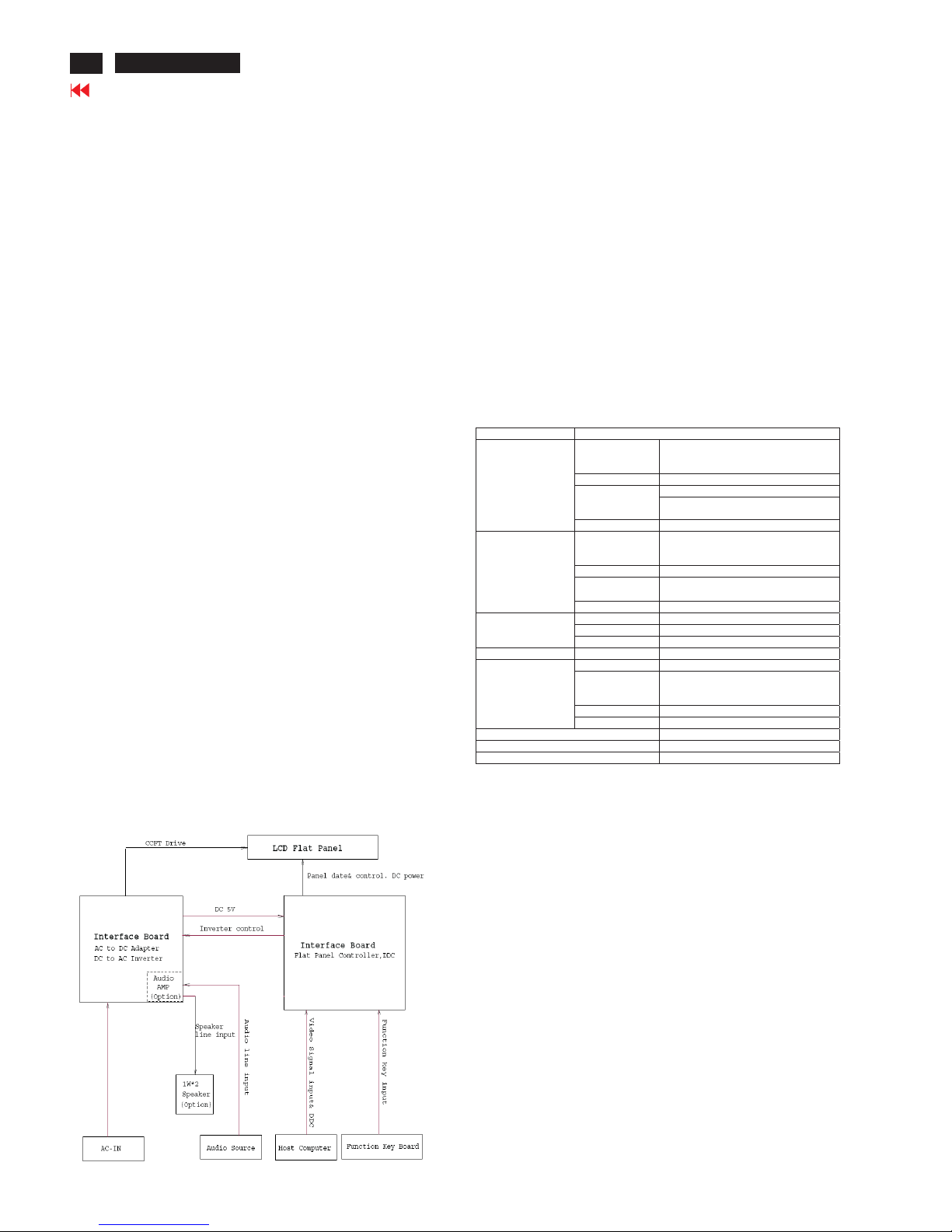

1.3.5 Controller Requirements

1.3.5.1 General Requirements

The monitor shall include a controller capable of

converting the analog RGB signal from a standard

SXGA resolution video controller in the CPU to a

signal which can be displayed on the panel. The

controller will include a PLL, A/D converters, LVDS

transmitter and other circuitry necessary to perform

its function. The PLL shall be stable enough to

ensure that a static image from the CPU is placed

in the same physical location on the flat panel in

each frame.

