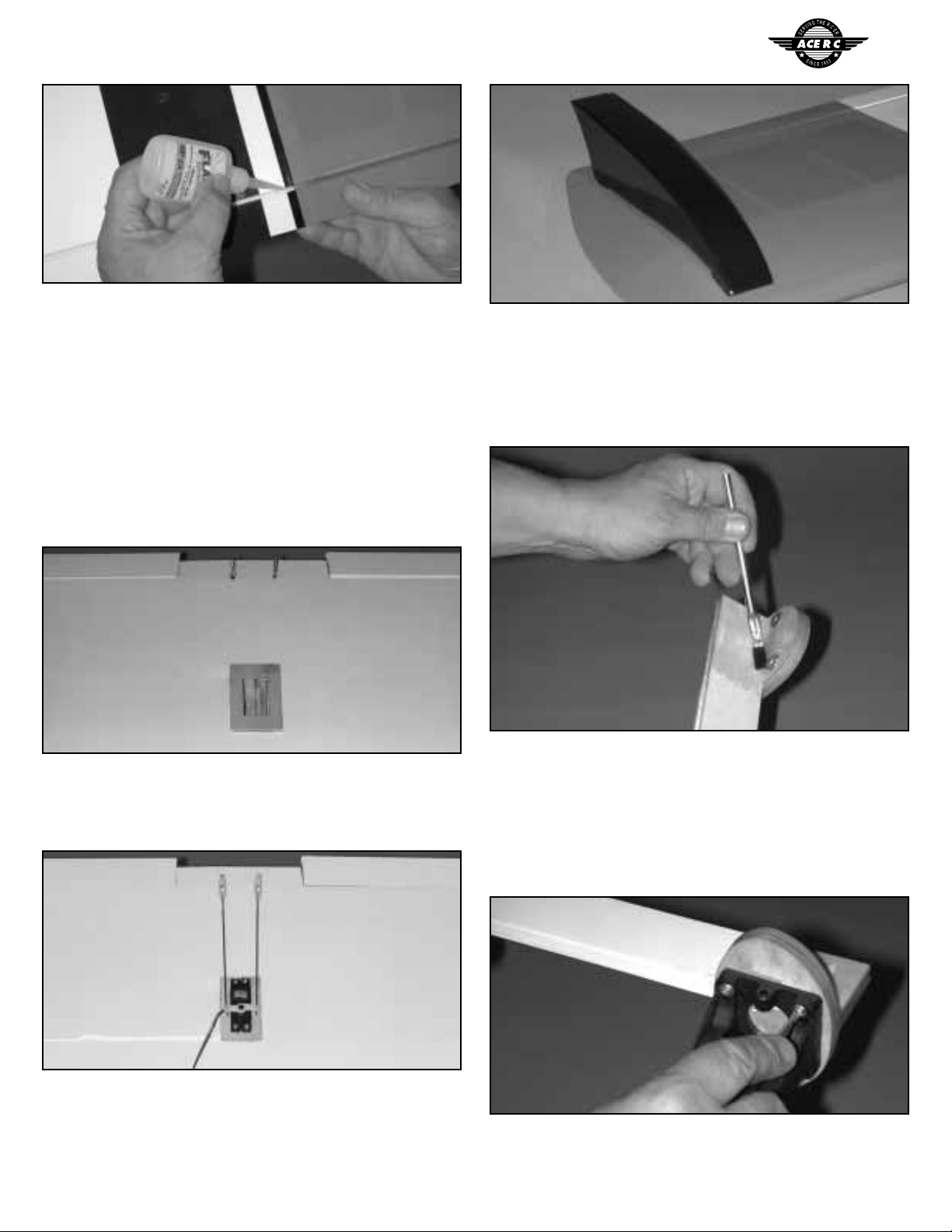

Locate the plastic water

rudder. Place it on the rudder so

it is in the "kicked-up" mode;

i.e., flush with the bottom and

rear of the rudder. Drill a 1/8"

hole through both the water

rudder and the rudder, using the

location that is marked on the

water rudder as a guide. Secure

with the furnished 4mm screw

and locking nut. Tighten until

the water rudder is held firmly

in the down position, yet can be

kicked-up when it hits some-

thing harder than water.

