aci A/MCS-A Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 6.0

I0000558

PRECAUTIONS

• This product is not intended to be used for

Life or Safety applications.

• This product is not intended for use in any

hazardous or classied locations.

HIGH VOLTAGE

• Disconnect and lock out all power sources

before installation as severe injury or death

may result from electrical shock due to

contact with high voltage wires.

GENERAL INFORMATION

The Miniature Adjustable Current switches are

designed for use in any AC current monitoring

application in which you are looking for an adjustable

current switch to monitor normal operating conditions,

equipment failure or preventative maintenance

scheduling for a particular piece of equipment. The

adjustable current switches should be installed on the

line side of the power to the motor, pump, compressor

or other equipment. The adjustable current status

switches can also be used to determine the run time of

your equipment where you want to know when your

piece of equipment runs and for how long it runs when

logging the contact closures on your building

management system or PLC.

MOUNTING INSTRUCTIONS

Make sure that all installations are in compliance with

all national and local electrical codes. Only qualied

individuals that are familiar with codes, standards,

and proper safety procedures for high-voltage

installations should attempt installation. The current switches will not require external power, since the power

for the current switch is induced from the conductor being monitored.

The A/MCS-A and A/MSCS-A Current Switches should be used on Insulated Conductors Only! The current

switch may be mounted in any position using the (2) #8 x 3/4”Tek screws and the mounting holes in the base

(see Figure 2 (p.2)). Leave a minimum distance of 1”(3 cm) between the current switch and any other magnetic

devices such as contactors and transformers.

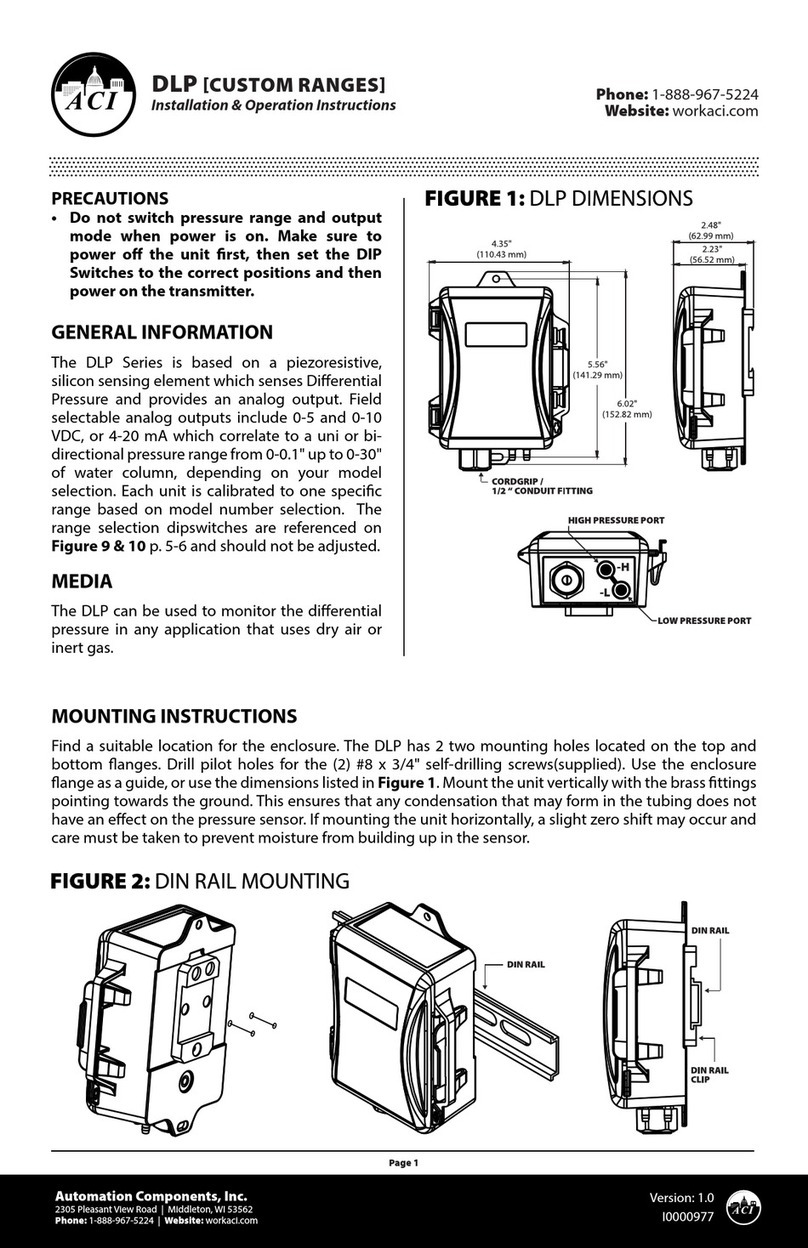

FIGURE 1: DIMENSIONS

MINI ADJUSTABLE STATUS

SWITCH SERIES

Installation & Operation Instructions

A/MCS-A, A/MSCS-A

Phone: 1-888-967-5224

Website: workaci.com

WIRING INSTRUCTIONS

ACI recommends the use of a two conductor 16 to 22 AWG shielded cable or twisted pair copper wire only

