ACS contsys Thermocont TS4S User manual

07.17

Technical manual

Applications

General applications in

• Machinery and plant engineering

• Air-conditioning and refrigeration plant engineering

• Hydraulic and pneumatic systems

• Process industry

• Environmental technology

Thermocont TS4S

Temperature switch for general applications

Monitoring of temperatures

in gases, vapors, liquids and dust

Main features

Wide range of applications

• Wide process temperature range –99,9°C to +500°C

• High process pressure tightness up to 100 bar

• Wide variety of process connections

• High protection class IP65 / IP67

• Wide environmental temperature range –40°C to +85°C

Long term stable temperature sensor platinum Pt100 class A – DIN EN

60751

Increased process safety and cost saving by self-supervising

measuring system for drift monitoring and redundancy function

High accuracy – characteristic deviation ≤ 0,5% of measuring range

Short response time

Integrated evaluation electronic

• Digital display, function LED’s, keyboard

• 2x PNP switch output

• 1x current output 4…20mA

• Connector plug M12

High operating comfort

• Enclosure and display rotatable for optimal operability in each

installation position

• Robust high brightness LED display for best readability

• 3-key operation without additional assistance with tactile feedback

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

2

You have purchased a high-grade and modern measuring device of ACS-CONTROL-SYSTEM GmbH.

We want to give thanks for your purchase and for your condence to us.

The actual technical manual includes instructions for installation, electrical connection and inauguration,

as well as the technical data of the device.

Modications, that answer the purpose of the technical progress, are reserved by

ACS-CONTROL-SYSTEM GmbH without prior notice.

If a question occurs, that can‘t be answered by the listed informations, please call on our technicians

All rights reserved

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 3

1 Index

1 Systemdescription................................................4

1.1 Intended use................................................... 4

1.2 Field of application ........................................... 4

1.3 System components ......................................... 5

1.4 Function ......................................................... 5

2 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Operational safety............................................ 6

2.2 Installation, connection, commissioning, operation6

3 Installation......................................................7

3.1 Installation place ............................................. 7

3.2 Process and environmental temperature ............. 8

3.3 Installation notes ............................................. 8

4 Electricalconnection ..............................................9

4.1 Potential equalization – earthing ........................ 9

4.2 Connection cable ............................................. 9

4.3 Supply voltage ................................................ 9

4.4 Load resistor .................................................. 9

4.5 Switch output.................................................. 9

4.6 Connection scheme .......................................... 10

5 Operation......................................................11

5.1 Operation and display parts............................... 11

5.2 Function modes ............................................... 11

5.3 Switch output S1 / S2 ...................................... 12

5.4 Current output ................................................ 13

5.5 Self-supervising function................................... 14

5.6 Menu structure ................................................ 15

5.7 Parameter overview ......................................... 18

5.8 Error indication at operation .............................. 21

5.9 Software history .............................................. 21

6 Service........................................................22

6.1 Maintenance.................................................... 22

6.2 Dismounting.................................................... 22

6.3 Repair ............................................................ 22

6.4 Return............................................................ 22

6.5 Disposal ......................................................... 22

7 TechnicalData ..................................................23

7.1 Auxiliary power supply...................................... 23

7.2 Output Switch output ....................................... 23

7.3 Output current 4…20mA ................................... 23

7.4 Measuring accuracy.......................................... 23

7.5 Process conditions............................................ 24

7.6 Environmental conditions .................................. 25

7.7 Materials - process wetted ................................ 25

7.8 Materials - not process wetted ........................... 25

8 Dimensiondrawings..............................................26

8.1 Terminal enclosure ........................................... 26

8.2 Process connection........................................... 26

8.3 Sensor tube .................................................... 27

9 Orderinginformation.............................................28

9.1 Order code...................................................... 28

9.2 Additional options ............................................ 29

9.3 Accessories ..................................................... 29

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

4

1 System description

1.1 Intended use

The device is an electronic temperature switch for monitoring, control as well as continuous

measurement of temperatures in gases, vapors, liquids and dusts.

The operational reliability of the device is ensured only at the intended use.

1.2 Field of application

Due to the device construction with

• Process temperature from up to –99,9°C to +500°C

• Process pressures up to 100 bar

• Process contacting material stainless steel V4A

as well as the availability of a variety of process connections like

• connection for compression tting

• thread connections ISO 228-1

• thread connection ISO 228-1 with front-ush O-ring gasket

the device is especially suitable for the use for

• machinery and plant engineering

• air-conditioning and refrigeration plant engineering

• hydraulic and pneumatic systems

• process industry

• environmental technology

• paint and coating industry

The temperature switch is suitable for demanding measuring requirements.

Due to its high accuracy and the high exibility of conguration, the device can be suited a wide

variety of applications.

Compared with temperature sensors, which are calibrated cyclic, the process safety increases when

using the temperature switch with self-supervision. At cyclic calibration an occurring drift will be

also detected, but an undened time it has been produced with a drift aected sensor. Because the

device generates a signal immediately at exceedance of the set drift limit, it must not be waited until

to the end of the calibration interval. Thus the process safety and with this the product quality will be

improved signicantly.

Besides the increased process safety, the use of the temperature switch with self-supervision

allows substantial cost savings. Due to the use of two redundantly working sensors, which are

mutually monitored, the calibration intervals can be increased und thus calibrations can be saved.

Although the device is a little bit more expensive at the acquisition costs than a standard temperature

sensor, when saving only one calibration the acquisition price will pay o shortly.

The pressure switch with front-ush O-ring gasket has been specically designed for the measurement

of viscous, paste-like, adhesive, crystallizing, particle-laden and contaminated media. The process

connection is supplied with a positive seal. A reliable, dead-space free sealing between the process

connection and the process adapter resp. measuring medium is thus assured.

The robust design and the high-quality workmanship turns the device into a very high quality

product, which even the most adverse environmental conditions cannot aect, whether the lowest

temperatures when used outdoors, extreme shock and vibration or aggressive media.

A captive laser marking of the type label ensures the identiability throughout the entire lifetime of

the device.

Obviously is the optional marking of a measurement point designation resp. TAG, a customer label or

of a neutral type label, of course also per laser marking.

A LABS-free resp. silicone-free version, a factory calibration with calibration certicate and a customer

specic conguration resp. preset is also optionally available like a material test certicate EN10204

3.1 or factory certications for drink water resp. food suitability.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 5

Customer specic special versions can be realized short-term on request, e.g.

• software adaption (menu navigation, special functions, etc.),

• changed terminal assignment resp. connector orientation,

• design adaption of the user surface,

• special designs for the process connection

thread connection acc. to ANSI NPT, DIN 13 or JIS

thread connection ISO 225-1 - M18x1,5, inner thread

• other process materials, e.g. Hastelloy, Titan, etc.

• surface coating, e.g. PTFE

• special adjustment

1.3 System components

The device consists on the components:

• Sensor tube, as junction point in direct contact with the applied medium.

• Process connection, for installation into the wall of the container or of the pipeline.

• Neck tube, for decoupling of the terminal enclosure from high process temperatures.

• Terminal enclosure, rotatable by 300°, for protection of the integrated signal processing

electronic and for the electrical connection.

The components cannot be separated by the user.

1.4 Function

1.4.1 Measuring principle

The detection of the process temperature is made by the measurement of the temperature dependent

change of resistance of a precise and long term stable resistive temperature sensor Pt100 class A,

which is installed in the sensor tube.

1.4.2 Self-supervision function

At the self-supervising measuring system with drift monitoring and redundancy function the recording

of the Temperature is made additionally by a semiconductor temperature sensor.

