aci INTERFACE AUD Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 7.0

I0000598

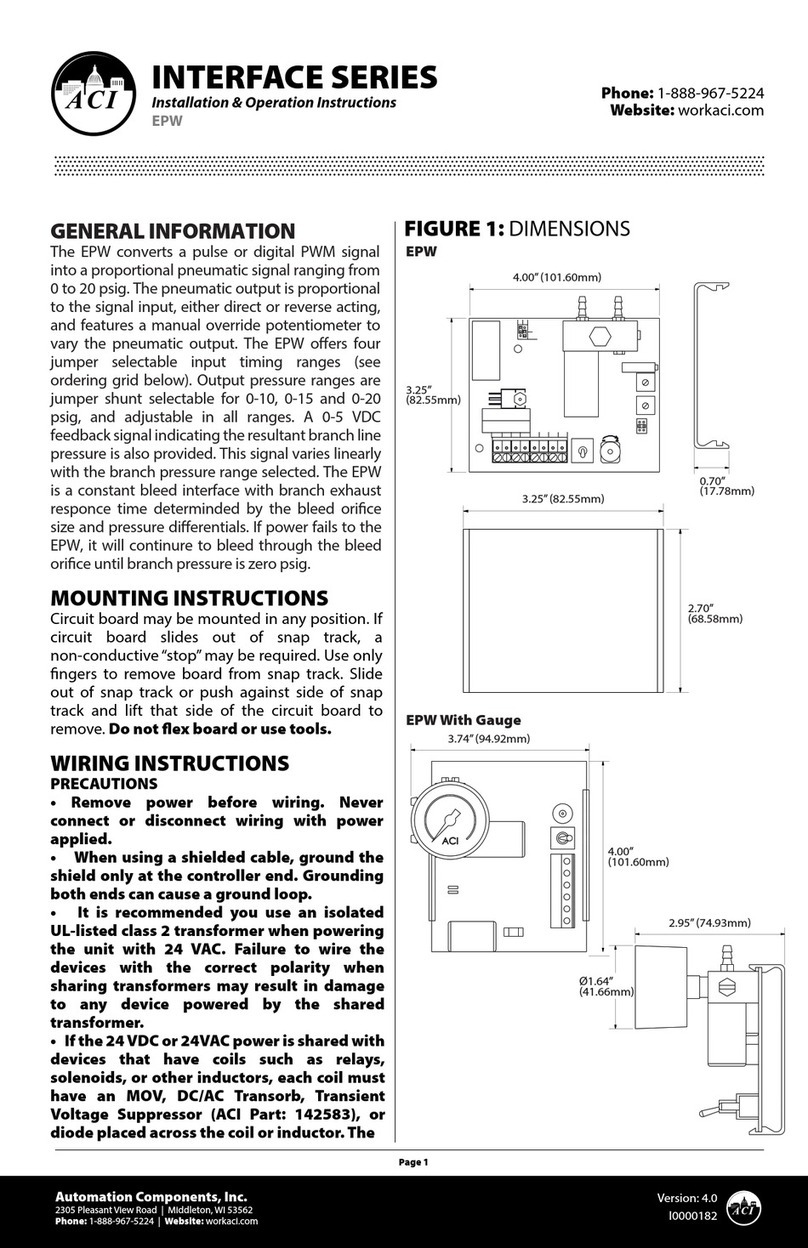

FIGURE 1: DIMENSIONS

INTERFACE SERIES

Installation & Operation Instructions

AUD

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The AUD converts a oating point signal into a

linear analog output. There are two inputs on the

AUD, one to increase the analog output and one to

decrease the analog output. The output of the AUD

is stable when the inputs are both o. A contact

closure or voltage signal to either input will cause

the output of the AUD to begin to ramp either up or

down depending on which input was activated.

The output stops ramping once the up or down

input is deactivated, and will remain at that value

until another up or down signal is received. If both

inputs are “ON,” the output will reset to the lowest

value of the selected range.

The output and the AUD

is in the form of an analog, steady state voltage or

current. This signal can be scaled to t the needs of the

application by selecting one of several preset ranges

by dip switch or by adjusting the oset and the gain of

the output with two potentiometers.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If circuit board slides out of snap track, a non-conductive

“stop”may be required. Use only ngers to remove board from snap track. Slide out of snap track or push

against side of snap track and lift that side of the circuit board to remove. Do not ex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both

ends can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

3.75” (95.25mm)

2.20”

(55.88mm)

2.18”

(55.37mm)

3.88” (98.55mm)

0.70”

(17.78mm)

Note: If the end device has an earth ground(SCR, VFD), the

ground/common must be isolated. This can be achieved by using an

isolated transformer. R16 resistor will be extremely hot to the touch if

there is a ground loop.

Note: If J1 jumpers are set to the NRM position, but the controller is

outputting a Triac signal for UP pulse, the UP LED will be turned on

and the DOWN LED will be slightly dim. This would be an indication

that the jumpers need to be set for TRIAC.