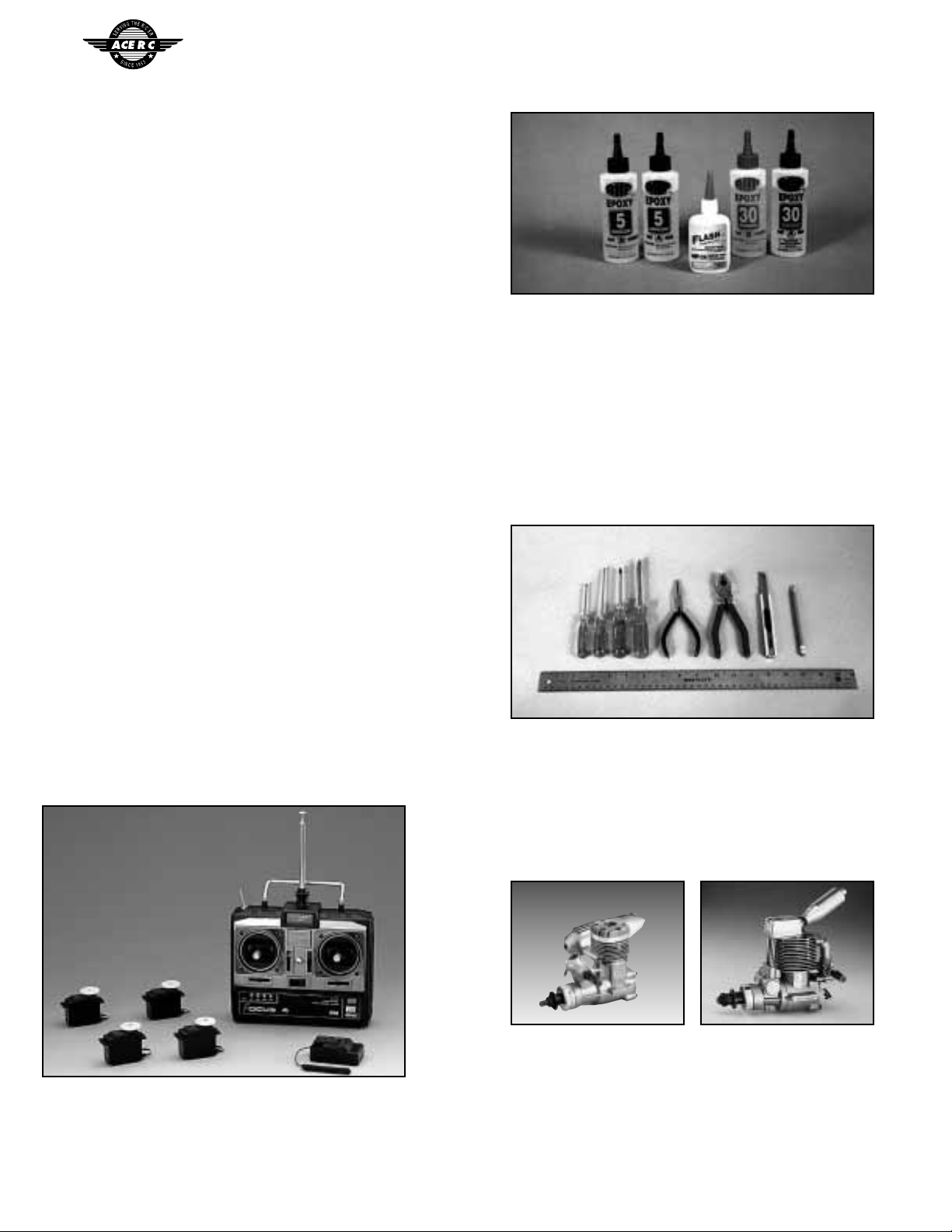

Radio Installation

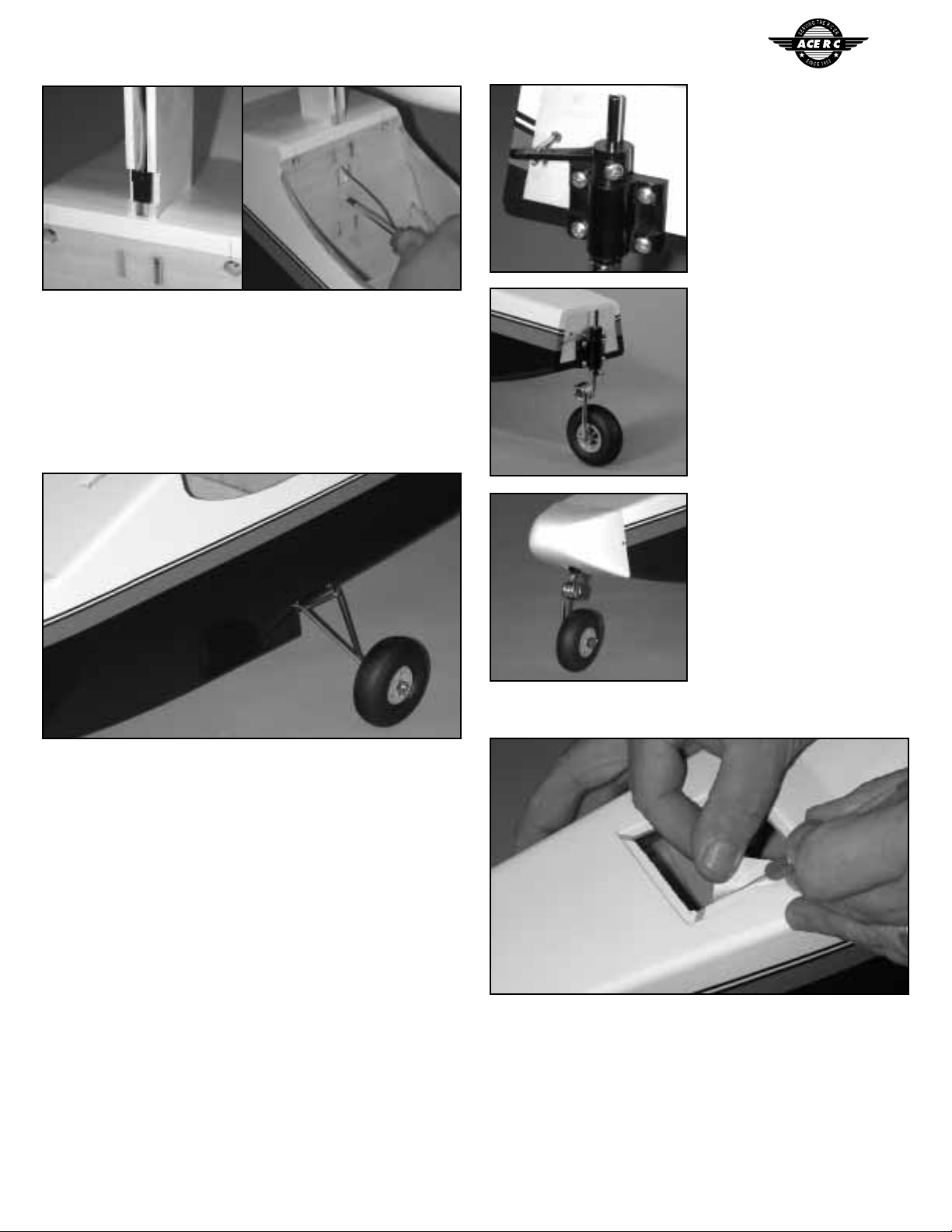

Installation of the rudder and elevator servos are next.

The servo rails are laminated from two pieces of 1/8" ply to form

a part that is 1/4" x 3/8". They rest on top of the doubler that is sup-

porting the landing gear tubes. One rail fits all the way to the rear of

the doubler, and the other is spaced forward to fit the servos being

used. Plywood "U" shaped mounts further secure the rail in place. Go

ahead and install the servo rails at this time.

Install the servos next. The nosegear is linked via an EZ connect

and the inner nyrods are hooked to the servo arms with a threaded

stud and nylon clevis. Trim the nyrods to length as needed.

