ACPro A Series User manual

AC Pro A-Series 18-24K

Service Manual

Models

AWH18QD-D3DNB8K/I

AWH18QD-D3DNA5K/O

AWH24QE-D3DNB8K/I

AWH24QE-D3DNA5K/O

(Refrigerant R410A)

We reserve the right to correct any clerical errors.

Copyright 2018 AC pro.

Technical Information

1

PART I :INSTALLATION &MAINTENANCE

1. NOTES FOR INSTALLATION AND MAINTENANCE

SAFETY PRECAUTIONS:

IMPORTANT!

Please read the safety precautions carefully before

installation or prior to performing any maintenance.

Please follow instructions below.

• Maintenance or installation MUST be in accordance

with instructions.

• Comply with ALL local and national electrical codes.

• Pay attention to ALL warnings and cautions in this

manual.

• Any maintenance and/or installation shall be

performed by distributors or licensed and qualified

individual.

• Electrical work MUST be performed by licensed

technician according to local regulations and the

instructions given in this manual.

• Use extreme caution when performing electrical

installation tasks – Electric shock can result in

severe injury or death.

WARNINGS!

1. Disconnect power supply prior to ANY work.

2. The air conditioner is a specialized circuit that

requires its own power supply – this is not to be

shared with ANY other electrical appliances.

3. The air conditioner should be installed in a suitable

location and the power supply should be easily

reachable by ALL users.

4. During maintenance and installation, make sure

wiring terminals are securely fastened.

5. Ground wire MUST be firmly connected and NOT

used for other purposes.

6. Use protective accessories as necessary, (IE:

protective boards, cable-cross loop, wire clips, etc.).

7. Live wire, neutral wire, and ground wire MUST

correspond to the live wire, neutral wire, and ground

wire of the air conditioner.

8. Power cord and power connections MUST be free

of obstruction and CANNOT be compressed.

9. Should power cord or power connection become

severed, they MUST be repaired/replaced by

qualified technician.

10. If the power cord or power connection wire is not

long enough, replace with specialized cable from

manufacturer before proceeding with installation or

repair. DO NOT elongate these wires.

11. An air switch MUST be installed if there is no plug

found on the air conditioner. The air switch MUST

be all-pole parting and the contact parting distance

MUST be at 1/8” or greater.

12. All wires and pipes MUST be connected firmly prior

to supplying the unit with power.

13. Eliminate any electric leakage on the unit body.

14. Fuses MUST be replaced with fuse of the same

specification(s). DO NOT replace with copper wire

or conducting wire.

15. If the unit is being installed in a humid climate, a

circuit breaker MUST also be installed.

INSTALLATION SAFETY PRECAUTIONS

1. Select installation location according to

the requirements of this manual. (See the

requirements of installation section in this manual.).

2. Handle unit with care. If unit exceeds 44.09

pounds, use the two-person lift technique to

transport.

3. Use a sufficient fixing bolt when installing both

the indoor and outdoor unit(s). Ensure installation

support is firm.

4. Use safety belt and personal protection equipment

(PPE) while working above a height of 6’.

5. Use equipped components or appointed

components during installation.

6. Make sure to clear the unit of any/all foreign objects

prior to completion of installation.

REFRIGERANT SAFETY PRECAUTIONS

1. Avoid contact of fire and refrigerant as the

combination creates poisonous gas.

2. Use only specified refrigerant. DO NOT mix

refrigerant types. DO NOT allow air to remain in

refrigerant lines as this may lead to pipe rupture or

other hazards.

3. Check entire system for refrigerant leaks prior to

completing installation.

Technical Information 2

IF SAFETY PRECAUTIONS

FOR INSTALLING AND

RELOCATING THE UNIT:

WARNINGS!

1. When installing or relocating the unit, be sure to

keep the refrigerant circuit free from air and other

substances other than the specified refrigerant.

Presence of air or other foreign substance in the

refrigerant lines will cause the system pressure to

rise and could cause the compressor to rupture –

causing injury.

2. When installing or moving the unit, DO NOT charge

with refrigerant other than the specified type listed

on the nameplate of the unit.

This will cause abnormal operation, improper actions

and mechanical malfunction and may result in

serious injury.

3. Refrigerant recovery during relocation or repair:

Ensure unit is running in cooling mode. Fully close

valve at high pressure side (liquid valve). After 30

seconds, fully close valve at low pressure side (gas

valve). Immediately stop the unit and disconnect

power. Total time for refrigerant recovery should not

exceed 1 minute.

If refrigerant recovery takes too much time, air may

be sucked in causing the pressure to rise and the

compressor to rupture which can lead to severe

injury or death.

4. During refrigerant recovery, make sure the liquid and

gas lines are fully closed and power is disconnected

before detaching the connection pipe.

If the compressor starts running while stop valve is

open and connection pipe is not affixed, air will be

sucked in causing pressure to rise and potentially

causing compressor rupture which may lead to

severe injury or death.

5. When installing the unit, make sure the connection

pipe is securely connected before the compressor

starts running.

If the compressor starts running while stop valve is

open and connection pipe is not affixed, air will be

sucked in causing pressure to rise and potentially

causing compressor rupture which may lead to

severe injury or death.

6. DO NOT install the unit in an area exposed to (or

potentially exposed to) corrosive or flammable gas

leaks.

Leaking gas near the unit may cause fire or

explosion leading to property damage, severe injury

or death.

7. DO NOT use extension cords for electrical

connections. If the electrical wire in not long

enough, contact a local service authorized center to

install the proper length wiring.

Poor connections may lead to electrical shock or fire.

8. Use manufacturer specific wires for connections

between indoor and outdoor units. Firmly clamp

wires between indoor and outdoor units. Ensure

terminals receive NO external stress.

Electric wires with insufficient capacity, improper

connection points, and/or improperly secure

terminals may cause electric shock or fire.