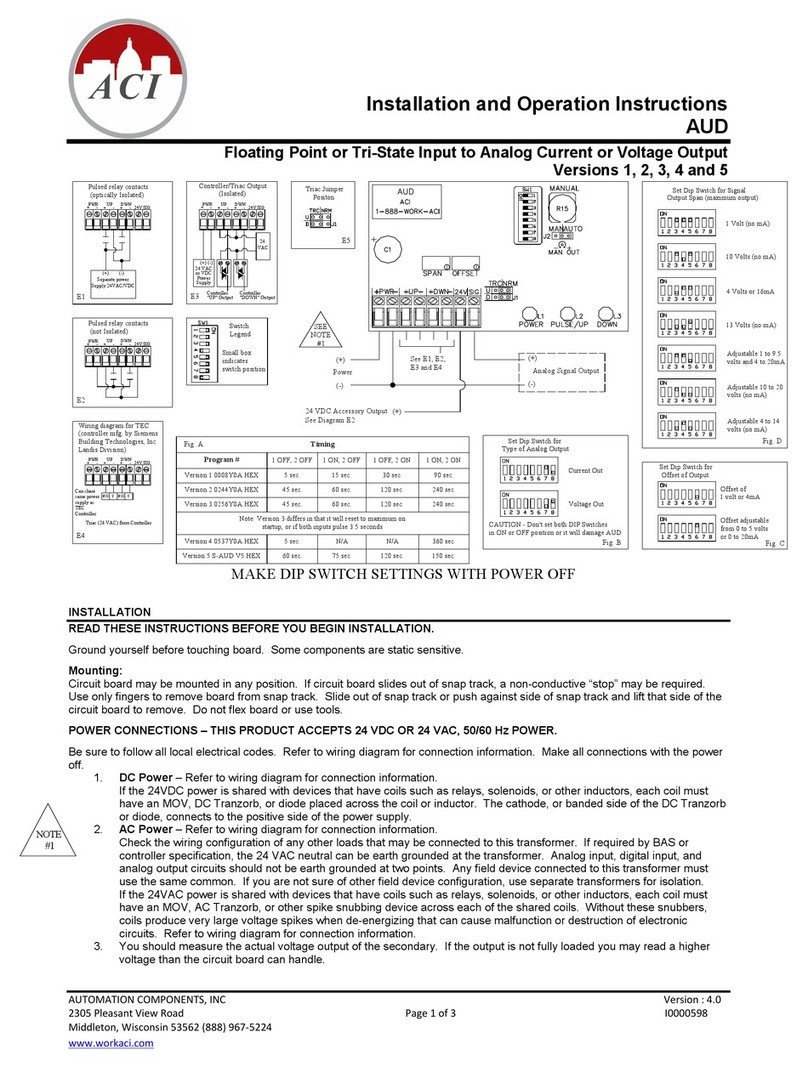

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 7.0

I0000598

GENERAL INFORMATION

The AUD converts a oating point signal into a

linear analog output. There are two inputs on the

AUD, one to increase the analog output and one to

decrease the analog output. The output of the AUD

is stable when the inputs are both o. A contact

closure or voltage signal to either input will cause

the output of the AUD to begin to ramp either up or

down depending on which input was activated.

The output stops ramping once the up or down

input is deactivated, and will remain at that value

until another up or down signal is received. If both

inputs are “ON,” the output will reset to the lowest

value of the selected range.

The output and the AUD

is in the form of an analog, steady state voltage or

current. This signal can be scaled to t the needs of the

application by selecting one of several preset ranges

by dip switch or by adjusting the oset and the gain of

the output with two potentiometers.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If circuit board slides out of snap track, a non-conductive

“stop”may be required. Use only ngers to remove board from snap track. Slide out of snap track or push

against side of snap track and lift that side of the circuit board to remove. Do not ex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both

ends can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

1-888-WORK-ACI

ACI

AUD

O

SIG24V

+ UP -+ PWR- + DWN-

TRC NRM

PULSE/UP DOWNPOWER

+

SPAN

AUTOMAN

MANUAL

OFFSET

D

U

MAN OUT

- +

J1

L1 L2 L3

C1

R15

J2

(+)

(-)

(+)

(-)

Analog Signal Output

See E1, E2,

E3 and E4

24 VDC Accessory Output

See Diagram E2

(+)

Pulsed relay contacts

(optically Isolated)

24 VAC

Power

Supply

(+) (-)

or VDC

Controller/Triac Output

(Isolated)

+ -

PWR + -

UP + -

DWN 24V SIG

24

VA C

+ -

PWR + -

UP + -

DWN 24V SIG

Separate power

(+) (-)

Supply 24VAC/VDC

E3

E1 Controller Controller

"UP" Output "DOWN" Output

Pulsed relay contacts

(not Isolated)

+ -

PWR + -

UP + -

DWN 24V SIG

E2

Wiring diagram for TEC

(controller mfg. by Siemens

Building Technologies, Inc.

Landis Division)

+ -

PWR + -

UP + -

DWN 24V SIG

E4

Triac (24 VAC) from Controller

Can share

same power

supply as

TEC

Controller

N.O. N.O.

CC

NRM

TRC

U

D J1

Triac Jumper

Positon

E5

24 VAC/DC

Power Supply

Note: If the end device has an earth ground(SCR, VFD), the

ground/common must be isolated. This can be achieved by using an

isolated transformer. R16 resistor will be extremely hot to the touch if

there is a ground loop.

Note: If J1 jumpers are set to the NRM position, but the controller is

outputting a Triac signal for UP pulse, the UP LED will be turned on

and the DOWN LED will be slightly dim. This would be an indication

that the jumpers need to be set for TRIAC.

TABLE 1: VERSION CHART

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 7.0

I0000598

CALIBRATION AND CHECKOUT

SIGNAL INPUTS

See gures E1, E2, E3, and E4 for wiring details. The AUD accepts pulsed relay contact inputs, pulsed DC,

or pulsed AC voltage inputs (see E5 for Triac jumper position).

DIP SWITCH PROGRAMMING

1. Select the rate of change by setting the DIP switch as shown in Figure A. The rate of change is the time

it takes for the analog output to go from minimum to maximum. Rate of change selections are as follows:

Version 1: 5, 15, 30 and 90 seconds.

