aci ACCESS series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 6.0

I0000588

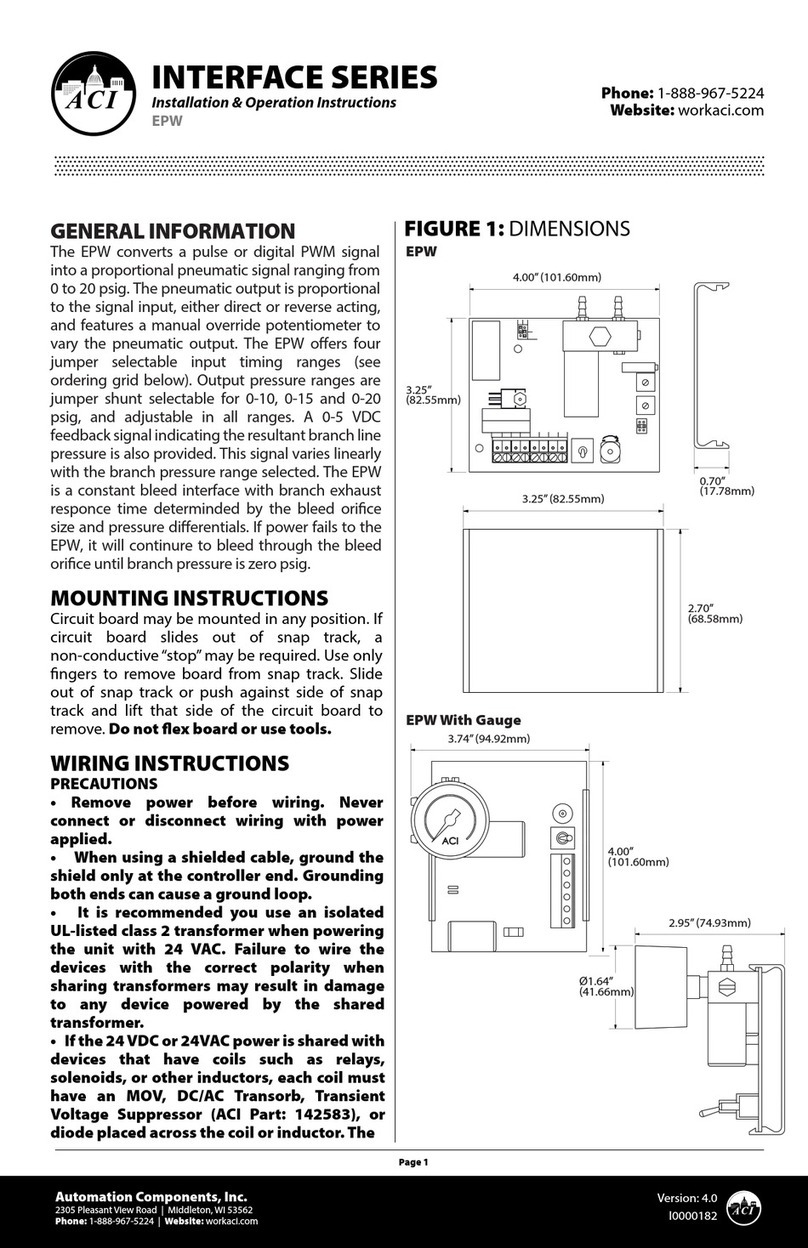

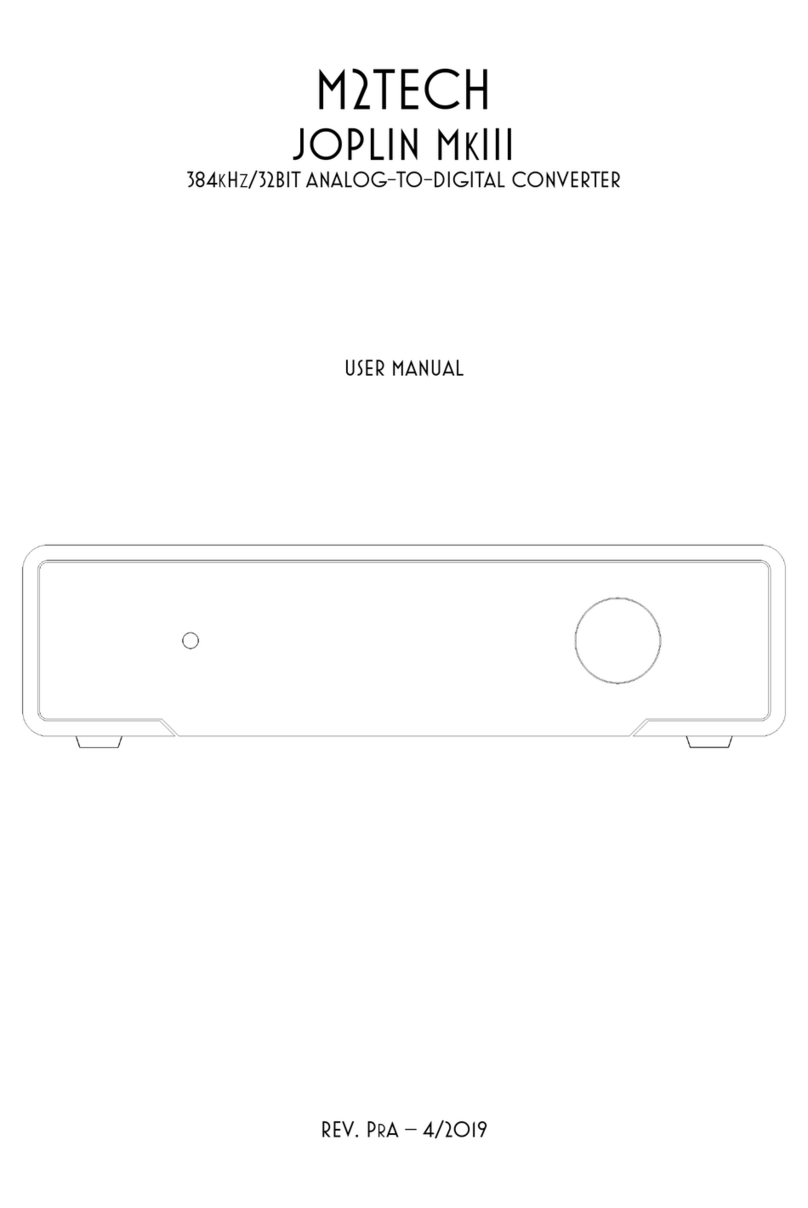

FIGURE 1: DIMENSIONS

INTERFACE SERIES

Installation & Operation Instructions

EFP2, EFP2FS

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The EFP2 converts a oating point signal into a

proportional pneumatic signal ranging from

0-20 psig. The pneumatic output is proportional

to the signal input. The EFP2 has a manual

override switch with terminal strip contacts to

indicate its status and a potentiometer to vary

the pneumatic output. Two LEDs indicate UP or

DOWN excursions, with an additional one for

power indication. The EFP2 oers four jumper

selectable rates of change in the output

pressure. Output pressure ranges are jumper

shunt selectable for 0 to 10, 0 to 15 and 0 to 20

psig, and adjustable in all ranges. A 0-5 VDC

feedback signal, indicating the resultant branch

line pressure, is also provided. This signal varies

linearly with the branch pressure range selected.

It is designed with electrical terminals on one

end and pneumatic connections on the other,

allowing for maximum convenience in wiring

and tubing installation when panel mounted.

The EFP2 incorporates two valves (one controls

exhaust) and does not bleed air at set point. Its

branch exhaust ow and response time are not

limited by an internal restrictor and are similar to its

load rate. If power fails to the EFP2, branch line

pressure remains constant if the branch line does

not leak air. The EFP2FS is a two valve fail safe model.

Its three-way branch exhaust valve allows exhaust of

branch line air on a power failure.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop”may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of theDC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

EFP2

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter. Periodically check the lter for contamination and ow reduction, and

clean with a brush or replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal: do NOT stress the circuit

board or allow the manifold to move. Hold the manifold in one hand while installing pneumatic tubing

onto the barbed ttings, and use care when removing tubing to avoid damaging ttings or moving

manifold.

1. Setting the input timing range: With power removed, place jumpers in the conguration that most

closely matches the timing range from the controller.

2. Setting the output pressure range: Apply power. Choose a pressure range on the EFP2/EFP2FS that

matches or is just above maximum range of device being controlled. Example: 8-13 psi choose B (15 psi