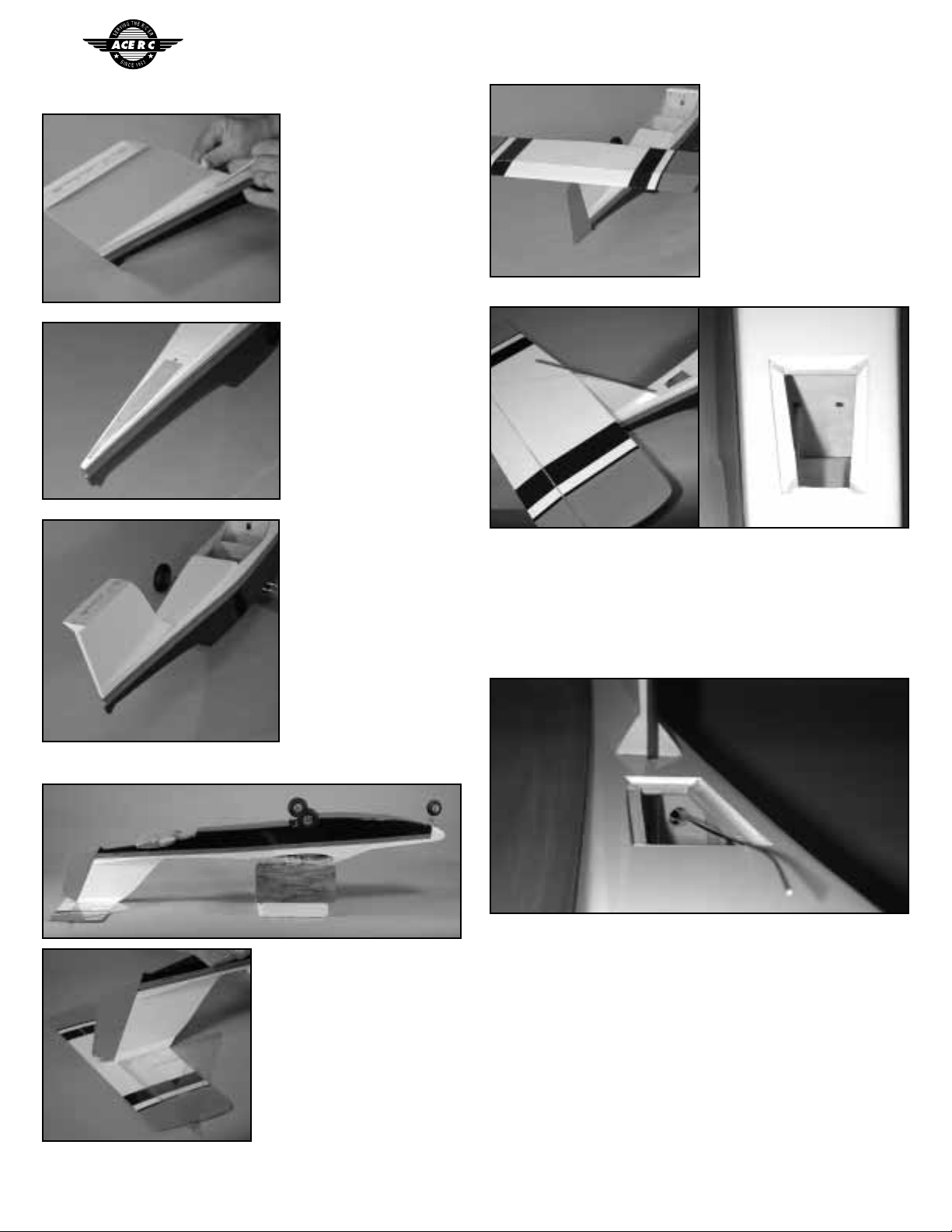

The receiver and battery pack should be foam mounted in the

compartment ahead of the servos. It is suggested that the receiver be

protected from water by putting it in a plastic bag or balloon. It is also

suggested to build a platform to rest the receiver on. That way if water

does get into the hull, the receiver will stay up out of the water. Also

note that you may need a servo extension cable for the throttle servo

as well as the aileron servo.

You may find it necessary to move the battery pack into the for-

ward compartment of the fuselage to achieve proper balance. If so, an

access hatch is furnished plus there is already a hole in the bulkhead

for the cable to pass through.

A good way to mount the switch is with a Dubro Kwik Switch

Mount. It is easy to install and relatively water tight. Mount it up high

in the fuselage, right under the wing saddle doubler.

Photo 30

Photo 31

Photo 32

Photo 33

Photo 34

Photo 28 Photo 29