1.3.4.3 Mode Recognition Pull-in

The monitor shall recognize preset modes within a

range of +/-1KHz whichever is less for horizontal ;

and within +/-1Hz for vertical.

1.3.4.4 User Display Modes

In addition to the factory pre-set video modes,

provisions shall be made to store up to 9 user

modes. If the current mode is a user mode, the

monitor shall select its previously stored settings.

If the user alters a setting, the new setting will be

stored in the same user mode. The user modes

are not affected by the pre-set command. If the

input signal requires a new user mode, storage of

the new format is automatically performed during

user adjustment of the display (if required).(

Please see Note.(4) )

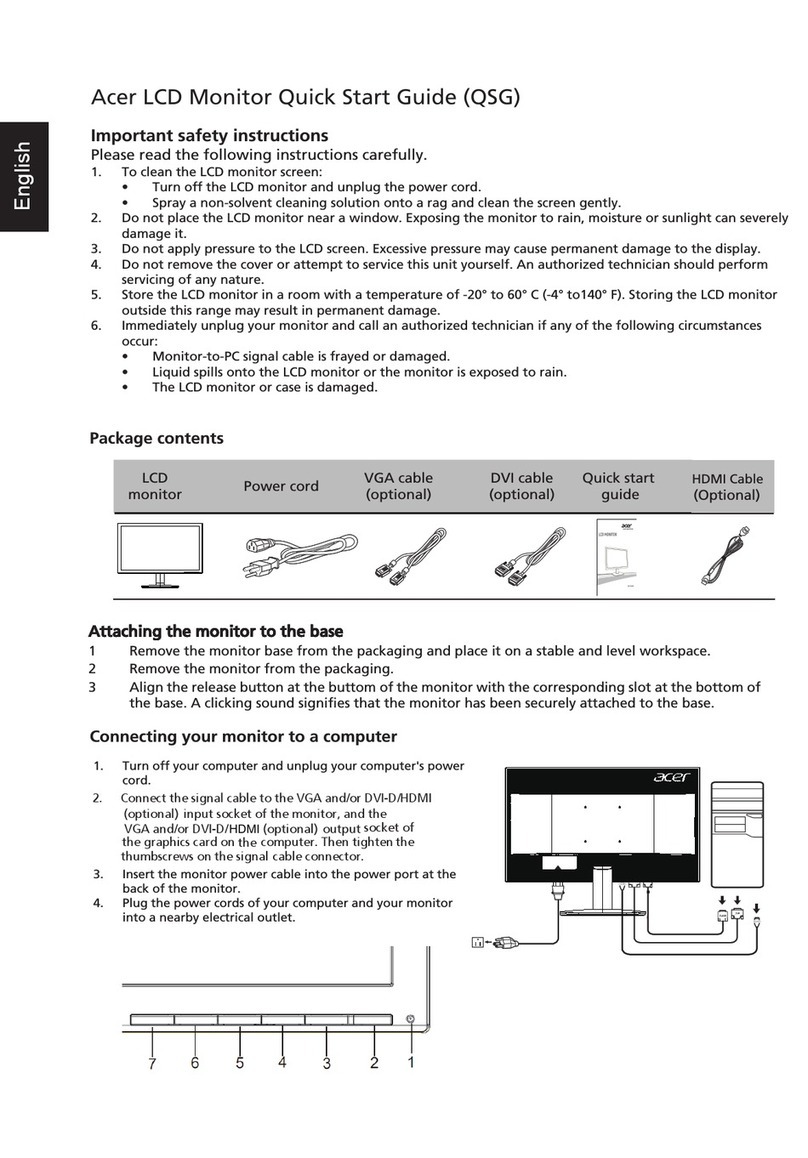

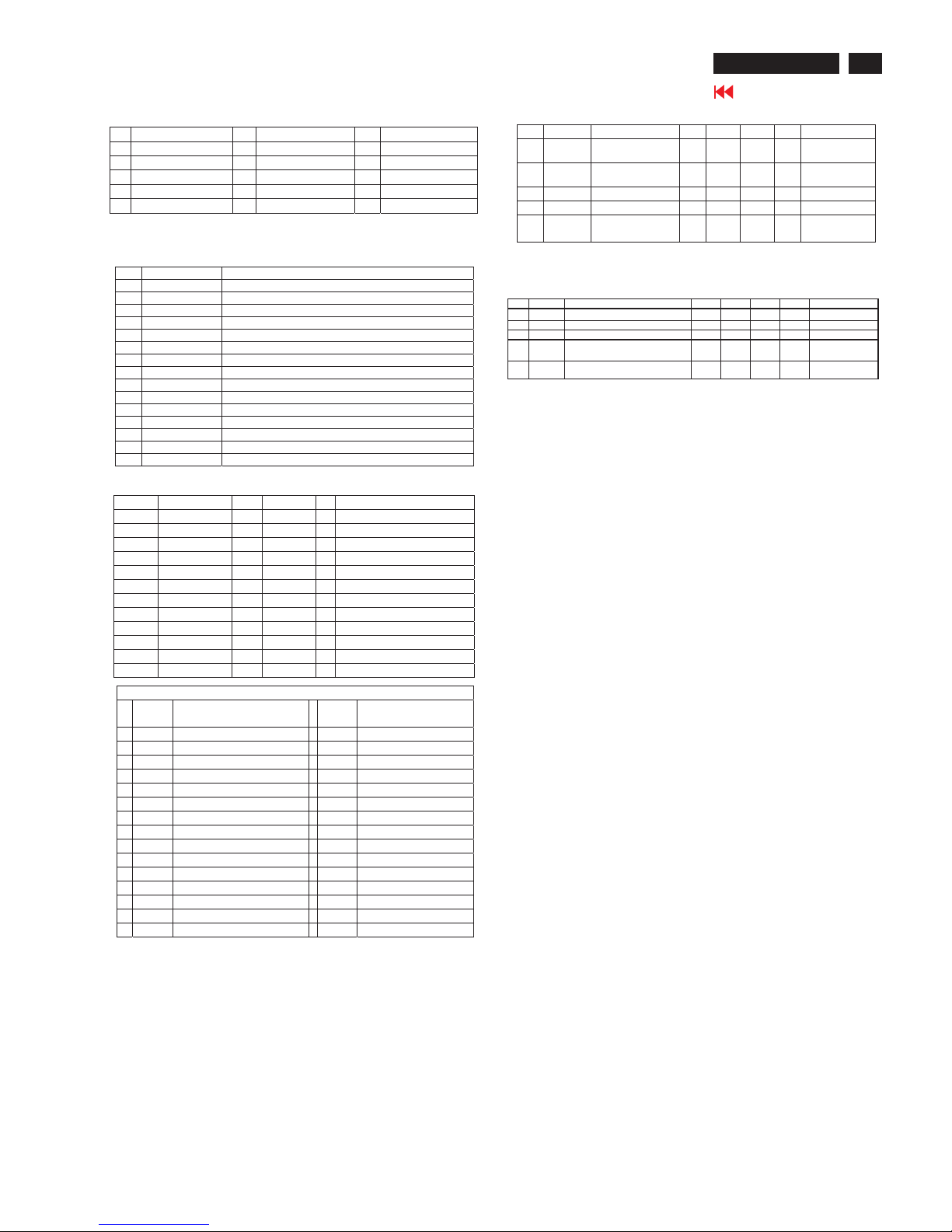

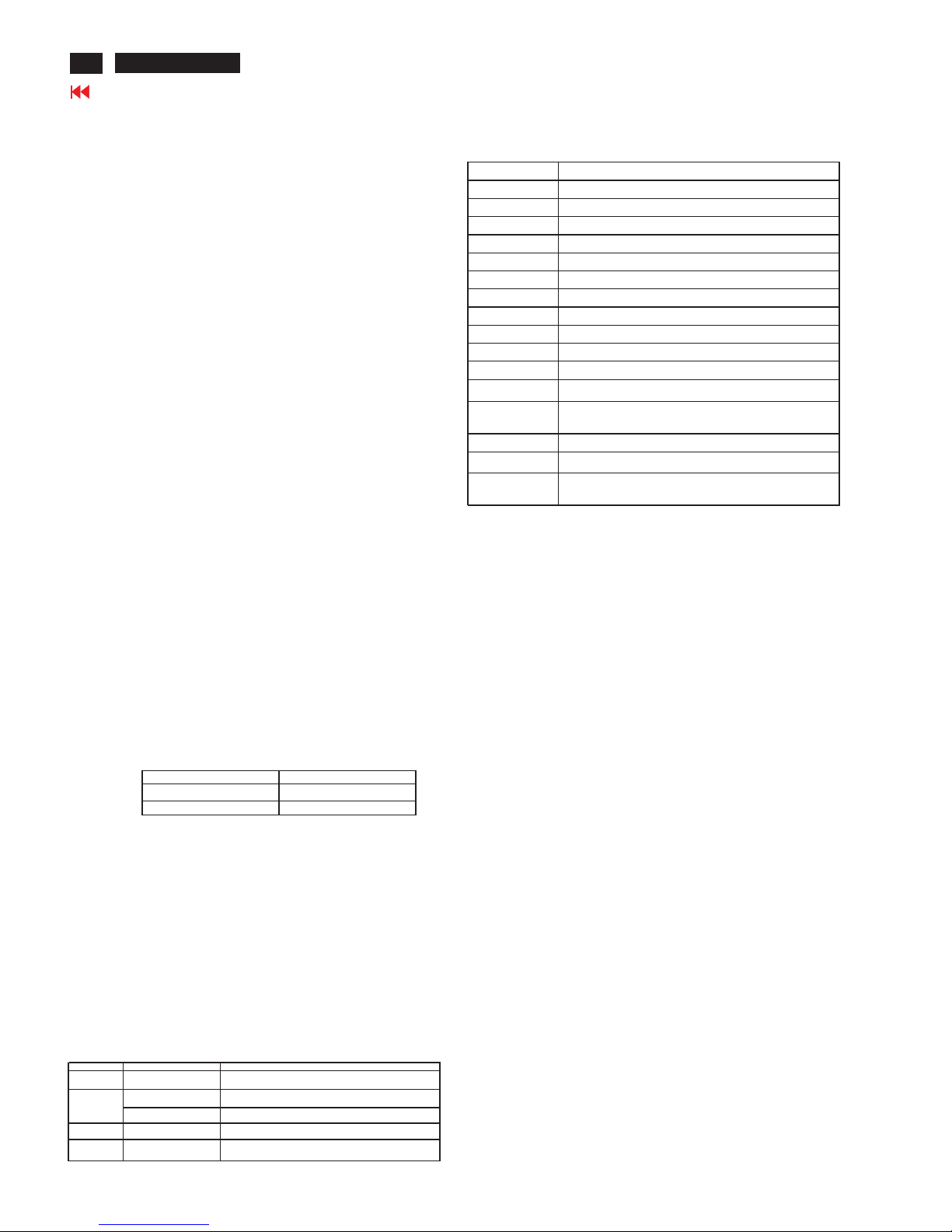

Preset timing Chart

