Ace RELIANCE User manual

Other Ace Accessories manuals

Ace

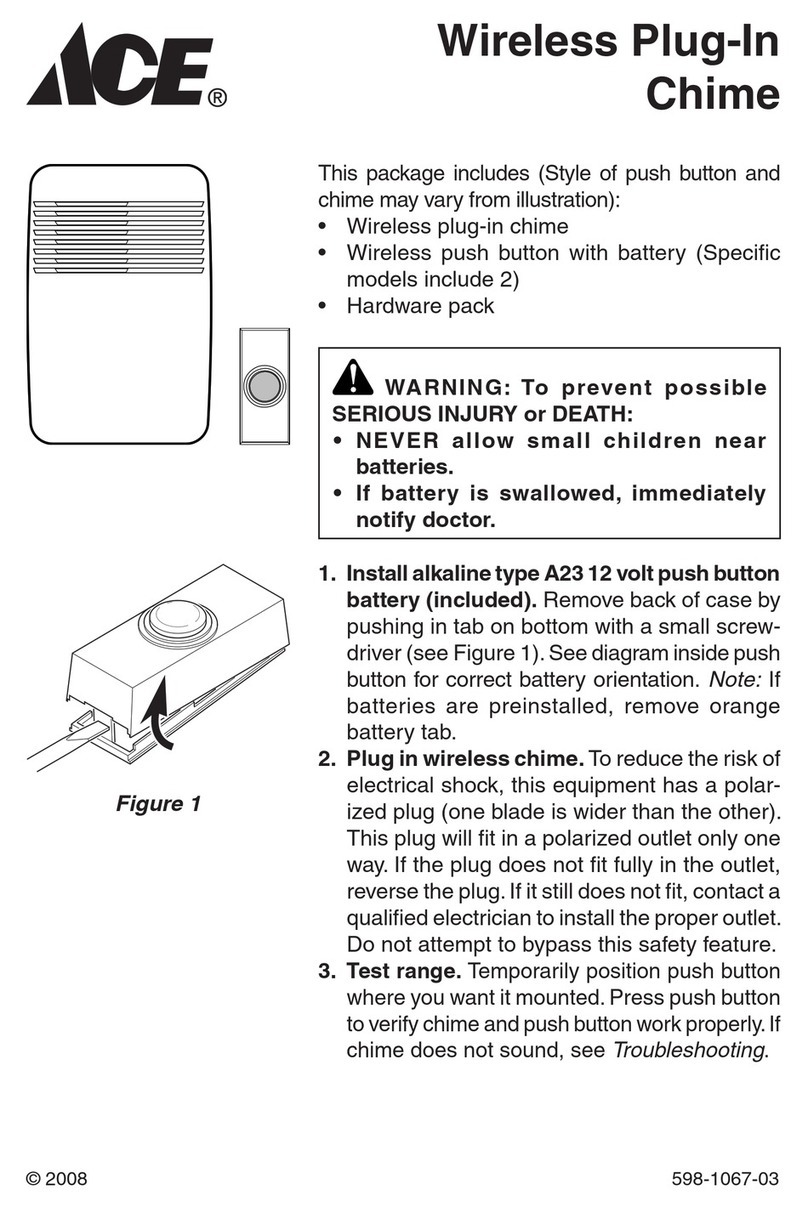

Ace Wireless Plug-In Chime 598-1067-03 User manual

Ace

Ace 3003530 User manual