setting).

3. Setting the maximum pressure: With all pneumatic and power connections made, place the Manual

override switch in the “MAN” position. Turn the override pot full clockwise. Adjust the “SPAN” pot until

the desired maximum output is achieved.

4. Setting the oset: Conrm the green “DN” LED is blinking only, this indicates the output is at

minimum. Place the Manual override switch in the “AUTO” position. Turn the “OFFSET” pot until the

desired minimum pressure is achieved.

5. Calibration can also be made by sending the appropriate timing pulse and adjusting the“OFFSET”and

“SPAN”pots to the desired pressure output.

LED INDICATIONS

POWER LED: LED lit indicates power is received by the board.

UP and DOWN LED’s: Solid lit LED indicates the EFP2 is receiving an Up or Down command. Single

blinking LED indicates that the EFP is at the minimum or maximum of the timing range selected. Both

LED’s blinking indicates the EFP2/EFP2FS is at set-point.

Connect the normally open (NO) terminals of two separate relays, triac outputs, or the normally open

terminals of a tri-state relay to the “DN” and “UP” inputs. Connect the common terminal of the relay(s) to

terminal SC (signal common) on the EFP2 or EFP2FS. A

signal to both up and down inputs for 3 seconds will

cause branch line pressure to drop to 0 psi (see Table

1).

The branch exhaust response time is determined by

the combined exhaust air ow as well as pressure

dierentials. If power to the EFP2 is lost, it will contin-

ue to hold branch pressure if no branch line leaks. If

power to the EFP2FS is lost, the branch line will bleed

to 0 psi.

Manual override

Move the AUTO/MAN toggle switch to the MAN position. Turn the shaft on the MAN pot to vary the

pneumatic output. Return AUTO/MAN switch to AUTO position when nished.

Override Terminals (OV)

When manual override switch is in manual position, contact between terminals is closed. When manual

override switch is in auto position, contact between terminals is open.

For optimum performance and reduced

noise, the EFP2FS unit requires a branch

air line capacity equal to at least 25 feet of

1/4" O.D. polyethylene tubing to operate

without oscillation, and the EFP2 unit

requires a branch air line capacity equal

to at least 15 feet of 1/4" O.D.

polyethylene tubing to operate without

oscillation.

FIELD CALIBRATION

The default jumper setting from the

factory for the EFP2/EFP2FS is B (15 psi)

for the output range and A0, B0 for the

input timing range. There are four (4)

input timing ranges available per version

and three (3) selectable output pressure

ranges. NOTE: The ZERO potentiometer

is factory calibrated. Do not adjust.

