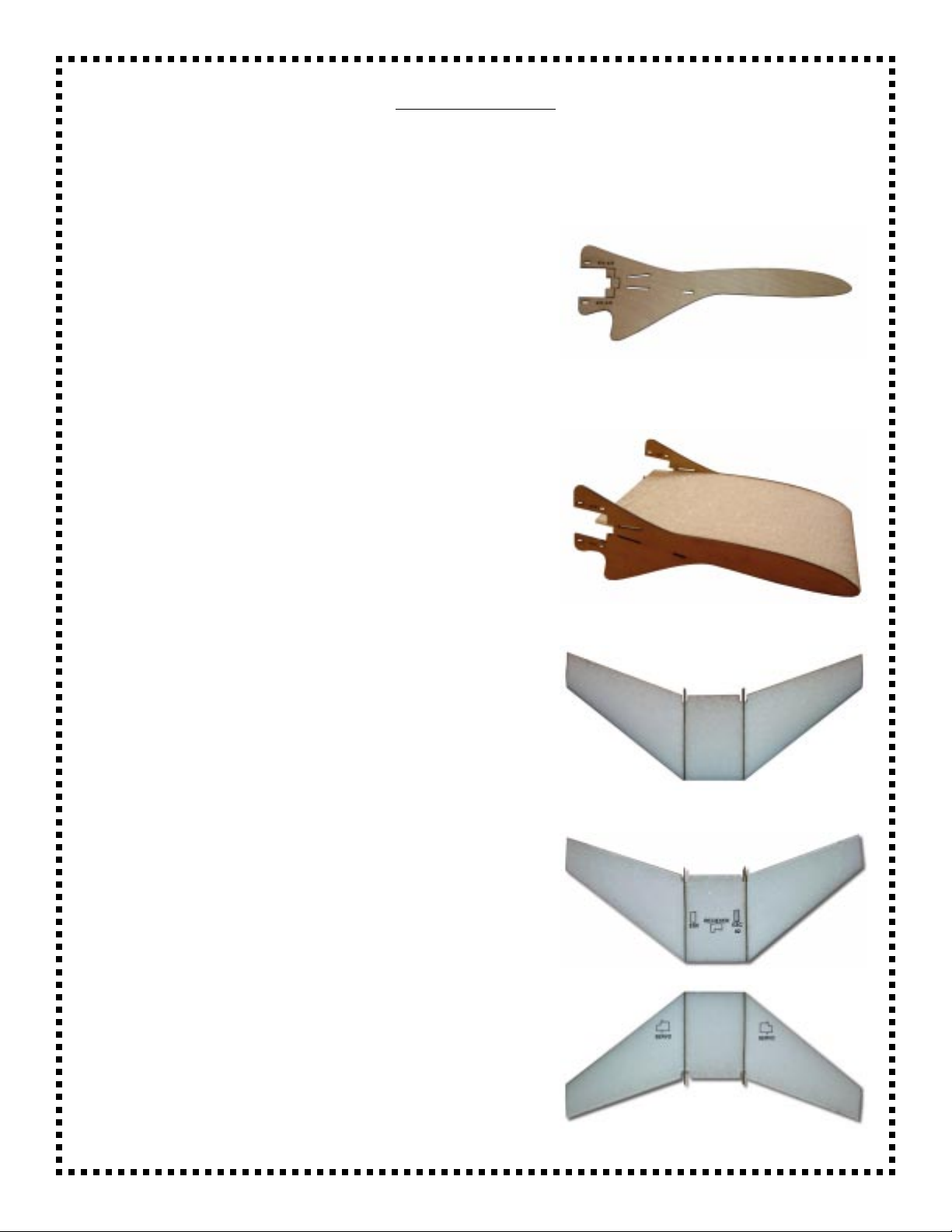

Installing the Carbon Fiber Reinforcement

To install the carbon fiber tape, you’ll need some paper masking tape, thin CA, a plastic

sandwich bag or wrap, your wing beds, some type of weights , a pair of small scissors and a

hobby knife. We would recommend you read this portion of the instructions over fully before

attempting this procedure. Remember that all CA products will bond instantly with skin (as

they were designed to do) and it is always best to understand completely what you intend to

do the CA before you start!

1. First, we are going to install the carbon fiber on the bottom of the wing. Take your upper

wing beds and place them on an elevated surface (use a few short pieces of 2x4’s or

something to hold the beds about 1-1/2” or more off the table, yet fully supporting the beds).