Because of the parallel measurement with two physically dierent thermal coupled sensor elements,

the device detects impermissible drifts of a sensor and errors at the temperature measurement

automatically.

At the failure of one of the two sensor elements the temperature measurement can be also continued

with the second element, what realizes a redundancy function.

1.4.3 Signal processing

The temperature signal is converted by the temperature sensor into an electrical signal and processed

by the integrated evaluation electronic according to the respective preferences:

• The measuring value is monitored by two PNP switch outputs for exceedance of limit values.

• The measuring value is converted into a continuous current signal 4...20mA.

• The measuring value is displayed at the robust high brightness LED display.

• Several function LED’s signal the device state.

• All settings can be changed comfortable and easy by a 3-key operation without additional

assistance with tactile feedback.

The device includes numerous functions to the adaption to nearly each measuring task:

• Adjustable measuring range down to 25% of nominal measuring span

• Integrated unit conversion °C – °K – °F

• Peak value memory minimum – maximum

• Error memory for fast failure analysis

• Hysteresis or window function, time delay and working principle of the switch outputs

• Error indication function to switch output, current output and display

• Simulation of the switch outputs and the current output

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

6

2 Safety notes

2.1 Operational safety

The device is safely built and tested according to state-of-the-art technology and has left the factory in

perfect condition as regards technical safety.

The device meets the legal requirements of all relevant EU directives. This is conrmed by attaching

the CE mark.

This measuring device meets article 4 (3) of the EU directive 2014/68/EU (pressure equipment device

directive) and is designed and produced in good engineer practice.

2.2 Installation, connection, commissioning, operation

Installation, electrical connection, commissioning and operation of the device must be made by a

qualied and authorized expert according to the information’s in this technical manual and the relevant

standards and rules. This expert must have read and understood this technical manual and especially

the safety notes.

The device may only be used within the permitted operation limits that are listed in this technical

manual. Every use besides these limits as agreed can lead to serious dangers.

The materials of the device must be checked for compatibility with the respective application

requirements (contacting materials, process temperature) before use. An unsuitable material can lead

to damage, abnormal behavior or destruction of the device and to the resulting dangers.

The sensors may not be used as sole device for prevention of dangerous conditions in machines and

plants.

Using the device in a manner that does not fall within the scope of its intended use, disregarding

this instruction, using under-qualied personnel, or making unauthorized alterations releases the

manufacturer from liability for any resulting damage. This renders the manufacturer‘s warranty null

and void.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 7

3 Installation

The correct function of the device within the specic technical data can only be guaranteed, if

the permitted process and environmental temperatures (see chapter „Technical data“) will not be

exceeded.

3.1 Installation place

The choice of the place of installation of the sensor and the length of the sensor tube are of

considerable importance for the quality and the reliability of the measuring results.

If the sensor isn’t installed deeply enough, an error in the measured temperature can occur because of

the dierent process ow temperature at the pipeline wall and the heat transfer along the sensor tube.

The appearance of the error should not be ignored if a considerable dierence between process

temperature and environmental temperature exists.

Thus it is suggested to use an installation length of at least 80...100 mm.

The shorter the installation length, the greater is the deviation against the real medium temperature

caused by the heat transfer.

The following general recommendations can be applied as approximately guideline:

• In liquids, the sensor tube length should be 5...6 times greater than the diameter of the

sensor tube plus the sensitive length of 50 mm.

• In steam, air and gases, the sensor tube length should be 10...15 times greater than the

diameter of the sensor tube plus the sensitive length of 50 mm.

In pipelines with small diameter the tip of the sensor tube should reach the axis line, that means the

middle of the pipeline, and if possible additionally a little more.

By isolating the external parts of the sensor, the eect caused by too low installation depth, can be

reduced.

An additional solution for optimizing the measurement quality of small formatted pipelines could be

the installation of the sensor tube diagonal to the pipeline longitudinal axis or the installation of the

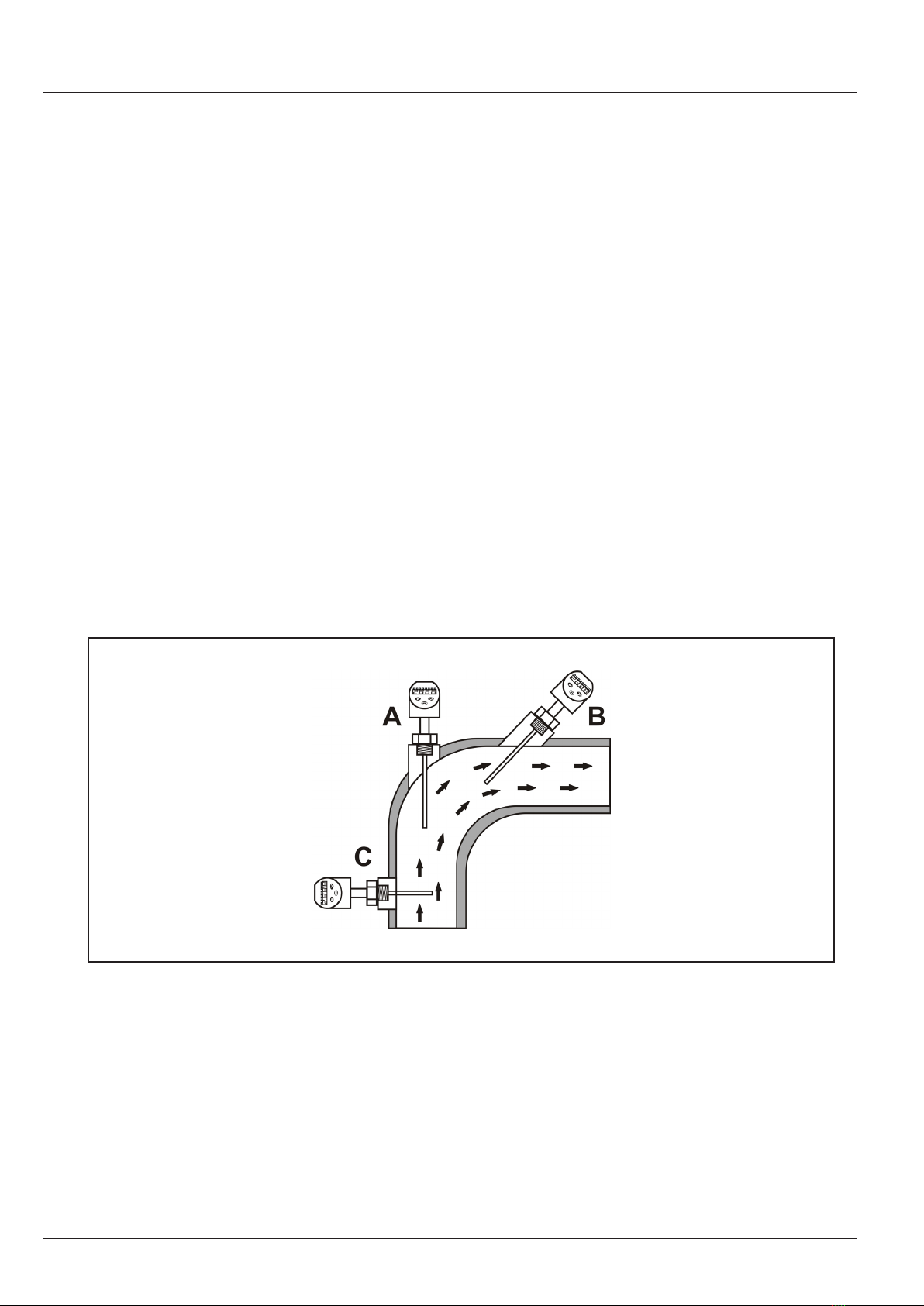

sensor tube in the pipeline arc.