Technical Information

3

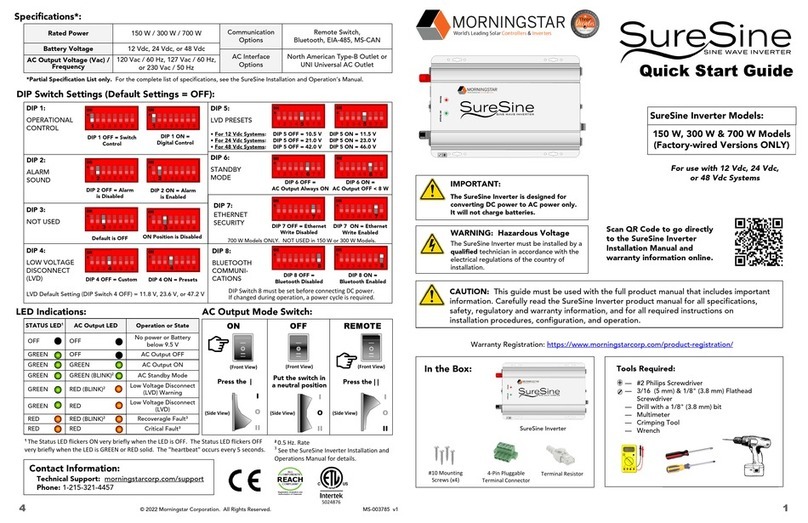

MAIN TOOLS FOR INSTALLATION AND MAINTENANCE

1. Level meter, measuring

tape

2. Screwdrivers 3. Impact drill, drill head, electric drill

4. Electroprobe 5. Universal meter 6.Torque wrench, open-end wrench, inner

hexagon spanner

7. Electronic leakage detector 8. Vacuum pump 9. Pressure meter

10. Pipe pliers, pipe cutter 11. Pipe expander, pipe bender 12. Soldering appliance, refrigerant container

Technical Information 4

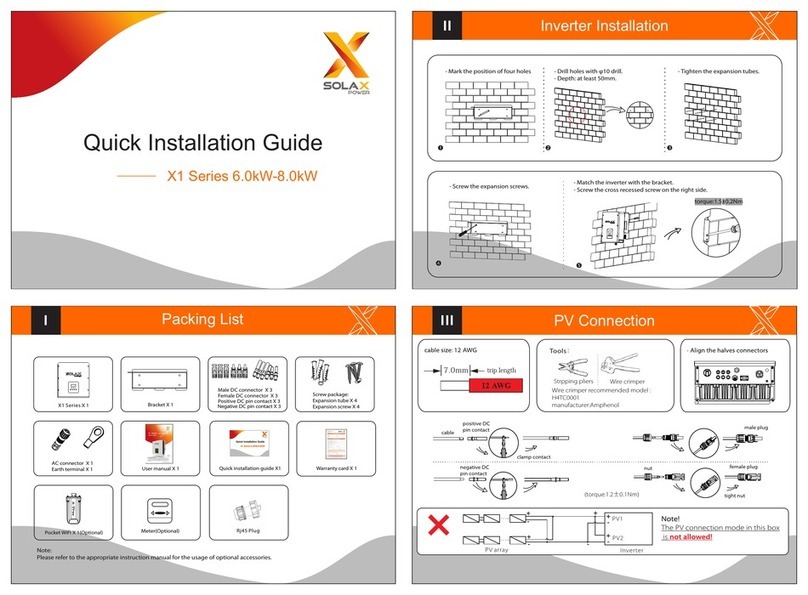

2. INSTALLATION

2.1INSTALLATION DIMENSION DIAGRAM

53

Installation and Maintenance

Service Manual

8. Installation

8.1 Installation Dimension Diagram

unit:inch

Space to the ceiling

Space to the wall

At least 8

At least 72

At least 6

At least 6

Space to the wall

Space to the obstruction

roolfehtotecapS

Space to the obstruction

Drainage pipe

Space to the wall

Space to the obstruction

Space to the obstructi

o

Space to the obstruction

At least 24

At least 12

At least 24

At least 12

At least 78

At least 118

Space to the obstruction

Technical Information

5

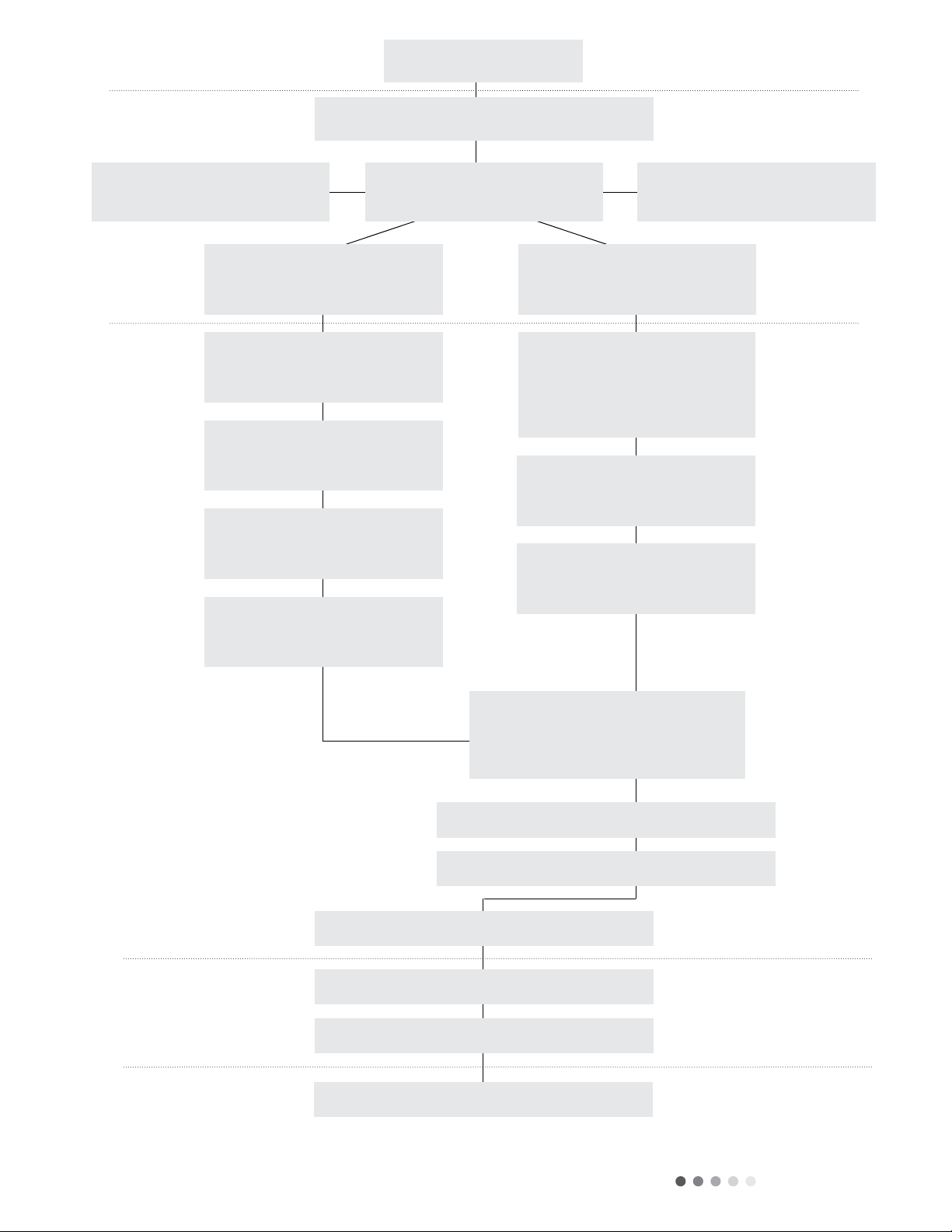

Start installation

Preparation before installation

Read the requirements for

electric connection Select installation location Prepare tools

Select indoor unit

installation location

Select outdoor unit

installation location

Install wall-mounting frame,

drill wall holes

Connect pipes of indoor unit

and drainage pipe

Connect wires of

indoor unit

Bind up pipes and hang

the indoor unit

Install the support of

outdoor unit

(select it according to the

actual situation)

Fix outdoor unit

Make the bound pipes pass

through the wall hole and then

connect outdoor unit

Install drainage joint of

outdoor unit (only for cooling

and heating unit)

Connect pipes of outdoor unit

Connect wires of outdoor unit

Neaten the pipes

Vacuum pumping and leakage detection

Check after installation and test operation

Finish installation

Note: this flow is only for reference; please find the more detailed installation steps in this section.