for all current switch applications. A maximum wire length of less than 30 meters (98.4 feet) should be

used between the A/MCS-A and A/MSCS-A current switches and the Building Management System or

controller.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller.

Connecting both ends of the shield to ground may cause a ground loop. When removing the shield from

the sensor end, make sure to properly trim the shield so as to prevent any chance of shorting. The current

switch output terminals represent a solid-state switch for controlling both AC and DC loads and is not

polarity sensitive. The recommended torque to be used on the terminal block connections is 0.67 Nm or

5.93 in-lbs. The aperture (hole) size of the current switch is 0.53” (1.35 cm) and will accept a 1 AWG

maximum wire diameter.

For applications in which the normal operating current is below the 0.20 Amps (A/MCS-A) or 0.55 Amps

(A/MSCS-A) trip point (See Figure 3 below), the conductor being monitored may be looped through the

sensor 4 times giving you a total operating current of 4X the original current.

Example: A small fan operating at 0.2A should be wrapped through the sensor 4 times to give you a total

operating current of 0.8Amps owing through the A/MCS-A or A/MSCS-A.

Solid-Core

Split-Core

2.51” (63.82mm)

1.99”

(50.48mm)

0.99”

(25.06mm)

2.00” (50.80mm)

1.82” (46.14mm)

2.38”

(60.49mm)

2.65” (67.19mm)

0.99”

(25.06mm)

2.15” (54.49mm)

#8 x 3/4" Tek Screw

(Qty. 2/Unit)

PRECAUTIONS

• This product is not intended to be used for

Life or Safety applications.

• This product is not intended for use in any

hazardous or classied locations.

HIGH VOLTAGE

• Disconnect and lock out all power sources

before installation as severe injury or death

may result from electrical shock due to

contact with high voltage wires.

GENERAL INFORMATION

The Miniature Adjustable Current switches are

designed for use in any AC current monitoring

application in which you are looking for an adjustable

current switch to monitor normal operating conditions,

equipment failure or preventative maintenance

scheduling for a particular piece of equipment. The

adjustable current switches should be installed on the

line side of the power to the motor, pump, compressor

or other equipment. The adjustable current status

switches can also be used to determine the run time of

your equipment where you want to know when your

piece of equipment runs and for how long it runs when

logging the contact closures on your building

management system or PLC.

MOUNTING INSTRUCTIONS

Make sure that all installations are in compliance with

all national and local electrical codes. Only qualied

individuals that are familiar with codes, standards,

and proper safety procedures for high-voltage

installations should attempt installation. The current switches will not require external power, since the power

for the current switch is induced from the conductor being monitored.

