FLOWTECH 103 User manual

1

First Publication Date: 01/09/2020

Revision:

Revision Date:

OPERATION AND

MAINTENANCE MANUAL

VSD - G Inverter

flow

con

©

CONTENTS

OPERATION & MAINTENANCE

General Information 3

Safety Information 4

Safety Warnings & Precautions 5

Customer / Contractor Responsibilities 6

Protection of the environment 7

Sites exposed to ionizing radiations 7

Transportation and Storage 7

Unit handling 7

Storage 8

Technical Description 8

Motor data plate 9

Motor type definition code 9

Pump Data Plate 10

Design and layout 10

Mechanical installation 12

Operation 19

Control panel 20

LEDs description 21

Parameters menu visualization 23

Technical references 30

Troubleshooting 32

Alarm codes 33

Error codes 34

Technical Data 35

Dimensions and weights 36

2

Definitions of Safety Warnings and

Precautions

WARNING!

Indicates a potentially hazardous situation which, if

not avoided, can result in serious injury or death.

CAUTION!

Indicates a potentially hazardous situation which, if

not avoided. Can result in minor to moderate injury, or

serious damage to the product.

General

Information

These instructions are to assist in the installation of the flowcon VSD - G Inverter please follow

them carefully.

If, having read this Operation & Maintenance Manual, there is any doubt about any aspect of

the installation please don't hesitate to contact our technical team.

flowcon VSD - G Inverter

3

Safety

Information

It is essential that correct and safe working practices are adhered to at all times when installing,

operating and/or maintaining any piece of equipment. Always consult safety data sheets, operating

and maintenance manuals, Health & Safety legislation and recommendations and specific

requirements of any equipment manufacturer, site controller, building manager or any other persons

or organisation relating to the procurement, installation, operation and/or maintenance of any piece

of equipment associated or in conjunction with any product provided by flowech Water Solutions.

This document is intended for ALL installers, operators, users and persons carrying out maintenance

of this equipment and must be kept with the equipment, for the life of the equipment and made

available to all persons at all times. Prior to carrying out any work associated with the set it is essential

that the following sheets are read, fully understood and adhered to at all times.

Equipment must only be installed, operated, used, and/or maintained by a competent person. A

competent person is someone who is technically competent and familiar with all safety practices

and all of the hazards involved.

Any damage caused to any equipment by misapplication, mishandling or misuse could lead to risk of

Electrocution, Burns, Fire, Flooding, death or injury to people and/or damage to property dependent

upon the circumstances involved. flowech Water Solutions accepts no responsibility or liability for

any damage, losses, injury, fatalities or consequences of any kind due to misapplication, mishandling

or misuse of any equipment, or as a result of failure to comply with this manual.

Failure to install, operate, use or maintain the equipment in accordance with the information contained

within this document could cause damage to the equipment and any other equipment subsequently

connected to it, invalidating any warranties provided by flowech Water Solutions to the buyer.

4

Safety Warnings &

Precautions

These instructions should be read and clearly understood before working on the system. Please

read this manual carefully and all of the warning signs aached before installing or operating the

equipment keep this manual handy for your reference. This equipment should be installed, adjusted

and serviced by trained and qualified personnel. Failure to observe this precaution could result in

bodily injury.

WARNING! - Install an emergency stop key separately from the isolator. Rotating

shas can be hazardous.

WARNING! - This equipment has a high leakage current and must be permanently

fixed to earth.

WARNING! - Do not aach or remove wiring or connectors when the power is applied.

Do not check signals during operation. When the power is turned on and the running

command is on, the motor will start rotating. The stop key is only eective when the

function is set. If there is a power failure and an operation instruction is given the unit

may start automatically when the power is reinstated.

WARNING! - Make sure that the input voltage is correct. Be sure to install the unit in

a room that is not exposed to direct sunlight and is well ventilated.

Avoid environments which have a high ambient temperature, high humidity or

excessive condensation. Avoid dust. Corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist and salt damage, etc.

WARNING! - Do not connect the power source to any terminals except power

connectors.

WARNING! - Motor control equipment and electronic controllers are connected to

hazardous line voltages. When servicing drives and electronic controllers, you may be

exposed to components at or above the line potential. Extreme care should he taken

to protect against shock. Dangerous voltage may exist aer the power light is o.

Wait more than 5 minutes aer turning o the power supply before performing

maintenance or inspection. Hazard of electric shock. Disconnect incoming power

before working on this unit.

WARNING! - The inverter should be protected separately against ground fault.

Observe the regional regulations for electrical installation!

flowcon VSD - G Inverter

5

Customer / Contractor

RESPONSIBILITIES

It is the responsibility of the customer and/or the contractor:

• To ensure that anyone working on the equipment is wearing all necessary protective gear

and/or clothing.

• Is aware of appropriate health & safety warnings.

• Has read the information in this section of the manual.

CAUTION! - It is strongly recommended that all electrical equipment conforms

to National Electrical Codes and local regulations. Only qualified personnel should

perform installation, alignment and maintenance. The manufacturer reserves the right

to alter the technical data in order to make improvements or update information.

CAUTION! - Failure to observe these rules will render the guarantee invalid. The same

applies to repair jobs and/or replacement. Your legal rights are not aected.

CAUTION! - The manufacturer declines all responsibility in the event of damage or

injury caused as a result of tampering with the equipment.

CAUTION! - Do not switch on/o power supply to run/stop the motor/system! Start

the unit only by using run buon or external run command.

6

Protection of the environment

Disposal of packaging and product

Comply with the current regulations on sorted waste disposal.

Sites exposed to ionizing radiations

If the product has been exposed to ionizing radiations, implement the necessary safety measures for the

protection of people. If the product needs to be despatched, inform the carrier and the recipient accordingly,

so that appropriate safety measures can be put in place.

Spare parts

When contacting Flowtech to request technical information or spare parts, always indicate the product type

and code.

Product warranty

For information on the warranty refer to the documentation of the sale contract.

Transportation and Storage

Packaging inspection

1. Check that quantity, descriptions and product codes match the order.

2. Check the packaging for any damage or missing components.

3. In case of immediately detectable damage or missing parts:

• Accept the goods with reserve, indicating any findings on the transport document, or

• Reject the goods, indicating the reason on the transport document.

• In both cases, promptly contact Flowtech from whom the product was purchased.

Unpacking and inspection of the unit

1. Remove packing materials from the product.

2. Release the product by removing the screws and/or cuing the straps, if fied.

CAUTION: Cut and abrasion hazard

Always wear personal protective equipment.

3. Check the product for integrity and to make sure that there are no missing components.

4. In case of damage or missing components, promptly contact Flowtech.

Unit handling

The unit must be harnessed and lied as shown in Figure 1.

• The product and its components may be heavy: risk of crushing

• Always wear personal protective equipment

• Manual handling of the product and its components must be in compliance with the current

regulations on “manual load handling”, to avoid unfavourable ergonomic conditions causing

• risks of back-spine injury.

• Use cranes, ropes, liing straps, hooks and clasps that comply with current regulations and that are

suitable for the specific use

• Make sure that the harnessing does not damage the unit

• During the liing operations, always avoid sudden movements that could compromise the stability of

the load

• During handling, make sure to avoid injury to people and animals, and/or damage to property.

flowcon VSD - G Inverter

7

Figure 1: Liing

Storage

The product must be stored:

• In a covered and dry place

• Away from heat sources

• Protected from dirt

• Protected from vibrations

• At an ambient temperature between -25°C and +65°C (-13°F and 149°F), and relative humidity

between 5% and 95%.

• Do not place heavy loads on top of the product

• Protect the product from collisions.

Technical Description

Designation

Variable speed pump unit, vertical/horizontal, multi-stage, non self-priming.

Data plates

The data plate is a label showing:

• The main product details

• The identification code

Approval and certifications

For the approvals see the motor data plate:

8

Motor data plate

Figure 2: Motor data plate

1. Type definition code 15. Duty type

2. Rated voltage 16. Enclosure type (NEMA)

3. Rated frequency 17. Weight

4. Rated power [kW] 18. Protection class

5. Rated power [HP] 19. Sha power

6. Part number 20. Voltage

7. Insulation class 21. Current

8. Serial number 22. Part number

9. Maximum ambient temperature 23. Serial number

10. Power factor 24. Power factor

11. Rated current 25. Speed

12. Motor drive eciency 26. Power drive system eciency class (to EN 50598-2)

13. Full power speed range 27. Full load eciency

14. Code leer for locked rotor

Motor type definition code

1. Series

2. Motor frame dimension 90R: Oversized Flange

80: Standard Flange

3. Sha extension □□: Standard sha extension

S8: Custom Sha extension

4. Power supply 1: single phase power supply

3: three phase power supply

5. Sha power•10 [kW] 03: 0.37kW (0.50HP)

05: 0.55 kW (0.75 HP)

07: 0.75 kW (1.00 HP)

11: 1.10 kW (1.50 HP)

15: 1.50 kW (2.00 HP)

22: 2.20 kW (3.00 HP)

6. Motor frame arrangement SVE: Flange with tapped holes and sha w/o keyseat

B14: Flange with tapped holes

B5: Flange with free holes

HMHA: Suitable for 1-5 HM monolithic pumps

HMHB: Suitable for 1-5 HM pumps w/sleeve

HMVB: Suitable for 1-5 VM pumps

flowcon VSD - G Inverter

9

HMHC: Suitable for 10-22 HM pumps

HMVC: Suitable for 10-22 VM pumps

LNEE: Suitable for In-Line pumps

56J: Compliant to NEMA 56 Jet standard

56C: Compliant to NEMA 56C standard

7. Reference market □□: Standard

EU:EMEA

8. Voltage 208-240 : 208-240VAC 50/60Hz

380-460 : 380-460VAC 50/60Hz

230/400: 208-240/380-460VAC 50/60Hz

Pump Data Plate

Figure 4: data plate

1. Head range 9. Maximum operating ambient temperature

2. Flow range 10. Minimum head (EN 60335-2-41)

3. Pump/electric pump unit type definition

code

11. Maximum operating pressure

4. Protection class 12. Electric pump unit weight

5. Frequency 13. Electric pump unit absorbed power

6. Serial number (date + progressive number) 14. Electrical data

7. Electric pump unit/pump part number 15. Maximum operating liquid temperature (uses other

than as EN 60335-2-41)

8. Maximum operating liquid temperature

(uses as EN60335-2-41)

Design and layout

The unit can be fied with the features the application requires

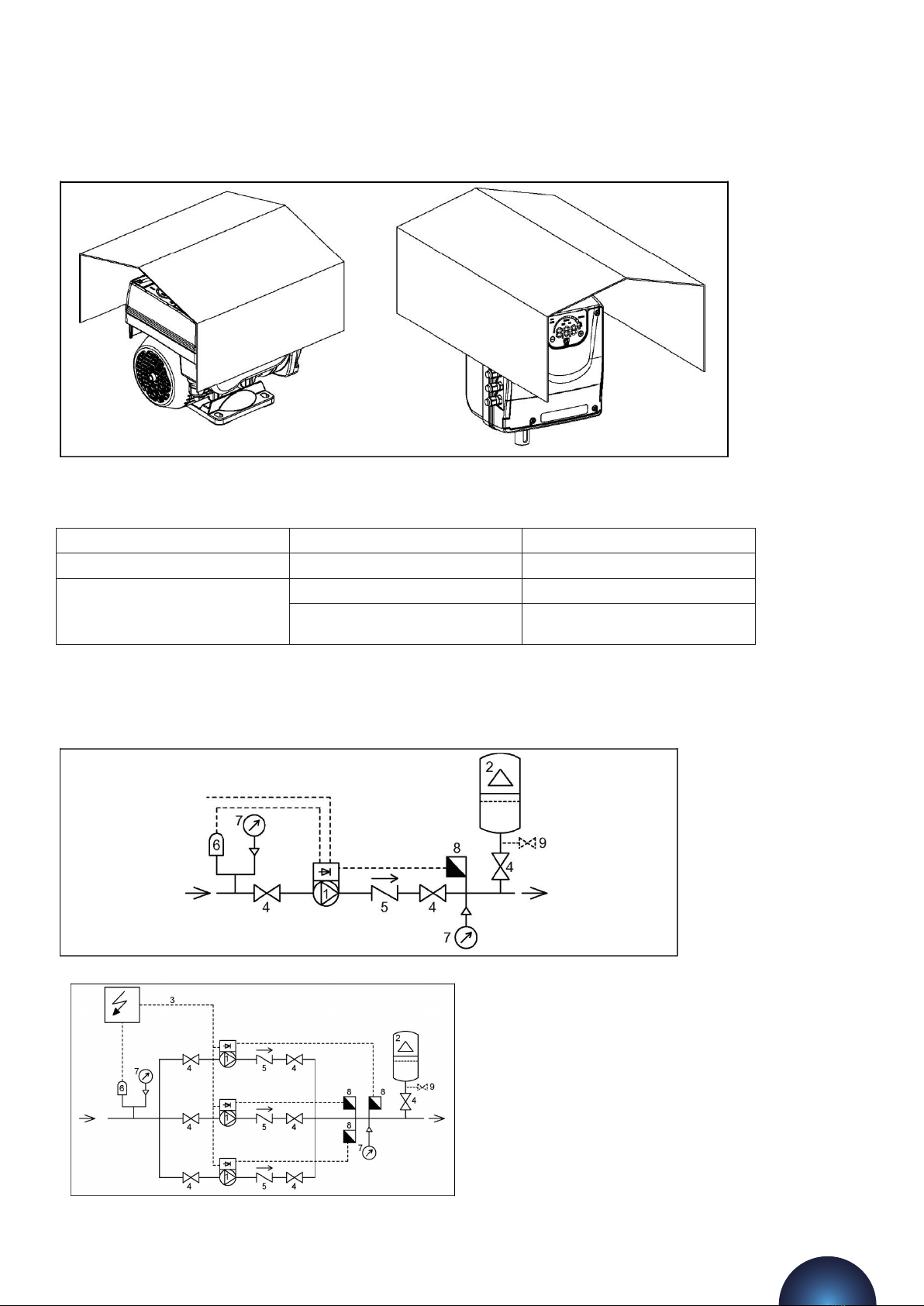

Figure 9: Main components - Single-phase and three-phase models

10

Table 1: Description of components

Position

number

Description Tightening torque ±15%

[Nm] [in•lbs]

1 Screw 1.4 12.4

2 Terminal Box Cover - -

3 Optional module with strip - -

4 M12 I/O cable gland 2.0 17.7

5 M20 cable gland for power supply cables 2.7 23.9

6 M16 I/O cable gland 2.8 24.8

7 Drive (single-phase model) - -

8 Motor - -

9 Screw 6.0 53.1

10 Drive (three-phase model) - -

11 Spacer - -

Pre-assembled ex factory components

Table 2: Included components

Component Quantity Notes

Plug for Cable

Gland

M12 3

M16 1

M20 1

Cable gland and

lock nut

M12 3 Cable Outer Diameter: 3.7 to 7.0 mm (0.145-0.275 in)

M16 1 4.5 to 10.0 mm (0.177-0.394 in)

Cable Gland M20 1 7.0 to 13.0 mm (0.275-0.512 in)

Optional components

Table 3: Optional components

Component Description

Sensors The following sensors can be used with the unit:

Level-sensor

RS485 Module For the connection of a multi-pump system to a supervision system, via

cable (Modb us or BACnet MS/TP protocol)

Wireless Module To connect and interact wireless with e-SM Drive

Adaptor M20 Metric to 1/2” NPT Adapter

The product can be used to pump:

• cold water

• Hot water

The variable speed pump units are made for the following applications:

• Pressure, level, and flow regulation (open loop systems)

• Single or multi pump irrigation systems.

Actuator (constant speed)

The unit operates as an actuator according to speed set point; this is done through user interface, the

corresponding analog input or the communication bus.

Controller (constant pressure)

This mode is set as the default operating mode, and is used for single pump operating units.

Cascade serial / Cascade synchronous

The units are connected via the RS485 interface and communicate via the provided protocol. The

flowcon VSD - G Inverter

11

combination of the dierent units which are used in a multi-pump system depends on the system

requirements.

It is possible to run all pumps in cascade serial mode and cascade synchronous mode as well. If one unit

fails, then each pump of the system can become the lead pump and can take control.

Improper use

The product must not be used for closed loop systems.

Mechanical installation

Installation area

Potentially explosive atmosphere hazard

The operation of the unit in environments with potentially explosive atmospheres or with combustible dusts

(e.g.: wood dust, flour, sugars and grains) is strictly forbidden.

WARNING:

Always wear personal protective equipment

Always use suitable working tools

When selecting the place of installation and connecting the unit to the hydraulic and electric power supplies,

strictly comply with current regulations.

Ensure that the input protection rating of the unit (IP 55, NEMA Type 1) is suitable for the installation

environment.

CAUTION:

Input protection: to ensure the IP55 (NEMA type 1) protection index make sure that the unit is closed correctly.

Before opening the terminal box cover, make sure that there is no water in the unit

Make sure that all unused cable glands and cable holes are correctly sealed

Make sure that the plastic cover is correctly closed

Do not leave the terminal box without cover: risk of damage due to contamination.

Unit installation

See the Quick Startup Guide instructions

Position the unit as shown in Figure 10

Install the unit according to the systems liquid flow.

The arrows on the pump body indicate the flow and the rotation direction

The standard rotation direction is clockwise (looking at the fan cover)

Always install a backflow-prevention device on the suction side.

Always install the pressure sensor on the delivery side, aer the check valve.

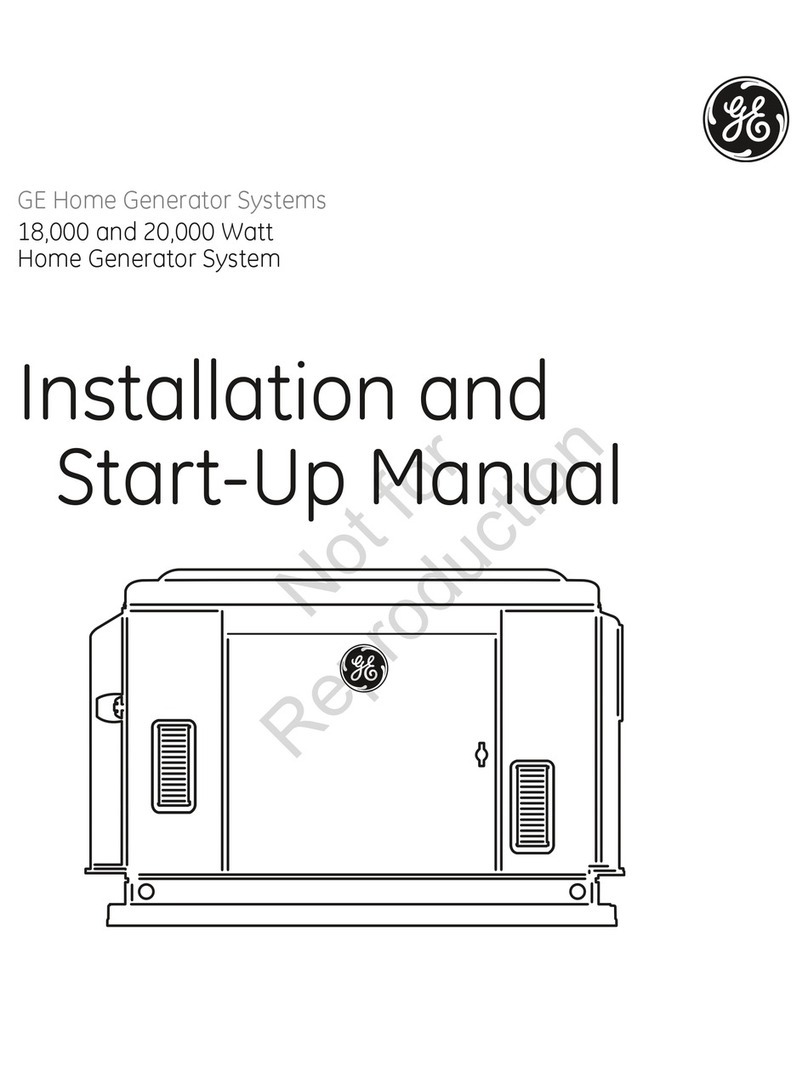

Figure 10: Permied positions

12

Outdoor unit installation

In case of outdoor unit installation, ensure appropriate cover (see example in Figure 11).

The size of the cover must be such that the motor is not exposed to snow, rain or direct sunlight;

comply with the guidelines of Table 16.

Figure 11: Outdoor installation

Minimum spacing

Area Model Free Distance

Above the unit 103..105..107..111..115 > 260mm (10.2 in)

Center-distance between

units (to ensure space for

cabling)

103..105..107..111..115 > 260mm (10.2 in)

303..305..307..311..315..322 ≥ 300mm (11.8 in)

Hydraulic installation

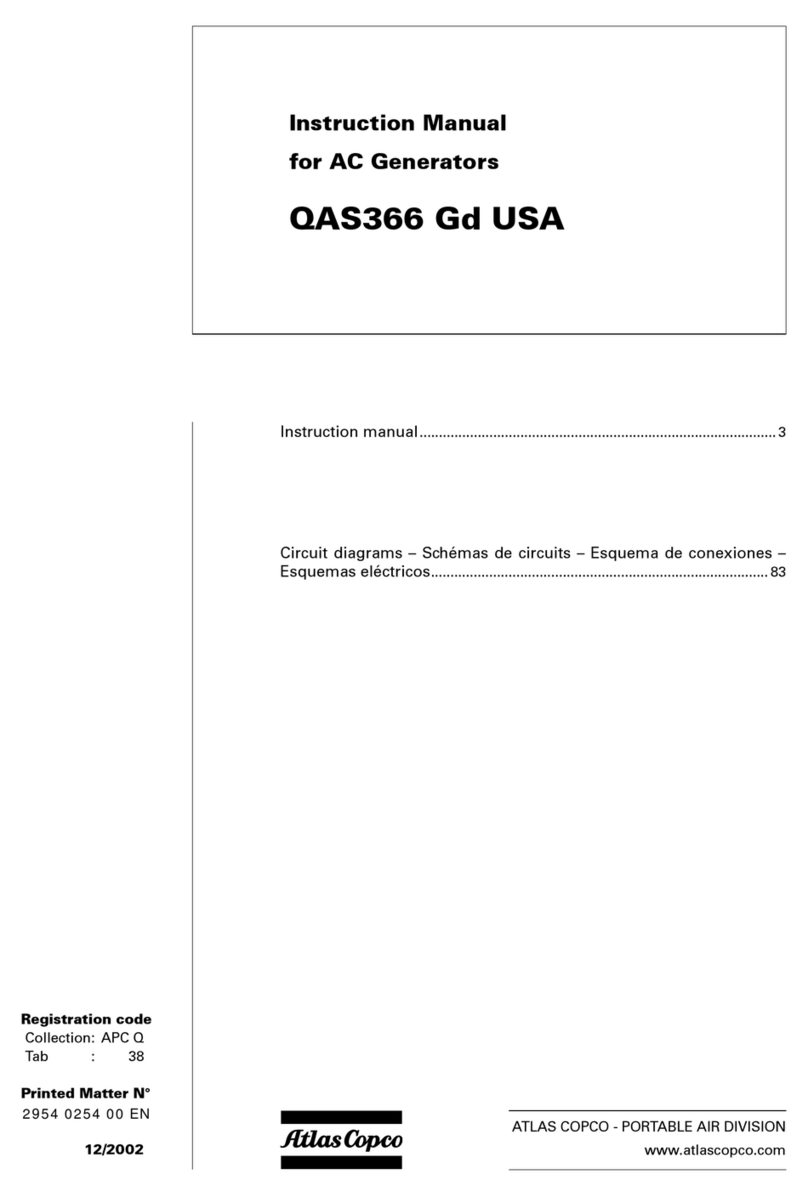

Figure 12 and 13 show a single pump system and a multi-pump system respectively.

NOTICE:

If the system is directly connected to the water network, install a minimum pressure switch on the suction

side.

Figure 12: Single-pump system

Figure 13: Multi-pump system

flowcon VSD - G Inverter

13

1. Pump with Motor Drive

2. Diaphragm pressure tank

3. Distribution panel

4.On-o valve

5. Non-return valve

6. Low water control

7. Pressure gauge

8. Pressure sensor

9. Drain tap

Pressure tank

On the pump delivery side there is a membrane expansion vessel, which gives the possibility of maintaining

the pressure inside the piping when the system is not being used. The unit stops the pump from continuing

to run at zero demand and reduce the size of the tank that is required for supply purposes.

Select a vessel suitable for the system pressure, and pre-load it in accordance with the values indicated in the

Quick Startup Guide.

Electrical Installation

The connection to the electric power supply must be completed by an electrician possessing the technical-

professional requirements outlined in the current regulations.

Electrical requirements

Local directives prevail on the specific requirements indicated below.

Electrical connection checklist

• Check that the following requirements are met:

• The electrical leads are protected from high temperature, vibrations, and collisions.

• The current type and voltage of mains connection must correspond to the specifications on the data

plate on the pump.

• The power supply line is provided with:

• A high-sensitivity dierential switch (30 mA) [residual current device RCD] suitable for

earth fault currents with DC or pulsating DC content (a Type B RCD is suggested).

• A mains isolator switch with a contact gap of at least 3 mm.

The electrical control panel checklist

The control panel must match the ratings of the electric pump. Inappropriate combinations do not guarantee

the protection of the unit.

Check that the following requirements are met:

• The control panel must protect the pump against short-circuit. A time lag fuse or a circuit breaker (Type C

model is suggested) can be used to protect the pump.

• The pump has built in overload and thermal protection, no additional overload protection is required.

•

Electrical hazard

Before starting work on the unit, make sure that the unit and the control panel are isolated from the power

supply and cannot be energized.

Grounding (earthing)

• Always connect the external protection conductor to the ground terminal before aempting to make

any other electrical connections

• Connect all the electric accessories of the pump and the motor to the ground, making sure that the

connections are completed correctly

• Check that the protection conductor (ground) is longer than the phase conductors; in case of acci-

dental disconnection of the power supply conductor, the protection conductor (ground) must be the

last one to detach itself from the terminal.

Use a cable with several strands to reduce electric noise.

14

Wire types and ratings

All cables must comply with local and national standards in terms of section and ambient temperature

Use cables with minimum heat resistance +70°C (158°F); to ensure compliance with UL (Underwriters

Laboratories) regulations, all power supply connections must be completed using the following types of

copper cables with minimum resistance +75°C: THW, THWN

Cables must never enter into contact with the motor body, the pump and the piping.

The wires connected to the power supply terminals and the fault signal relay (NO, C) must be separated from

the others by means of reinforced insulation.

Table 4: Electric connection cables

Models Power supply input cable + PR Tightening Torque

Wire numbers

x Max. copper

section

Wire numbers x

Max. AWG

Mains and

motor cable

terminals

Earth

conductor

103, 105, 107,

111,115

3 x 1.5 mm2

3 x 0.0023 sq.in

3 x 15 AWG Spring

connectors

Spring

connectors

303, 305, 307,

311,315, 322

4 x 1.5 mm2

4 x 0.0023 sq.in

4 x 15 AWG 0.8 Nm

7.1 lb-in

3 Nm

26.6 lb-in

Control cables

External volt free contacts must be suitable for switching < 10 VDC.

:

• Install the control cables separate from the power supply cables and the fault signal relay cable

• If the control cables are installed in parallel with the power supply cable or the fault signal relay, the

distance between the cables must exceed 200 mm

• Do not intersect the power supply cables; should this be necessary, a 90°intersection angle is permit-

ted.

Table 5: Recommended control cables

Drive control

cables

Wires number x Max. copper

Section AWG Tightening torque

All I/O conductors 0.75-1.5 mm

0.00012-0.0023 sq.in 18-16 AWG 0.6 Nm

5.4 lb-in

Power supply connection

Contact with electric components may cause death, even aer the unit has been switched o. Before any

interventions on the unit, the network voltage and any other input voltages must be disconnected for the

minimum time indicated in Table 9.

Table 6: Power supply wiring procedure

1. Open the terminal box cover (2) by removing the screws (1). Fig. 9

2. Insert the power cable in the M20 cable gland (5) Fig 14

3. Connect the cable according to the wiring diagram. Fig. 9

Table 7: I/O wiring procedure

1. Open the terminal box cover (2) by removing the screws (1). Fig. 9

2. Connect the cable according to the wiring diagram. Fig. 15

3. Close the cover (2) and tighten the screws (1). Fig. 9

flowcon VSD - G Inverter

15

Figure 14: Wiring diagram

Figure 15: Connection label

Table 8: I/O terminals

16

1~ Item Terminals Ref. Description Notes

Fault Signal C 4 COM - error status relay

NO 5 NO - error status relay

Auxiliary Voltage

Supply

15V 6 Auxiliary voltage supply +15

VDC

15VDC, max. 100 mA

Analog input 0-10V P2IN/S+ 7 Actuator mode 0-10 V input 0-10 VDC

P2C/S- 8 GND for 0-10 V input GND, electronic ground (for

S+)

External Pressure

sensor [also

Dierential]

P1+ 9 Power supply external sensor

+15 VDC

15VDC, max. 100 mA

P1- 10 External sensor 4-20 mA

input

4-20 mA

External Start/Stop Start 11 External ON/OFF input

reference

Default short circuited Pump

is enabled to RUN

Stop 12 External ON/OFF input

External Lack of

Water

Low + 13 Low water input Default short circuited

Lack of water detection:

enabled

Communication bus Low - 14 Low water reference

B1 15 RS485 port 1: RS485-1N B (-) ACT, HCS control mode:

RS 485 port1 for external

communication

MSE, MSY control mode: RS

485 port 1 for multi-pump

systems

A1 16 RS485 port 1: RS485-1P A (+)

GND 17 Electronic GND

B2 18 RS485 port 2: RS485 port 2:

RS485-2N B (-) active only

with optional module

RS 485 port2 for external

communication

A2 19 RS485 port 2: RS485 port 2:

RS485- 2P A (+) active only

with optional module

GND 20 Electronic GND

flowcon VSD - G Inverter

17

3~

Item Terminals Ref. Description Notes

Fault signal C 25 COM - error status relay In case of power cables: use

the M20 cable gland

NO 24 NO - error status relay

Motor running

signal

C 23 Common contact In case of power cables: use

the M20 cable gland

NO 22 Normally open contact

Auxiliary Voltage

Supply 15V 21 Auxiliary voltage supply +15

VDC 15VDC, max. 100 mA

Analog input

0-10V

S+ 20 Actuator mode 0-10 V input 0-10 VDC

S- 19 GND for 0-10 V input GND, electronic ground (for S+)

External Pressure

sensor [also

Dierential]

P1+ 18 Power supply external sensor

+15VDC 15VDC, max. 100 mA

P1- 17 External sensor 4-20 mA

input 4-20 mA

External pressure

sensor

P2+ 16 Power supply external sensor

+15VDC 15VDC, max. 100 mA

P2- 15 Sensor 4-20 mA input 4-20 mA

External Start/

Stop

Start 14 External ON/OFF input Default short circuited Pump is

enabled to RUN

Stop 13 External ON/OFF input

reference

External Lack of

Water

Low+ 12 Low water input Default short circuited Lack of

water detection: enabled

Low- 11 Low water reference

Communication

Bus

B2 10

RS485 port 2: RS485 port 2:

RS485-2N B (-) active only

with optional module RS 485 port2 for external

communication

A2 9

RS485 port 2: RS485 port 2:

RS485-2P A (+) active only

with optional module

GND 8 Electronic GND

B1 7 RS485 port 1: RS485-1N B (-) ACT, HCS control mode:

RS 485 port 1 for external

communication

Control mode MSE, MSY: RS

485 port 1 for multi-pump

systems

A1 6 RS485 port 1: RS485-1P A (+)

GND 5 Electronic GND

18

Operation

In case of co-existence of two or more of the following conditions:

• High ambient temperature

• High water temperature

• Duty points insisting on unit maximum power

• persisting under voltage of mains, may jeopardise the life of the unit, and/or derating may occur: for further

information contact Flowtech.

Wait times

Contact with electric components may cause death, even aer the unit has been switched o. Before any

interventions on the unit, the network voltage and any other input voltages must be disconnected for the

minimum time indicated in Table 9.

Table 9: Wait times

Model Minimum waiting time (min)

103, 105, 107, 111, 115 4

303, 305, 307, 311, 315, 322 5

Frequency converters contain DC-link capacitors that can remain charged even when the frequency

converter is not powered.

To avoid electrical hazards:

• Disconnect the AC power supply

• Disconnect all types of permanent magnet motors

• Disconnect all DC-link remote power supplies, including the baery backups, the

• Uninterrupted Power Supply units and the DC-link connections to other frequency converters

• Wait for the capacitors to discharge completely before carrying out any maintenance or repairs; see

Table 9 for the waiting times

Programming Precautions

• Carefully read and follow the following instructions before starting the programming activities, to avoid

wrong seings that may cause malfunctioning

• All modifications must be done by qualified technicians.

flowcon VSD - G Inverter

19

Control panel

Figure 16: Control panel

Table 10: Description of the control panel

Position number Position number

1 Decrease buon

2 Increase buon

3 START/STOP and menu access buon

4 POWER LED

5 Status LED

6 Speed LED bar

7 Communication LED

8 Unit of measure LEDs

9 Display

Description of the buons

Table 11: Functions of push buons

Push Buon Function

• Main view: decreases the required value for the selected control mode

• Parameter menu: decreases the displayed parameter index

• Parameter view / editing: decreases the value of the displayed parameter

• Zero pressure auto-calibration: automatic calibration of the pressure sensor.

• Main view: increases the required value for the selected control mode

• Parameter menu: increases the displayed parameter index

• Parameter view / editing: increases the value of the displayed parameter

• Zero pressure auto-calibration: automatic calibration of the pressure sensor.

• Main view: START/STOP the pump

• Parameter menu: switches to parameter view / editing

• Parameter view / editing: saves the value of the parameter.

Long press

• Main view: switches to parameter selection

• Parameters Menu: switches to Main Visualization

+

• Main view: alternates between Speed and Head units of measure.

+

• Main view: alternates between Speed and Head units of measure.

20

This manual suits for next models

10

Table of contents

Other FLOWTECH Inverter manuals

Popular Inverter manuals by other brands

YASKAWA

YASKAWA PVI 23 TL Installation and operation manual

GE

GE HOME NERATOR SYSTEM 18000 WATT Installation and start-up manual

Atlas Copco

Atlas Copco QAS366 Gd USA instruction manual

Winco

Winco W6000HE-03/A Installation & operator's manual

Solectria Renewables

Solectria Renewables PVI 13KW Installation and operation manual

Solax

Solax X3 series Quick installation guide