Technical Information 6

2.2 INSTALLATION PARTS CHECKING

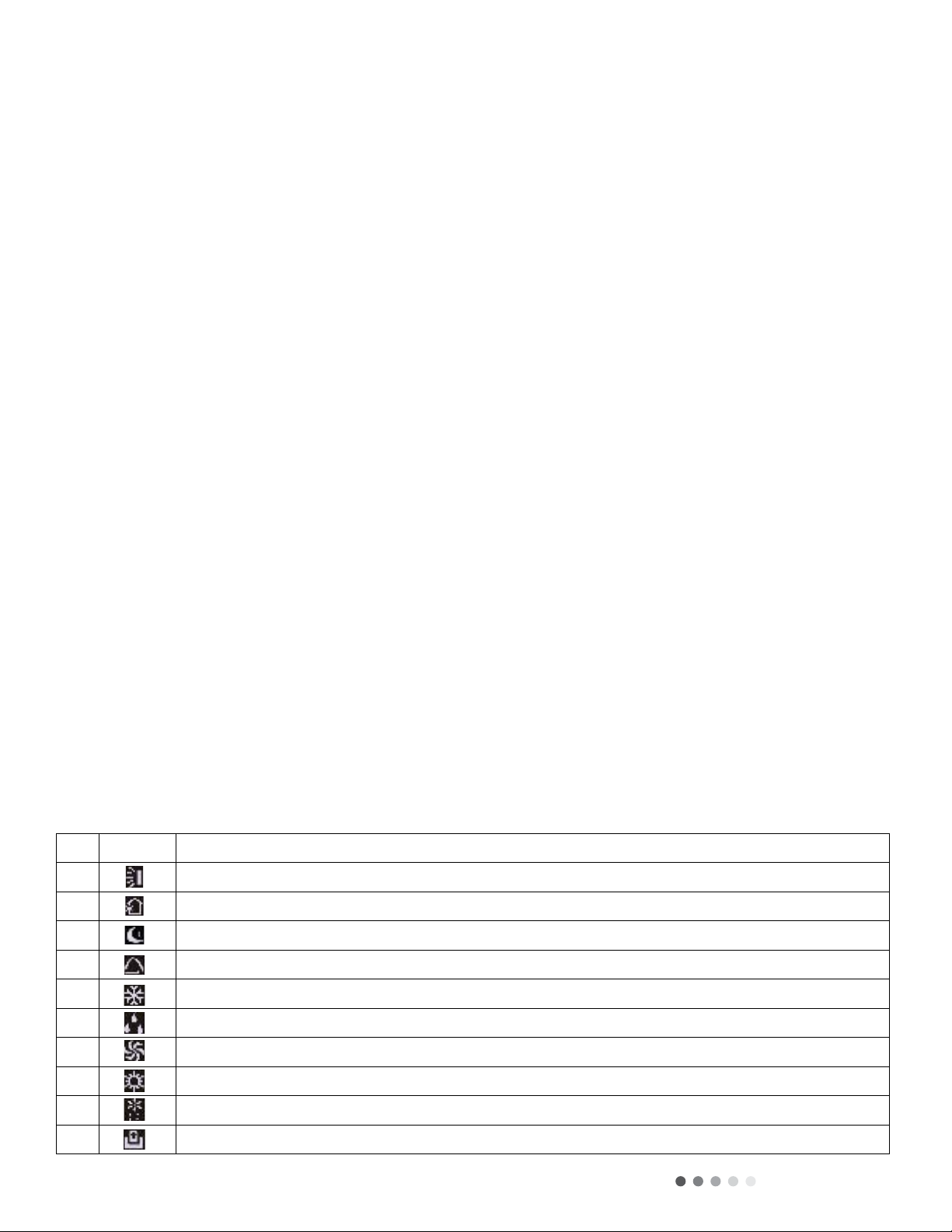

No. Name No. Name

1Indoor Unit 8Sealing Gum

2Outdoor Unit 9Wrapping Tape

3 Connection Pipe 10 Support of Outdoor

Unit

4 Drainage Pipe 11 Fixing screw

5 Wall Mounting

Frame

12 Drainage plug (cooling

and heating unit)

6Power Cord 13 Owner’s Manual,

Remote Controller

7 Wall Pipe

!

Note:

1. Installation MUST be completed by qualified technician.

2. Use manufacturer provide power cord.

2.3 SELECTION OF INSTALLATION

LOCATION

1. Basic Requirement:

Installing the unit in the following places may cause

malfunction. If installation location is unavoidable, consult local

dealer for advice.

• Locations with strong heat sources, vapors, and/or

flammable or explosive gases.

• Locations with high frequency devices such as medical

equipment and welding machines.

• Areas of high humidity.

2. Indoor Unit:

• There should be no obstruction near the air inlet/outlet.

• Select a location where the condensate can be dispersed

easily.

• Location of outdoor unit should be close to connect to

outdoor power supply.

• Location should be out of the reach of children.

• The location should be able to withstand the weight of the

indoor unit without increasing noise and vibration.

• Appliance MUST be installed 72” above the floor.

• The appliance CANNOT be installed in a laundry area.

3. Outdoor Unit:

• Select location so outflow air and noise emitted by outdoor

unit will not affect neighborhood.

• Location should be in well ventilated area and away from

strong wind.

• The foundation should be able to withstand the weight of

the outdoor unit.

• Ensure installation adheres to the installation diagram

dimensions.

• Select installation location which is out of the reach of

children, animals and plant growth. If this is unavoidable,

install protective fencing.

2.4 REQUIREMENTS FOR

ELECTRIC CONNECTION

1. Safety Precaution

• Follow ALL electric safety requirements during

installation.

• Use qualified power supply circuit and air switch –

according to local safety regulations.

• Power supply MUST match the requirement of the air

conditioner. Unstable power supply or incorrect wiring

may result in electric shock, fire hazard, or malfunction.

Install proper power supply cables prior to using air

conditioner.

• Properly connect the live wire, neutral wire and grounding

wire.

• Prior to engaging in any electrical work, disconnect the

power supply.

• DO NOT energize system prior to installation completion.

• Instructions for Y-Type attachment installation:

o If power supply cord is damaged in any way, it MUST

be replace by manufacturer.

• Keep interconnection cable away from copper tube.

Temperature of refrigerant circuit is high.

2. Grounding Requirement:

• Electric shock may result if air conditioner is not grounded

properly.

• Grounding wire in air conditioner is yellow-green and MAY

NOT be used for ANY other purposes.

• Grounding resistance MUST comply with national electric

safety regulations.

• Position appliance so plug is accessible.

• All-pole disconnect switch MUST have contact separation

of at least 1/8” in all poles.

NOTE:

Following table for air switch capability:

Air-conditioner Air switch capacity

18/24K 25A

2.5 INSTALLATION OF INDOOR UNIT

1. Choosing Installation Iocation

• Recommend location to client for approval.

2. Install Wall-mounting Frame

• Position wall-mounting frame on wall, adjust horizontal

position with level, and mark screw holes on wall.

• Drill screw fixing holes with drill motor. Install plastic

expansion screw set.

• Fix wall-mounting frame to wall with tapping screws

(STA.2X25TA) and check that frame is securely fastened.

• If plastic expansion piece is loose, drill a second hole that

lines up with the frame.

• Choose position of piping hole according to the direction

of the outlet pipe. The position of the piping hole should

be just slightly lower than the wall-mounted frame.

(Shown in figure #1).

