2

www.acs-controlsystem.com

ACS-CONTROL-SYSTEM GmbH | Lauterbachstr. 57 | 84307 Eggenfelden | Germany

YOUR PARTNER FOR MEASUREMENT & AUTOMATION

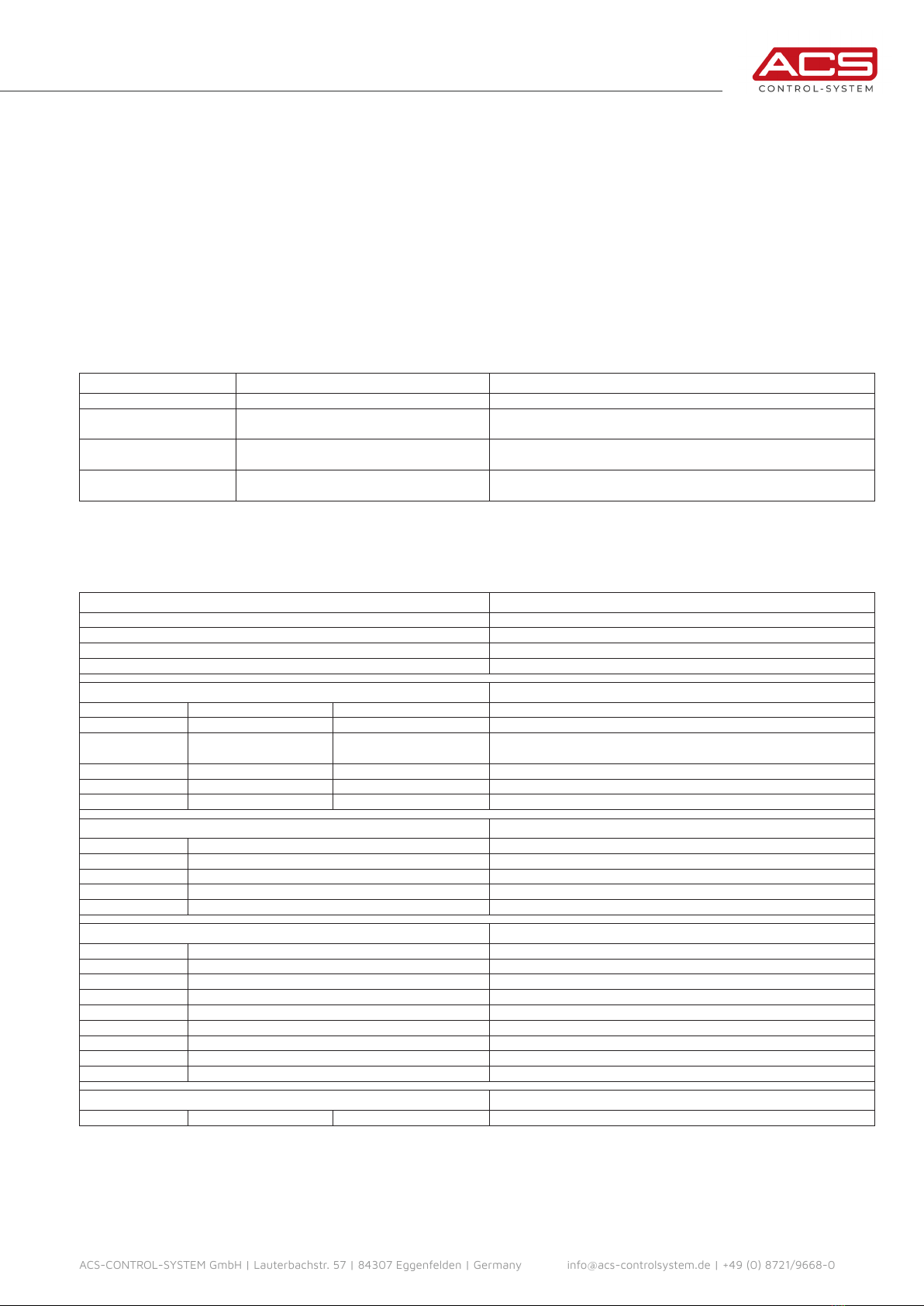

Index

1 Safety instructions ��������������������������������������������������������������������������������������������������������������������������������������������������3

1.1 Authorized personnel.................................................................................................................................................................... 3

1.2 Terms .............................................................................................................................................................................................. 3

1.3 Appropriate use ............................................................................................................................................................................. 3

1.4 Operational safety......................................................................................................................................................................... 3