A) In the pipe arc against the ow direction

B) In small pipes diagonal against the ow direction

C) Vertical to the ow direction

At a horizontal installation, especially in hygienic applications, the probe should be installed with a

decline against the horizontal of minimum 3°, to ensure a self-emptying.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

8

3.2 Process and environmental temperature

At high process temperatures a heat transfer to the terminal enclosure can be reduced by isolation of

the medium carrying part of the plant or by the use of a neck tube.

3.2.1 Neck tube

The neck tube is used to decouple the temperatures between medium and the terminal enclosure in

order to reduce the temperature at the terminal enclosure.

By using a neck tube at extreme process temperatures it can be achieved, that the permitted

environmental temperature range in the area of the terminal enclosure will not be exceeded.

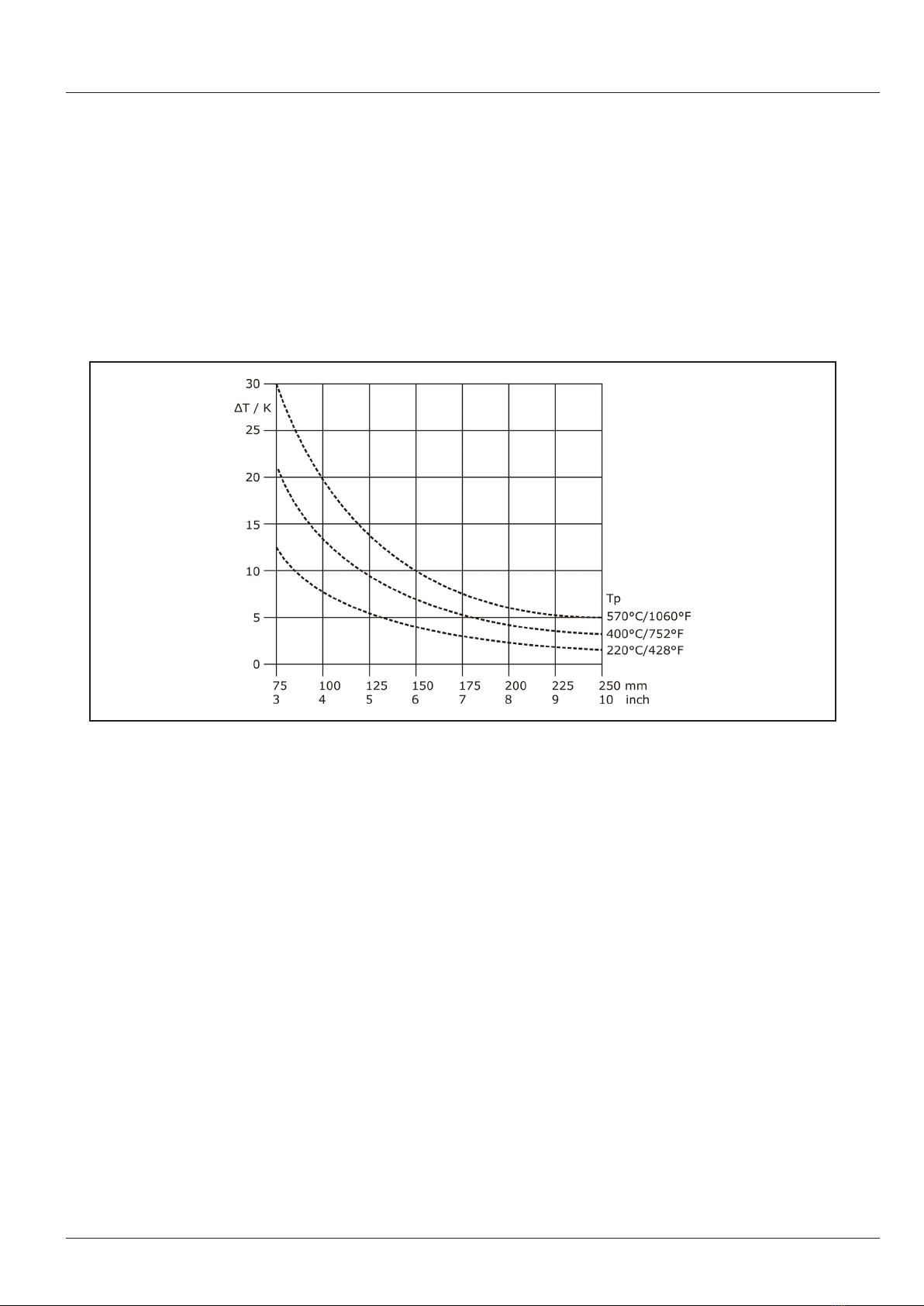

The length of the needed neck tube depends on the height of the process temperature and the

respective installation situation.

Like shown in the graphic, the length of the neck tube can considerably inuence the temperature at

the terminal enclosure.

The graphic is only an approximately guide, because the real heating of the terminal enclosure can be

inuenced by additional factors, e.g. a system isolation or also the position of the terminal enclosure.

3.3 Installation notes

Drive the system pressure free prior installation resp. deinstallation of the sensor.

Be sure that no medium is owing in the system. At extreme system or medium temperatures there

could exist serious dangers.

The screw-in of the thread process connection by using the terminal enclosure, the connection plug

resp. the connection cable is not permitted.

The tightening of the thread process connection may only be done at the hexagon by a suitable

spanner and with the maximum permitted torque strength (see chapter „Technical data“).

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 9

4 Electrical connection

The electrical connection of the device must be carried out according to the respective country specic

standards.

Incorrect installation or adjustment could cause applicationally conditioned risks.

Warning!

The instrument may only be installed if the supply voltage is switched o.

4.1 Potential equalization - earthing

The device must be grounded.

The earthing can be carried out by the metallic process connection.

The metallic parts of the device are electrically connected with the socket of the plug M12.

4.2 Connection cable

Use only shielded signal and measurement wires and install these wires separated from power leading

wires.

Connect the cable shield of a connected cable only at one side to earth, ideally at the installation place

of the device.

4.3 Supply voltage

The voltage applied to the terminal contacts may not exceed the maximum permitted supply voltage

to avoid damage of the electronic.

The maximum permitted supply voltage range is:

All versions 10,5…35VDC

All connections are reverse polarity protected.

4.4 Switch output

Warning!

Inductive loads at the PNP switch outputs, e.g. relays, contactors or magnetic vents may only be used

with a free-wheeling diode or a RC protection circuit to avoid high voltage peaks.

Note!

For inauguration it is suggested, to deactivate all connected control devices, to avoid unwanted control

reactions.

The load at the PNP switch output will be connected to the terminal +L of the supply voltage by a

semiconductor switch contactless and by this bounce-free.

At an activated switch state a positive signal near supply voltage is feed to the output.

At deactivated switch state and at failure of supply voltage the semiconductor switch is shut o.

The PNP switch output is current limited, overload and short circuit protected.