Now set your wing into the beds upside down. If the top of the motor-mount hits the tabletop,

you will have to elevate the beds somewhat higher. When setting the top of the wings into the

beds, you will notice that the servo control arms hit slightly into the foam of the beds. Just

press them in a little with your thumb on top of the servo areas on the wing, then lift out the

wing and set it aside for a moment. Using a hobby knife, look into the beds for 2 small

impressions where the control arms hit and cut out around those indentations slightly and

shallowly. Return the wings into the beds, making sure they seat fully, if not cut some more

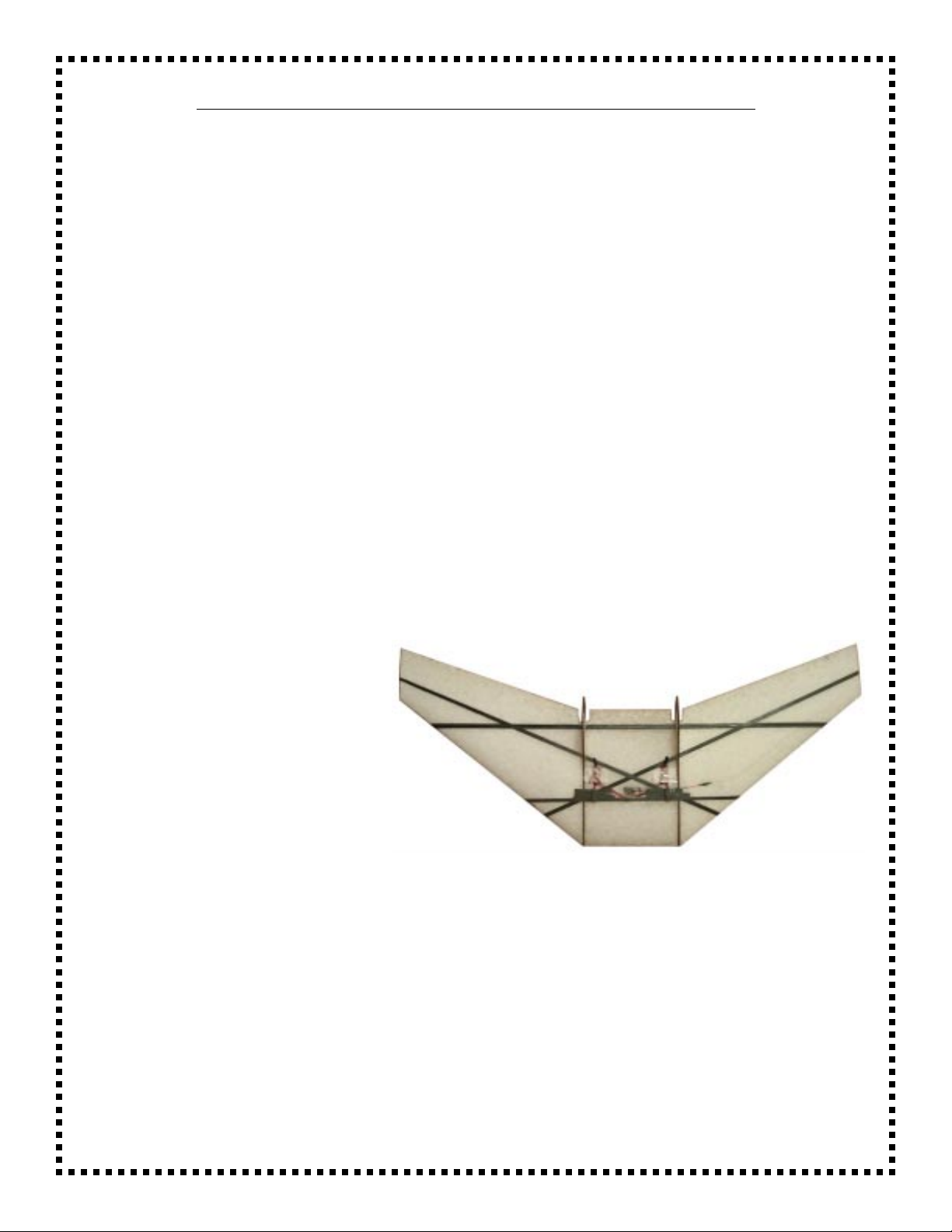

1a. Place one of the lengths of carbon fiber tape through one of the holes in the rear portion of

the mount. Leaving about 1” overlap past the wing on both ends, cut the CF tape to length -

MAKING SURE TO LEAVE THE 1” OVERLAP AT BOTH ENDS! Using some masking tape,

secure one side of the CF tape

down tightly to one side of the core

-- NOT ONTO THE WING

ITSELF! Stretch the other end of

the CF tape tightly, then mask

down this other end to the other

core side as well. Using this same

process, apply the two remaining

lengths of CF tape to this side of

the wing -- just as you see

illustrated here. We can’t

emphasize enough how important

it is to keep the CF tape stretch very taught and mask very tightly down to the beds. Done

right, this is by far the strongest and lightest method available to reinforce an EPP foam wing,

Done wrong... Well you know the rest.

