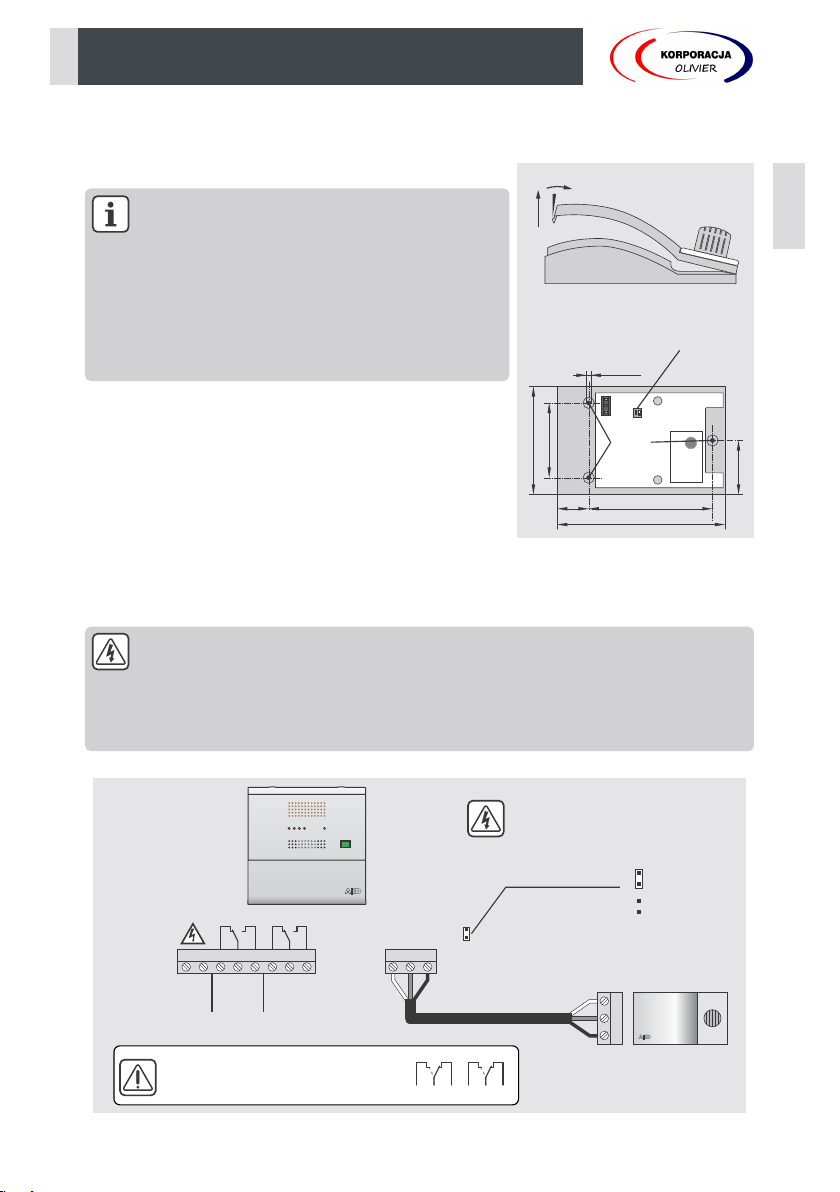

Detector heating time

After receiving the electrical power supply, the gas detector needs a heating time of around 5 minutes,

during which it will NOT detect leaks. This time is indicated by means of a quick flashing of the green led

on the detector itself.

Self-diagnosis function

The unit incorporates a self-diagnosis system of the detector and the wiring between the detector and alarm station.

In the case of malfunction, the station will alert making three consecutive tones every 2 minutes, and activating the

visual alarm and the detector status led, while the detector will alternately activate its status leds.

AKO-52210

AKO-52211/52212

7.- Maintenance

Power supply ........................................................................................................................90-260 V~ 50/60 Hz

Maximum input power ................................................................................................................................10 VA

No. of inputs.......................................................................................................................................................1

Compatibility of inputs ......................................................................................Only AKO-52211/52212 detectors

Alarm / pre-alarm relay ...........................................................................................SPDT 230 Vac, 16 A, cos j =1

Working ambient temperature ..........................................................................................................0 ºC to 50 ºC

Storage ambient temperature ........................................................................................................-30 ºC to 70 ºC

Protection degree .........................................................................................................................................IP 40

Installation category ....................................................................................................................II s/ EN 61010-1

Pollution degree ..........................................................................................................................II s/ EN 61010-1

Double isolation between power supply, secondary circuit and relay output.

Sound power..........................................................................................................................90 dB(A) at 1 metre

EMC Standard.......................................................................................................................................EN 61000

Power supply..................................................................................................................................15 Vdc ±3 Vdc

Consumption Typical................................................................................................................................75 mA

Maximum.........................................................................................................................100 mA

Working ambient temperature.......................................................................................................-20 ºC to 50 ºC

Storage ambient temperature ........................................................................................................-20 ºC to 60 ºC

Range of maximum allowed humidity .............................................................5 - 85% RH (without condensation)

Protection degree .........................................................................................................................................IP 40

Life...................................................................................Depending on the temperature and humidity conditions

EMC Standard.......................................................................................................................................EN 61000

ŸClean the surface of the equipment with a soft cloth, water and soap.

ŸDo not use abrasive detergents, petrol, alcohol or solvents, as this might damage the sensor.

ŸAKO guarantees the correct operation of the detectors during the first 3 years from the date of purchase,

and after this time, it is advisable to replace the detector.

ŸWe recommend changing the detector in the event of having been exposed to high gas concentrations.

The correct operation of the detector should be checked at least once a year, ask about if

your current local regulations require lower intervals.

This check consists of exposing the detector to a small gas concentration and check that

all the relay indications and outputs work correctly.

8.- Technical data

English

7

Korporacja Olivier Sp. z o.o. tel. 696 035 469