Page 7 of 9

Acorn Safety a division of Acorn Engineering

Manual #7109-305-001

Installation & Operation Manual

4. Connect the ground wires and ground in

accordance of local and NEC National Electrical

Code requirements. A green ground screw is

provided on the alarm box (or J-box).

STEP ONE:

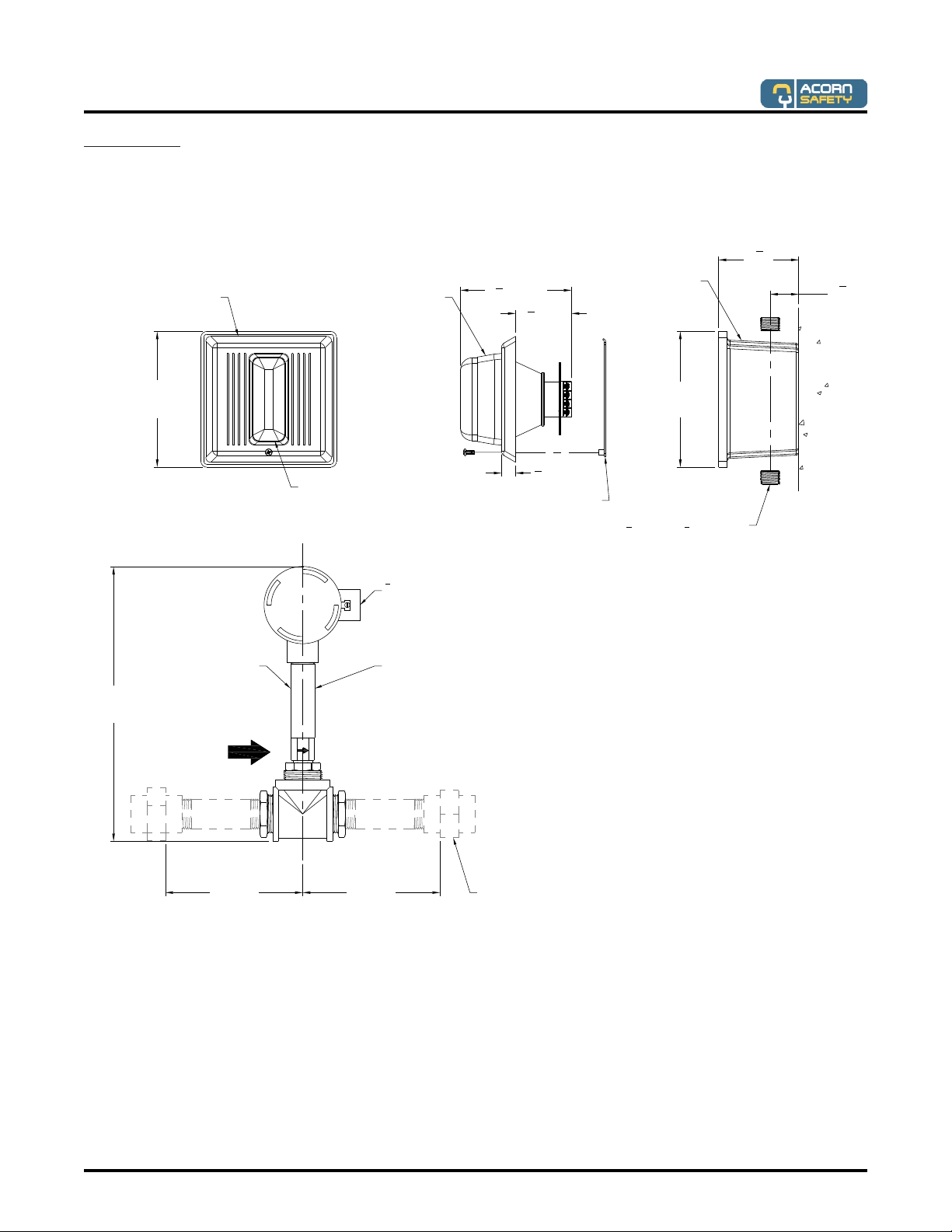

FLOW SWITCH INSTALLATION

1. Determine location of flow switch in water

supply line. The inlet and outlet ports of the flow

switch must be a minimum of 6” from any tees

or elbows (as shown on page 3) in the water

supply line. Refer to page 6 and rough-in

drawing.

2. Pipe the flow switch in-line of fixture supply

inlet. The switch body must be in the vertical

position with the water pipe horizontal. The

water flow must be in the direction of the arrow

that is marked on the flow switch body. Refer to

page 6 and rough-in drawing.