4.5 Analogue output

4.5.1 Current output – Load resistor

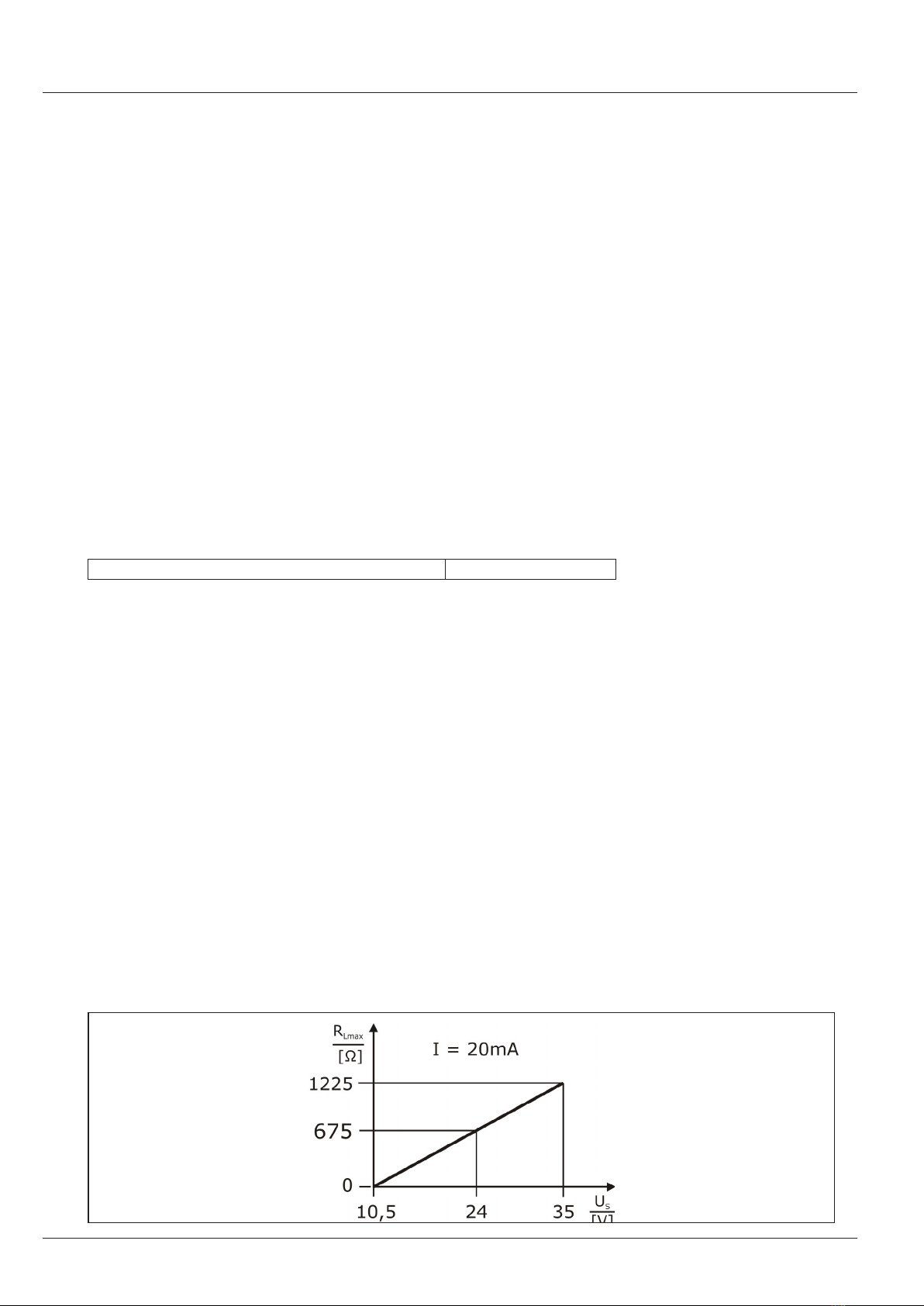

A load resistor, e.g. the measuring shunt of an evaluation device, requires a minimum supply voltage.

Dependent on the connected supply voltage and the maximum output current, it results in a maximum

value for this resistor, where a correct function is still possible.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

10

4.6 Connection scheme

Conductor color standard connection cable M12 – A-coded:

• BN = brown

• WH = white

• BU = blue

• BK = black

• GY = grey

1.1.1 Electronic output type A

2x switch PNP, supply 24VDC

1.1.2 Electronic output type B

1x signal 4…20mA, 1x switch PNP, supply 24VDC

1.1.3 Electronic output type C

1x signal 4…20mA, 2x switch PNP, supply 24VDC

1.1.4 Electronic output type D

1x signal 4…20mA, 1x switch PNP, supply 24VDC / Desina conformal

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 11

5 Operation

5.1 Operation and display parts

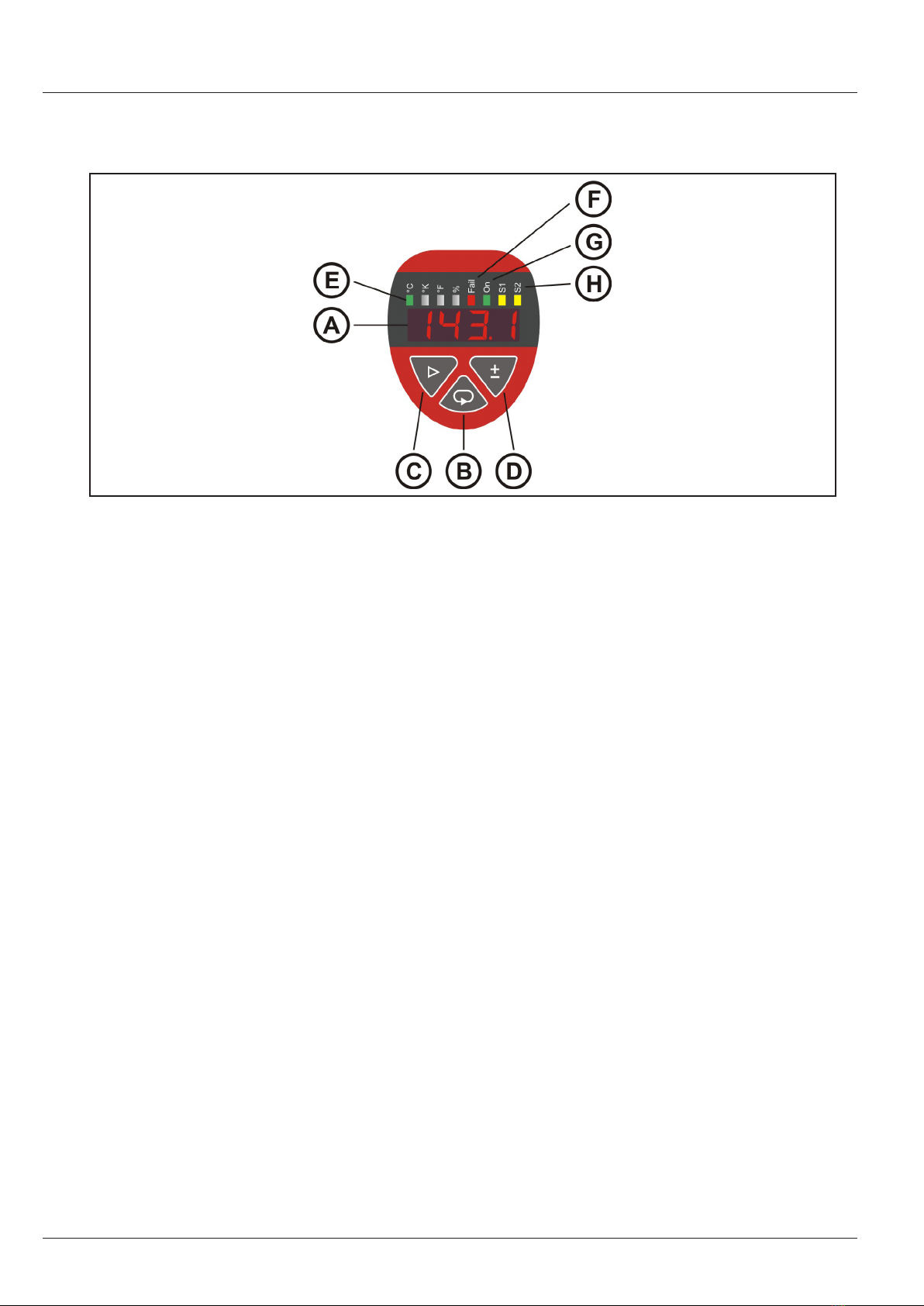

A – LED display

• Display of measuring value and operation menu

B - Key Set

• Access to operation menu

• In the selection menu entering the selected sub menu

• In the set menu applying the new value

C - Key Change

• Change between sub menu

• Cancel value input without applying

• Changeover the counter advance sense of the key +/- from + resp. increasing to - resp.

decreasing.