Ace

Ace Reliance 1K User manual

Ace

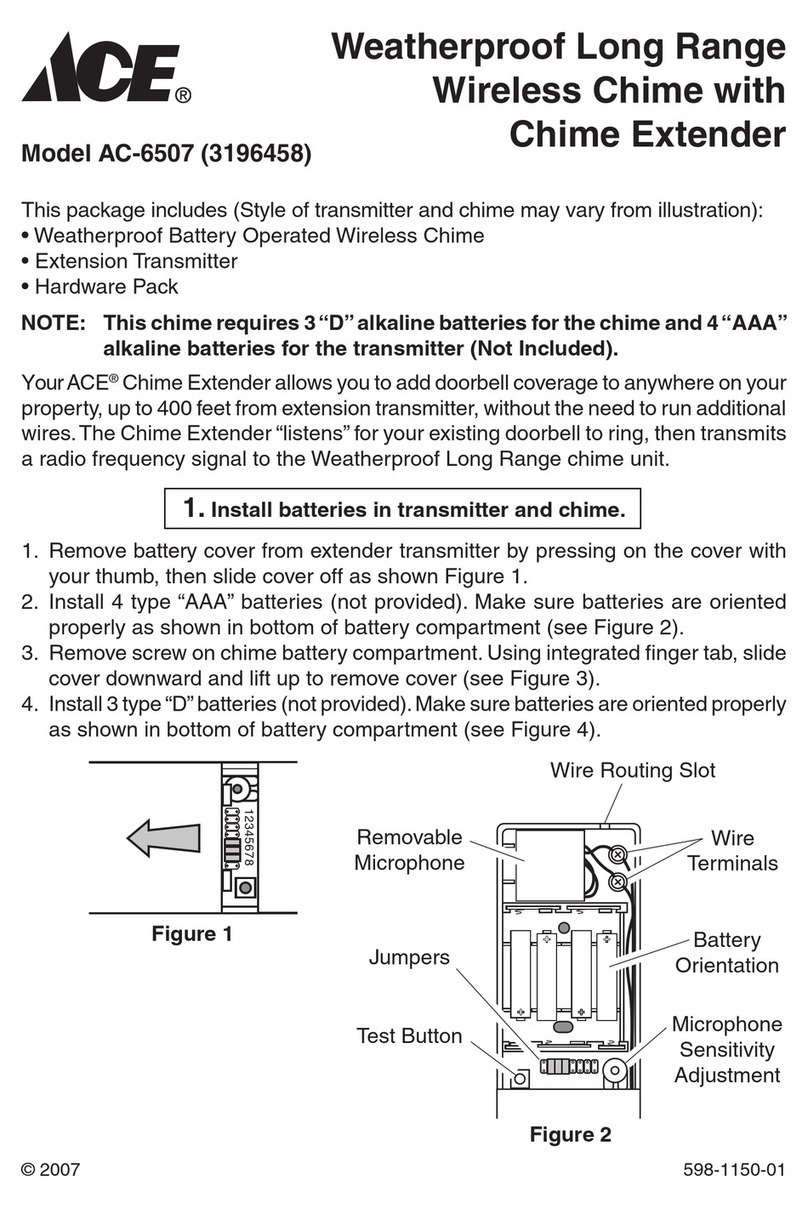

Ace Weatherproof Long Range Wireless Chime with Chime Extender... User manual

Ace