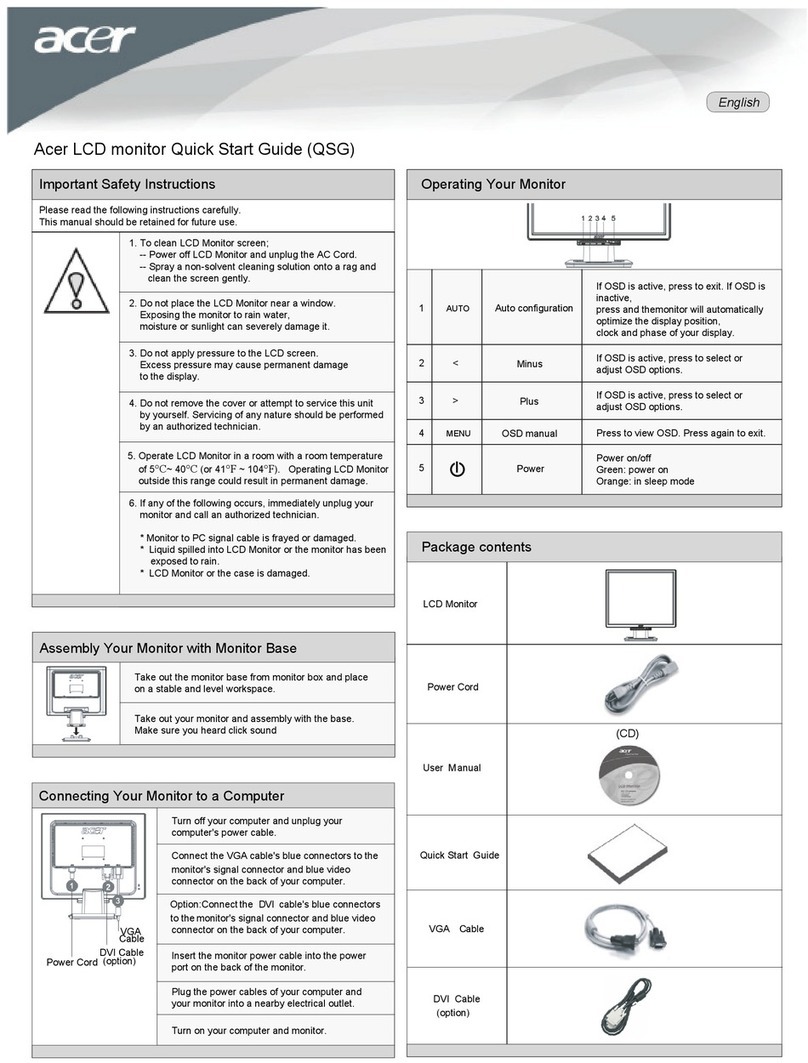

1.3.5.2 Video Stretching

The monitor shall contain provisions to “stretch” the

video signal, so that an input signal from the

computer in any resolution smaller than 1366 x

768 is automatically expanded to fill the entire

screen.