Technical Information

7

• Choose position of piping hole according to the direction of

the outlet pipe. The position of the piping hole should be

just slightly lower than the wall-mounted frame. (Shown in

figure #1).

• Open pipe hole with diameter of ɸ2 1/6” on selected outlet

pipe position. For smooth drainage, pitch the pipe hole on

wall slightly downward to the outdoor side with a gradient of

5-10O – (Shown in Figure #2).

!

Note:

• Attend to dust prevention by taking safety measure while

drilling.

• Plastic expansion screw set not included.

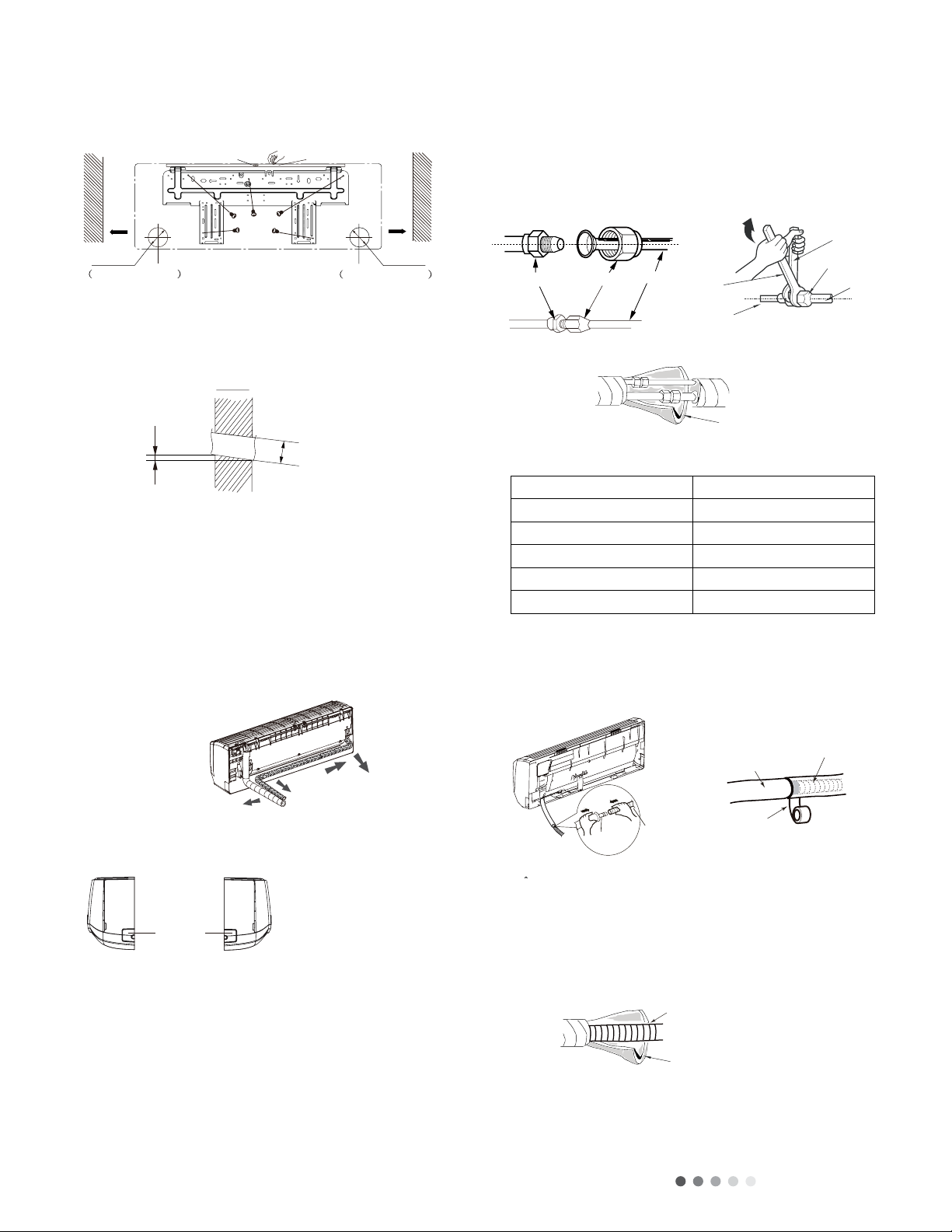

3. Outlet Pipe

• Pipe can be led out in the direction of right, rear right, left or

rear left – (Shown in Figure #3 below).

• When selecting leading out pipe (from left or right), cut out

corresponding hole on bottom (Shown in Figures 4 below).

4. Indoor Unit Pipe Connect

• Aim pipe to the corresponding bellmouth (Shown in Figure

#5 below).

• Pre-tighten union nut by hand.

• Use following torque table as reference below. Use double

wrench technique on union nut and pipe joint. Tighten the

union nut with torque wrench (Shown in Figure #6).

• Use insulation tape to wrap indoor pipe and joint of

connection pipe (Shown in Figure #7 below).

Refer to the following table for wrench moment of force:

Hex nut diameter(inch) Tightening Torque (ft:lb)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

5. Install Drain Hose

• Connect drain hose to outlet pipe of indoor unit. (Shown in

Figure #8 below).

• Bind the joint with tape (Shown in Figure #9 below).

!

Note:

• Prevent condensation by adding insulation to indoor

drain hose. (Shown in Figure #10 below).

• Plastic expansion screw set not included.

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

56 Installation and Maintenance

Service Manual

Outlet

pipe

Drain hose

Drain hose

Tape

Outlet pipe

Insulating pip

e

Torque wrenc

h

Open-end

wrench

Indoor pipe

Pipe

Union nut

Union nutPipe joint Pipe

Refer to the following table for wrench moment of force:

Left

Rear left

Right

Rear right

Cut off

the hole

Left Right

Drain hose

Insulating pip

e

5-10

°

Φ2 3/16 or

(Φ2 3/4)inch

Indoor Outdoor

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

(1) Add insulating pipe in the indoor drain hose in order to

prevent condensation.

(2) The plastic expansion particles are not provided.

(As show in Fig.10)

Fig.1

Fig.2

Fig.5 Fig.6

Fig.7

Fig.8 Fig.9

Fig.10

Fig.3

Fig.4

in the holes.

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole according to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As show in Fig.1)

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As show

in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut with

torque wrench.(As show in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As show in Fig.7)

6. Install Drain Hose

(1) Connect the drain hose to the outlet pipe of indoor unit.(As

show in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As show in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

(2) Open a piping hole with the diameter of Φ2 3/16(Φ2 3/4)

inch on the selected outlet pipe position.In order to drain

smoothly, slant the piping hole on the wall slightly downward to

the outdoor side with the gradient of 5-10°.(As show in Fig.2)

Note:

Note:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Left

Wall

Φ2 3/16(2 3/4) Φ2 3/16(2 3/4)