[101.60mm]

4.00”

[68.58mm]

2.70”

[82.55mm]

3.25”

[92.71mm]

3.65”

[17.78mm]

.70”

[76.01mm]

2.99”

[17.78mm]

.70”

[76.01mm]

2.99”

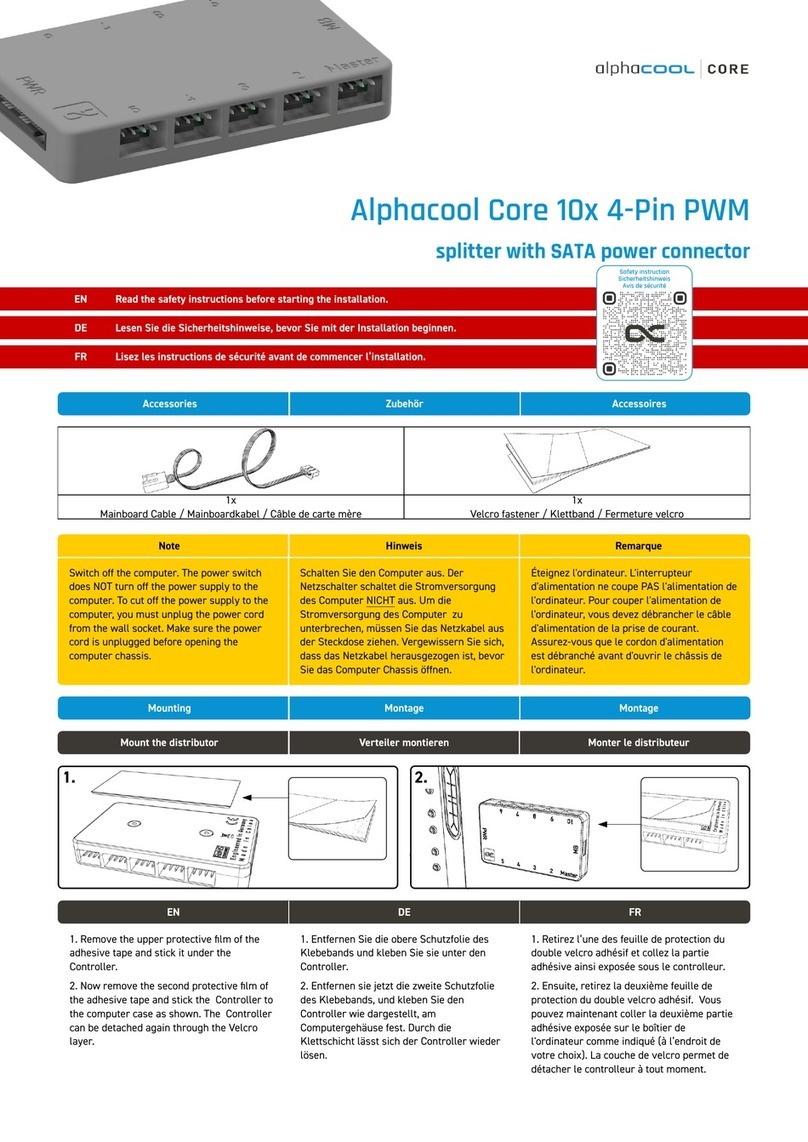

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 6.0

I0000588

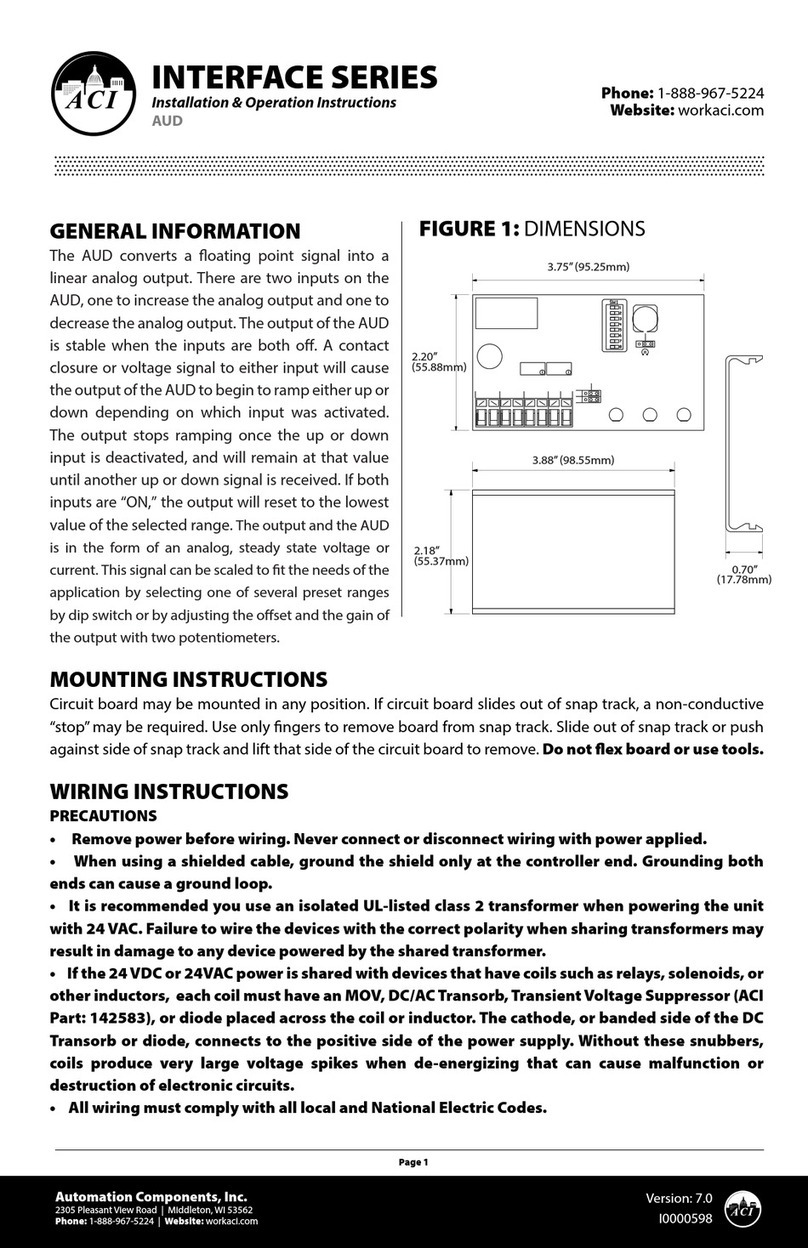

GENERAL INFORMATION

The EFP2 converts a oating point signal into a

proportional pneumatic signal ranging from

0-20 psig. The pneumatic output is proportional

to the signal input. The EFP2 has a manual

override switch with terminal strip contacts to

indicate its status and a potentiometer to vary

the pneumatic output. Two LEDs indicate UP or

DOWN excursions, with an additional one for

power indication. The EFP2 oers four jumper

selectable rates of change in the output

pressure. Output pressure ranges are jumper

shunt selectable for 0 to 10, 0 to 15 and 0 to 20

psig, and adjustable in all ranges. A 0-5 VDC

feedback signal, indicating the resultant branch

line pressure, is also provided. This signal varies

linearly with the branch pressure range selected.

It is designed with electrical terminals on one

end and pneumatic connections on the other,

allowing for maximum convenience in wiring

and tubing installation when panel mounted.

The EFP2 incorporates two valves (one controls

exhaust) and does not bleed air at set point. Its

branch exhaust ow and response time are not

limited by an internal restrictor and are similar to its

load rate. If power fails to the EFP2, branch line