D - Key +/-

• Value changing by + resp. increasing or - resp. decreasing. The counter advance sense is at

rst always + resp. increasing. Change counter advance sense by the key Change.

• Change setting in a selection menu

E - Unit LED

• Indication unit by green LED

F - Error indication LED

• Indication abnormal behavior by red LED

G - Operation LED

• Indication ready status by green LED

H - Switch condition LED

• Indication of an active switch output by the respective yellow LED

5.2 Function modes

5.2.1 Run mode

The device records the applied physical measurand and proceeds the chosen functions according to

the set parameter.

The active operation is conrmed by the green operation LED.

The measuring value is displayed in the display window.

The chosen unit is marked through the come on of the respective green unit LED.

The current output and the switch outputs and are driven.

A turned on switch output is signaled by the come on of the respective yellow switch condition LED.

The exceedance of the frame specications, abnormal operation conditions and also device

malfunctions are displayed by the red error indication LED.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

12

5.2.2 Programming mode

Access to the function menus by the key Set.

• In the switch function menu – password 1903 – all the adjustable parameter and functions are

chosen especially for the use of the device as switch.

• In the transmitter function menu – password 3009 – all the adjustable parameter and

functions are chosen especially for the use of the device as transmitter by using the current

output.

• In the switch point menu – password 1111 – only switch resp. switch back point of the PNP

switch output resp. outputs are accessible for fast adjustment. The function of the switch

outputs can be displayed.

5.3 Switch output S1 / S2

5.3.1 Switch point / Reset switch point

The input values refer to the current measuring value or acc. to display scaling.

The reset switch point must be lower or equal to the switch point.

For both switch functions, there is no default minimum dierence (hysteresis) between switch resp.

switch back point resp. between upper and lower switch point.

If the switch back point is set higher or equal to the switch point resp. the lower switch point is set

higher or equal to the upper switch point the switch back point is set automatically to the switch point

resp. the lower switch point is set automatically to the upper switch point.

The red error indication LED is ashing.

In the error memory service (SEr) / error memory (ErrN) there will be the indication of the

concerning switch output (S1oG or S2oG).

5.3.2 Switch delay time / Reset switch delay time

The activation resp. deactivation of the switch output can be biased with a delay time (resolution

0,1s), to realize simple sequence control system.

5.3.3 Operating mode

The operating mode denes the function direction of the switch output.

Normal Open / NO

• At the output there is no signal, if the switch condition is not fullled.

• At the output there is a signal, if the switch condition is fullled.

Normal Close / NC

• At the output there is a signal, if the switch condition is not fullled.

• At the output there is no signal, if the switch condition is fullled.

5.3.4 Hysteresis function

The hysteresis function realizes a stable switch state, independent from system conditioned signal

uctuations around the adjusted set point.

It can be used for realizing a signal controlled two-position control.

The switch range is determined by input the switch point and switch back point.

The switch output is activated, if the current measuring value exceeds the switch point and if the set

switch point delay time has been expired.

The switch output is deactivated, if the current measuring value exceeds the reset switch point and if

the set reset switch point delay time has been expired.

The actual applied measuring signal can be applied or an arbitrary value can be set as switch resp.

switch back point.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 13

5.3.5 Window function

The window function realizes a signal range – acceptance region –, where the switch output is set to a

denitive switch state.

The switch range is determined by input the switch point and switch back point.

The switch output is activated, if the current measuring value is inside the area that is dened by the

switch point and the reset switch point and if the set switch point delay time has been expired.

The switch output is deactivated, if the current measuring value is outside the area that is dened

by the switch point and the reset switch point and if the set reset switch point delay time has been

expired.

The actual applied measuring signal can be applied or an arbitrary value can be set as switch resp.

switch back point.

5.3.6 Error indication function

The switch output S1 can be alternatively used for error indication function. Doing this a switch action

happens, if the output current becomes higher than 20mA resp. lower than 4mA.

5.4 Current output

The nominal values of the current output (4mA/20 mA) refers to the set signal zero and signal end

value.

5.4.1 Error signal

Denes the current output regarding operating range and if errors are registered.

A - O >> 3.9-21mA

B - 3.8mA

C - 22mA

5.4.2 Invert signal

Inverts the current output.

• 4-20mA >> 20-4mA

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

14

5.5 Self-supervising function

5.5.1 Drift monitoring function

The drift monitoring function is only adjustable at devices with option self-supervising.

Each sensor element that is used for the recording of temperatures has the unavoidable characteristic

a specic behavior concerning long term drift and ageing.

This behavior is very similar if not identically at physically equal-type sensor elements like e.g.

multiple resistive sensors Pt100.

At physically dierent sensor elements like resistive sensors Pt100 and semiconductor sensors or also

NTC however these characteristics are serious dierent.

In the tip of the sensor tube are two physically dierent sensor elements mounted thermal coupled.

For the realizing of a reliable drift supervising a dierent drift behavior of the two sensor elements is

necessary.

Therefore e.g. not two resistive sensors Pt100 are uses, but only one resistive sensor element Pt100

and a semiconductor sensor element.

Under nominal conditions the temperature measuring values, which are recorded by the sensor

elements and transmitted to the processor are identically. Because of the not exactly identical position

of both sensor elements within the sensor tube, the installation position of the sensor tube and the

present process conditions temperature dierences of up to ±0,1K can occur, already at a new device.

This does not aect the function of the drift supervision concerning ageing.

Because of the use of two physically dierent sensor elements it is guaranteed, that the ageing

conditioned characteristic drift of both sensor elements is dierent. At the occurring of an ageing

conditioned characteristic drift in one or also in both sensor elements the dierence between the

temperature measuring values of both sensor elements increases.

The detected dierence between the temperature measuring values is compared with the set drift

response value (drAL) by the processor.

If the temperature dierence between the temperature measuring values transgresses the set drift

response value (drAL), the drift alarm will be registered in the error memory (ErrN), the red error

indication LED starts ashing and the switch output 1, if congured for error function, will be activated

corresponding to the settings in normally open or normally closed function.

The display and the current output generate furthermore a temperature proportional signal, referring

to the temperature measuring value of the primary sensor element, the resistive sensor Pt100. The

switch outputs, which are congured for normal function, refers also to this temperature measuring

values.

Because of the dierent response time of the two sensor elements, at fast and strong temperature

uctuations in the measured medium, e.g. at lling a hot medium in a cold container, it can come to

short time dierences between the two temperature measuring values that are higher than the set

drift response value (drAL).

A wrong drift alarm would be detected.

For the compensation of such wrong behaviors a drift delay time (drd) can be set.

Due to this a drift alarm will only be detected, if after the transgression of the drift response value

(drAL) and after the set drift delay time (drd) the set drift response value (drAL) is already

transgressed.

5.5.2 Redundancy function

The redundancy function is only adjustable at devices with option self-supervising.

The display, the switching output resp. outputs and the current output refers principally to the

temperature measuring value of the primary sensor element, the resistive sensor Pt100.

In the case of a short circuit or a wire break of the primary sensor element, the resistive sensor Pt100

there is the possibility to continue the measurement automatically with the secondary sensor element,

the semiconductor sensor.