Right

Mark in the middle of it Level meter

Rear piping hole

Wall

Space

to the

wall

above

6inch

Space

to the

wall

above

6inch

Rear piping hole

Technical Information 8

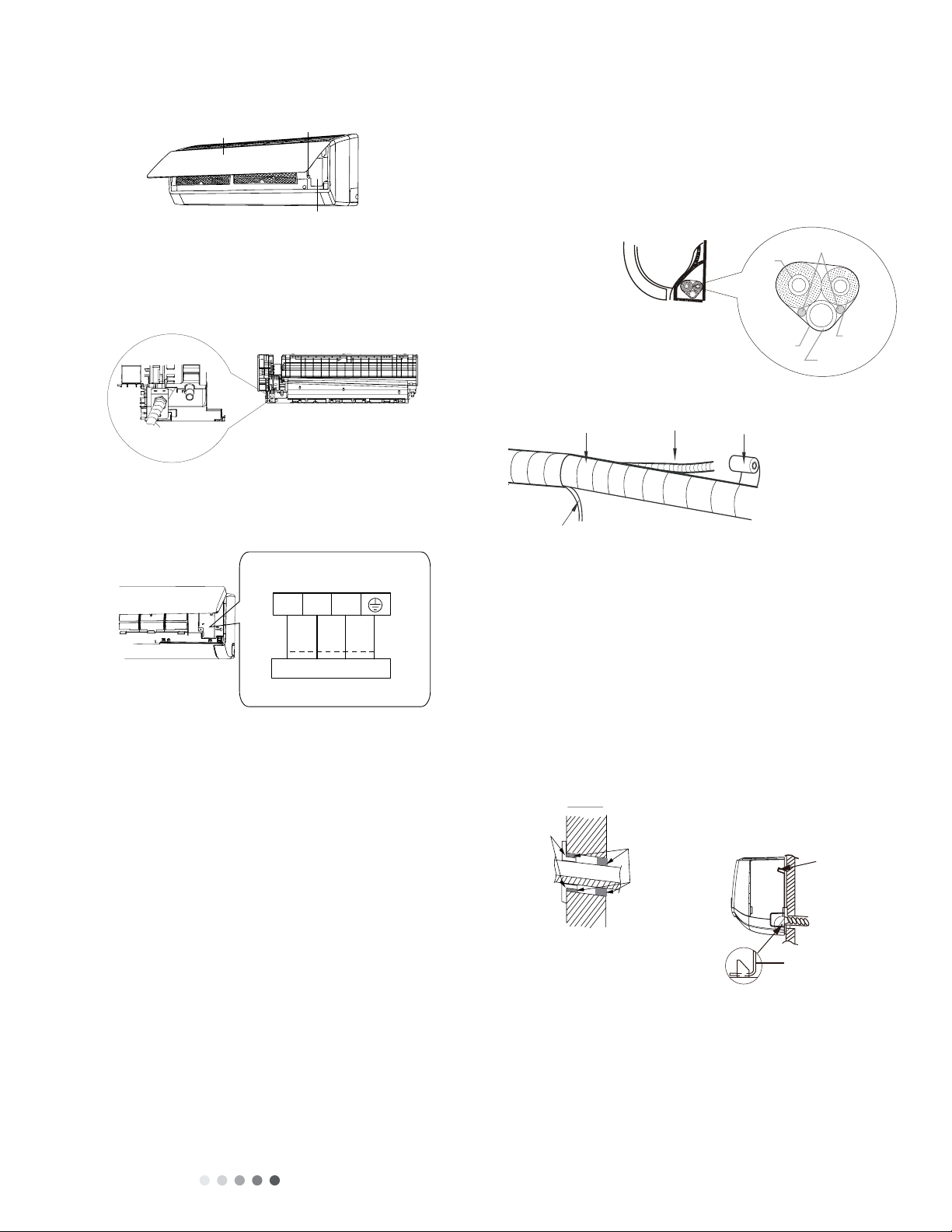

6. Indoor Unit Wire Connection

• Open panel. Remove screw on wiring panel and detach

cover (Shown in Figure #11 below).

• Affix the wire crossing board on the connection wire sleeve

to the bottom of the case. Position the connection wire

sleeve through the wire crossing hole at the back of the

indoor unit. Pull through front (Shown in Figure #12

below).

• Remove wire clip. Attached power connection wire to the

wiring terminal by color. Tighten screw(s) and attach power

connection wire with wire clip (Shown in Figure #13 below).

Note: The wiring connect is for reference only, please refer to

the actual one.

• Wiring board is for reference only.

• Replace wire cover back and tighten screw.

• Close panel.

Note:

• All wires for both indoor and outdoor units MUST be

connected by a professional.

• If the length of the power supply connection cable is

insufficient, contact the supplier for a new one.

• Units that contain plugs MUST have plugs in convenient/

reachable location.

• Units without plugs MUST have an air switch installed in

the line. The air switch MUST be all-pole parting and the

contact distance MUST be more than 1/8”.

7. Bind Up Pipe

• Bind the connection pipe, power cord and drain hose with

band. Shown in Figure #14 below).

• Reserve a length of drain hose and power cord for installation

during binding. When binding to a specific degree, separate

the indoor power and separate the drain hose (Shown in Figure

#15 below).

• Bind all cordage and hoses evenly.

• The liquid and gas pipes should be bound separately at the

end.

Note:

• The power cord and control wire cannot be crossed.

• The drain hose should be bound to the bottom.

8. Hang the Indoor Unit

• Insert bound pipes in to wall pipe and pass them through hole

in wall.

• Hang indoor unit on the wall mounting frame.

• Stuff gap between pipes and wall hole with sealing gum.

• Affix the wall pipe (Shown in Figure #16 below).

• Ensure indoor unit is close to the wall and installed securely

(shown in Figure #17 below).

Note:

• DO NOT excessively bend the drain hose. Doing so may

cause a blockage.

57

Installation and Maintenance

Service Manual

connection wire sleeve

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor unit Gas

pipe

Indoor and

outdoor power cord

Liquid

pipe

Drain hose

Band

Drain hose Band

Connection pipe

Indoor power cord

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioner with plug, the plug should be

reachable after nishing installation.

(4) For the air conditioner without plug, an air switch must be

installed in the line. The air switch should be all-pole parting

and the contact parting distance should be more than 3mm.

(1) The power cord and control wire cant be crossed or

winding.

(2) The drain hose should be bound at the bottom.

Do not bend the drain hose too excessively in order to prevent

blocking.

7. Connect Wire of Indoor Unit

(1) Open the panel, remove the screw on the wiring cover and

then take down the cover.(As show in Fig.11)

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and drain hose

with the band.(As show in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the drain

hose.(As show in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.(As show in Fig.16)

(5) Check if the indoor unit is installed rmly and closed to the

wall.(As show in Fig.17)

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As show in Fig.12)

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then x the power

connection wire with wire clip.(As show in Fig.13)

Note:

Note:

Note:

Indoor Outdoor

Wall pipe Sealing gum

Upper hook

Lower hook of

wall-mounting frame

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Wiring cover

Screw

Panel

Note: the wiring board is for reference only,please refer to the

actual one.

Outdoor unit connection

3

2

N(1)

green

green)

red

black

(yellow-

(brown)

white

(blue)

Note: the wiring board is for reference only,please refer to the actual one.

57

Installation and Maintenance

Service Manual

connection wire sleeve

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor unit Gas

pipe

Indoor and

outdoor power cord

Liquid

pipe

Drain hose

Band

Drain hose Band

Connection pipe

Indoor power cord

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioner with plug, the plug should be

reachable after nishing installation.

(4) For the air conditioner without plug, an air switch must be

installed in the line. The air switch should be all-pole parting

and the contact parting distance should be more than 3mm.

(1) The power cord and control wire cant be crossed or

winding.

(2) The drain hose should be bound at the bottom.