Ace Hardwired Mechanical Chime 598-1223-01 User manual

Ace

Ace 3196425 User manual

Ace

Ace PC-300 Technical Document

Ace

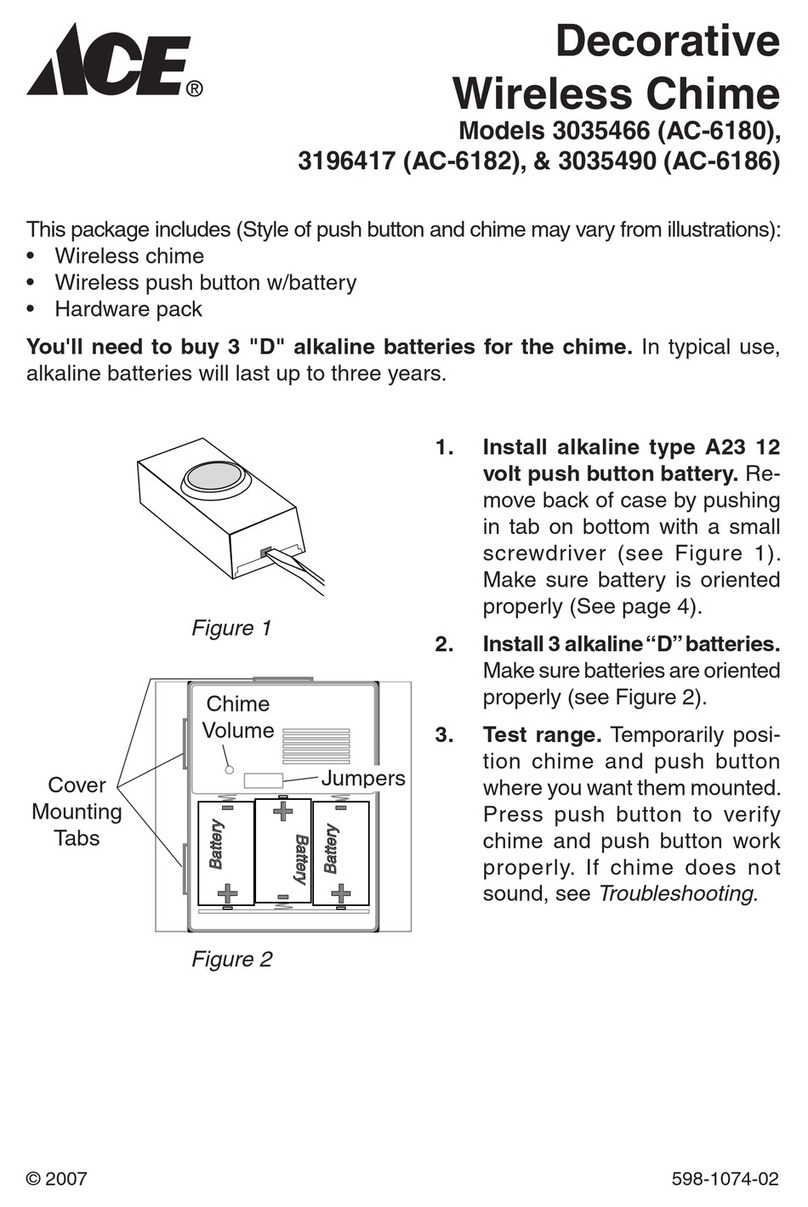