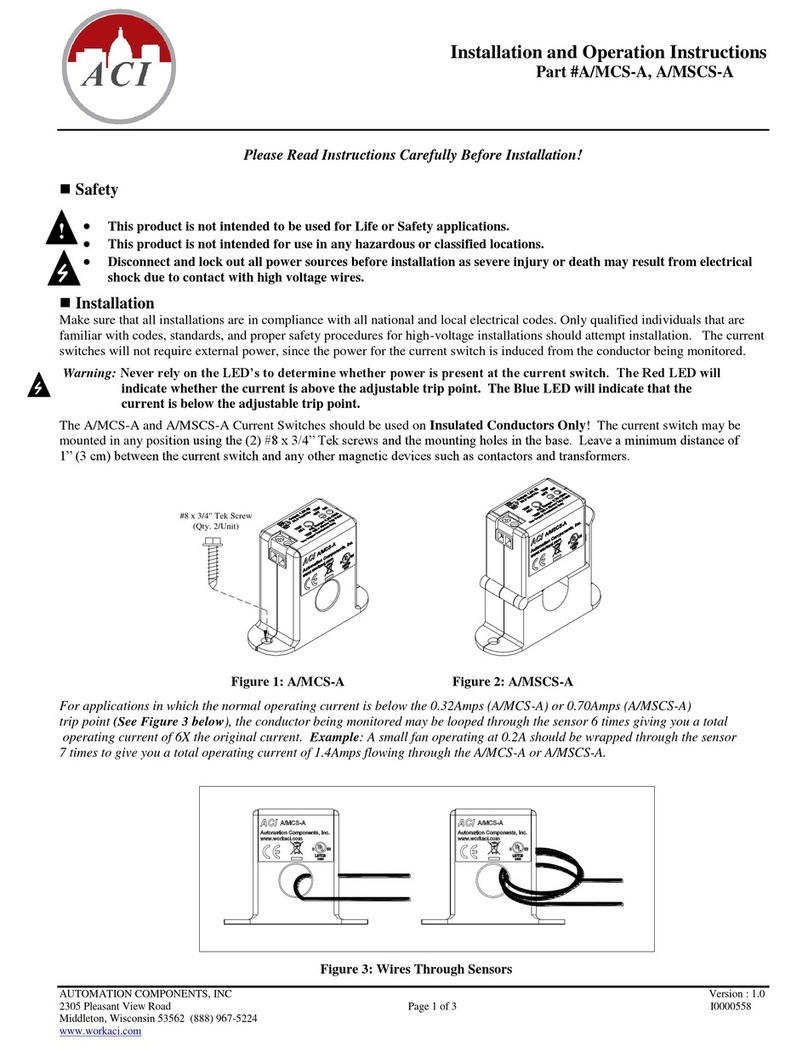

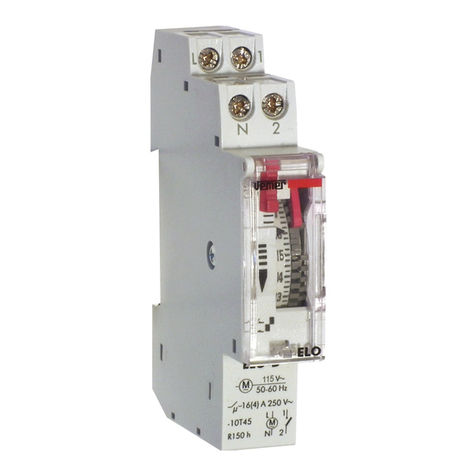

The A/MCS-A and A/MSCS-A Current Switches should be used on Insulated Conductors Only! The current

switch may be mounted in any position using the (2) #8 x 3/4”Tek screws and the mounting holes in the base

(see Figure 2 (p.2)). Leave a minimum distance of 1”(3 cm) between the current switch and any other magnetic

devices such as contactors and transformers.

FIGURE 2: MOUNTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 6.0

I0000558

WIRING INSTRUCTIONS

ACI recommends the use of a two conductor 16 to 22 AWG shielded cable or twisted pair copper wire only

for all current switch applications. A maximum wire length of less than 30 meters (98.4 feet) should be

used between the A/MCS-A and A/MSCS-A current switches and the Building Management System or

controller.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller.

Connecting both ends of the shield to ground may cause a ground loop. When removing the shield from

the sensor end, make sure to properly trim the shield so as to prevent any chance of shorting. The current

switch output terminals represent a solid-state switch for controlling both AC and DC loads and is not

polarity sensitive. The recommended torque to be used on the terminal block connections is 0.67 Nm or

5.93 in-lbs. The aperture (hole) size of the current switch is 0.53” (1.35 cm) and will accept a 1 AWG

maximum wire diameter.