Do not bend the drain hose too excessively in order to prevent

blocking.

7. Connect Wire of Indoor Unit

(1) Open the panel, remove the screw on the wiring cover and

then take down the cover.(As show in Fig.11)

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and drain hose

with the band.(As show in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the drain

hose.(As show in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.(As show in Fig.16)

(5) Check if the indoor unit is installed rmly and closed to the

wall.(As show in Fig.17)

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As show in Fig.12)

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then x the power

connection wire with wire clip.(As show in Fig.13)

Note:

Note:

Note:

Indoor Outdoor

Wall pipe Sealing gum

Upper hook

Lower hook of

wall-mounting frame

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Wiring cover

Screw

Panel

Note: the wiring board is for reference only,please refer to the

actual one.

Outdoor unit connection

3

2

N(1)

green

green)

red

black

(yellow-

(brown)

white

(blue)

Note: the wiring board is for reference only,please refer to the actual one.

57

Installation and Maintenance

Service Manual

connection wire sleeve

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor unit Gas

pipe

Indoor and

outdoor power cord

Liquid

pipe

Drain hose

Band

Drain hose Band

Connection pipe

Indoor power cord

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioner with plug, the plug should be

reachable after nishing installation.

(4) For the air conditioner without plug, an air switch must be

installed in the line. The air switch should be all-pole parting

and the contact parting distance should be more than 3mm.

(1) The power cord and control wire cant be crossed or

winding.

(2) The drain hose should be bound at the bottom.

Do not bend the drain hose too excessively in order to prevent

blocking.

7. Connect Wire of Indoor Unit

(1) Open the panel, remove the screw on the wiring cover and

then take down the cover.(As show in Fig.11)

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and drain hose

with the band.(As show in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the drain

hose.(As show in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.(As show in Fig.16)

(5) Check if the indoor unit is installed rmly and closed to the

wall.(As show in Fig.17)

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As show in Fig.12)

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then x the power

connection wire with wire clip.(As show in Fig.13)

Note:

Note:

Note:

Indoor Outdoor

Wall pipe Sealing gum

Upper hook

Lower hook of

wall-mounting frame

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Wiring cover

Screw

Panel

Note: the wiring board is for reference only,please refer to the

actual one.

Outdoor unit connection

3

2

N(1)

green

green)

red

black

(yellow-

(brown)

white

(blue)

Note: the wiring board is for reference only,please refer to the actual one.

57

Installation and Maintenance

Service Manual

connection wire sleeve

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor unit Gas

pipe

Indoor and

outdoor power cord

Liquid

pipe

Drain hose

Band

Drain hose

Band

Connection pipe

Indoor power cord

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioner with plug, the plug should be

reachable after nishing installation.

(4) For the air conditioner without plug, an air switch must be

installed in the line. The air switch should be all-pole parting

and the contact parting distance should be more than 3mm.

(1) The power cord and control wire cant be crossed or

winding.

(2) The drain hose should be bound at the bottom.

Do not bend the drain hose too excessively in order to prevent

blocking.

7. Connect Wire of Indoor Unit

(1) Open the panel, remove the screw on the wiring cover and

then take down the cover.(As show in Fig.11)

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and drain hose

with the band.(As show in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the drain

hose.(As show in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.(As show in Fig.16)

(5) Check if the indoor unit is installed rmly and closed to the

wall.(As show in Fig.17)

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As show in Fig.12)

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then x the power

connection wire with wire clip.(As show in Fig.13)

Note:

Note:

Note:

Indoor Outdoor

Wall pipe Sealing gum

Upper hook

Lower hook of

wall-mounting frame

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Wiring cover

Screw

Panel

Note: the wiring board is for reference only,please refer to the

actual one.

Outdoor unit connection

3

2

N(1)

green

green)

red

black

(yellow-

(brown)

white

(blue)

Note: the wiring board is for reference only,please refer to the actual one.

57

Installation and Maintenance

Service Manual

connection wire sleeve

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor unit Gas

pipe

Indoor and

outdoor power cord

Liquid

pipe

Drain hose

Band

Drain hose Band

Connection pipe

Indoor power cord

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioner with plug, the plug should be

reachable after nishing installation.

(4) For the air conditioner without plug, an air switch must be

installed in the line. The air switch should be all-pole parting

and the contact parting distance should be more than 3mm.

(1) The power cord and control wire cant be crossed or

winding.

(2) The drain hose should be bound at the bottom.

Do not bend the drain hose too excessively in order to prevent

blocking.

7. Connect Wire of Indoor Unit

(1) Open the panel, remove the screw on the wiring cover and

then take down the cover.(As show in Fig.11)

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and drain hose

with the band.(As show in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the drain

hose.(As show in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.(As show in Fig.16)

(5) Check if the indoor unit is installed rmly and closed to the

wall.(As show in Fig.17)

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As show in Fig.12)

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then x the power

connection wire with wire clip.(As show in Fig.13)

Note:

Note:

Note:

Indoor Outdoor

Wall pipe Sealing gum

Upper hook

Lower hook of

wall-mounting frame

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Wiring cover

Screw

Panel

Note: the wiring board is for reference only,please refer to the

actual one.

Outdoor unit connection

3

2

N(1)

green

green)

red

black

(yellow-

(brown)

white

(blue)

Note: the wiring board is for reference only,please refer to the actual one.