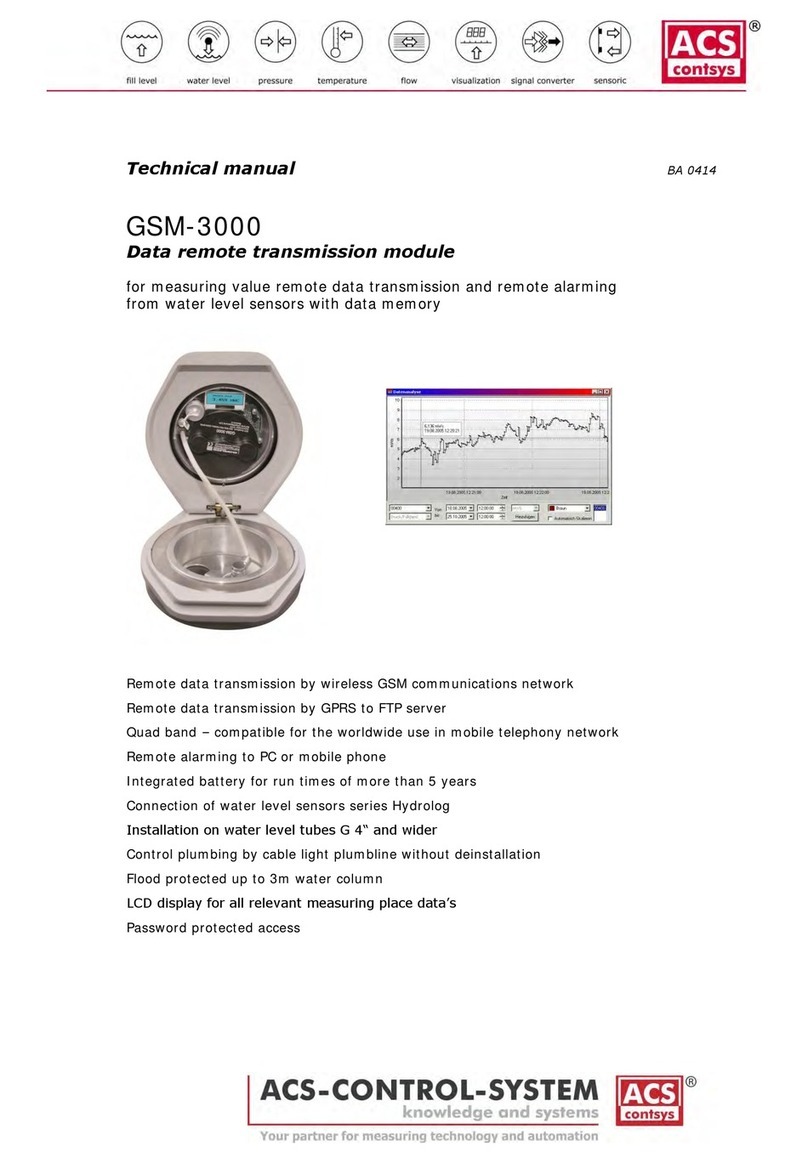

2 Product description�������������������������������������������������������������������������������������������������������������������������������������������������4

2.1 Product code.................................................................................................................................................................................. 4

2.2 Function.......................................................................................................................................................................................... 5

2.3 Conguration ................................................................................................................................................................................. 5

2.4 Product label.................................................................................................................................................................................. 5

2.5 Packaging, transport, storage..................................................................................................................................................... 5