Ace 3035466 (AC-6180) User manual

Ace

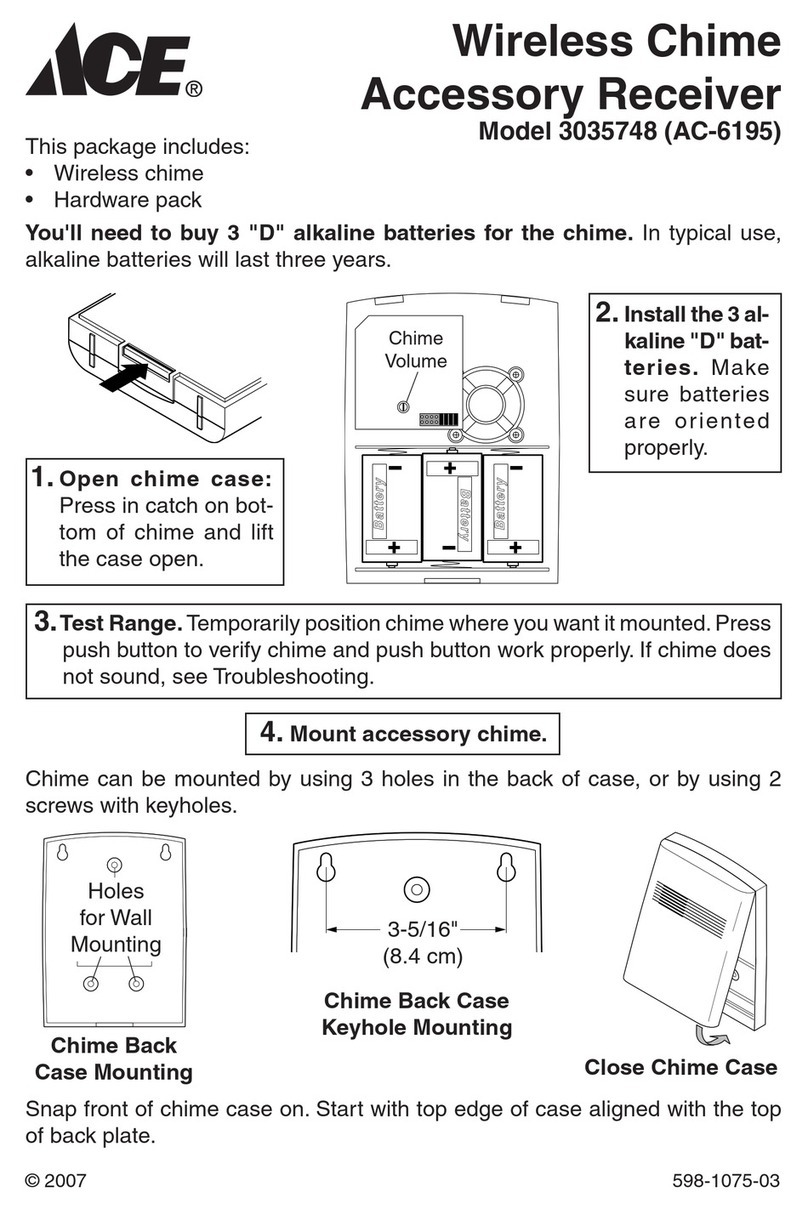

Ace 3035748 (AC-6195) User manual

Ace

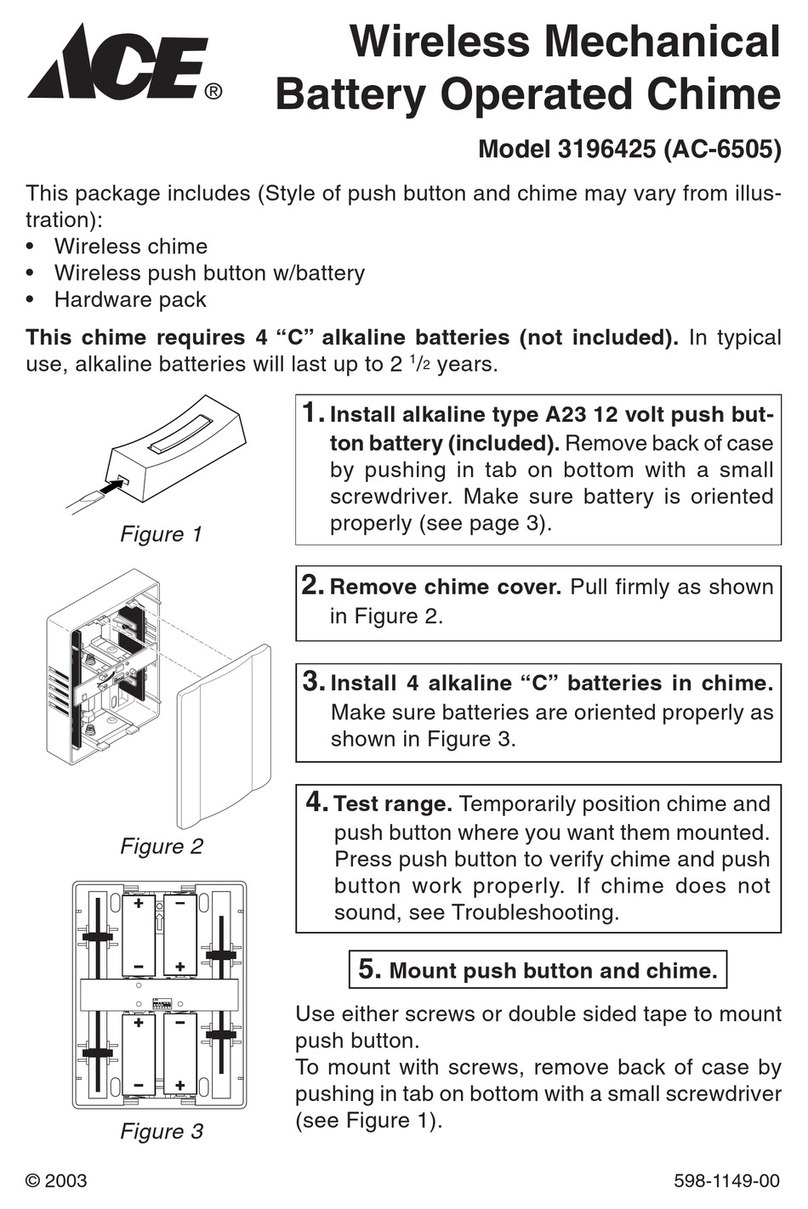

Ace 3196425 Installation guide