Version 2 & 3: 45, 60, 120, and 240 seconds (Version 3 diers in that it will reset to maximum on

start-up, or if both inputs pulse 3.5 seconds).

Version 4: 5 and 360 seconds. Changing the timing range with power on will result in reset to

minimum on Versions 1, 2 and 4.

Version 5: 60, 75, 120, and 150 seconds.

Verify that the chip numbers on your AUD corresponds to version ordered - See Table 1.

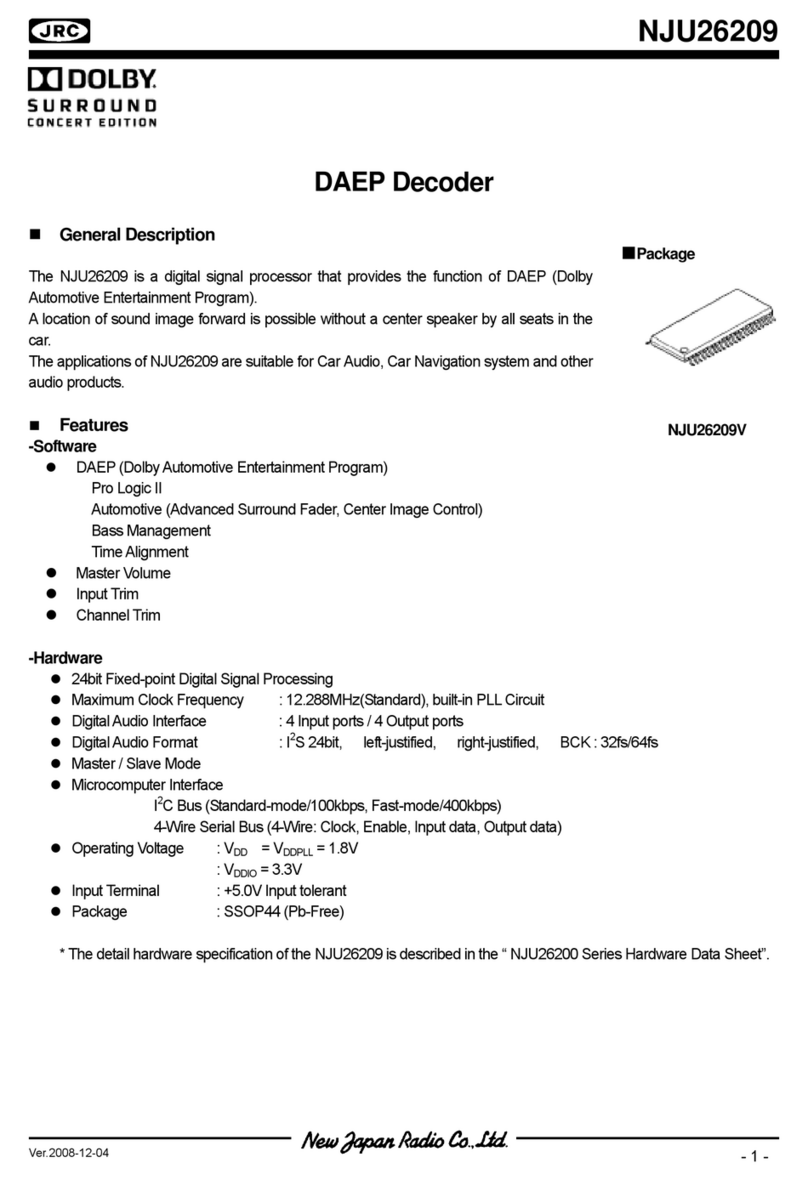

2. Select either current or voltage output with the two switches shown in Figure B (on p. 4). NEVER have

both switches on or o at the same time while powered, or chip failure may occur.

3. Select oset of 1 volt/4 mA or adjustable oset by switch 6 as shown in Figure C. With the adjustable

oset setting, you can adjust the “OFFSET” trim pot as desired. For oset higher than 5 volts contact

customer service.

4. Select the desired span by setting the three switches as shown in Figure D. If you chose an adjustable

span, you can adjust the“SPAN” trim pot, as necessary. After all connections have been made, activate the

power source. The “POWER” LED should light. The “UP” and “DOWN” LED’s will light when the AUD is

receiving input signals.

ADJUSTABLE OFFSET AND SPAN

If you do not wish to use any of the preset selections and

desire to set your own minimum and maximum output,

you must make potentiometer adjustments to the AUD. The OFFSET DIP switch

(shown in Figure C) should be set for adjustable oset and the SPAN DIP switches (shown in Figure D)

should be set for the span desired. The minimum output signal will be equal to the oset. The maximum

output signal will be equal to the oset plus the span. Examples:

If the Span is set at 4 VDC and the Oset is set at 0 VDC

Minimum Output will be 0 VDC, Maximum Output will be 4 VDC

Or… If the Span is set at 16 mA and the Oset is set at 4 mA

Minimum Output will be 4 mA, Maximum Output will be 20 mA

To Set an Adjustable Oset:

Turn power OFF, set DIP switch 6 for adjustable oset (see Figure 3), connect multimeter to the output and

turn the power on.

Place Man/Auto jumper in the Manual position.

Turn the Manual Override potentiometer counter clockwise until it stops. It is a 3/4 turn pot.

Oset Pot turns counter clockwise to Decrease and clockwise to Increase.

Turn the Oset potentiometer until the desired minimum output is read on meter.

To Set an Adjustable Span:

Turn the power OFF, set DIP switches 3,4 and 5 for one of the 3 desired adjustable ranges (see Figure 3).

Connect multimeter to the output and turn power ON.