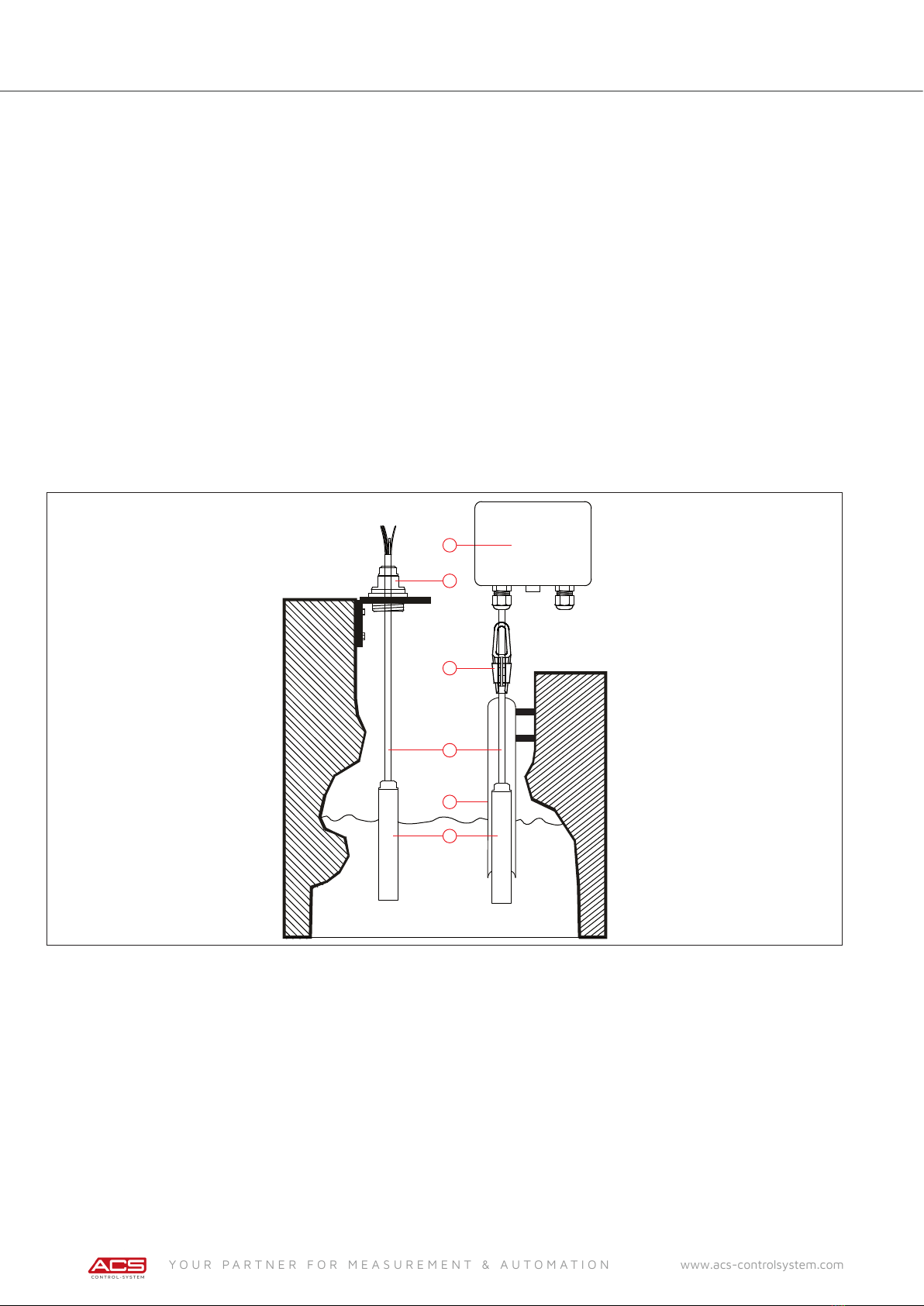

3 Installation ����������������������������������������������������������������������������������������������������������������������������������������������������������������6

3.1 Ambient and process conditions ................................................................................................................................................. 6

3.2 Installation place ........................................................................................................................................................................... 6

3.3 Installation notes ........................................................................................................................................................................... 6

3.4 Field enclosure............................................................................................................................................................................... 7

4 Electrical connection����������������������������������������������������������������������������������������������������������������������������������������������� 7