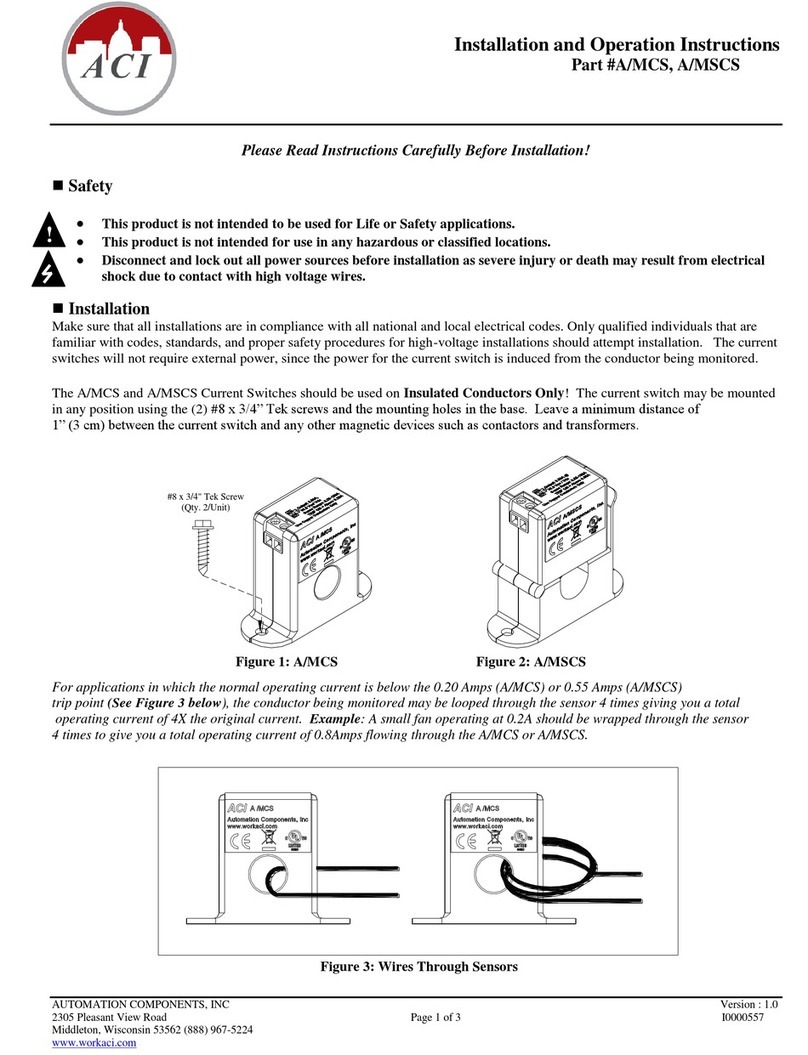

For applications in which the normal operating current is below the 0.20 Amps (A/MCS-A) or 0.55 Amps

(A/MSCS-A) trip point (See Figure 3 below), the conductor being monitored may be looped through the

sensor 4 times giving you a total operating current of 4X the original current.

Example: A small fan operating at 0.2A should be wrapped through the sensor 4 times to give you a total

operating current of 0.8Amps owing through the A/MCS-A or A/MSCS-A.

FIGURE 3: WIRES THROUGH SENSORS

ONE LOOP FOUR LOOPS

FIGURE 4: CURRENT TRANSFORMER FIGURE 5: DIGITAL CIRCUIT

FIGURE 6: MOTOR/FAN CONTROL

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 6.0

I0000558

Insulated

Nut

Conductor

600:5 Ratio 5A C.T.

Wire

For applications in which the normal operating current is greater than 150 Amps or for conductor diame-

ters larger than 0.530” (1.35 cm) in diameter, an external 5 Amp Current Transformer must be used as

shown in Figure 4 below.

Remember that the secondary of the 5A CT must be shorted together before the power may be

turned onto the monitored device.

Example: For currents up to 600 Amps (and not below 70 Amps (A/MCS-A) or 95 Amps (A/MSCS-A), where

Current Transformer (C.T.) secondary falls below 1 Amp use a 600:5 ratio C.T. as shown in Figure 4.

RELAY

MOTOR

EXHAUST FAN

ACI SPLIT-CORE SWITCH

NEUTRAL

120 VOLT HOT

120 VOLT HOT

NEUTRAL

24 VAC HOT

NEUTRAL

MOTOR

RANGE HOOD FAN

APPLICATION EXAMPLES

See Figure 5 (p.3) and Figure 6 (p.3) for two dierent current switch applications. Figure 5 (p.3) is showing

the use of the Mini Go/No Go Current Switch as a Digital Input to your BAS/PLC Controller. Figure 6 (p.3)

shows a Mini Go/No/Go Current Switch in conjunction with a Contactor to control an exhaust fan.

Note: The ACI Mini Adjustable Go/No Go Current switches(MCS-A & MSCS-A Series) are only rated at 1.0A

Continuous @ 36 VAC/VDC. These switches must use an additional Contactor if controlling motor/fans.

Building Management

Digital Input #1

System

WARRANTY

The ACI Current Switch Series are covered by ACI’s Five (5) Year Limited Warranty, which is located in the front of

ACI’S SENSORS &TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

CALIBRATION OF ADJUSTABLE TRIP POINT

The adjustable current switch has an operating range of 0-150 Amps. Do not exceed! The adjustable current

switch comes with its fteen-turn adjustment potentiometer set to the 100 Amp trip point position. The

adjustable current switch can be used to monitor Under Load, Normal Load, and Over Load conditions,

depending on how it’s set. The procedure below is for the Normal load condition for part numbers A/MCS-A &

A/MSCS-A.