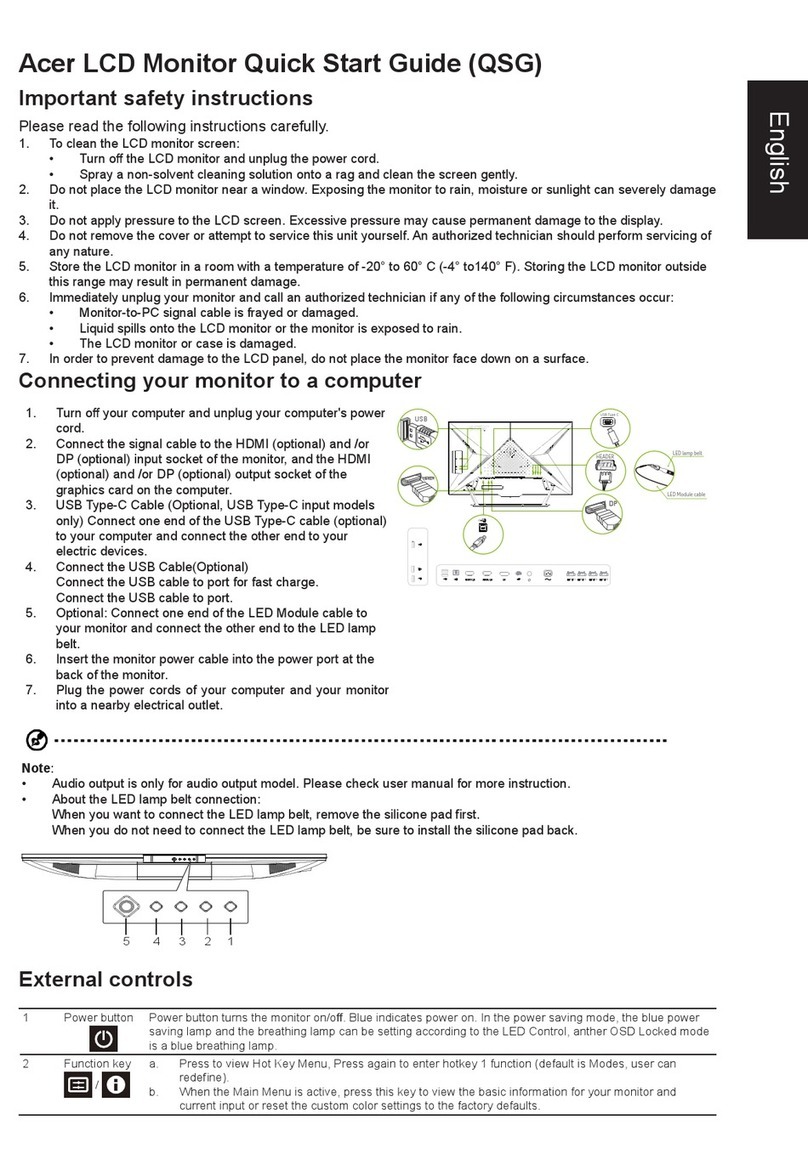

1.3.5.3 Panel Timing and Interface

The controller supplied with the monitor shall

control all panel timing. This controller shall

adequately insulate the monitor from the computer,

so that no possible combination of input signals

from the computer shall cause damage to the flat

panel or any other component of the monitor. The

LCD panel interface shall support the TFT

standard.

1.3.6 DC - AC Inverter Requirements

The DC-AC inverter is on the power board. The

frequencies used by the DC-AC inverter used to power the

backlight shall be chosen so as to prevent any noticeable

effects on the flat panel (such as a rolling effect).

1.3.7 Power Supply Requirements

The AC to DC converter power supply for the monitor shall

be an external AC to DC converter ”brick” This brick shall

have an IEC receptacle for main power input and a pin - in

---socket for DC power out. The brick shall provide

sufficient power for both the monitor and the backlight

assembly, and shall meet requirements specified in Table

2.