pressure remains constant if the branch line does

not leak air. The EFP2FS is a two valve fail safe model.

Its three-way branch exhaust valve allows exhaust of

branch line air on a power failure.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop”may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of theDC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

MAN

AUTO

POWER

LED

Manual Override Potentiometer

Manual Override Switch

MAN

- +

PWR CSC DN UP FB OV OV

L3

Factory set - do not adjust

Branch Line Output

SPAN Potentiometer

Set for maximum

desired pressure with

maximum input signal

Offset Potentiometer

Set for minimum desired

pressure with minimum

input signal

OFFSET

SPAN

ZERO

A B J1

0

1

Set Timing Range

Main Air Supply

UP

Down

(LED)

(LED)

(+)

Power

24 VDC/VAC

(-)

Signal Common (-)

Down

Up

Override Feedback (Dry Contact)

(+)

Branch Pressure

Feedback Signal

(-)

A

B

C

J2

Output pressure range

selector factory set 0-15

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter. Periodically check the lter for contamination and ow reduction, and

clean with a brush or replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal: do NOT stress the circuit

board or allow the manifold to move. Hold the manifold in one hand while installing pneumatic tubing

onto the barbed ttings, and use care when removing tubing to avoid damaging ttings or moving

manifold.

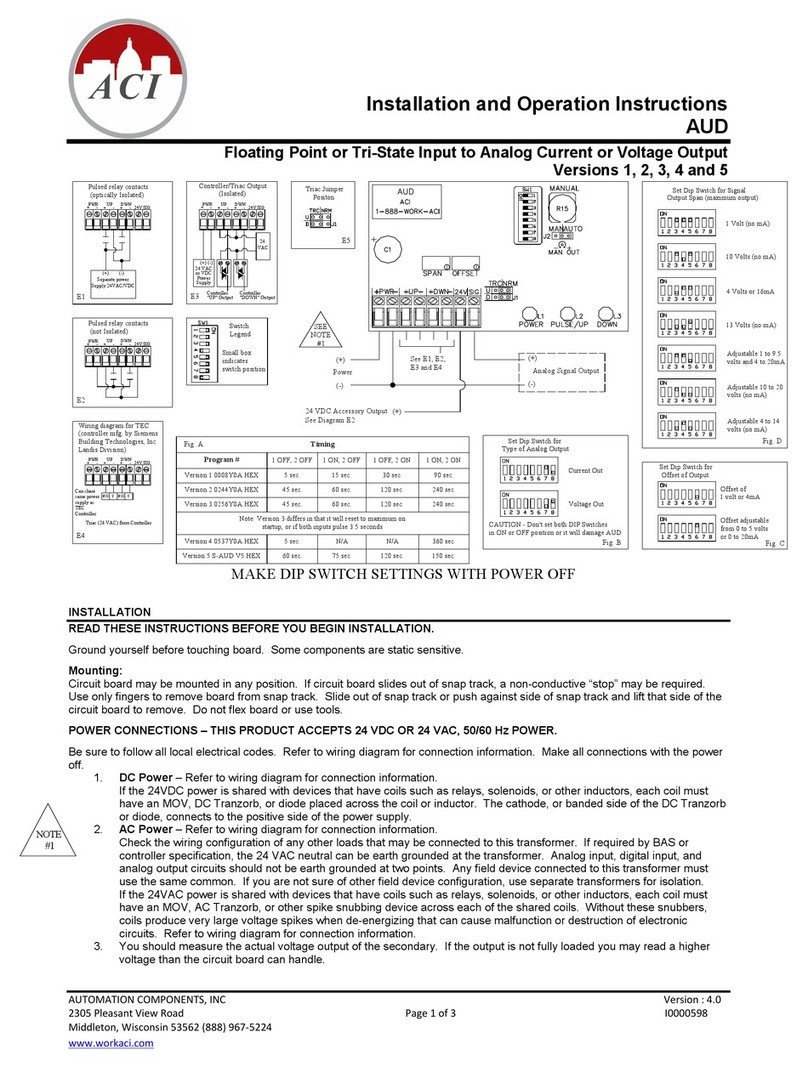

Pulsed relay contacts

(optically isolated)