Place (or leave) the Man/Auto jumper in the manual position.

Turn the override potentiometer clockwise until it stops.

Turn the Span potentiometer until the desired maximum output is read on meter (turn counter clockwise

to increase and clockwise to decrease).

Check full range and repeat if needed. (Note: If powered when making DIP switch settings, power must be

reset to allow DIP switch settings to be recognized.

When power is rst applied or restored after power interruption, the AUD automatically resets to the

minimum output signal as dened by the output DIP switch settings or the adjusted minimum.

Triac input – Follow wiring example in Figure 2 (p. 2).

Manual Override Potentiometer – If you want to manually increase and decrease the output within the

selected signal span (to test the hookup to the actuator), place Jumper J2 in MAN (manual) position, and

turn the manual potentiometer. Be sure to return Jumper J2 to AUTO position after testing.

TROUBLE SHOOTING AND TESTING

1. Apply 24 VAC or 24 VDC to “PWR” terminal, conrm power LED is on and measure voltage to conrm

proper voltage.

2. Check the DIP settings. Depressing the switch closest to the MAN/AUTO pot selects the ON position. You

must reset power if switch changes are made with power on or they will not be recognized.

3. Testing the output. Connect power. Place MAN/AUTO jumper to Manual.

Voltage Out:

Conrm DIP switch setting for “Voltage Out” (See (see Figure 3 (p. 4))) Should be 7 OFF & 8 ON. With

meter only connected to the SIG and PWR (-), turn the manual pot full left and then full right. The output

should vary from 0 to 100% of calibrated or jumper selected range.

If no change is seen, contact ACI Tech Support at (888) 967-5224.

If yes, connect load/device and meter to SIG and PWR (-) terminals. Turn override pot and measure

voltage. Do the readings match the no load test?

If no, check load impedance mismatch or a possible ground loop problem and/or call ACI Tech Support

at (888) 967-5224.

If yes, voltage output is functioning properly.

Current Out:

Conrm DIP Switch setting for “Current Out”(See (see Figure 3 (p. 4)). With meter only connected to the

Fig. A Timing

Program # 1 OFF, 2 OFF 1 ON, 2 OFF 1 OFF, 2 ON 1 ON, 2 ON

Version 1 0008Y0A.HEX 5 sec. 15 sec. 30 sec. 90 sec.

Version 2 0244Y0A.HEX 45 sec. 60 sec. 120 sec. 240 sec.

Version 3 0256Y0A.HEX 45 sec. 60 sec. 120 sec. 240 sec.

Note: Version 3 differs in that it will reset to maximum on

startup, or if both inputs pulse 3.5 seconds

Version 4 0537Y0A.HEX 5 sec. N/A N/A 360 sec.

Version 5 S-AUD V5.HEX 60 sec. 75 sec. 120 sec. 150 sec.

SIG and PWR(-) turn the manual pot full left and then full right. The output should vary from 0 to 100%

of the calibrated or jumper selected range. If not, measure the voltages and turn the Manual override

pot clockwise. Is voltage present? If no, contact ACI Tech Support at (888) 967-5224.

A voltage between 15-39 VDC indicates the AUD is attempting to generate the desired mA. Load or

meter may have an open, blown fuse or connected improperly. A 250 or 500 ohm resistor will also work

to test the output. Connect the resistor to the SIG and PWR(-) terminal. With 250 ohms on the output

the voltage from one side of the resistor to the other will be 1VDC @ 4mA and 5VDC @ 20mA. Using the

500 ohm will give 2 VDC @ 4mA and 10VDC @ 20mA. Does the unit function as stated above?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, current output is functioning properly.

4. Testing the input – To manually test the input.

Apply 24 VAC or 24 VDC to the PWR terminal. Connect your meter to the SIG and PWR(-) terminal. Set

meter to match output DIP switch settings. Place MAN/AUTO jumper to AUTO. Connect a jumper wire

from UP + to the PWR(+). Connect a jumper wire to the PWR(-) only. You are now ready to simulate an

input pulse signal.

For testing purposes, select the 15 second range (DIP switch 1 ON, DIP switch 2 OFF). Be sure to reset

power to allow the AUD to recognize new settings.

Take the free end of the jumper wire from “PWR”(-) and connect by holding wire to the “UP”(-) terminal.

Verify the pulse LED indication. Read output. Has the output changed? The output should be increasing

and stop when maximum span is reached.

Placing the wires on the DWN + and – terminals should decrease the output signal. If no, change the

TRC/NRM to the opposite setting and repeat test. Has the output changed?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, unit is functioning properly.

FIGURE 3: OUTPUT DIP SWITCH SETTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 7.0

I0000598

CALIBRATION AND CHECKOUT

SIGNAL INPUTS

See gures E1, E2, E3, and E4 for wiring details. The AUD accepts pulsed relay contact inputs, pulsed DC,

or pulsed AC voltage inputs (see E5 for Triac jumper position).

DIP SWITCH PROGRAMMING

1. Select the rate of change by setting the DIP switch as shown in Figure A. The rate of change is the time

it takes for the analog output to go from minimum to maximum. Rate of change selections are as follows:

Version 1: 5, 15, 30 and 90 seconds.

Version 2 & 3: 45, 60, 120, and 240 seconds (Version 3 diers in that it will reset to maximum on

start-up, or if both inputs pulse 3.5 seconds).

Version 4: 5 and 360 seconds. Changing the timing range with power on will result in reset to

minimum on Versions 1, 2 and 4.

Version 5: 60, 75, 120, and 150 seconds.

Verify that the chip numbers on your AUD corresponds to version ordered - See Table 1.