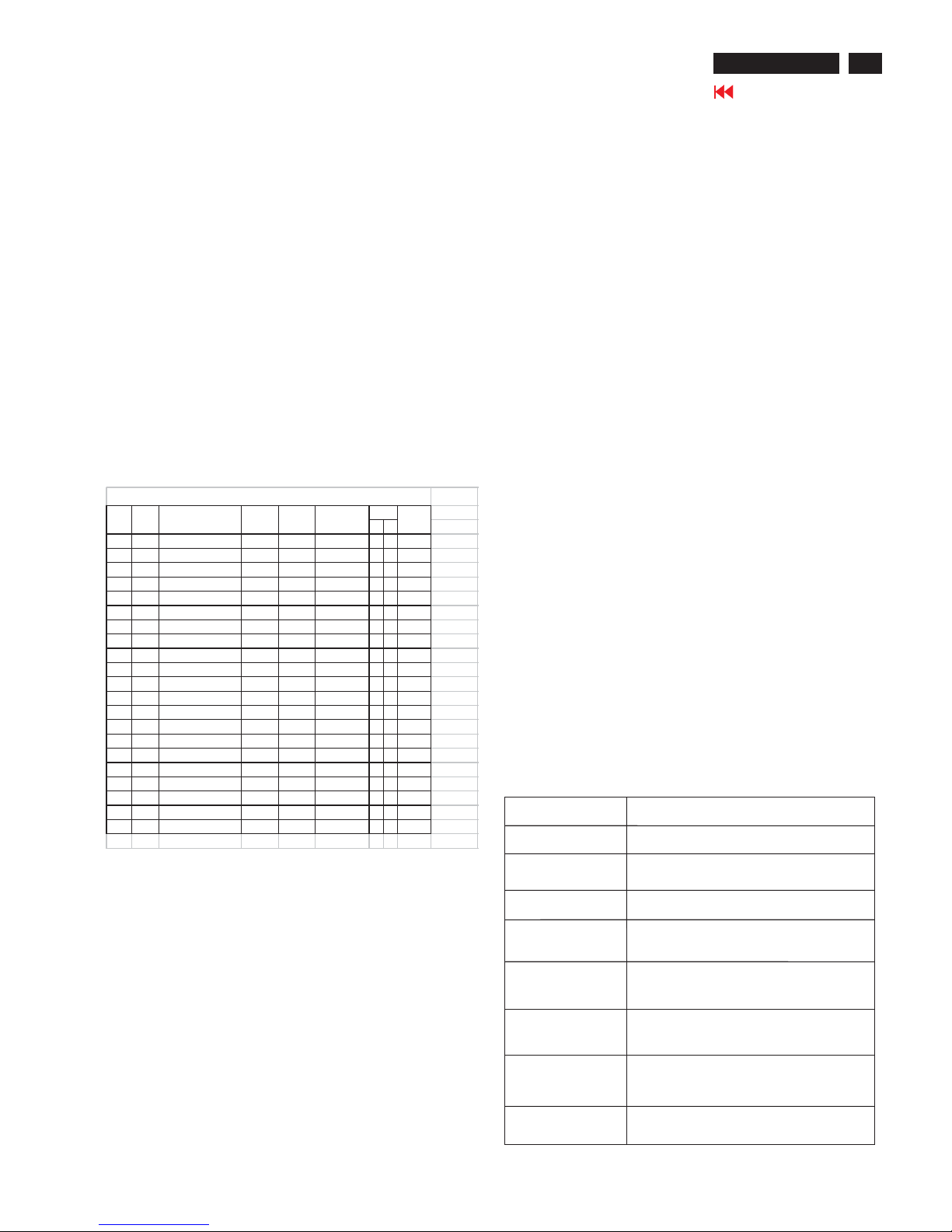

1. Product Specification (continued)

Table 2. AC TO DC Converter Requirements

HV

1 T103 640x480@60Hz 31.469 59.941 25.175 - - VESA

2 T173 640x480@72Hz 37.861 72.809 31.500 - - VESA

3 T109 640x480@75Hz 37.500 75.000 31.500 - - VESA

4 T182 640x480@66.66Hz 35 66.66 30.24 - - MAC

5 T102 720x400@70Hz 31.469 70.087 28.322 - + VGA

6 T104 800x600@56Hz 35.156 56.250 36.000 + + VESA

7 T116 800x600@60Hz 37.879 60.317 40.000 + + VESA

8 T117 800x600@72Hz 48.077 72.188 50.000 + + VESA

9 T110 800x600@75Hz 46.875 75.000 49.500 + + VESA

11 T118 1024x768@60Hz 48.363 60.004 65.000 - - VESA

12 T157 1024x768@70Hz 56.476 70.069 75.000 - - VESA

13 T141 1024x768@75Hz 60.023 75.029 78.750 + + VESA

14 T203 1152x870@75Hz 68.700 75.000 84.520 - -

15 T126 1152x864@75Hz 67.5 75 108 + +

16 T161 1280x960@60Hz 60 60 108 + + VESA

17 T179 1280x1024@60Hz 63.981 60.020 108.000 + + VESA

18 T131 1280x1024@75Hz 79.976 75.025 135.000 + + VESA

19 T339 1280x720@60Hz 44.955 59.940 74.176 ++

20 T213 1280x800@60Hz 49.702 59.810 83.500 ++

21 T278 1366x768@60Hz 47.712 59.790 85.500 --

Preset Timing Chart

V-Sync

(KHz)

Band Width

(MHz)

Polarit SourceItem No Resoulution H-Sync

(KHz)

