Page 9 of 11

Revised: 11/12/18

Installation & Operation Manual

Manual #7109-208-001

1. Check for obvious signs of wear, broken or defective

equipment. Re-paint if necessary. Replace missing or

defective equipment such as broken push paddles,

missing signs and inspection tags.

2. Lower both eyes into flow. Both eyes should be flushed

to prevent contamination from one eye from being

delivered to unaffected eye. Personnel who wear contact

lenses should remove them immediately prior to or

during the flush to prevent the contamination from

remaining against the cornea possibly causing

unnecessary damage or pain.

4. When finished return the push paddle to the vertical or

fully “OFF” position and return spray nozzle assembly to

standby position. Flushing fluid should stop. Once

flushing fluid has stopped flowing, return spray nozzle

lids to the closed position to protect from airborne

contaminates.

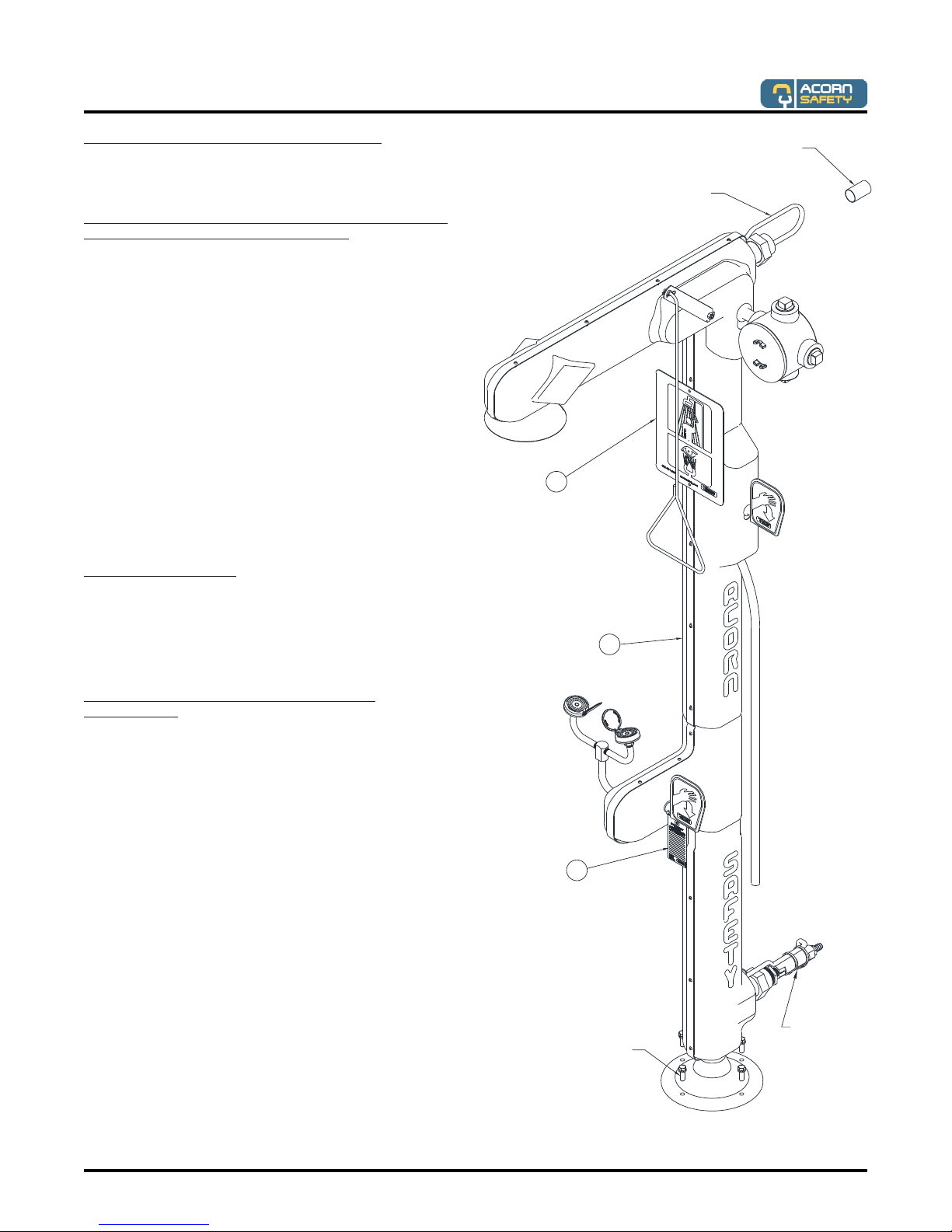

EYE/FACE WASH OPERATION

INSTRUCTIONS:

Maintain and inspect in accordance with ANSI Z358.1-2009

Employees who work with hazardous materials should

become familiar with the location and operation of the

nearest emergency plumbing fixture. Emergency plumbing

fixtures stations are simple to use and require hands free

operation once the station is activated. Regular instruction

regarding proper care and use will increase confidence that

the units are accessible and function properly.

EYE/FACE WASH MAINTENANCE

GUIDE:

2. Remove strainer and washout any debris collected

–replace as required.

The route and area surrounding the Eye Wash should be

clear and unobstructed; the sooner eyes are flushed, the

less likelihood of damage. Eye Wash stations should be

located in close proximity to the hazard and take no more

than 10 seconds to reach. In the case of sever eye

contamination the victim may require assistance to the Eye

Wash station and help flushing their eyes.

Safety plumbing fixture equipment should be operated

weekly for a period long enough to verify operation, clear

the supply line of any sediment build-up and minimize

microbial contamination due to sitting water.

1. To start the Eye Wash, swing spray nozzle assembly over

the basin and push the paddle forward to the horizontal

or fully “ON” position. Flushing should start, popping the

spray nozzle caps open.

3. Using thumb and forefingers, fully open eyelids and flush

eyes thoroughly for approximately 15 minutes or until

medical personnel arrive. Be prepared to let the doctor

know what type of contamination has entered the eye.

Acorn Safety a division of Acorn Engineering Company™

5. Return push paddle to vertical or fully “OFF” position and

swing back to stand by position. To prevent Eye Wash

spray nozzles from becoming contaminated, always

close nozzle lids after each use.

4. While in operation, inspect spray nozzles for clogs or

debris correct or replace as required.

3. Operate Eye Wash nozzles using the push paddle to

place ball valve in the fully “ON” position checking for

smooth operation of valve push paddle mechanism at the

same time ensuring that the Eye Wash spray nozzle caps

pop off immediately when actuated. If the ball valve does

not operate smoothly check the actuating assembly for

binding or missing parts. If the Eye Wash spray nozzle

caps do not pop off immediately when actuated check for

correct supply inlet pressure.