PWR CSC DN UP FB

24 VAC

Power

Supply

or VDC

(+) (-)

24 VAC

Power

Supply

or VDC

(+) (-)

Pulsed relay contacts

(not isolated)

PWR CSC DN UP FB

24 VAC

Power

Supply

or VDC

(+) (-)

PWR CSC DN UP FB

24 VAC

Power

Supply

or VDC

(+) (-)

Controller / Triac Output

(isolated)

Controller

Down Output

Controller

Up Output

24 VAC

Power

Supply

PWR CSC DN UP FB

Controller / Triac Output

(not isolated)

Controller

Down Output

Controller

Up Output

24 VAC

Power

Supply

1. Setting the input timing range: With power removed, place jumpers in the conguration that most

closely matches the timing range from the controller.

2. Setting the output pressure range: Apply power. Choose a pressure range on the EFP2/EFP2FS that

matches or is just above maximum range of device being controlled. Example: 8-13 psi choose B (15 psi

setting).

3. Setting the maximum pressure: With all pneumatic and power connections made, place the Manual

override switch in the “MAN” position. Turn the override pot full clockwise. Adjust the “SPAN” pot until

the desired maximum output is achieved.

4. Setting the oset: Conrm the green “DN” LED is blinking only, this indicates the output is at

minimum. Place the Manual override switch in the “AUTO” position. Turn the “OFFSET” pot until the

desired minimum pressure is achieved.

5. Calibration can also be made by sending the appropriate timing pulse and adjusting the“OFFSET”and

“SPAN”pots to the desired pressure output.

LED INDICATIONS

POWER LED: LED lit indicates power is received by the board.

UP and DOWN LED’s: Solid lit LED indicates the EFP2 is receiving an Up or Down command. Single

blinking LED indicates that the EFP is at the minimum or maximum of the timing range selected. Both

LED’s blinking indicates the EFP2/EFP2FS is at set-point.

Connect the normally open (NO) terminals of two separate relays, triac outputs, or the normally open

terminals of a tri-state relay to the “DN” and “UP” inputs. Connect the common terminal of the relay(s) to

terminal SC (signal common) on the EFP2 or EFP2FS. A

signal to both up and down inputs for 3 seconds will

cause branch line pressure to drop to 0 psi (see Table

1).

The branch exhaust response time is determined by

the combined exhaust air ow as well as pressure

dierentials. If power to the EFP2 is lost, it will contin-

ue to hold branch pressure if no branch line leaks. If

power to the EFP2FS is lost, the branch line will bleed

to 0 psi.

Manual override

Move the AUTO/MAN toggle switch to the MAN position. Turn the shaft on the MAN pot to vary the

pneumatic output. Return AUTO/MAN switch to AUTO position when nished.

Override Terminals (OV)

When manual override switch is in manual position, contact between terminals is closed. When manual

override switch is in auto position, contact between terminals is open.

For optimum performance and reduced

noise, the EFP2FS unit requires a branch

air line capacity equal to at least 25 feet of

1/4" O.D. polyethylene tubing to operate

without oscillation, and the EFP2 unit

requires a branch air line capacity equal

to at least 15 feet of 1/4" O.D.

polyethylene tubing to operate without

oscillation.

FIELD CALIBRATION

The default jumper setting from the

factory for the EFP2/EFP2FS is B (15 psi)

for the output range and A0, B0 for the

input timing range. There are four (4)

input timing ranges available per version

and three (3) selectable output pressure

ranges. NOTE: The ZERO potentiometer

is factory calibrated. Do not adjust.