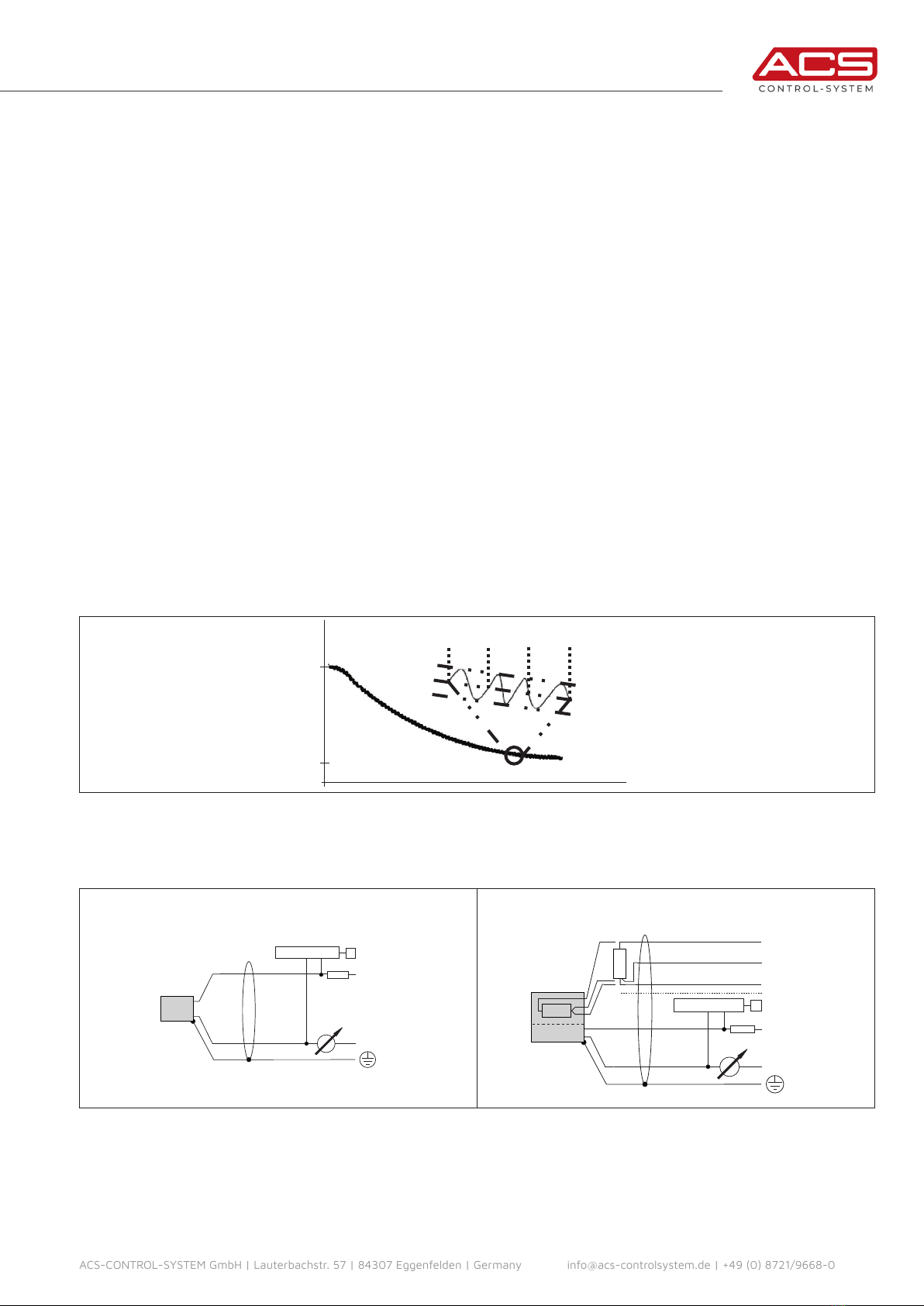

4.1 Electronic output 09-A – 4…20mA, FSK interface ................................................................................................................... 7

4.2 Electronic output 09-V – Interface RS485 Modbus-RTU......................................................................................................... 8

5 Operation ������������������������������������������������������������������������������������������������������������������������������������������������������������������9

5.1 Electronic output 09-A – 4…20mA, FSK interface................................................................................................................... 9

5.2 Electronic output 09-V – Interface RS485 Modbus-RTU......................................................................................................... 9

6 Service ���������������������������������������������������������������������������������������������������������������������������������������������������������������������10

6.1 Maintenance................................................................................................................................................................................. 10

6.2 Dismounting................................................................................................................................................................................. 10

6.3 Troubleshooting / Repair............................................................................................................................................................ 10

6.4 Return........................................................................................................................................................................................... 10

6.5 Disposal ........................................................................................................................................................................................ 10

7 Technical Data ���������������������������������������������������������������������������������������������������������������������������������������������������������11

7.1 Filling level sensor ........................................................................................................................................................................11

7.2 Field enclosure............................................................................................................................................................................. 12

8 Dimensions�������������������������������������������������������������������������������������������������������������������������������������������������������������� 13

8.1 Sensor........................................................................................................................................................................................... 13

8.2 Field enclosure............................................................................................................................................................................. 13

9 Accessories�������������������������������������������������������������������������������������������������������������������������������������������������������������� 14

9.1 Mounting clamp........................................................................................................................................................................... 14

9.2 Mounting screw ........................................................................................................................................................................... 14

9.3 Field enclosure............................................................................................................................................................................. 14

9.4 Installation material .....................................................................................................................................................................15

9.5 Signal processing..........................................................................................................................................................................15