NORMAL LOADS

With current owing through the aperture of the A/MCS-A and A/MSCS-A current switches, rst verify that

the Blue LED is on. If the Blue LED is on, now slowly adjust the potentiometer clockwise until the Red LED

just turns on and stop immediately. This will set the trip point at your normal operating load current.

If the RED LED is on after initial power up, this means that you will need to slowly adjust the potentiometer

counter-clockwise until the Blue LED turns on and then slowly adjust the potentiometer clockwise until the

Red LED just turns on and stop immediately. The adjustable current switch is now tripped. Now verify the

output with an Ohmmeter to verify that the contacts of the switch are approximately 0.200 Ohms. The

adjustable current switch Hysteresis (Dead Band) is typically 10% of the trip point.

Clockwise = Decrease Trip Point

Counter-clockwise = Increase Trip Point

TROUBLESHOOTING

PROBLEM

Current switch didn’t activate (Test #1)

Current switch didn’t activate (Test #2)

SOLUTION(S)

Disconnect the wires from the current switch output. Measure the resistance

across the contacts with an Ohmmeter. See Standard Ordering Table (p.5) for

the actual resistance readings for an open or closed switch reading.

Verify that the current owing in the conductor being monitored is above

the xed trip point as listed in the operating specications. If the sensor is

monitoring less than the xed trip point, see Figure 3.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 6.0

I0000558

ACI Model #

Resistance if switch open

Resistance if switch closed

A/MCS-A

Greater than 1 Meg ohms

Approximately 0.2 ohms

A/MSCS-A

Greater than 1 Meg ohms

Approximately 0.2 ohms

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 6.0

I0000558

PRODUCT SPECIFICATIONS

AC Current

600 VAC

50/60 kHz

Solid-Core and Split-Core Versions available (See Ordering Grid)

Induced from the Monitored Conductor (Insulated Conductors only)

See Ordering Grid

2200 VAC

Adjustable Trip Point | See Ordering Grid

10% Trip Point, typical

Normally-Open “N/O”

1A Continuous @ 36 VAC/VDC

< 0.5 Ohms (tripped) | > 1 Meg Ohms (Open)

A/MCS-A:

< 90 mS typical |

A/MSCS-A:

< 45 mS typical

Red LED (Current above trip point) | Blue LED (Current below trip point)

0.53” (13.46 mm)

-22 to 140ºF (-30 to 60ºC)

0 to 95%, non-condensing

2 Position Screw Terminal Block (Not Polarity Sensitive)

16 to 22 AWG (1.31 mm to 0.33 mm) Copper Wires only

4.43 to 5.31 in-lbs. (0.5 to 0.6 Nm)

1” (2.6 cm) between current switch (Relays, Contactors, Transformers)

SENSOR NON-SPECIFIC INFORMATION

Monitored Current Type:

Maximum AC Voltage:

Operating Frequency Range:

Core Style:

Sensor Power:

Amperage Range:

Isolation Voltage:

Trip Point Style | Trip Point:

Hysteresis:

Contact Type:

Contact Rating:

Contact “On” Resistance | “O” Resistance:

Response Time:

Status LED Indication:

Aperture Size:

Operating Temperature Range:

Operating Humidity Range:

Wiring Connections:

Wire Size:

Terminal Block Torque Rating:

Minimum Mounting Distance¹:

STANDARD ORDERING

Model #

A/MCS-A

A/MSCS-A

Item #

117854

117855

Trip Point Type

Adjustable

Adjustable

N/O

•

•

Solid-Core

•

Split-Core

•

Amp Range

0.32 to 150A

0.70 to 150A

Amp Range

0.32 to 150A

0.70 to 150A

Contact Rating

1A @ 36 VAC/VDC

1A @ 36 VAC/VDC

Note¹: The LED should not be used to determine if current is present. At low currents the LED may not be visible.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 6.0

I0000558

NOTES

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 7

Version: 6.0

I0000558

NOTES

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 8

Version: 6.0

I0000558

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

This manual suits for next models

4

Table of contents

Other aci Switch manuals

Popular Switch manuals by other brands

Festo

Festo SME-8M-xxx-24V series instructions

Panasonic

Panasonic SG-C1-21-EG instruction manual

TRENDnet

TRENDnet TE100-DX8 - Specifications

CP Plus

CP Plus CP-TNW-HP4H1-6 quick start guide

Aruba

Aruba 2930F 24G 4SFP Plus Installation and getting started guide

Mellanox Technologies

Mellanox Technologies Mellanox SX1018 user manual