Ace

Ace Lighted Wireless Push Button Accessory... User manual

Ace

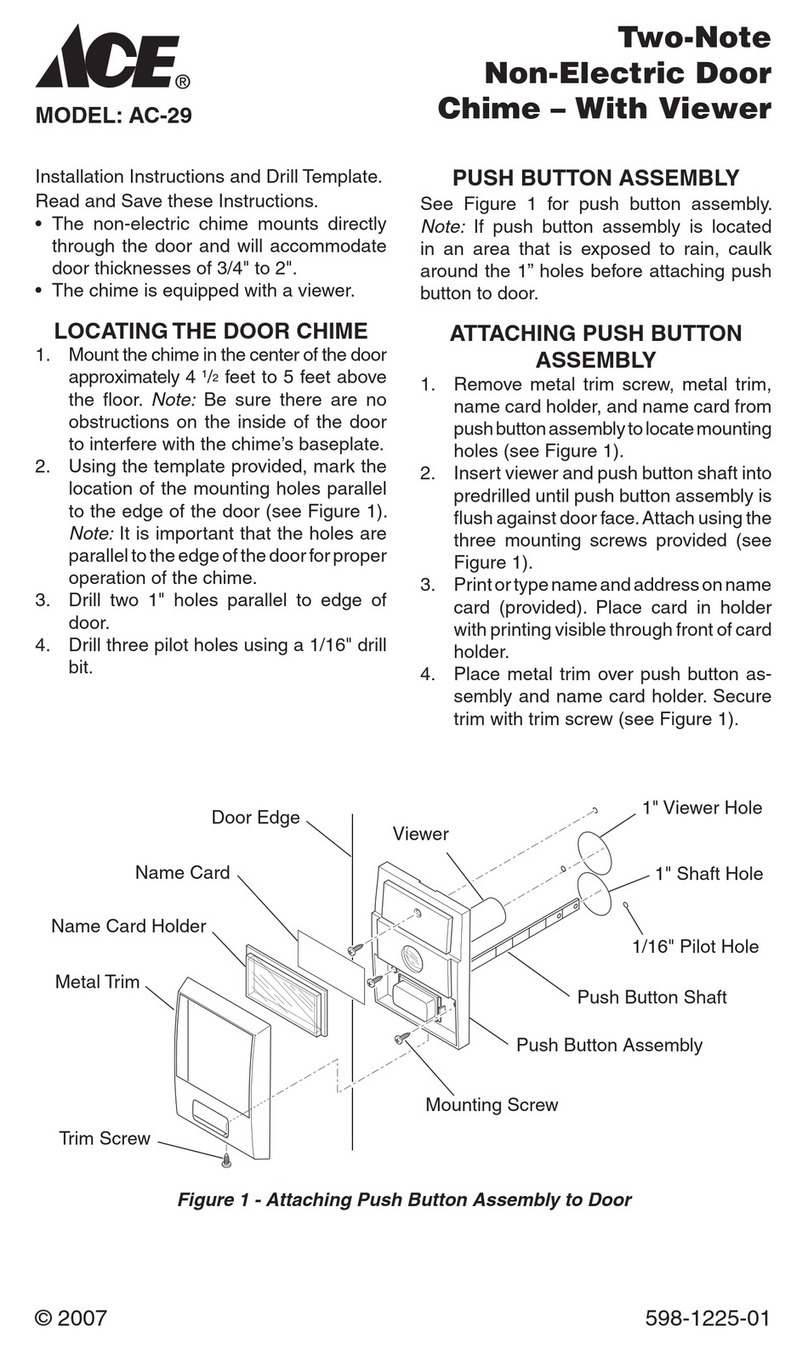

Ace ac-29 User manual

Ace

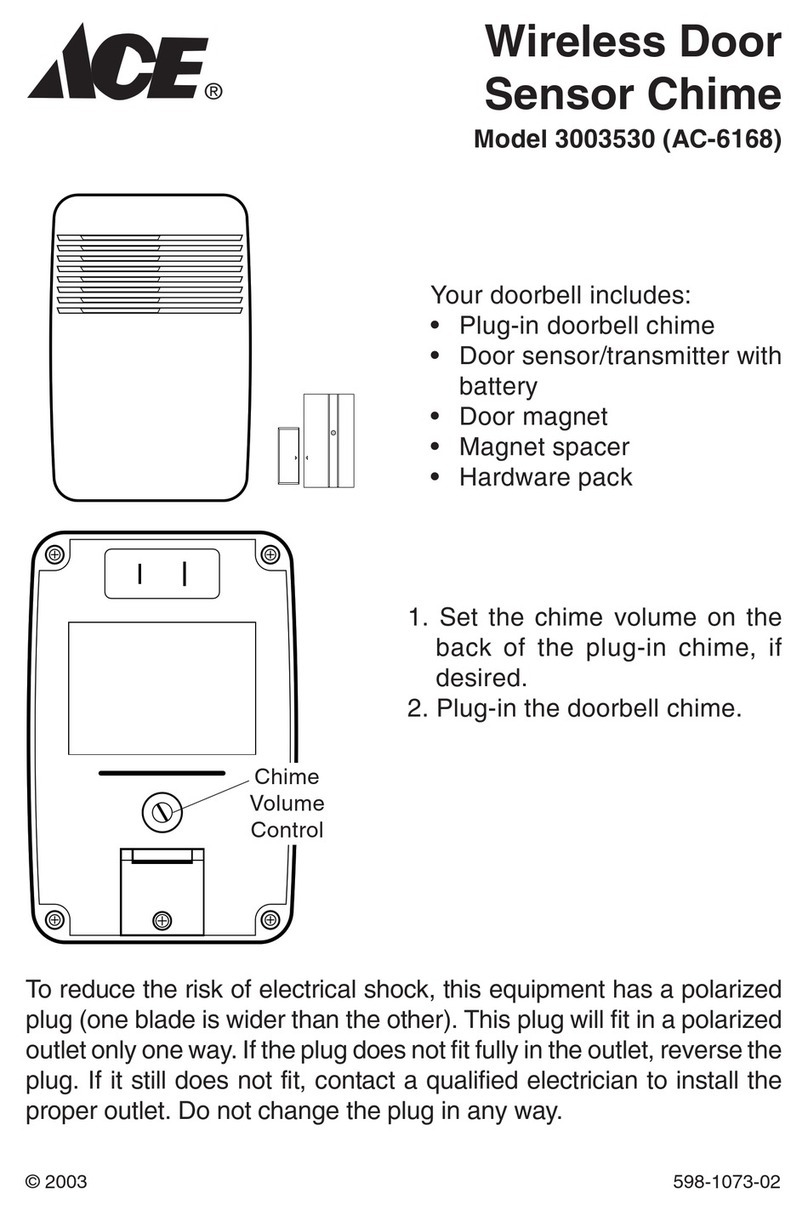