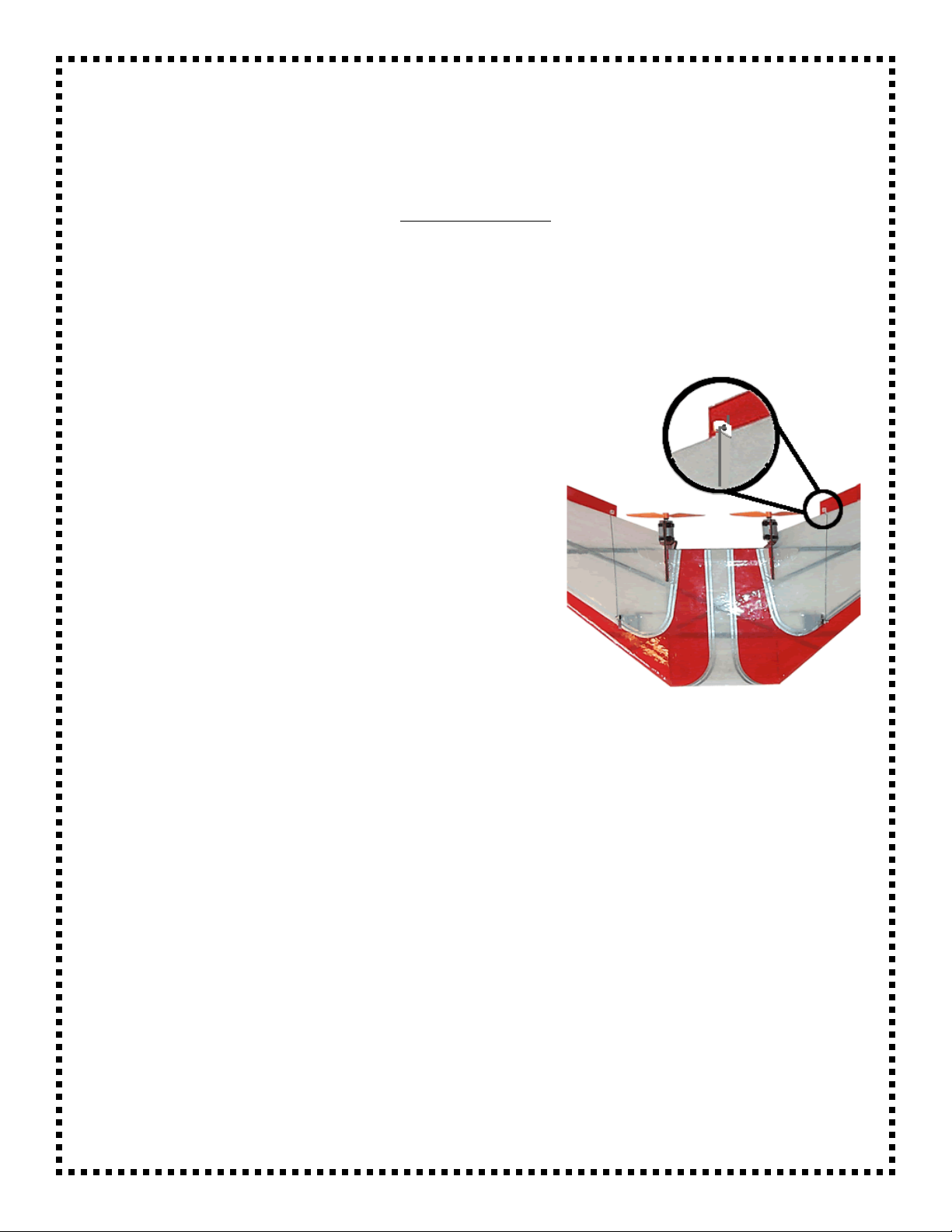

1b. After all the CF tape has been placed and masked down securely, put some small weights

on the top of the wing, making sure to miss placing them on the CF tape. Look over your work

carefully at this point making sure that the wing set perfectly flat on the table in fully down into

the beds. Now wrap your finger in a double layer of plastic sandwich bag or wrap (to keep the

CA off of you) and working on one line of CF tape at a time, squeeze out some thin CA on top

of one of the CF tapes while using your plastic wrapped finger to rub it in and spread it out.

You may notice some heating as the Carbon and the CA chemically react, but keep rubbing

as long as you comfortably can. Using this same procedure, complete the thin CA application

5