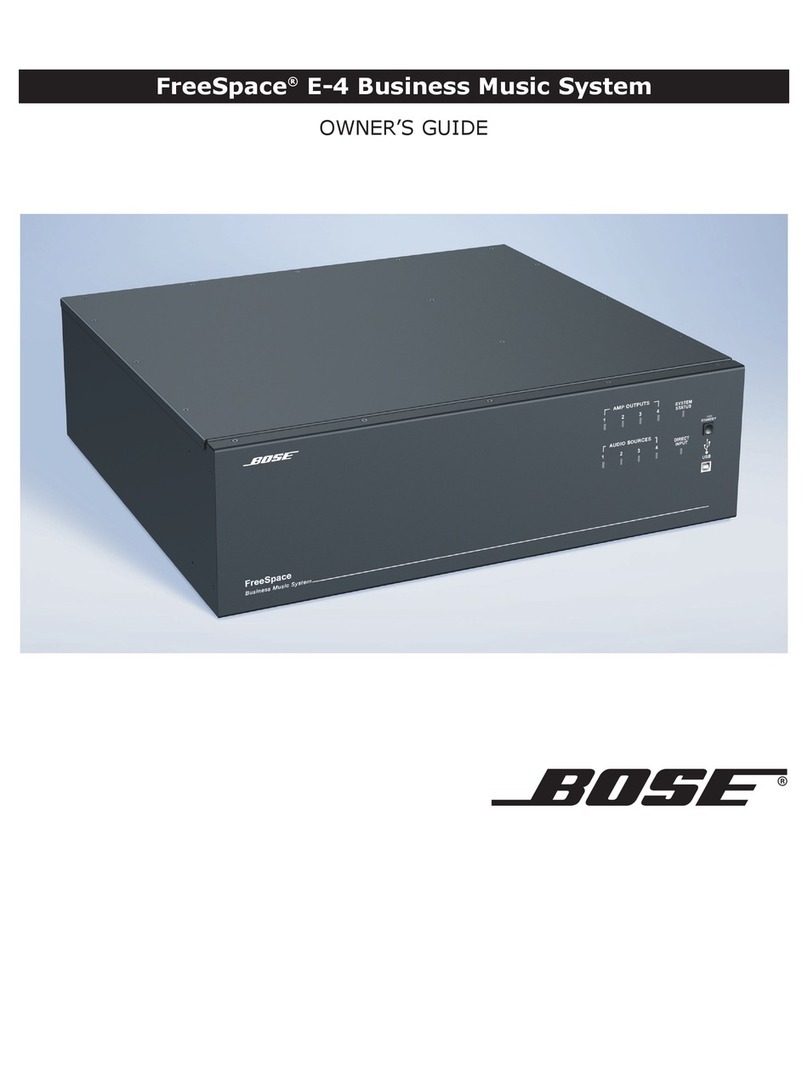

FIGURE 3: JUMPER SETTINGS

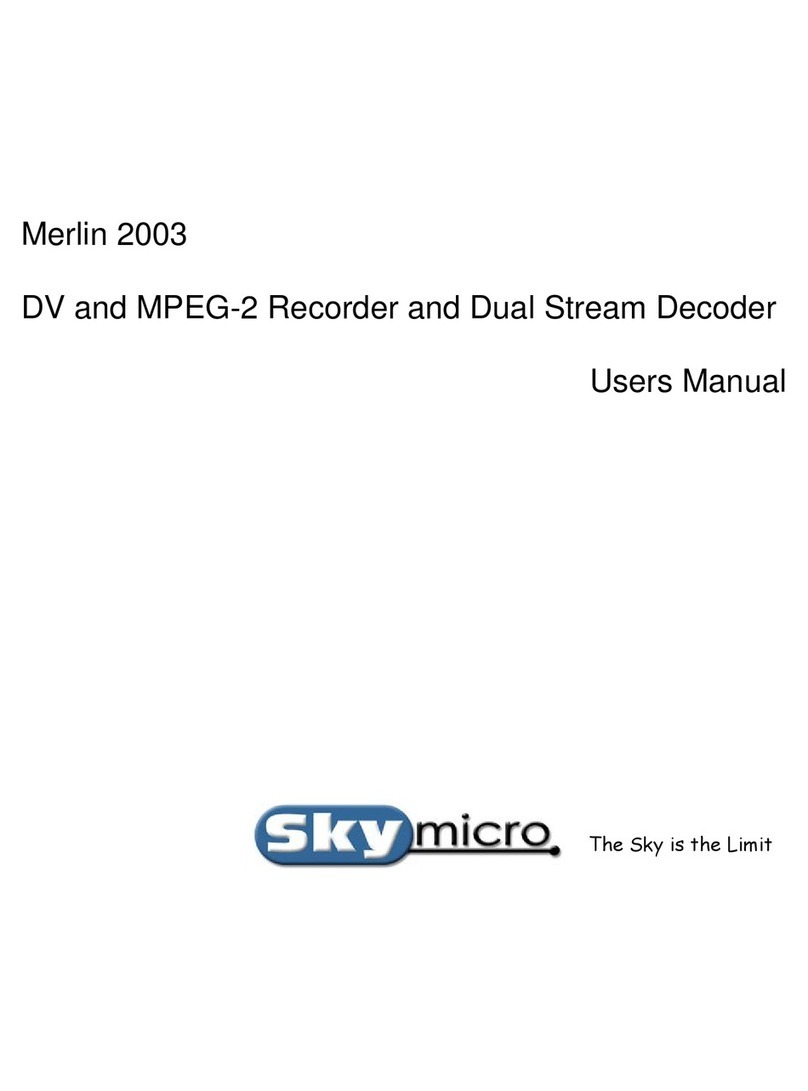

FIGURE 4: PNEUMATIC TUBING

INSTALLATION

GENERAL INFORMATION

The EFP2 converts a oating point signal into a

proportional pneumatic signal ranging from

0-20 psig. The pneumatic output is proportional

to the signal input. The EFP2 has a manual

override switch with terminal strip contacts to

indicate its status and a potentiometer to vary

the pneumatic output. Two LEDs indicate UP or

DOWN excursions, with an additional one for

power indication. The EFP2 oers four jumper

selectable rates of change in the output

pressure. Output pressure ranges are jumper

shunt selectable for 0 to 10, 0 to 15 and 0 to 20

psig, and adjustable in all ranges. A 0-5 VDC

feedback signal, indicating the resultant branch

line pressure, is also provided. This signal varies

linearly with the branch pressure range selected.

It is designed with electrical terminals on one

end and pneumatic connections on the other,

allowing for maximum convenience in wiring

and tubing installation when panel mounted.

The EFP2 incorporates two valves (one controls

exhaust) and does not bleed air at set point. Its

branch exhaust ow and response time are not

limited by an internal restrictor and are similar to its

load rate. If power fails to the EFP2, branch line

pressure remains constant if the branch line does

not leak air. The EFP2FS is a two valve fail safe model.

Its three-way branch exhaust valve allows exhaust of

branch line air on a power failure.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop”may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 6.0

I0000588

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of theDC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter. Periodically check the lter for contamination and ow reduction, and

clean with a brush or replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal: do NOT stress the circuit

board or allow the manifold to move. Hold the manifold in one hand while installing pneumatic tubing

onto the barbed ttings, and use care when removing tubing to avoid damaging ttings or moving

manifold.