The display, the switching output resp. outputs and the current output refers now to the temperature

measuring value of the secondary sensor element, the semiconductor sensor.

A drift monitoring is not possible in the case of the failure of one of the two sensor elements.

The behavior of the temperature switch in the case of the failure of the primary sensor Pt100 resp. the

activation of the redundancy function is made by the parameter (drb).

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 15

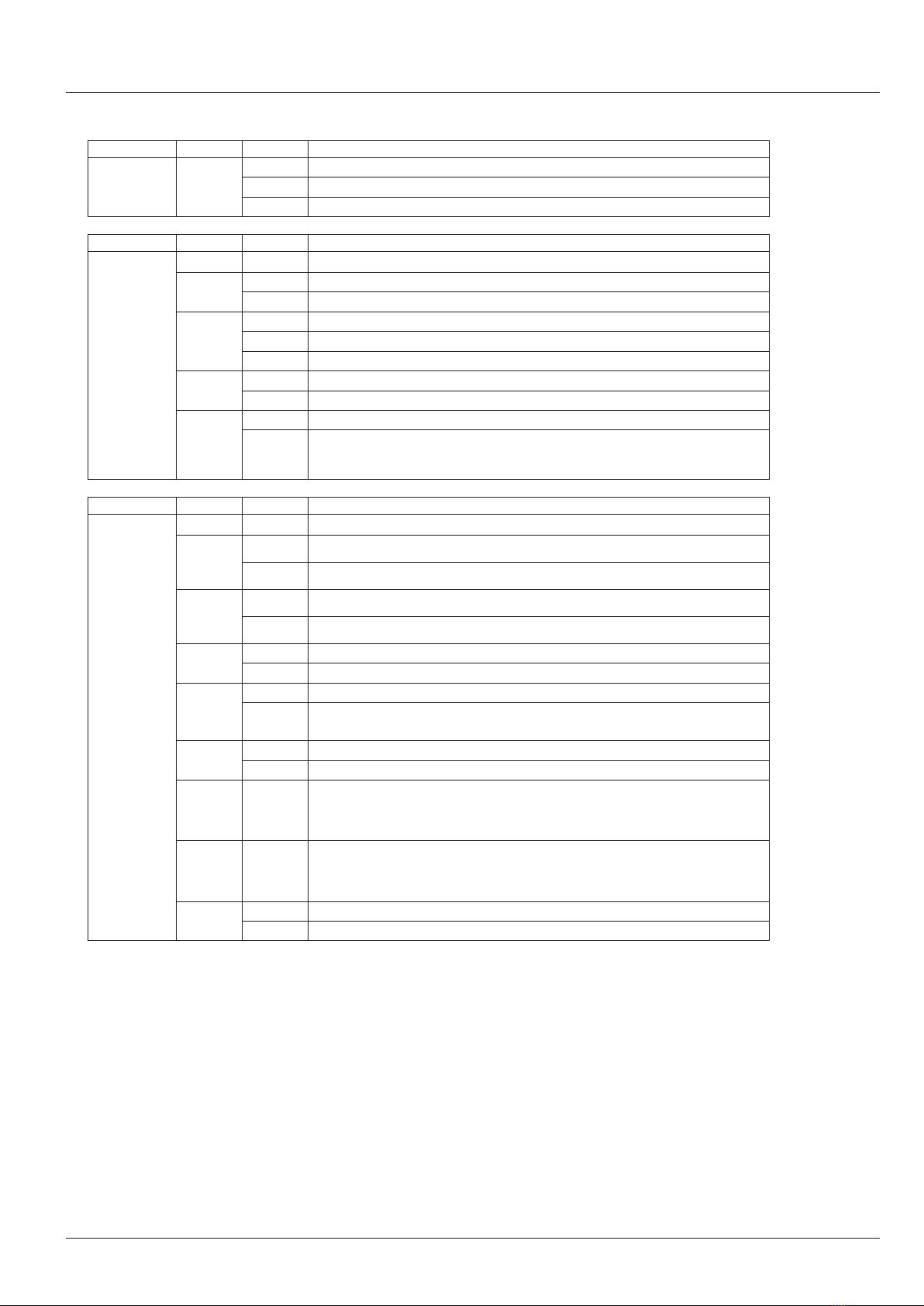

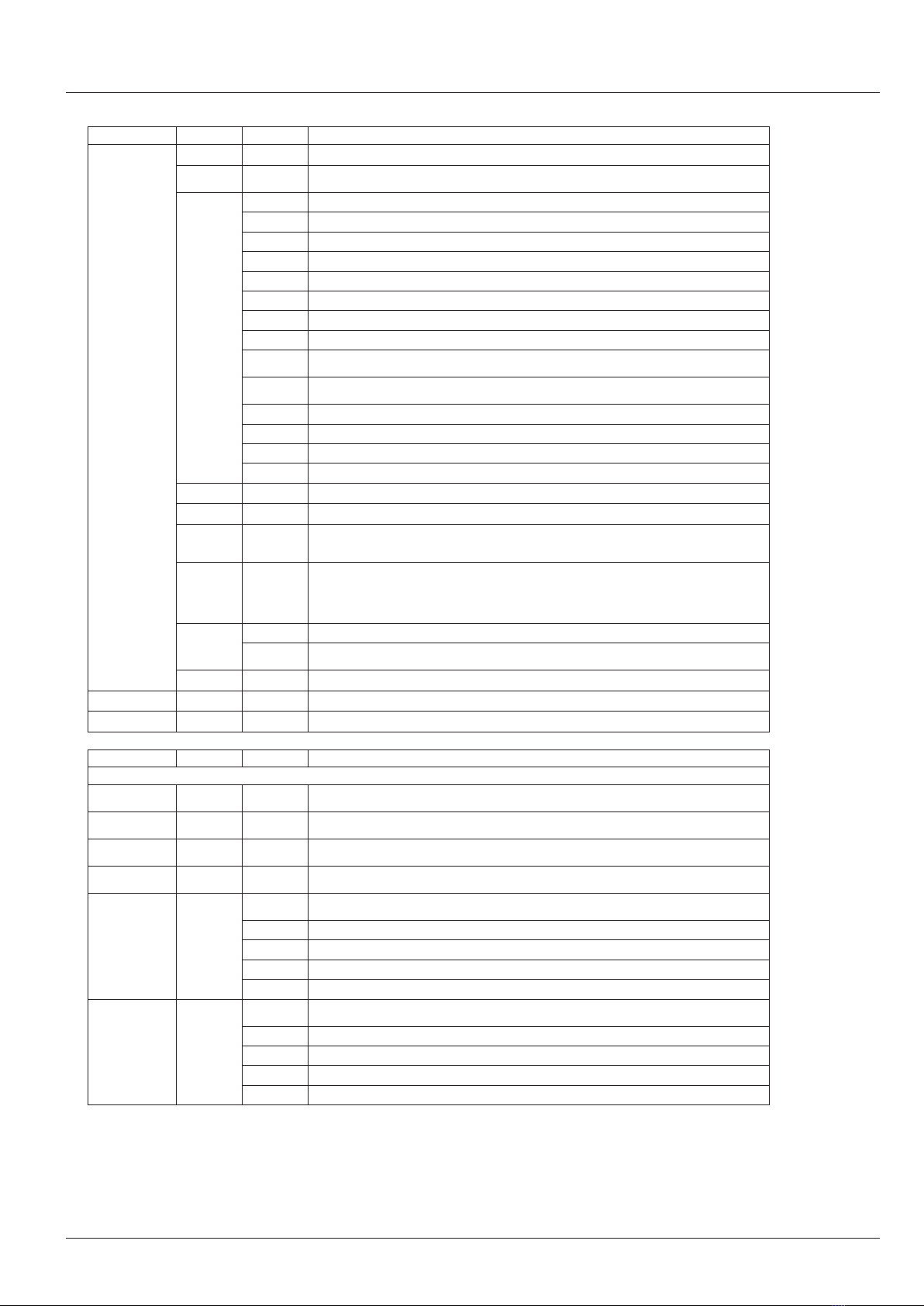

5.6 Menu structure

5.6.1 Menu structure switch function - password 1903

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

16

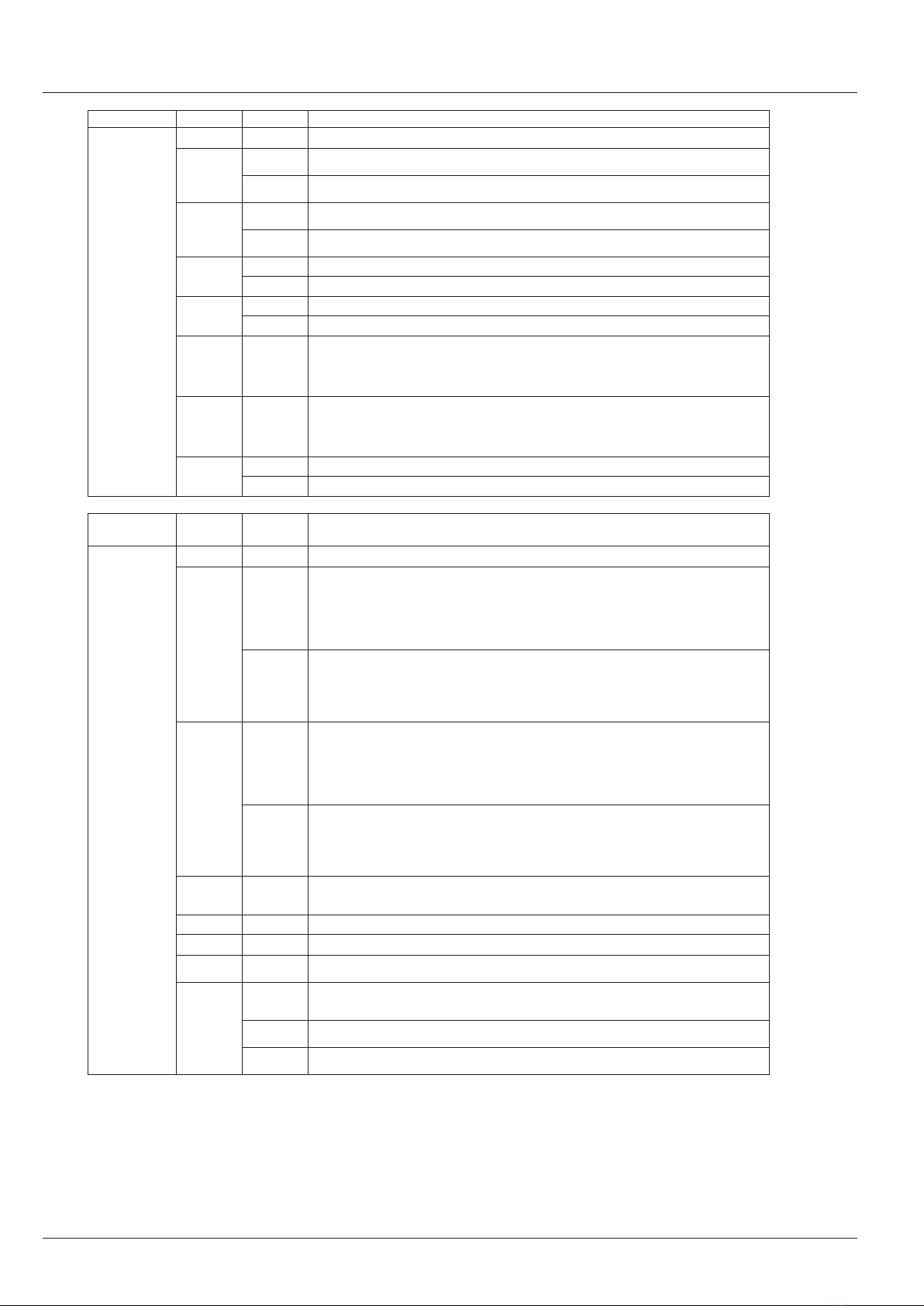

5.6.2 Menu structure transmitter function - password 3009

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 17

5.6.3 Menu structure switch point - password 1111

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

18

5.7 Parameter overview

Menu group Function Input Description

codE 3009 Password input for the access to the transmitter function menu

1903 Password input for the access to the switch function menu

1111 Password input for the access to the switch point menu

Menu group Function Input Description

diSP DISPLAY – includes all parameters concerning the display

AnSi norA View normal

GEdA View rotated by 180°

Unit C Unit °C

HUnit °K

FUnit °F

SPoN NA Display measuring value - the actual measuring value is shown in the display

SPA Display switch value - the upper limit value of the switch point 1 is shown in the display

dEA don Display indication on – measurement value and status LED are indicated

doFF Display indication o – measurement value and unit LED are deactivated in the run mode.

The operation, error and switch condition indicator LED are still in process.

When accessing the password input by simultaneous pushing the two operation keys +/- and >

for three seconds, the complete display is switched on again.

Menu group Function Input Description

SP1 Switch output 1 – includes all parameters concerning the switch output 1

SP_1 NSiG Adjustment with applied signal – The actual applied temperature value is captured as switch

point resp. upper switch point

oSiG Adjustment without applied signal – The actual switch point / upper switch point is shown in

the display and can now be adjusted by the operation keys +/- and >.

rSP1 NSiG Adjustment with applied signal – The actual applied temperature value is captured as switch

back point resp. lower switch point

