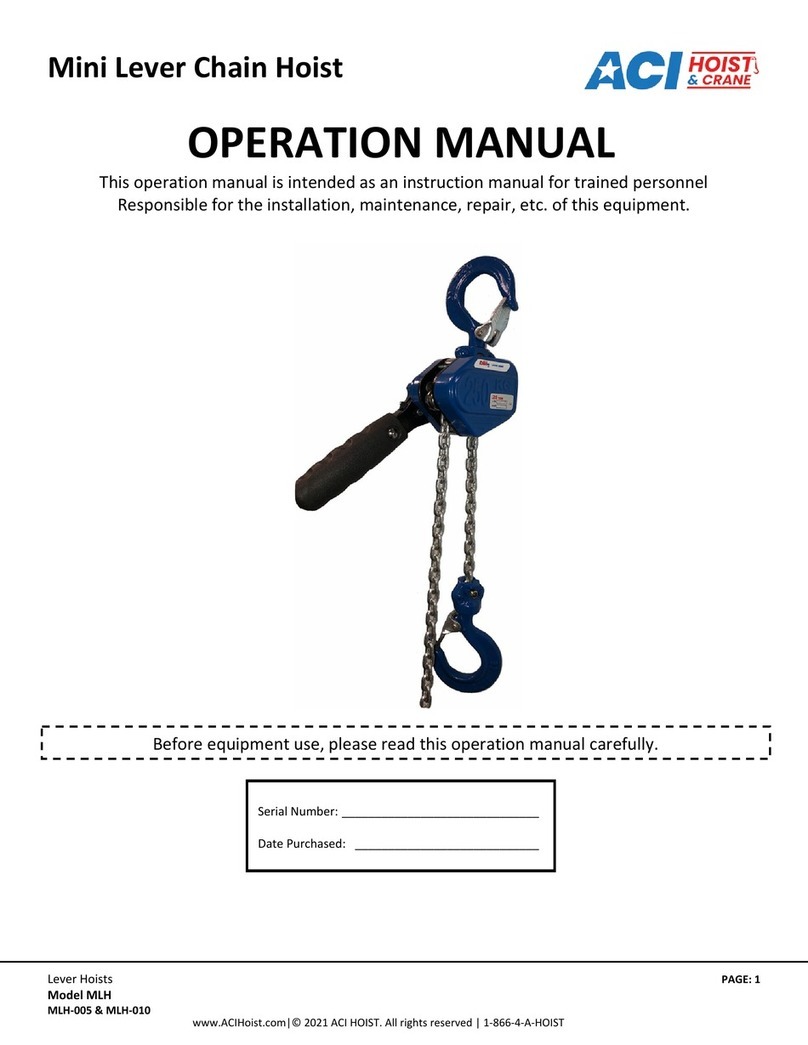

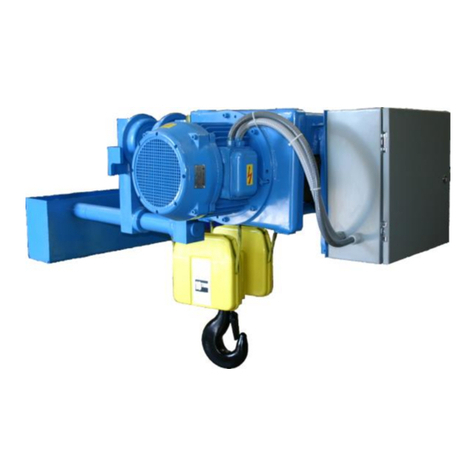

Mechanics Hoists PAGE: 3

Model MH MH-0214

2721 NE 4th Ave Pompano FL 33064| (954) 367-6116 Visit WWW.ACIHOIST.COM for the most current information

TABLE OF CONTENTS

1.0 WARRANTY .............................................................................................................................................................. 5

2.0 SAFETY PRECAUTIONS........................................................................................................................................... 6

2.1 Safety Alert Symbols...................................................................................................................................... 6

3.0 INSTALLATION......................................................................................................................................................... 7

3.1 Unpacking ..................................................................................................................................................... 7

3.2 Pre-installation Checks .................................................................................................................................. 7

3.3 Power Supply System.................................................................................................................................... 7

3.4 Connection to the Electrical Supply ............................................................................................................... 8

3.5 Mounting the Hoist ........................................................................................................................................ 8

3.6 Hook and Eye Suspension Hoists.................................................................................................................. 8

3.7 Load Chain.................................................................................................................................................... 8

3.8 Load Chain Lubrication.................................................................................................................................. 8

3.9 Chain Container............................................................................................................................................. 9

3.9.1 Installation of Standard Chain Container.......................................................................................... 9

4.0 OPERATION............................................................................................................................................................ 10

4.1 Test and Operational Checks........................................................................................................................10

4.2 Operation Personnel.....................................................................................................................................11

4.3 Product Warnings .........................................................................................................................................11

4.4 Product Cautions..........................................................................................................................................12

5.0 INSPECTION........................................................................................................................................................... 14

5.1 General.........................................................................................................................................................14

5.2 Inspection Classification ...............................................................................................................................14

5.3 Frequent Inspection......................................................................................................................................15

5.4 Periodic Inspection .......................................................................................................................................15

5.5 Occasionally Used Hoist...............................................................................................................................16

5.6 Inspection Reports........................................................................................................................................16

5.7 Inspection Methods and Criteria ...................................................................................................................16

5.8 Chain Inspection...........................................................................................................................................18

6.0 MAINTENANCE AND REPAIR................................................................................................................................ 19

6.1 Cutting the Chain..........................................................................................................................................19

6.2 Lubrication....................................................................................................................................................19

6.3 Replacing Gear Brakes & Oil.........................................................................................................................20

6.4 Testing .........................................................................................................................................................21

7.0 TROUBLESHOOTING............................................................................................................................................. 22

8.0 WIRING DIAGRAM ................................................................................................................................................. 23

9.0 DIMENSIONS & SPECIFICATIONS........................................................................................................................ 24

10.0 EXPLODED VIEWS & PARTS LISTS..................................................................................................................... 26