Technical Information

9

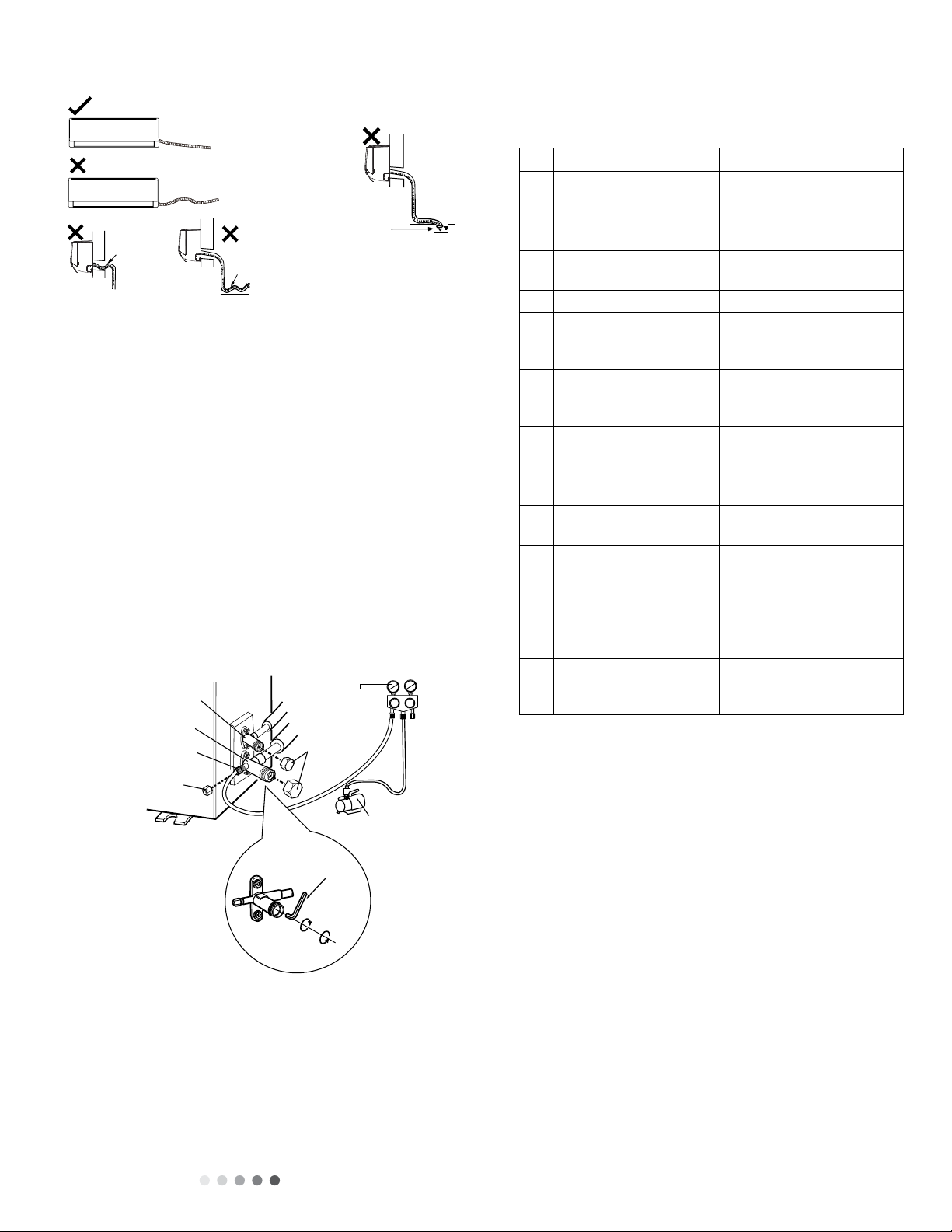

2.6 INSTALLATION OF OUTDOOR UNIT

1. Support of Outdoor Unit

• Select according to actual installation situation. Select

installation location according to the structure.

• Affix outdoor unit support with expansion screws.

!

Note:

• Use personal protection equipment while performing

installation.

• Prep the outdoor unit to support up to four times the weight of

the unit.

• Outdoor unit should be installed at least 1 1/16” above the floor

in order to install drain joint. (Shown in Figure #18 below).

• Six expansion screws should be used for units with cooling

capacities of 2,300W – 5,000W.

• Eight expansion screws should be used for units with cooling

capacities of 6,000W – 8,000W.

• Ten expansion screws should be used for units with cooling

capacities of 10,000W – 16,000W.

2. Install Drain Joint

• Connect outdoor drain joint to the hole in the chassis.

• Connect drain hose to drain vent (Shown in Figure #19

above).

3. Outdoor Unit

• Place outdoor unit on support.

• Affix the foot holes of the outdoor unit with appropriate

bolts. (Shown in Figure #20 below).

4. Connect Indoor and Outdoor Pipes

• Remove screw on right cable cross plate sub-assy and valve

cover of outdoor unit then remove the cable cross plate sub-

assy and valve cover (Shown in Figure #21 above).

• Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe (Shown in Figure #22 below).

• Pretighten the union nut by hand.

• Tighten the union nut with torque wrench. Refer to table.

Refer to the following table for wrench moment of force:

Hex nut diameter(inch) Tightening Torque (ft:lb)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

5. Connect Outdoor Electric Wire

• Insert power connection wire and power wire through wire-

passing hole.

• Remove wire clip and connect the power connect wire and

the power wire to wiring terminal. Affix with screws (Shown

in Figure #23 below).

• Affix the power connection wire and power wire with wire

clip.

• Install the cable cross plate sub-assy.

!

Note:

• After tightening the screw, pull the power cord slightly to check

if it is firm.

• NEVER cut the power connection wire to prolong or shorten

the overall length of the wire.

• Connecting wire and connection pipe CANNOT touch each

other.

• Top cover of outdoor unit and electric box assembly should

be secured by screws. WARNING: Water and dust can cause

short circuit and fire if top cover is not secured.

6. Neaten the Pipes

• Pipes should be placed along the wall, reasonably bent and

hidden if possible. Minimum semi-diameter of bending pipe

is 4 inches.

• If outdoor unit is higher than wall hole, set U-shaped curve

in pipe before inserting into wall hole in order to prevent rain

from getting in the room (Shown in Figure #24 below).

!

Note:

• The through-wall height of drain hose should not be higher

than the outlet pipe hole of the indoor unit (Shown in Figure

#25 above).

• Angle drain hose slightly downward. Drain hose CANNOT be

curved or bent (Shown in Figure #26 above).

• In order to drain smoothly, the water outlet CANNOT be placed

in water (Shown in Figure #27 below).

58 Installation and Maintenance

Service Manual

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 3/16 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

(1) The through-wall height of drain hose shouldnt be higher

than the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose

cant be curved, raised and uctuant, etc.(As show in Fig.26)

Note:

Note:

Note:

The drain hos

can't raise

upwards

gas pipe

Liquid pipe

Liquid

valve

gas valve

Union nut

Pipe joint

Foot holes

Foot holes

8.6 Installation of Outdoor Unit

1. Fix the Support of Outdoor Unit(Select it according to

the actual installation situation)

(1) Select installation location according to the house structure.

(2) Fix the support of outdoor unit on the selected location with

expansion screws.

5. Connect Outdoor Electric Wire

(1) Let the connection wire sleeve go through the two holes of

bafe; tighten the connection joint of sleeve and bafe; remove

the wire clip; connect the power connection wire and power

cord to the wiring terminal according to the color; x them with

screws.(As show in Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably

and hidden possibly. Min. semidiameter of bending the pipe is 3

15/16inch.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room,

in order to prevent rain from getting into the room.(As show in

Fig.24)

(2) Fix the power connection wire and power cord with wire clip.

(3) Fix the stopper on handle with screw.

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the chassis.

(2) Connect the drain hose into the drain vent.

(As show in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2) Fix the foot holes of outdoor unit with bolts.

(As show in Fig.20)

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle and valve cover of

outdoor unit and then remove the handle and valve cover.(As

show in Fig.21)

(2) Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe.(As show in Fig.22)

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Refer to the following table for wrench moment of force:

Fig.18 Fig.19

Fig.20 Fig.21

Fig.22

Fig.23

Fig.24

Fig.25

U-shaped curve

Wall

Drain hose

A

t least 1 3/16 inch above the floo

r

Chassis

Outdoor drain join

t

Drain hose

Drain ven

t

Handle

Valve cover

Note: the wiring board is for reference only,please refer to the

actual one.

Handle

Indoor unit connection

POWER

N(1) 23L1

L1

L2 G

L2

(blue)

white (blue)

whitered

black

(brown)

(brown)

black

(yellow-

green

green) (yellow-

green

green)

58 Installation and Maintenance

Service Manual

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 3/16 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

(1) The through-wall height of drain hose shouldnt be higher

than the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose

cant be curved, raised and uctuant, etc.(As show in Fig.26)

Note:

Note:

Note:

The drain hos

can't raise

upwards

gas pipe

Liquid pipe

Liquid

valve

gas valve

Union nut

Pipe joint

Foot holes

Foot holes

8.6 Installation of Outdoor Unit

1. Fix the Support of Outdoor Unit(Select it according to

the actual installation situation)

(1) Select installation location according to the house structure.