2. Select either current or voltage output with the two switches shown in Figure B (on p. 4). NEVER have

both switches on or o at the same time while powered, or chip failure may occur.

3. Select oset of 1 volt/4 mA or adjustable oset by switch 6 as shown in Figure C. With the adjustable

oset setting, you can adjust the “OFFSET” trim pot as desired. For oset higher than 5 volts contact

customer service.

4. Select the desired span by setting the three switches as shown in Figure D. If you chose an adjustable

span, you can adjust the“SPAN” trim pot, as necessary. After all connections have been made, activate the

power source. The “POWER” LED should light. The “UP” and “DOWN” LED’s will light when the AUD is

receiving input signals.

ADJUSTABLE OFFSET AND SPAN

If you do not wish to use any of the preset selections and

desire to set your own minimum and maximum output,

you must make potentiometer adjustments to the AUD. The OFFSET DIP switch

(shown in Figure C) should be set for adjustable oset and the SPAN DIP switches (shown in Figure D)

should be set for the span desired. The minimum output signal will be equal to the oset. The maximum

output signal will be equal to the oset plus the span. Examples:

If the Span is set at 4 VDC and the Oset is set at 0 VDC

Minimum Output will be 0 VDC, Maximum Output will be 4 VDC

Or… If the Span is set at 16 mA and the Oset is set at 4 mA

Minimum Output will be 4 mA, Maximum Output will be 20 mA

To Set an Adjustable Oset:

Turn power OFF, set DIP switch 6 for adjustable oset (see Figure 3), connect multimeter to the output and

turn the power on.

Place Man/Auto jumper in the Manual position.

Turn the Manual Override potentiometer counter clockwise until it stops. It is a 3/4 turn pot.

Oset Pot turns counter clockwise to Decrease and clockwise to Increase.

Turn the Oset potentiometer until the desired minimum output is read on meter.

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

Set Dip Switch for

Offset of Output

Offset of

1 volt or 4mA

Offset adjustable

from 0 to 5 volts

or 0 to 20mA

Fig. C

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

Set Dip Switch for Signal

Output Span (maximum output)

1 Volt (no mA)

10 Volts (no mA)

4 Volts or 16mA

13 Volts (no mA)

Adjustable 1 to 9.5

volts and 4 to 20mA

Adjustable 10 to 20

volts (no mA)

Adjustable 4 to 14

volts (no mA)

Fig. D

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

Set Dip Switch for

Type of Analog Output

Current Out

Voltage Out

Fig. B

CAUTION - Don't set both DIP Switches

in ON or OFF position or it will damage AUD

To Set an Adjustable Span:

Turn the power OFF, set DIP switches 3,4 and 5 for one of the 3 desired adjustable ranges (see Figure 3).

Connect multimeter to the output and turn power ON.

Place (or leave) the Man/Auto jumper in the manual position.

Turn the override potentiometer clockwise until it stops.

Turn the Span potentiometer until the desired maximum output is read on meter (turn counter clockwise

to increase and clockwise to decrease).

Check full range and repeat if needed. (Note: If powered when making DIP switch settings, power must be

reset to allow DIP switch settings to be recognized.

When power is rst applied or restored after power interruption, the AUD automatically resets to the

minimum output signal as dened by the output DIP switch settings or the adjusted minimum.

Triac input – Follow wiring example in Figure 2 (p. 2).

Manual Override Potentiometer – If you want to manually increase and decrease the output within the

selected signal span (to test the hookup to the actuator), place Jumper J2 in MAN (manual) position, and

turn the manual potentiometer. Be sure to return Jumper J2 to AUTO position after testing.

TROUBLE SHOOTING AND TESTING

1. Apply 24 VAC or 24 VDC to “PWR” terminal, conrm power LED is on and measure voltage to conrm

proper voltage.

2. Check the DIP settings. Depressing the switch closest to the MAN/AUTO pot selects the ON position. You

must reset power if switch changes are made with power on or they will not be recognized.

3. Testing the output. Connect power. Place MAN/AUTO jumper to Manual.

Voltage Out:

Conrm DIP switch setting for “Voltage Out” (See (see Figure 3 (p. 4))) Should be 7 OFF & 8 ON. With

meter only connected to the SIG and PWR (-), turn the manual pot full left and then full right. The output

should vary from 0 to 100% of calibrated or jumper selected range.

If no change is seen, contact ACI Tech Support at (888) 967-5224.

If yes, connect load/device and meter to SIG and PWR (-) terminals. Turn override pot and measure

voltage. Do the readings match the no load test?

If no, check load impedance mismatch or a possible ground loop problem and/or call ACI Tech Support

at (888) 967-5224.

If yes, voltage output is functioning properly.

Current Out:

Conrm DIP Switch setting for “Current Out”(See (see Figure 3 (p. 4)). With meter only connected to the

SIG and PWR(-) turn the manual pot full left and then full right. The output should vary from 0 to 100%

of the calibrated or jumper selected range. If not, measure the voltages and turn the Manual override

pot clockwise. Is voltage present? If no, contact ACI Tech Support at (888) 967-5224.

A voltage between 15-39 VDC indicates the AUD is attempting to generate the desired mA. Load or

meter may have an open, blown fuse or connected improperly. A 250 or 500 ohm resistor will also work

to test the output. Connect the resistor to the SIG and PWR(-) terminal. With 250 ohms on the output

the voltage from one side of the resistor to the other will be 1VDC @ 4mA and 5VDC @ 20mA. Using the

500 ohm will give 2 VDC @ 4mA and 10VDC @ 20mA. Does the unit function as stated above?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, current output is functioning properly.