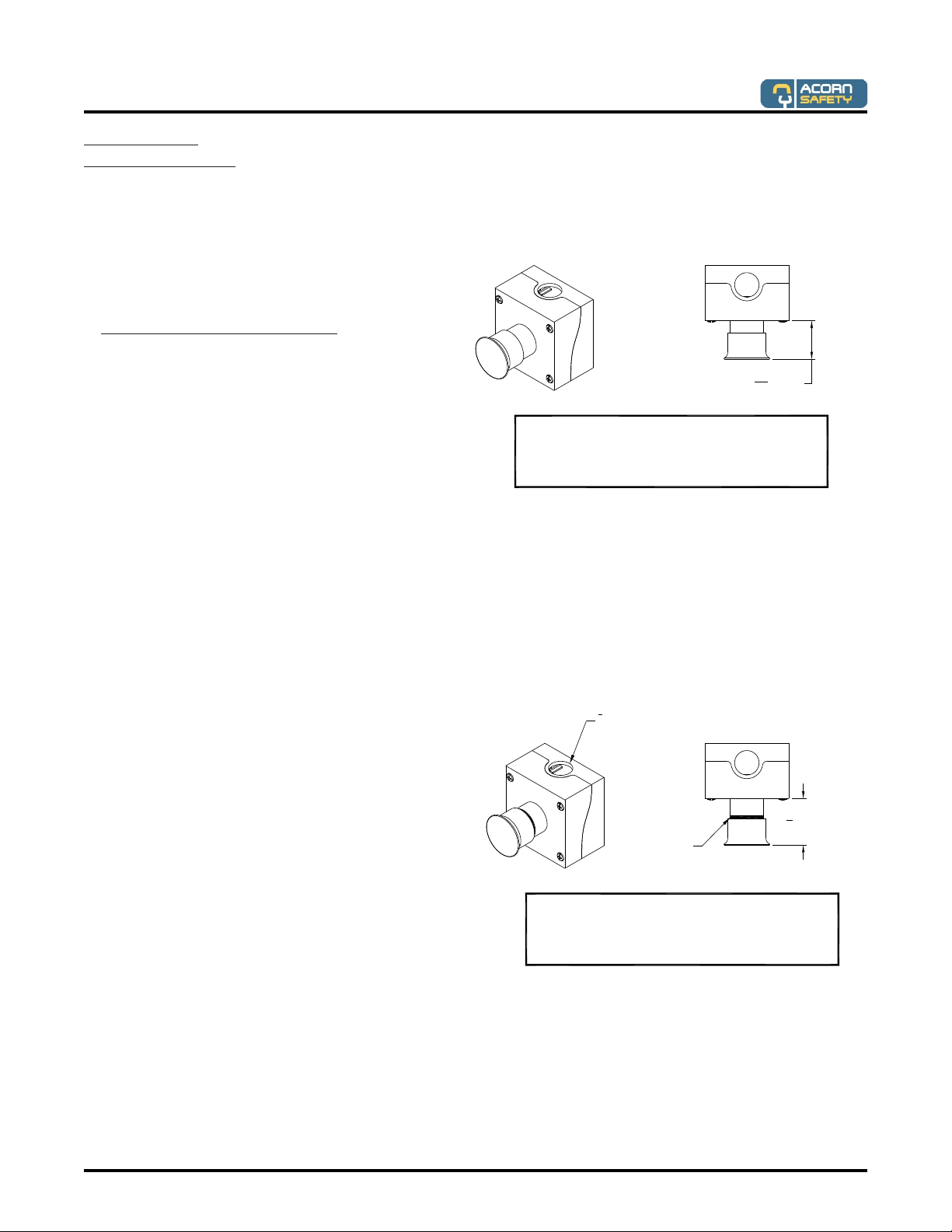

STEP TWO:

ALARM INSTALLATION

2.Attach alarm hanger plate as shown with angled

flange in an upward orientation.

1. Determine mounting method and location of

alarm. As a recommendation, locate the alarm

near emergency equipment and in a manner

that would allow it to be readily visible by

employees and quick reaction or emergency

personnel when activated.

3. Connect wiring (supplied by others) to the

terminals within the flow switch junction box as

shown in the appropriate wiring diagram. Extra

set of wiring terminals provided for remote

monitoring, not shown.

3. Field wire flow switch to alarm box (or J-box).

Provide electrical service wiring to alarm box (or

J-box). Note: Circuit wiring should not be

energized at this time. It is recommended that

the alarm and other components be installed in

accordance of national and local electrical

codes.

5. Connect flow switch field wiring and electrical

service wiring to alarm terminals as indicated in

wiring diagram.

6. Hang the horn/strobe assembly over the hanger

plate with the mounting screw at the bottom,

then tighten mounting screw to secure..

7. Apply power to the circuit and test to verify

operation.

SURFACE MOUNTING J-BOX

(NTS)

2" [51]

3"

[76]

1

2" NPT REMOVABLE

BOX PLUGS

#10 x 1-1-4" LONG PHILLIPS

HEAD SCREWS PROVIDED

CAP PLUGS

PROVIDED

Ø1

4" [6.3] FIELD

DRILLING REQUIRED

2" [51]

11

2"

[38]

HANGER PLATE

HORN / STROBE

ASSEMBLY

Revised: 12/10/18