oSig Adjustment without applied signal – The actual switch back point / lower switch point is shown

in the display and can now be adjusted by the operation keys +/- and >.

Fc_1 HF_1 The switch output 1 operates in hysteresis function with switch point and switch back point

FF_1 The switch output 1 operates in window function with lower and upper switch point

Func norF Normal function – The switch output 1 operates in hysteresis or in window function

ErrF Error indication function – The switch output 1 operates in error indication function for the

current output. At underrun of 4mA resp. at exceedance of 20mA, the switch output 1 is

activated depending on the settings as closed-circuit or as open-circuit.

nonc no The switch output 1 operates in open-circuit principle resp. – no normally open

nc The switch output 1 operates in closed-circuit principle resp. – nc normally closed

dSP1 Switch delay time for switch point / upper switch point of switching output 1.

The switching output 1 is only activated, if after the entrance of the switch condition and after

the set switch delay time the temperature signal already fullls the switch conditions. By this

e.g. temperature uctuations can be eliminated.

The adjustment range is 0...99 seconds, in steps of 0,1 seconds

drP1 Switch delay time for switch back point / lower switch point of switching output 1.

The switch output 1 is only activated, if after the entrance of the switch back condition

and after the set switch delay time the temperature signal already fullls the switch back

conditions. By this e.g. temperature uctuations can be eliminated.

The adjustment range is 0...99 seconds, in steps of 0,1 seconds

SiN1 AuS1 Simulation – the switch output 1 is deactivated

Ein1 Simulation – the switch output 1 is activated

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected] 19

Menu group Function Input Description

SP2 Switch output 2 – includes all parameters concerning the switch output 2

SP_2 NSiG Adjustment with applied signal – The actual applied temperature value is captured as switch

point resp. upper switch point

oSiG Adjustment without applied signal – The actual switch point / upper switch point is shown in

the display and can now be adjusted by the operation keys +/- and >.

rSP2 NSiG Adjustment with applied signal – The actual applied temperature value is captured as switch

back point resp. lower switch point

oSig Adjustment without applied signal – The actual switch back point / lower switch point is shown

in the display and can now be adjusted by the operation keys +/- and >.