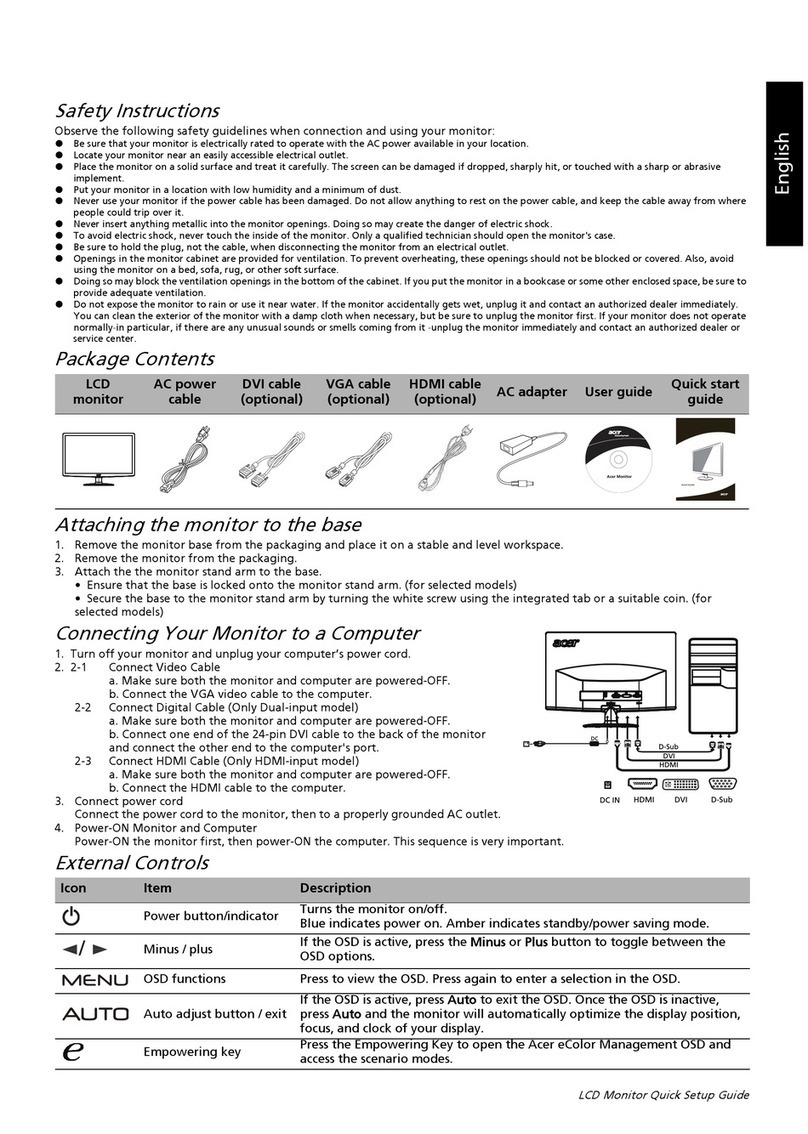

Input Voltage Range The operating range shall be from 90 to 132 and 195 to 265 AVC

sinusoidal for all models specified.

Input Frequency Range Input power frequency range sha;; be from 47.5 to 63 Hz over the

specified input voltage range.

Power Consumption

Power consumption for the monitor shall be less than30W over the

specified voltage and frequency ranges. In suspend or sleep mode

the power consumption will be less than 2W.

Line Fuse The AC input shall be fused and become electrically open as a result

on an unsafe current level. The fuse many not be user replaceable.

Initial Cold Start

The power supply shall start and function properly when under full

load, with worst case conditions of input voltage, input frequenct,

operating temperature, and cold backlight lamps.

Inrush Current

The inrush current must be limited to 30A when operated at

120VAC, and 50A when operated at 220VAC. Inrush current is

measured at an ambient temperature of 25 oC, with the unit

temperature stabilized in the power-off.

Hot Start Cycle

The power supply shall be damaged when switched ON for one

second and OFF for one second for seven consecutive after

operating for one hour at full load, 25 oC, and nominal input line

voltage.

Under Voltage

The power supply shall contain protection circuitry such that the

application of an input voltage below the minimum specified in this

table shall not cause damage to the power supply unit nor cause

failure of the input.

Line Transient

The power supply shalloperate within IEC 801-4 (± 1KV) and IEC

801-5 (± 2KV) for the domestic U.S. version. The UPS power

supply shall operate and comply with CE mark.

AC to DC Converter Requirements

Tab le 2

Go to cover page

5

ACER X193HQ