4. Testing the input – To manually test the input.

Apply 24 VAC or 24 VDC to the PWR terminal. Connect your meter to the SIG and PWR(-) terminal. Set

meter to match output DIP switch settings. Place MAN/AUTO jumper to AUTO. Connect a jumper wire

from UP + to the PWR(+). Connect a jumper wire to the PWR(-) only. You are now ready to simulate an

input pulse signal.

For testing purposes, select the 15 second range (DIP switch 1 ON, DIP switch 2 OFF). Be sure to reset

power to allow the AUD to recognize new settings.

Take the free end of the jumper wire from “PWR”(-) and connect by holding wire to the “UP”(-) terminal.

Verify the pulse LED indication. Read output. Has the output changed? The output should be increasing

and stop when maximum span is reached.

Placing the wires on the DWN + and – terminals should decrease the output signal. If no, change the

TRC/NRM to the opposite setting and repeat test. Has the output changed?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, unit is functioning properly.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 7.0

I0000598

CALIBRATION AND CHECKOUT

SIGNAL INPUTS

See gures E1, E2, E3, and E4 for wiring details. The AUD accepts pulsed relay contact inputs, pulsed DC,

or pulsed AC voltage inputs (see E5 for Triac jumper position).

DIP SWITCH PROGRAMMING

1. Select the rate of change by setting the DIP switch as shown in Figure A. The rate of change is the time

it takes for the analog output to go from minimum to maximum. Rate of change selections are as follows:

Version 1: 5, 15, 30 and 90 seconds.

Version 2 & 3: 45, 60, 120, and 240 seconds (Version 3 diers in that it will reset to maximum on

start-up, or if both inputs pulse 3.5 seconds).

Version 4: 5 and 360 seconds. Changing the timing range with power on will result in reset to

minimum on Versions 1, 2 and 4.

Version 5: 60, 75, 120, and 150 seconds.

Verify that the chip numbers on your AUD corresponds to version ordered - See Table 1.

2. Select either current or voltage output with the two switches shown in Figure B (on p. 4). NEVER have

both switches on or o at the same time while powered, or chip failure may occur.

3. Select oset of 1 volt/4 mA or adjustable oset by switch 6 as shown in Figure C. With the adjustable

oset setting, you can adjust the “OFFSET” trim pot as desired. For oset higher than 5 volts contact

customer service.

4. Select the desired span by setting the three switches as shown in Figure D. If you chose an adjustable

span, you can adjust the“SPAN” trim pot, as necessary. After all connections have been made, activate the

power source. The “POWER” LED should light. The “UP” and “DOWN” LED’s will light when the AUD is

receiving input signals.

ADJUSTABLE OFFSET AND SPAN

If you do not wish to use any of the preset selections and

desire to set your own minimum and maximum output,

you must make potentiometer adjustments to the AUD. The OFFSET DIP switch

(shown in Figure C) should be set for adjustable oset and the SPAN DIP switches (shown in Figure D)

should be set for the span desired. The minimum output signal will be equal to the oset. The maximum

output signal will be equal to the oset plus the span. Examples:

If the Span is set at 4 VDC and the Oset is set at 0 VDC

Minimum Output will be 0 VDC, Maximum Output will be 4 VDC

Or… If the Span is set at 16 mA and the Oset is set at 4 mA

Minimum Output will be 4 mA, Maximum Output will be 20 mA

To Set an Adjustable Oset:

Turn power OFF, set DIP switch 6 for adjustable oset (see Figure 3), connect multimeter to the output and

turn the power on.

Place Man/Auto jumper in the Manual position.

Turn the Manual Override potentiometer counter clockwise until it stops. It is a 3/4 turn pot.

Oset Pot turns counter clockwise to Decrease and clockwise to Increase.

Turn the Oset potentiometer until the desired minimum output is read on meter.

To Set an Adjustable Span:

Turn the power OFF, set DIP switches 3,4 and 5 for one of the 3 desired adjustable ranges (see Figure 3).

Connect multimeter to the output and turn power ON.

Place (or leave) the Man/Auto jumper in the manual position.

Turn the override potentiometer clockwise until it stops.

Turn the Span potentiometer until the desired maximum output is read on meter (turn counter clockwise

to increase and clockwise to decrease).

Check full range and repeat if needed. (Note: If powered when making DIP switch settings, power must be

reset to allow DIP switch settings to be recognized.

When power is rst applied or restored after power interruption, the AUD automatically resets to the

minimum output signal as dened by the output DIP switch settings or the adjusted minimum.

Triac input – Follow wiring example in Figure 2 (p. 2).

Manual Override Potentiometer – If you want to manually increase and decrease the output within the

selected signal span (to test the hookup to the actuator), place Jumper J2 in MAN (manual) position, and

turn the manual potentiometer. Be sure to return Jumper J2 to AUTO position after testing.

TROUBLE SHOOTING AND TESTING

1. Apply 24 VAC or 24 VDC to “PWR” terminal, conrm power LED is on and measure voltage to conrm

proper voltage.

2. Check the DIP settings. Depressing the switch closest to the MAN/AUTO pot selects the ON position. You

must reset power if switch changes are made with power on or they will not be recognized.

3. Testing the output. Connect power. Place MAN/AUTO jumper to Manual.

Voltage Out:

Conrm DIP switch setting for “Voltage Out” (See (see Figure 3 (p. 4))) Should be 7 OFF & 8 ON. With

meter only connected to the SIG and PWR (-), turn the manual pot full left and then full right. The output

should vary from 0 to 100% of calibrated or jumper selected range.

If no change is seen, contact ACI Tech Support at (888) 967-5224.