Ace 3003530 User manual

Ace

Ace Hardwired Electronic Chime 598-1224-01 User manual

Ace

Ace 3035698 (AC-6190) User manual

Ace

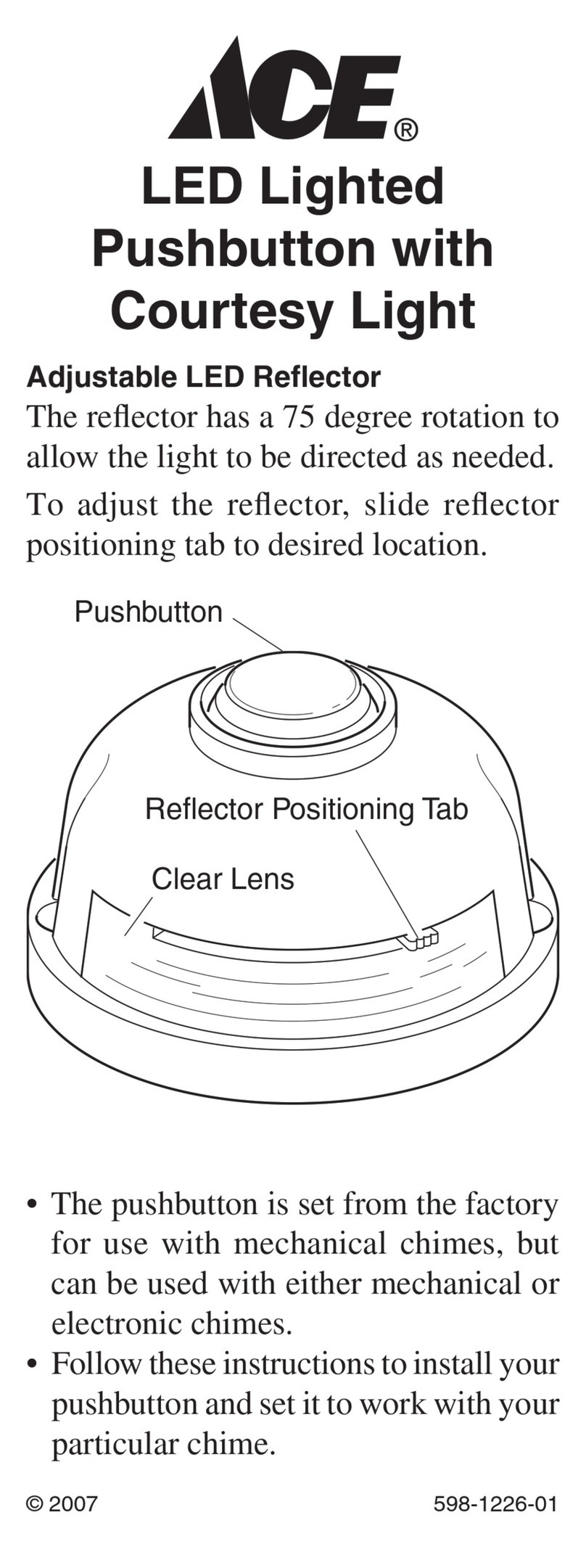