Fc_2 HF_2 The switch output 2 operates in hysteresis function with switch point and switch back point

FF_2 The switch output 2 operates in window function with lower and upper switch point

nonc no The switch output 2 operates in open-circuit principle resp. – no normally open

nc The switch output 2 operates in closed-circuit principle resp. – nc normally closed

dSP2 Switch delay time for switch point / upper switch point of switching output 2.

The switch output 2 is only activated, if after the entrance of the switch condition and after the

set switch delay time the temperature signal already fullls the switch conditions. By this e.g.

temperature uctuations can be eliminated.

The adjustment range is 0...99 seconds, in steps of 0,1 seconds

drP2 Switch delay time for switch back point / lower switch point of switching output 2.

The switch output 2 is only activated, if after the entrance of the switch back condition

and after the set switch delay time the temperature signal already fullls the switch back

conditions. By this e.g. temperature uctuations can be eliminated.

The adjustment range is 0...99 seconds, in steps of 0,1 seconds

SiN2 AuS2 Simulation – the switch output 2 is deactivated

Ein2 Simulation – the switch output 2 is activated

Menu group Function Input Description

AbGL Adjustment – includes all parameters concerning the temperature adjustment

2Ero NSiG Adjustment lower temperature reference value with applied signal

- The actual applied temperature value is captured as lower temperature reference value.

- The output current of 4mA, that can be adjusted by the control keys +/- and > arbitrarily, is

assigned to this temperature reference value. Adjustment range 3,9mA to 21mA.

- If the adjusted measuring range is lower than 25% of the nominal measuring range, the

change will be refused and the display shows EEEE.

- An already set oset will be regarded at the adjustment.

oSiG Adjustment lower temperature reference value without applied signal

- The freely adjustable pressure value, in the set unit - Unit-, is captured as lower temperature

reference value.

- The lower output current end value, 4mA, refers to this pressure reference value.

- The measuring span cannot be adjusted lower than 25% of the nominal measuring range.

- An already set oset will be regarded at the adjustment.

SpAn NSiG Adjustment upper temperature reference value with applied signal

- The actual applied temperature value is captured as upper temperature reference value.

- The output current of 20mA, that can be adjusted by the control keys +/- and > arbitrarily, is

assigned to this temperature reference value. Adjustment range 3,9mA to 21mA.

- If the adjusted measuring range is lower than 25% of the nominal measuring range, the

change will be refused and the display shows EEEE.

- An already set oset will be regarded at the adjustment.

oSiG Adjustment upper pressure reference value without applied signal

- The freely adjustable pressure value, in the set unit - Unit-, is captured as upper pressure

reference value.

- The upper output current end value, 20mA, refers to this pressure reference value.

- The measuring span cannot be adjusted lower than 25% of the nominal measuring range.

- An already set oset will be regarded at the adjustment.

oFFS The temperature measuring value can be shift by an oset of up to 25°C.

This can be necessary in unfavorable installation situations or at considerable temperature

dierences between medium and measurement position.

inS AUSA The output current corresponds to the assignment of the adjustment >> 4...20mA

EinA The output current behaves inverted to the assignment of the adjustment >> 20...4mA

SiNA The current output can be arbitrarily simulated in the whole utilizable range from 3,8mA to

22mA by using the operation keys +/- and >.

ErrS oFF The current output operates linear in the range from 3,9mA to 21,0mA. A current output

besides this limits is not possible, the end values are kept at exceedance. An error current

output at underrun resp. exceedance does not occur.

FS38 The current output operates linear in the range from 4,0mA to 20,0mA. At underrun of 4mA

resp. at exceedance of 20mA a constant current of 3,8mA is generated.

FS22 The current output operates linear in the range from 4,0mA to 20,0mA. At underrun of 4mA

resp. at exceedance of 20mA a constant current of 22mA is generated.

ACS-CONTROL-SYSTEMGmbHlLauterbachstr.57lD-84307Eggenfeldenlwww.acs-controlsystem.del[email protected]

20

Menu group Function Input Description

SEr Service – includes all parameters concerning service purposes

t_F Input of the system damping for reassuring of cyclic uctuating temperature signals.

The adjustment range is 0...40 seconds, in steps of 0,1 seconds

ErrN noE No error recorded in the error memory.

brch A wire break at the internal connections of the sensor element has been detected.

Hur A short circuit at the internal connections of the sensor element has been detected

FLAS An error in the internal nonvolatile data memory (ash) has been detected.

Nunt The lower measuring range limit value (display zero) has been underrun.

NuEb The upper measuring range limit value (display span) has been exceeded.

Aunt The lower limit value of the current output (3,9mA) has been underrun.

AuEb The upper limit value of the current output (21mA) has been exceeded.

S1oG The switch back point rSP1 of the switch output 1 has been adjusted higher or equal to the

switch point SP_1.

S2oG The switch back point rSP2 of the switch output 2 has been adjusted higher or equal to the

switch point SP_2.

S1oP The switch output 1 is not activated, although it should be.

S2oP The switch output 2 is not activated, although it should be.

rAN An error in the internal working memory (RAM) has been detected.

drFt The exceedance of the set drift threshold value has been detected.

NA Maximum value memory – display of the highest measured temperature value.

Nin Minimum value memory – display of the lowest measured temperature value.

drAL A drift alarm is only made, if the set drift threshold value, the dierence between the

temperature measuring values of the two sensor elements, has been exceeded.

The adjustment range is 0,2...5 K, in steps of 0,1K.

drd

A drift alarm is only made, if after the exceedance of the drift threshold value and after the set

drift delay time the drift threshold value has been already exceeded.

By this, e.g. the dierent response time of the two sensor elements at temperature deviations

can be compensated.

The adjustment range is 0...300 seconds, in steps of 1 second.

drb

AUS The redundancy function is deactivated

Ein The redundancy function is activated. At the failure of the sensor element Pt100 the measuring

is continued with the semiconductor sensor element.

301 Version number of the installed rmware

FrES Factory Reset – reset of all parameters to factory values

SPEi Storage – loss protected storage of all parameters

Menu group Function Input Description

Switch point menu

SP_1 The current switch point / upper switch point of switch output 1is shown in the display and can

be adjusted by the control keys +/- and >.

rSP1 The current switch back point / lower switch point of switch output 1 is shown in the display

and can be adjusted by the control keys +/- and >.

SP_2 The current switch point / upper switch point of switch output 2 is shown in the display and can

be adjusted by the control keys +/- and >.

rSP2 The current switch back point / lower switch point of switch output 2 is shown in the display

and can be adjusted by the control keys +/- and >.

Fc_1 The set switch function of the switch output 1 is displayed. This setting cannot be changed

here.

HFno The switch output 1 operates in hysteresis function with working principle normal open

HFnc The switch output 1 operates in hysteresis function with working principle normal closed

FFno The switch output 1 operates in window function with working principle normal open

FFnc The switch output 1 operates in window function with working principle normal closed

Fc_2 The set switch function of the switch output 2 is displayed. This setting cannot be changed

here.

HFno The switch output 2 operates in hysteresis function with working principle normal open

HFnc The switch output 2 operates in hysteresis function with working principle normal closed

FFno The switch output 2 operates in window function with working principle normal open

FFnc The switch output 2 operates in window function with working principle normal closed

Table of contents