If yes, connect load/device and meter to SIG and PWR (-) terminals. Turn override pot and measure

voltage. Do the readings match the no load test?

If no, check load impedance mismatch or a possible ground loop problem and/or call ACI Tech Support

at (888) 967-5224.

If yes, voltage output is functioning properly.

Current Out:

Conrm DIP Switch setting for “Current Out”(See (see Figure 3 (p. 4)). With meter only connected to the

SIG and PWR(-) turn the manual pot full left and then full right. The output should vary from 0 to 100%

of the calibrated or jumper selected range. If not, measure the voltages and turn the Manual override

pot clockwise. Is voltage present? If no, contact ACI Tech Support at (888) 967-5224.

A voltage between 15-39 VDC indicates the AUD is attempting to generate the desired mA. Load or

meter may have an open, blown fuse or connected improperly. A 250 or 500 ohm resistor will also work

to test the output. Connect the resistor to the SIG and PWR(-) terminal. With 250 ohms on the output

the voltage from one side of the resistor to the other will be 1VDC @ 4mA and 5VDC @ 20mA. Using the

500 ohm will give 2 VDC @ 4mA and 10VDC @ 20mA. Does the unit function as stated above?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, current output is functioning properly.

4. Testing the input – To manually test the input.

Apply 24 VAC or 24 VDC to the PWR terminal. Connect your meter to the SIG and PWR(-) terminal. Set

meter to match output DIP switch settings. Place MAN/AUTO jumper to AUTO. Connect a jumper wire

from UP + to the PWR(+). Connect a jumper wire to the PWR(-) only. You are now ready to simulate an

input pulse signal.

For testing purposes, select the 15 second range (DIP switch 1 ON, DIP switch 2 OFF). Be sure to reset

power to allow the AUD to recognize new settings.

Take the free end of the jumper wire from “PWR”(-) and connect by holding wire to the “UP”(-) terminal.

Verify the pulse LED indication. Read output. Has the output changed? The output should be increasing

and stop when maximum span is reached.

Placing the wires on the DWN + and – terminals should decrease the output signal. If no, change the

TRC/NRM to the opposite setting and repeat test. Has the output changed?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, unit is functioning properly.

CALIBRATION AND CHECKOUT

SIGNAL INPUTS

See gures E1, E2, E3, and E4 for wiring details. The AUD accepts pulsed relay contact inputs, pulsed DC,

or pulsed AC voltage inputs (see E5 for Triac jumper position).

DIP SWITCH PROGRAMMING

1. Select the rate of change by setting the DIP switch as shown in Figure A. The rate of change is the time

it takes for the analog output to go from minimum to maximum. Rate of change selections are as follows:

Version 1: 5, 15, 30 and 90 seconds.

Version 2 & 3: 45, 60, 120, and 240 seconds (Version 3 diers in that it will reset to maximum on

start-up, or if both inputs pulse 3.5 seconds).

Version 4: 5 and 360 seconds. Changing the timing range with power on will result in reset to

minimum on Versions 1, 2 and 4.

Version 5: 60, 75, 120, and 150 seconds.

Verify that the chip numbers on your AUD corresponds to version ordered - See Table 1.

2. Select either current or voltage output with the two switches shown in Figure B (on p. 4). NEVER have

both switches on or o at the same time while powered, or chip failure may occur.

3. Select oset of 1 volt/4 mA or adjustable oset by switch 6 as shown in Figure C. With the adjustable

oset setting, you can adjust the “OFFSET” trim pot as desired. For oset higher than 5 volts contact

customer service.

4. Select the desired span by setting the three switches as shown in Figure D. If you chose an adjustable

span, you can adjust the“SPAN” trim pot, as necessary. After all connections have been made, activate the

power source. The “POWER” LED should light. The “UP” and “DOWN” LED’s will light when the AUD is

receiving input signals.

ADJUSTABLE OFFSET AND SPAN

If you do not wish to use any of the preset selections and

desire to set your own minimum and maximum output,

you must make potentiometer adjustments to the AUD. The OFFSET DIP switch

(shown in Figure C) should be set for adjustable oset and the SPAN DIP switches (shown in Figure D)

should be set for the span desired. The minimum output signal will be equal to the oset. The maximum

output signal will be equal to the oset plus the span. Examples:

If the Span is set at 4 VDC and the Oset is set at 0 VDC

Minimum Output will be 0 VDC, Maximum Output will be 4 VDC

Or… If the Span is set at 16 mA and the Oset is set at 4 mA

Minimum Output will be 4 mA, Maximum Output will be 20 mA

To Set an Adjustable Oset:

Turn power OFF, set DIP switch 6 for adjustable oset (see Figure 3), connect multimeter to the output and

turn the power on.

Place Man/Auto jumper in the Manual position.

Turn the Manual Override potentiometer counter clockwise until it stops. It is a 3/4 turn pot.

Oset Pot turns counter clockwise to Decrease and clockwise to Increase.

Turn the Oset potentiometer until the desired minimum output is read on meter.

To Set an Adjustable Span:

Turn the power OFF, set DIP switches 3,4 and 5 for one of the 3 desired adjustable ranges (see Figure 3).

Connect multimeter to the output and turn power ON.

Place (or leave) the Man/Auto jumper in the manual position.

Turn the override potentiometer clockwise until it stops.

Turn the Span potentiometer until the desired maximum output is read on meter (turn counter clockwise

to increase and clockwise to decrease).

Check full range and repeat if needed. (Note: If powered when making DIP switch settings, power must be

reset to allow DIP switch settings to be recognized.