A B J1

0

1

30 Seconds

3 Minutes

6 Minutes

8 Minutes

Version #2

0206Y0B.HEX

45 Seconds

60 Seconds

90 Seconds

120 Seconds

Version #1

0186Y1A.HEX

0 to 15 psig

(Factory Setting)

0 to 10 psig

0 to 20 psig

A

B

C

J2

A

B

C

J2

A

B

C

J2

1. Setting the input timing range: With power removed, place jumpers in the conguration that most

closely matches the timing range from the controller.

2. Setting the output pressure range: Apply power. Choose a pressure range on the EFP2/EFP2FS that

matches or is just above maximum range of device being controlled. Example: 8-13 psi choose B (15 psi

setting).

3. Setting the maximum pressure: With all pneumatic and power connections made, place the Manual

override switch in the “MAN” position. Turn the override pot full clockwise. Adjust the “SPAN” pot until

the desired maximum output is achieved.

4. Setting the oset: Conrm the green “DN” LED is blinking only, this indicates the output is at

minimum. Place the Manual override switch in the “AUTO” position. Turn the “OFFSET” pot until the

desired minimum pressure is achieved.

5. Calibration can also be made by sending the appropriate timing pulse and adjusting the“OFFSET”and

“SPAN”pots to the desired pressure output.

LED INDICATIONS

POWER LED: LED lit indicates power is received by the board.

UP and DOWN LED’s: Solid lit LED indicates the EFP2 is receiving an Up or Down command. Single

blinking LED indicates that the EFP is at the minimum or maximum of the timing range selected. Both

LED’s blinking indicates the EFP2/EFP2FS is at set-point.

Connect the normally open (NO) terminals of two separate relays, triac outputs, or the normally open

terminals of a tri-state relay to the “DN” and “UP” inputs. Connect the common terminal of the relay(s) to

terminal SC (signal common) on the EFP2 or EFP2FS. A

signal to both up and down inputs for 3 seconds will

cause branch line pressure to drop to 0 psi (see Table

1).

The branch exhaust response time is determined by

the combined exhaust air ow as well as pressure

dierentials. If power to the EFP2 is lost, it will contin-

ue to hold branch pressure if no branch line leaks. If

power to the EFP2FS is lost, the branch line will bleed

to 0 psi.

Manual override

Move the AUTO/MAN toggle switch to the MAN position. Turn the shaft on the MAN pot to vary the

pneumatic output. Return AUTO/MAN switch to AUTO position when nished.

Override Terminals (OV)

When manual override switch is in manual position, contact between terminals is closed. When manual

override switch is in auto position, contact between terminals is open.

Min. Tubing Length:

EFP2: 15 ft [4.752 m]

EFP2FS: 25 ft [7.62 m]

Air Compressor

For optimum performance and reduced

noise, the EFP2FS unit requires a branch

air line capacity equal to at least 25 feet of

1/4" O.D. polyethylene tubing to operate

without oscillation, and the EFP2 unit

requires a branch air line capacity equal

to at least 15 feet of 1/4" O.D.

polyethylene tubing to operate without

oscillation.

FIELD CALIBRATION

The default jumper setting from the

factory for the EFP2/EFP2FS is B (15 psi)

for the output range and A0, B0 for the

input timing range. There are four (4)

input timing ranges available per version

and three (3) selectable output pressure

ranges. NOTE: The ZERO potentiometer

is factory calibrated. Do not adjust.

Table 1: LED INDICATIONS

GENERAL INFORMATION

The EFP2 converts a oating point signal into a

proportional pneumatic signal ranging from

0-20 psig. The pneumatic output is proportional

to the signal input. The EFP2 has a manual

override switch with terminal strip contacts to

indicate its status and a potentiometer to vary

the pneumatic output. Two LEDs indicate UP or

DOWN excursions, with an additional one for

power indication. The EFP2 oers four jumper

selectable rates of change in the output

pressure. Output pressure ranges are jumper

shunt selectable for 0 to 10, 0 to 15 and 0 to 20

psig, and adjustable in all ranges. A 0-5 VDC

feedback signal, indicating the resultant branch

line pressure, is also provided. This signal varies

linearly with the branch pressure range selected.

It is designed with electrical terminals on one

end and pneumatic connections on the other,

allowing for maximum convenience in wiring

and tubing installation when panel mounted.

The EFP2 incorporates two valves (one controls

exhaust) and does not bleed air at set point. Its

branch exhaust ow and response time are not

limited by an internal restrictor and are similar to its

load rate. If power fails to the EFP2, branch line

pressure remains constant if the branch line does

not leak air. The EFP2FS is a two valve fail safe model.

Its three-way branch exhaust valve allows exhaust of

branch line air on a power failure.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop”may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WARRANTY

The EFP Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS &

TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 6.0

I0000588

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of theDC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter. Periodically check the lter for contamination and ow reduction, and

clean with a brush or replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal: do NOT stress the circuit

board or allow the manifold to move. Hold the manifold in one hand while installing pneumatic tubing

onto the barbed ttings, and use care when removing tubing to avoid damaging ttings or moving

manifold.

UP LED DOWN LED INDICATION

On Off Ramping Up

Off On Ramping Down

Fast Blink Off Maximum Output

Off Fast Blink Minimum Output

Slow Blink Slow Blink Output Holding

1. Setting the input timing range: With power removed, place jumpers in the conguration that most

closely matches the timing range from the controller.

2. Setting the output pressure range: Apply power. Choose a pressure range on the EFP2/EFP2FS that

matches or is just above maximum range of device being controlled. Example: 8-13 psi choose B (15 psi

setting).

