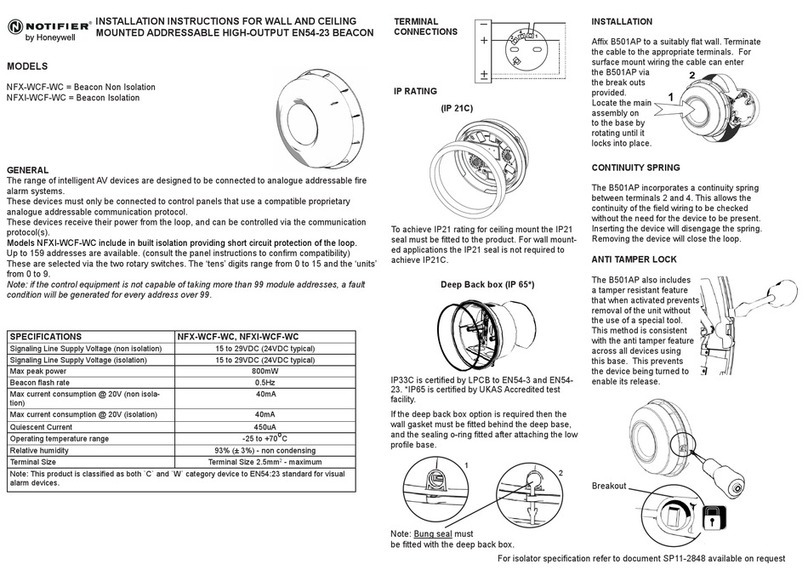

TENS

0

78

6

5

4

3

21

910

11

12

13

14

15

C0227-00

Figure 7

4. A shunt is provided to disable a maximum of three unused

modules (see Figure 8). Modules are disabled from the highest

address and work downward. If two modules are disabled, the

lowest four addresses will be functional, while the highest two

will be disabled. For example, if the shunt for Address Disable

is placed on “two” and the base address switch is set to 28,

the modules will be assigned to 28, 29, 30 and 31, disabling

the highest two positions.

NOTE: In Class A operation, placing the small shunt on “dis-

able 3″will disable all three addresses. Placing the small

shunt on “disable 2″will disable two out of the three

addresses. For example, if the address switch is set to 28

and the small shunt is placed on “disable 2″, addresses

30 and 32 will be disabled while address 28 will be

enabled. The XP6-C must have power cycled for shunt

changes to take effect.

5. There is an active short circuit protection option for each

address. The board is shipped with this option disabled for

each address represented by six large shunts on the “Disable

Short Circuit Protection” area. To enable short circuit protec-

tion for an address, remove the corresponding shunts on the

“Disable Short Protection” area. When enabled, this option

will isolate a short occurring on any active circuit allowing the

remaining circuits to continue normal operation.

NOTE: Power supply monitoring should not be used for audio

applications. The short circuit protection feature is also

not available for audio applications.

NOTE: The XP6-C does not provide ring back when used as a

firefighter telephone circuit.

NOTE: Short circuit protection may only be enabled if power

supply monitoring is enabled.

NOTE: This feature is not for use with all Fire Alarm Control

Panels. Please consult with Technical Services before

enabling this feature.

NOTE: Place unused shunts on single pin to store on board for

future use.

NOTE: Power must not be applied to the unit when changing

functionality of the shunts.

NOTE: Whether in Class B or Class A wiring, power supply

monitoring and short circuit protection must be enabled

on the NAC circuits that are sharing a power supply.

NOTE: Short circuit protection can only be disabled if a power

supply is not being shared by multiple NACs.

N500-79-00 4 I56-1805-012

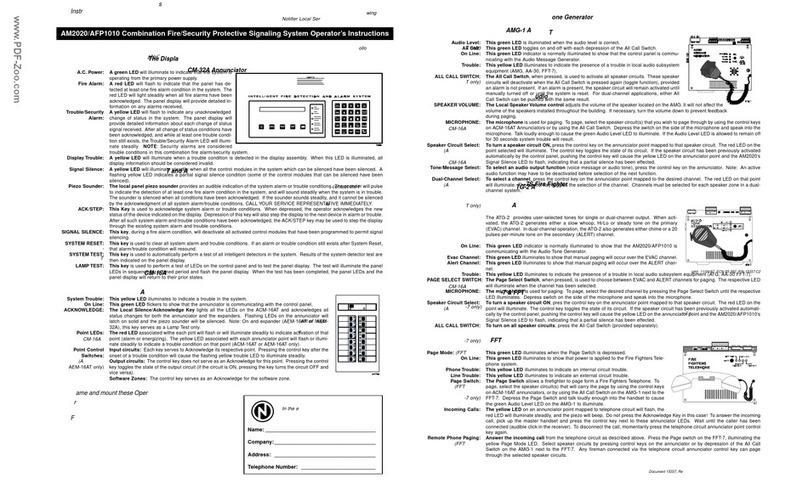

ENABLE POWER SUPPLY MONITOR

DISABLE SHORT CIRCUIT PROTECTION

SYNC GENERATOR

SIDE VIEW:

TOP VIEW:

SLC WIRING TERMINAL

NOTIFICATION APPLIANCE/

POWER SUPPLY TERMINAL

A/B SELECT

DISABLE 1

DISABLE 2

DISABLE 3

J1 Shunt

C0174-00

Figure 8

NOTE: SLC wiring is the top terminal block, notification appli-

ance/power supply is the bottom.

WIRING NOTES

• Power-limited circuits must employ type FPL, FPLR, or FPLP

cable as required by Article 760 of the NEC.

• For easier wiring, assign all power-limited wiring to one side of

the enclosure rather than alternating with non power-limited.

PROGRAMMING

The XP6-C module operates with the following Fire Alarm Control

Panels:

• AM2020/AFP1010

• AFP-200

• AFP-300/AFP-400

• System 5000 with AIM-200

• AFC-600

• NFS-640

• NFS-3030

The modules are programmed as devices in each system according

to the programming instructions in the appropriate FACP manual.

NAC Wiring and Supervision

For Class B, Style Y applications (figures 9, 10, and 13 are typi-

cal): connect the positive terminal of the notification appliance(s)

to the NAC+ terminal and the negative device terminal to the

adjacent NAC- terminal. Connect one (for each NAC) of the sup-

plied EOL resistors across the NAC+ and NAC- wires, at the ends

farthest away from the NAC terminal of the XP6-C.

For Class A, Style Z applications (figures 11, 12, and 14 are typi-

cal) wire the NACs per table 2. The A/B select shunt must be

removed prior to connecting the XP6-C to the SLC. The EOL

resistors should not be used. The XP6-C is capable of supporting

3 Class A, Style Z NACs. The XP6-C will only respond at the base

address, base address +2, and base address +4 (assuming no

addresses have been disabled).

TABLE 2

NAC# (+) CONNECTIONS (–) CONNECTIONS

+0 +0 NAC+, +1 NAC+, +0 NAC–, +1 NAC–

NOTIFICATION APPLIANCE+ NOTIFICATION APPLIANCE–

+2 +2 NAC+, +3 NAC+, +2 NAC–, +3 NAC–,

NOTIFICATION APPLIANCE+ NOTIFICATION APPLIANCE–

+4 +4 NAC+, +5 NAC+, +4 NAC–, +5 NAC–

NOTIFICATION APPLIANCE+ NOTIFICATION APPLIANCE–

Power Supply Wiring and Supervision

Table 3 gives an overview of how the power connectors, T0–T5

and T10–T15, are interconnected by the circuit board (PCB). The