When power is rst applied or restored after power interruption, the AUD automatically resets to the

minimum output signal as dened by the output DIP switch settings or the adjusted minimum.

Triac input – Follow wiring example in Figure 2 (p. 2).

Manual Override Potentiometer – If you want to manually increase and decrease the output within the

selected signal span (to test the hookup to the actuator), place Jumper J2 in MAN (manual) position, and

turn the manual potentiometer. Be sure to return Jumper J2 to AUTO position after testing.

TROUBLE SHOOTING AND TESTING

1. Apply 24 VAC or 24 VDC to “PWR” terminal, conrm power LED is on and measure voltage to conrm

proper voltage.

2. Check the DIP settings. Depressing the switch closest to the MAN/AUTO pot selects the ON position. You

must reset power if switch changes are made with power on or they will not be recognized.

3. Testing the output. Connect power. Place MAN/AUTO jumper to Manual.

Voltage Out:

Conrm DIP switch setting for “Voltage Out” (See (see Figure 3 (p. 4))) Should be 7 OFF & 8 ON. With

meter only connected to the SIG and PWR (-), turn the manual pot full left and then full right. The output

should vary from 0 to 100% of calibrated or jumper selected range.

If no change is seen, contact ACI Tech Support at (888) 967-5224.

If yes, connect load/device and meter to SIG and PWR (-) terminals. Turn override pot and measure

voltage. Do the readings match the no load test?

If no, check load impedance mismatch or a possible ground loop problem and/or call ACI Tech Support

at (888) 967-5224.

If yes, voltage output is functioning properly.

Current Out:

Conrm DIP Switch setting for “Current Out”(See (see Figure 3 (p. 4)). With meter only connected to the

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 7.0

I0000598

SIG and PWR(-) turn the manual pot full left and then full right. The output should vary from 0 to 100%

of the calibrated or jumper selected range. If not, measure the voltages and turn the Manual override

pot clockwise. Is voltage present? If no, contact ACI Tech Support at (888) 967-5224.

A voltage between 15-39 VDC indicates the AUD is attempting to generate the desired mA. Load or

meter may have an open, blown fuse or connected improperly. A 250 or 500 ohm resistor will also work

to test the output. Connect the resistor to the SIG and PWR(-) terminal. With 250 ohms on the output

the voltage from one side of the resistor to the other will be 1VDC @ 4mA and 5VDC @ 20mA. Using the

500 ohm will give 2 VDC @ 4mA and 10VDC @ 20mA. Does the unit function as stated above?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, current output is functioning properly.

4. Testing the input – To manually test the input.

Apply 24 VAC or 24 VDC to the PWR terminal. Connect your meter to the SIG and PWR(-) terminal. Set

meter to match output DIP switch settings. Place MAN/AUTO jumper to AUTO. Connect a jumper wire

from UP + to the PWR(+). Connect a jumper wire to the PWR(-) only. You are now ready to simulate an

input pulse signal.

For testing purposes, select the 15 second range (DIP switch 1 ON, DIP switch 2 OFF). Be sure to reset

power to allow the AUD to recognize new settings.

Take the free end of the jumper wire from “PWR”(-) and connect by holding wire to the “UP”(-) terminal.

Verify the pulse LED indication. Read output. Has the output changed? The output should be increasing

and stop when maximum span is reached.

Placing the wires on the DWN + and – terminals should decrease the output signal. If no, change the

TRC/NRM to the opposite setting and repeat test. Has the output changed?

If no, contact ACI Tech Support at (888) 967-5224.

If yes, unit is functioning properly.

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 7

Version: 7.0

I0000598

WARRANTY

The AUD Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS &

TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

24 VDC (24 VDC to 35 VDC) or 24 VAC (21.6 VAC to 28 VAC), 50/60 Hz.

208 mA maximum

Relay contact closure, transistor, or triac (24 VAC, 50/60 Hz)

Normal Mode: 5 to 26.4 VDC, 24 to 26.4 VAC | Triac Mode: 24 to 26.4 VAC

See page #3

0 to 1 VDC, 0 to 4 VDC, 0 to 10 VDC, 0 to 13 VDC, 1 to 2 VDC, 1 to 5 VDC, 1 to 11 VDC,

1 to 14 VDC

0 to 20 VDC (with adjustable oset and span)

3300 minimum at 20 VDC ± 10% , 400 ohms minimum at 10 VDC ± 10% (If the

voltage output is limited to 18 VDC on the high end of the output span, the DC supply

limit can be 24 VDC –10% and maintain stated accuracy

0 to 16 mA, 4 to 20 mA

0 to 20 mA (with adjustable oset and span)

0 to 750 maximum (If the load is lowered to 700, the DC supply can be 24 VDC –10%

and maintain stated accuracy

Absolute +/- 2% of span for adjustable ranges, 5% for preset

Absolute +/- 3% of span for adjustable ranges, 5% for preset

256 steps (all ranges)

24 VDC (+/- 10%), 48 mA maximum

90° Pluggable Screw Terminal Blocks

16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Signal Source:

Input Signal Trigger Level:

Input Full Range Rates of Change:

Output Voltage Fixed Signal

Ranges:

Output Voltage Adjustable Signal

Ranges:

Output Voltage Signal Load:

Output Current Fixed Signal Ranges:

Output Current Adjustable Signal

Ranges:

Output Current Signal Load:

Output Signal Accuracy (24 VAC, 60

Hz):

Output Signal Accuracy (24 VAC, 50

Hz):

Output Signal Resolution:

Regulated Power Output (User):

Connections:

Wire Size:

Terminal Block Torque Rating:

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

Page 8

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 7.0

I0000598

Table of contents

Other aci Media Converter manuals