(2) Fix the support of outdoor unit on the selected location with

expansion screws.

5. Connect Outdoor Electric Wire

(1) Let the connection wire sleeve go through the two holes of

bafe; tighten the connection joint of sleeve and bafe; remove

the wire clip; connect the power connection wire and power

cord to the wiring terminal according to the color; x them with

screws.(As show in Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably

and hidden possibly. Min. semidiameter of bending the pipe is 3

15/16inch.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room,

in order to prevent rain from getting into the room.(As show in

Fig.24)

(2) Fix the power connection wire and power cord with wire clip.

(3) Fix the stopper on handle with screw.

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the chassis.

(2) Connect the drain hose into the drain vent.

(As show in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2) Fix the foot holes of outdoor unit with bolts.

(As show in Fig.20)

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle and valve cover of

outdoor unit and then remove the handle and valve cover.(As

show in Fig.21)

(2) Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe.(As show in Fig.22)

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Refer to the following table for wrench moment of force:

Fig.18 Fig.19

Fig.20 Fig.21

Fig.22

Fig.23

Fig.24

Fig.25

U-shaped curve

Wall

Drain hose

A

t least 1 3/16 inch above the floo

r

Chassis

Outdoor drain joint

Drain hose

Drain ven

t

Handle

Valve cover

Note: the wiring board is for reference only,please refer to the

actual one.

Handle

Indoor unit connection

POWER

N(1) 23L1

L1

L2 G

L2

(blue)

white (blue)

whitered

black

(brown)

(brown)

black

(yellow-

green

green) (yellow-

green

green)

58 Installation and Maintenance

Service Manual

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 3/16 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

(1) The through-wall height of drain hose shouldnt be higher

than the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose

cant be curved, raised and uctuant, etc.(As show in Fig.26)

Note:

Note:

Note:

The drain hos

can't raise

upwards

gas pipe

Liquid pipe

Liquid

valve

gas valve

Union nut

Pipe joint

Foot holes

Foot holes

8.6 Installation of Outdoor Unit

1. Fix the Support of Outdoor Unit(Select it according to

the actual installation situation)

(1) Select installation location according to the house structure.

(2) Fix the support of outdoor unit on the selected location with

expansion screws.

5. Connect Outdoor Electric Wire

(1) Let the connection wire sleeve go through the two holes of

bafe; tighten the connection joint of sleeve and bafe; remove

the wire clip; connect the power connection wire and power

cord to the wiring terminal according to the color; x them with

screws.(As show in Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably

and hidden possibly. Min. semidiameter of bending the pipe is 3

15/16inch.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room,

in order to prevent rain from getting into the room.(As show in

Fig.24)

(2) Fix the power connection wire and power cord with wire clip.

(3) Fix the stopper on handle with screw.

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the chassis.

(2) Connect the drain hose into the drain vent.

(As show in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2) Fix the foot holes of outdoor unit with bolts.

(As show in Fig.20)

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle and valve cover of

outdoor unit and then remove the handle and valve cover.(As

show in Fig.21)

(2) Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe.(As show in Fig.22)

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Refer to the following table for wrench moment of force:

Fig.18 Fig.19

Fig.20 Fig.21

Fig.22

Fig.23

Fig.24

Fig.25

U-shaped curve

Wall

Drain hose

A

t least 1 3/16 inch above the floo

r

Chassis

Outdoor drain joint

Drain hose

Drain ven

t

Handle

Valve cover

Note: the wiring board is for reference only,please refer to the

actual one.

Handle

Indoor unit connection

POWER

N(1) 23L1

L1

L2 G

L2

(blue)

white (blue)

whitered

black

(brown)

(brown)

black

(yellow-

green

green) (yellow-

green

green)

58 Installation and Maintenance

Service Manual

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 3/16 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

(1) The through-wall height of drain hose shouldnt be higher

than the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose

cant be curved, raised and uctuant, etc.(As show in Fig.26)

Note:

Note:

Note:

The drain hos

can't raise

upwards

gas pipe

Liquid pipe

Liquid

valve

gas valve

Union nut

Pipe joint

Foot holes

Foot holes

8.6 Installation of Outdoor Unit

1. Fix the Support of Outdoor Unit(Select it according to

the actual installation situation)

(1) Select installation location according to the house structure.

(2) Fix the support of outdoor unit on the selected location with

expansion screws.

5. Connect Outdoor Electric Wire

(1) Let the connection wire sleeve go through the two holes of

bafe; tighten the connection joint of sleeve and bafe; remove

the wire clip; connect the power connection wire and power

cord to the wiring terminal according to the color; x them with

screws.(As show in Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably

and hidden possibly. Min. semidiameter of bending the pipe is 3

15/16inch.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room,

in order to prevent rain from getting into the room.(As show in

Fig.24)

(2) Fix the power connection wire and power cord with wire clip.

(3) Fix the stopper on handle with screw.

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the chassis.

(2) Connect the drain hose into the drain vent.

(As show in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2) Fix the foot holes of outdoor unit with bolts.

(As show in Fig.20)

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle and valve cover of

outdoor unit and then remove the handle and valve cover.(As

show in Fig.21)

(2) Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe.(As show in Fig.22)

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 22.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

Refer to the following table for wrench moment of force:

Fig.18 Fig.19

Fig.20 Fig.21

Fig.22

Fig.23

Fig.24

Fig.25

U-shaped curve

Wall

Drain hose

A

t least 1 3/16 inch above the floo

r

Chassis

Outdoor drain joint

Drain hose

Drain ven

t

Handle

Valve cover

Note: the wiring board is for reference only,please refer to the

actual one.

Handle

Indoor unit connection

POWER

N(1) 23L1

L1

L2 G

L2

(blue)

white (blue)

whitered

black

(brown)

(brown)

black

(yellow-

green

green) (yellow-

green

green)

58 Installation and Maintenance

Service Manual

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 3/16 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

(1) The through-wall height of drain hose shouldnt be higher

than the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose

cant be curved, raised and uctuant, etc.(As show in Fig.26)

Note:

Note:

Note:

The drain hos

can't raise

upwards

gas pipe

Liquid pipe

Liquid

valve

gas valve

Union nut

Pipe joint

Foot holes

Foot holes

8.6 Installation of Outdoor Unit

1. Fix the Support of Outdoor Unit(Select it according to

the actual installation situation)

(1) Select installation location according to the house structure.

(2) Fix the support of outdoor unit on the selected location with

expansion screws.

5. Connect Outdoor Electric Wire

(1) Let the connection wire sleeve go through the two holes of

bafe; tighten the connection joint of sleeve and bafe; remove

the wire clip; connect the power connection wire and power

cord to the wiring terminal according to the color; x them with

screws.(As show in Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably

and hidden possibly. Min. semidiameter of bending the pipe is 3

15/16inch.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room,

in order to prevent rain from getting into the room.(As show in

Fig.24)

(2) Fix the power connection wire and power cord with wire clip.

(3) Fix the stopper on handle with screw.

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the chassis.

(2) Connect the drain hose into the drain vent.

(As show in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2) Fix the foot holes of outdoor unit with bolts.

(As show in Fig.20)

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle and valve cover of

outdoor unit and then remove the handle and valve cover.(As

show in Fig.21)

(2) Remove the screw cap of valve and aim the pipe joint at the

bellmouth of pipe.(As show in Fig.22)

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .