Contents

1 Introduction........................................................................................................................................1

2 Types of Products...............................................................................................................................1

3 Technical parameters..........................................................................................................................2

4 Installation and connection................................................................................................................2

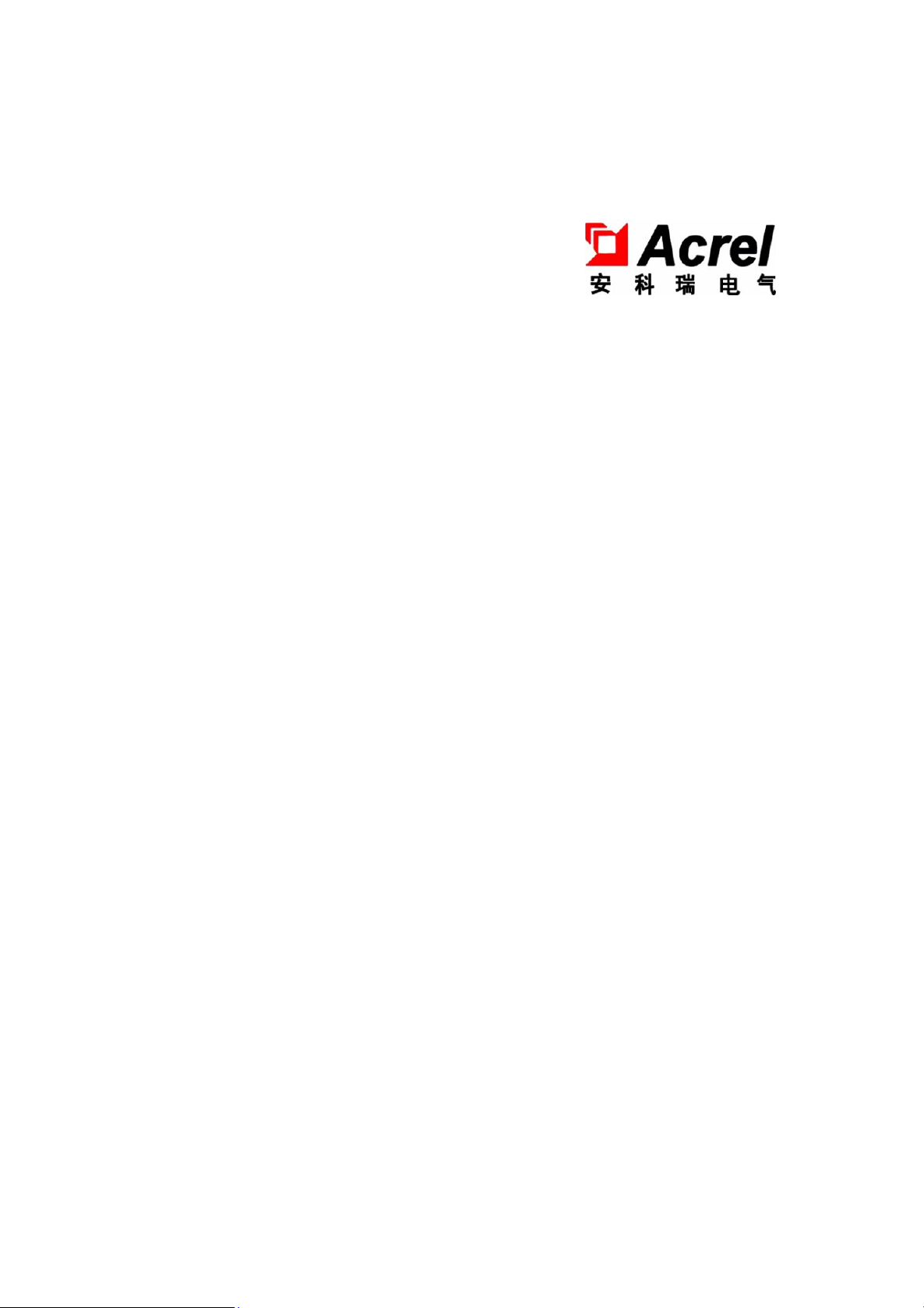

4.1 Shape and Installation Dimensions..........................................................................................2

4.2 Installation Instructions............................................................................................................3

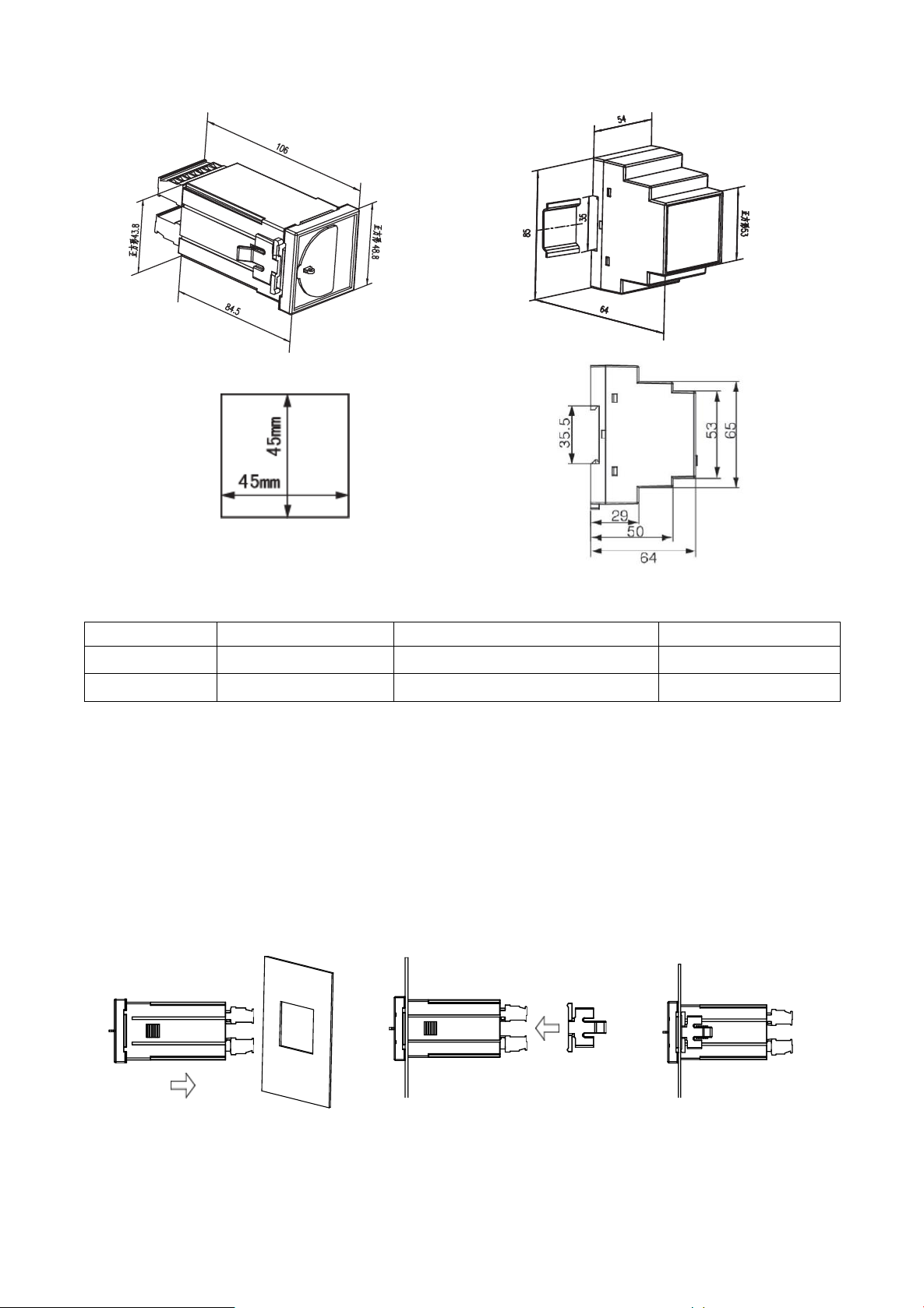

4.2.1 Installation Steps............................................................................................................3

4.2.2 Installation of accessories..............................................................................................4

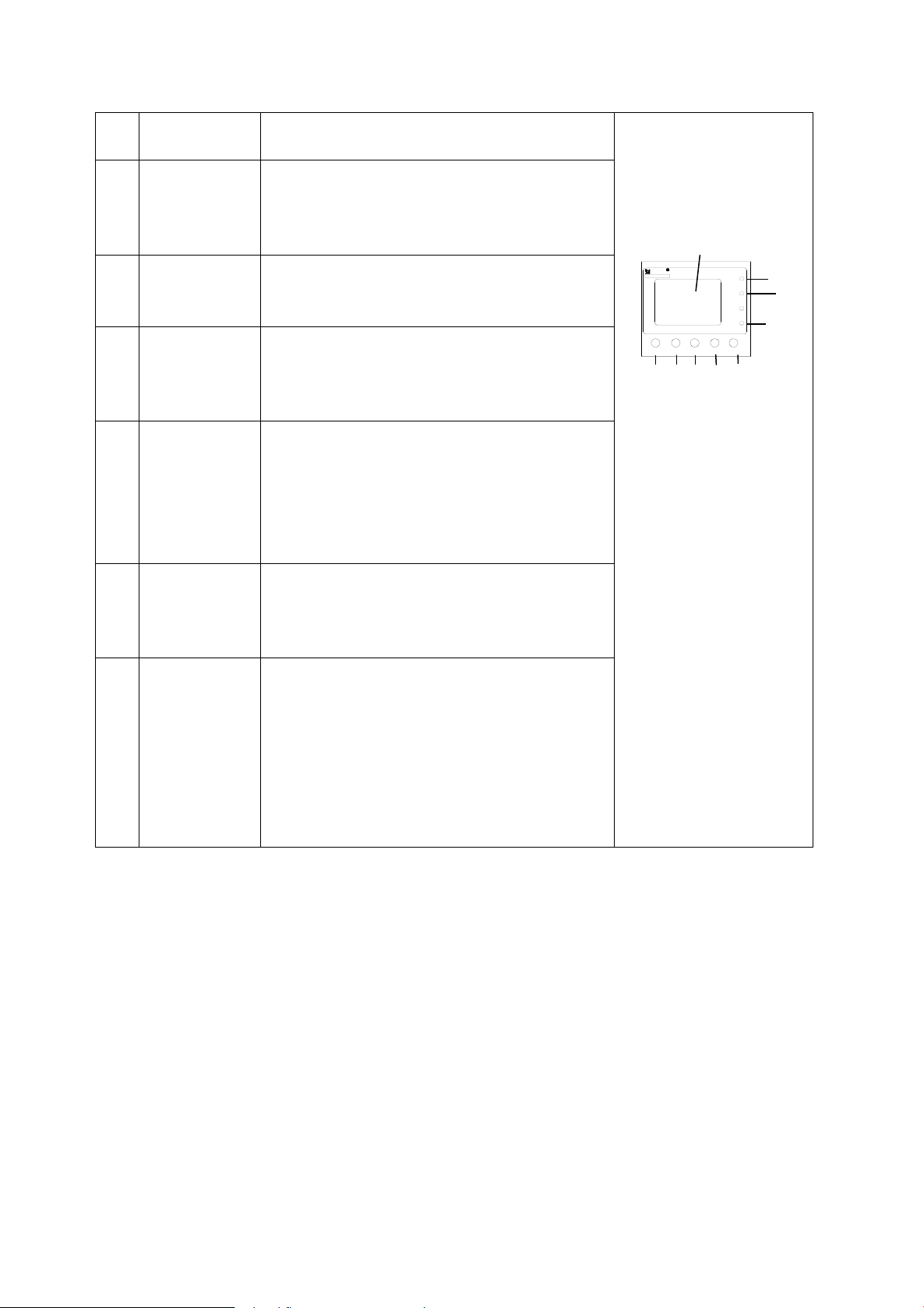

4.3 Terminals and wiring ...............................................................................................................4

4.4 Matters needing attention.........................................................................................................4

5 Operating Guide.................................................................................................................................5

5.1 Description of AC type Panel ..................................................................................................5

5.2 Description of A-type panel.....................................................................................................5

5.3 Description of LCD type panel................................................................................................5

5.4 Description of Selection...........................................................................................................6

5.5 Instructions for the selection of transformer............................................................................7

6 Typical applications ...........................................................................................................................8

7 Programming menu............................................................................................................................8

7.1 Programming Example ............................................................................................................9

7.2 Programming Example ..........................................................................................................12

8 Communication Guide.....................................................................................................................13

8.1 Overview of Communication Protocol..................................................................................13

8.2 Introduction to function code.................................................................................................14

8.3 Communication Address Table..............................................................................................15

9 Ordering example.............................................................................................................................16