Ace LED Lighted Pushbutton with Courtesy Light... User manual

Ace

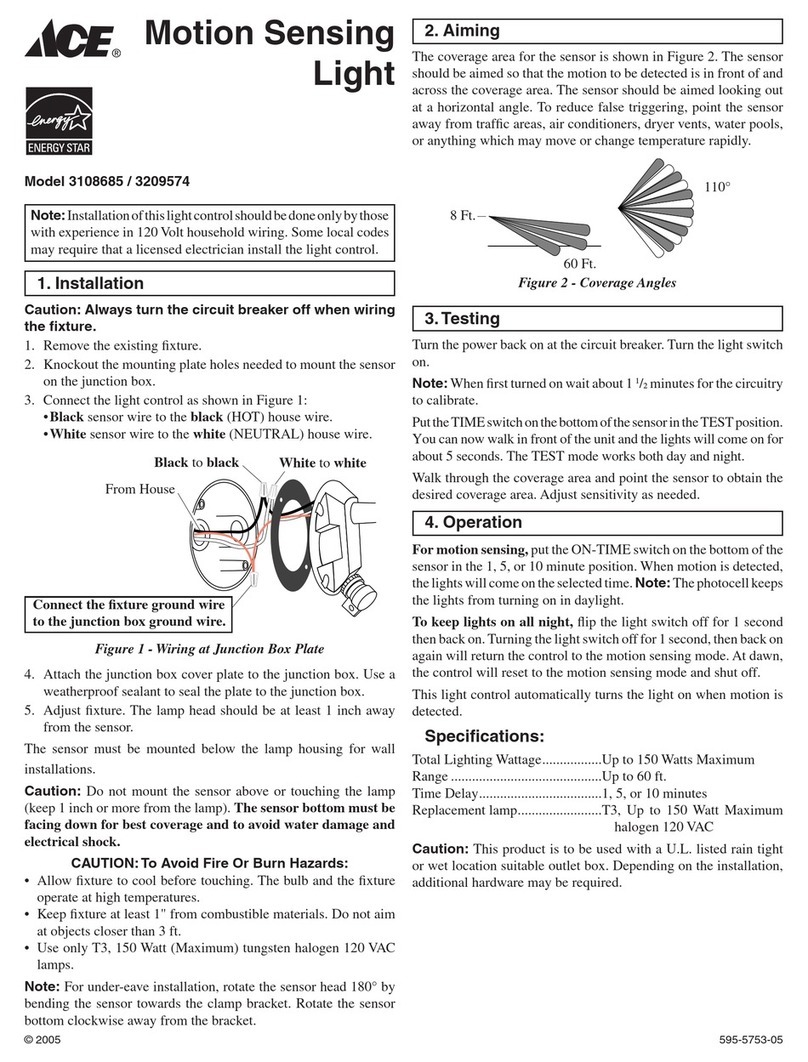

Ace 3108685 User manual

Ace

Ace 3108651 User manual