TABLE OF CONTENTS

1.0 WARRANTY .............................................................................................................................................................. 5

2.0 SAFETY PRECAUTIONS........................................................................................................................................... 6

2.1 Safety Alert Symbols .................................................................................................................................................. 6

2.2 Important Information and Warnings ................................................................................................................... 7

2.3 Safe Hoisting and OSHA Compliance ................................................................................................................. 8

2.4 Warning Tags and Labels .................................................................................................................................. 10

2.5 General Safe Operation Requirements.............................................................................................................. 11

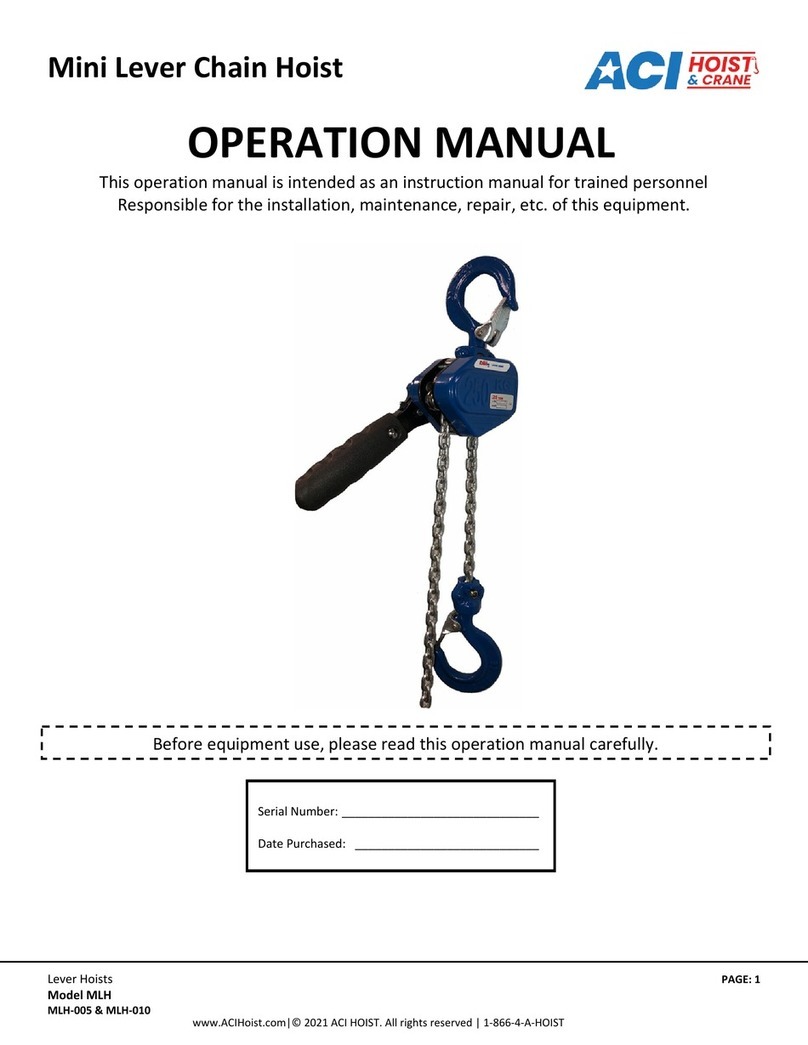

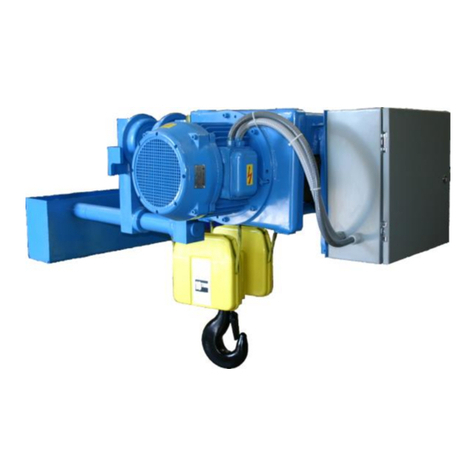

3.0 GENERAL DESCRIPTION & FEATURES.................................................................................................................12

3.1 Model Numbering .............................................................................................................................................. 12

3.2 Pendant Control ................................................................................................................................................. 13

4.0 INSTALLATION........................................................................................................................................................15

4.1 Prior to Installing Hoist ....................................................................................................................................... 15

4.2 Installation of Hoist............................................................................................................................................. 16

4.2.1 Installation of Hoist with Trolley .......................................................................................................... 17

4.2.2

Installation of Trolley Hoist on the Beam .................................................................................... 20

4.2.3 Connecting Power Supply to Hoist..................................................................................................... 21

4.2.4 Load Chain ......................................................................................................................................... 21

4.3 Prior To Operation.............................................................................................................................................. 23

4.3.1 Motor Phasing .................................................................................................................................... 23

4.3.1 Trolley Motor Phasing ......................................................................................................................... 24

4.4 Testing Limit Switches ....................................................................................................................................... 24

4.5 Hoist Load Test .................................................................................................................................................. 25

5.0 OPERATION ............................................................................................................................................................26

5.1 General Safety.................................................................................................................................................... 26

5.1.1 General DO’s and DO NOT’S ............................................................................................................. 27

5.2 Safety Rules before Operating the Hoist............................................................................................................ 27

5.3 Safety Rules for Operating the Hoist.................................................................................................................. 28

5.4 Safety Rules for Parking the Load...................................................................................................................... 28

5.5 Safety Rules before Each Shift........................................................................................................................... 29

6.0 INSPECTION ...........................................................................................................................................................30

6.1 Prior to Maintenance or Inspection.................................................................................................................... 30

6.1.1 Inspection Records ............................................................................................................................ 31

6.2 Inspection Classification .................................................................................................................................... 31

6.3 Daily, Frequent & Periodic Inspections.............................................................................................................. 32

6.4 Hook Inspection................................................................................................................................................. 34

6.5 Limit Switch Inspection ...................................................................................................................................... 36

6.6 Load Chain Inspection ....................................................................................................................................... 39

6.7 Hoist Motor Brake Inspection............................................................................................................................. 41