3. Setting the maximum pressure: With all pneumatic and power connections made, place the Manual

override switch in the “MAN” position. Turn the override pot full clockwise. Adjust the “SPAN” pot until

the desired maximum output is achieved.

4. Setting the oset: Conrm the green “DN” LED is blinking only, this indicates the output is at

minimum. Place the Manual override switch in the “AUTO” position. Turn the “OFFSET” pot until the

desired minimum pressure is achieved.

5. Calibration can also be made by sending the appropriate timing pulse and adjusting the“OFFSET”and

“SPAN”pots to the desired pressure output.

LED INDICATIONS

POWER LED: LED lit indicates power is received by the board.

UP and DOWN LED’s: Solid lit LED indicates the EFP2 is receiving an Up or Down command. Single

blinking LED indicates that the EFP is at the minimum or maximum of the timing range selected. Both

LED’s blinking indicates the EFP2/EFP2FS is at set-point.

Connect the normally open (NO) terminals of two separate relays, triac outputs, or the normally open

terminals of a tri-state relay to the “DN” and “UP” inputs. Connect the common terminal of the relay(s) to

terminal SC (signal common) on the EFP2 or EFP2FS. A

signal to both up and down inputs for 3 seconds will

cause branch line pressure to drop to 0 psi (see Table

1).

The branch exhaust response time is determined by

the combined exhaust air ow as well as pressure

dierentials. If power to the EFP2 is lost, it will contin-

ue to hold branch pressure if no branch line leaks. If

power to the EFP2FS is lost, the branch line will bleed

to 0 psi.

Manual override

Move the AUTO/MAN toggle switch to the MAN position. Turn the shaft on the MAN pot to vary the

pneumatic output. Return AUTO/MAN switch to AUTO position when nished.

Override Terminals (OV)

When manual override switch is in manual position, contact between terminals is closed. When manual

override switch is in auto position, contact between terminals is open.

For optimum performance and reduced

noise, the EFP2FS unit requires a branch

air line capacity equal to at least 25 feet of

1/4" O.D. polyethylene tubing to operate

without oscillation, and the EFP2 unit

requires a branch air line capacity equal

to at least 15 feet of 1/4" O.D.

polyethylene tubing to operate without

oscillation.

FIELD CALIBRATION

The default jumper setting from the

factory for the EFP2/EFP2FS is B (15 psi)

for the output range and A0, B0 for the

input timing range. There are four (4)

input timing ranges available per version

and three (3) selectable output pressure

ranges. NOTE: The ZERO potentiometer

is factory calibrated. Do not adjust.

PRODUCT SPECIFICATIONS

24 VAC (+/-10%), 50 or 60Hz, 24 VDC (+10%/- 5%)

50 mA, 150 mA (3.6 VA) on pressure excursions, 180 mA (4.3 VA) on pressure

excursions (FS model)

Relay Contact Closure, Transistor or Triac

9-24 VAC/VDC @ 750

EFP2: 45s, 90s, 1 min, 2 min | EFP2 Version 2: 30s, 3min, 6 min, 8 min

MAN function = output can be varied | AUTO function = output is controlled

from input signal

24 VDC/VAC @ 1A maximum, N.O. in AUTO operation (Optional: N.O. in MAN

operation)

0-5 VDC = Output Span

Maximum 28 psig (193.06 kPa), minimum 22 psig (151.69 kPa)

750 SCIM (12.29 liters)

0-10 psig (0-68.95 kPa), 0-15 psig (0-103.43 kPa) or 0-20 psig (137.9 kPa)

2% full scale at room temperature (above 1 psig or 6.895 kPa)

3% full scale across operating temperature range (above 1 psig)

Supply valves @ 20 psig (138 kPa) main/15 psig (103 kPa) out, 750 scim.

Branch Line requires 2 in or 33.78 cm (minimum) | Min. 25 ft of 1/4” O.D. poly

branch tubing

Furnished with integral-in-barb 80-100 micron lter (Part # PN004)

Optional standard barb (PN002) with external 5 micron in-line lter (PN021)

90° Pluggable Screw Terminal Blocks | 16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

1/4" O.D. nominal (1/8” I.D.) polyethylene

Removeable brass ttings for Main & Branch in machined manifold, Plugged

1/8-27-FNPT gauge port

0-30 psig (0-200 kPa)

± 2.5% Midscale (± 3.5% Full Scale)

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Digital Input Signal Source:

Digital Input Signal Level (@

Impedance):

Digital Input Rates of Change:

Manual / Auto Override Switch:

Manual / Auto Override

Feedback Output:

Feedback Output Signal Range:

Air Supply Pressure:

Air Supply Consumption:

Output Pressure Range

(Jumper Selectable):

Output Pressure Accuracy:

Air Flow:

Filtering:

Connections | Wire Size:

Terminal Block Torque Rating:

Connections | Pneumatic

Tubing Size-Type:

Pneumatic Fitting:

Gauge Pressure Range (Gauge

Models):

Gauge Pressure Accuracy

(Gauge Models):

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 6.0

I0000588

NOTES

Page 6

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 6.0

I0000588

NOTES

Page 7

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 6.0

I0000588

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

Page 8

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 6.0

I0000588

Other manuals for ACCESS series

16

This manual suits for next models

2

Table of contents

Other aci Media Converter manuals

Popular Media Converter manuals by other brands

PS Audio

PS Audio PerfectWave Transport Instructions for use

Cabletron Systems

Cabletron Systems MCC-16 user guide

StarTech.com

StarTech.com ET90110SC Spec sheet

almando

almando Multiplay Surround Decoder Installation and operating instructions

Sinovision

Sinovision HDCRGB102 user manual

Anda Telecom

Anda Telecom FE1/V.35 user manual