ADA GASTROGAZ ADA SCE 12 User manual

2

Dear Sirs,

Thank you for the credit shown us by buying our product, electric pressure fryer. We

hope that the device which you own will satisfy all your expectations.

In this construction we tried to leave up to all expectations of the users. Electric

pressure fryer assures short time frying of meat product in hot oil without penetrating

the oil into product, what gives excellent taste and wholesome values.

Before you start operating the device, it is recommended to familiarize with the content

of the hereby operating instruction where you find exact recommendations concerning

correct hold-down, use and preservation of the fryer.

ADA Gastrogaz

MANUFACTURER

3

CONTENT

1. Destination of the fryer 4

2. Technical characteristic and equipment 5

3. Technical manual for appliance installer 7

3.1. Assembly order 7

4. Instructions for use and maintenance 10

4.1. Operation and maintenance 10

4.2. Use and oil change 13

4.3. Cleaning the appliance 14

4.4. Additional maintenance performed periodically 15

4.5. Deletion of the disturbance of work 15

4.6. Rules for the safe use of the appliance 16

4.7. First aid 17

4.8. Warnings 17

5. Conditions of the guarantee certificate 19

Guarante Certificate 20

PRECAUTIONS FOR PURCHASERS AND USERS

Before starting to operate the appliance one should get acquainted with the operating instruction. The

instruction contains hints and recommendations concerning proper usage of the device.

Acting according to the present instruction will assure long lasting and infallible operation, bringing in

the same time profit and satisfaction with the product purchased.

It is not allowed to heat the oil alone under pressure!

4

1. DESTINATION OF THE FRYER

The electric pressure fryer ADA SCE 12 is intended for preparing dishes in hot oil under

pressure. It is used in food industry, but mainly in gastronomy.

The fryer is especially fitted to fry meat products ( poultry, pork, fish) in special coating

but they can be prepared without it as well. You can also use the fryer to prepare toasts,

doughnuts, chips etc.

In this type of pressure devices you receive the final product crisp, crunchy and not

saturated with oil. The pressure is obtained due to the release of natural moisture from

the product. Due to the fact that steam builds up very quickly, the fried product retains

most of its natural moisture.

Pic. 1. Electric pressure fryer ADA SCE 12

5

2. TECHNICAL CHARACTERISTIC AND EQUIPMENT

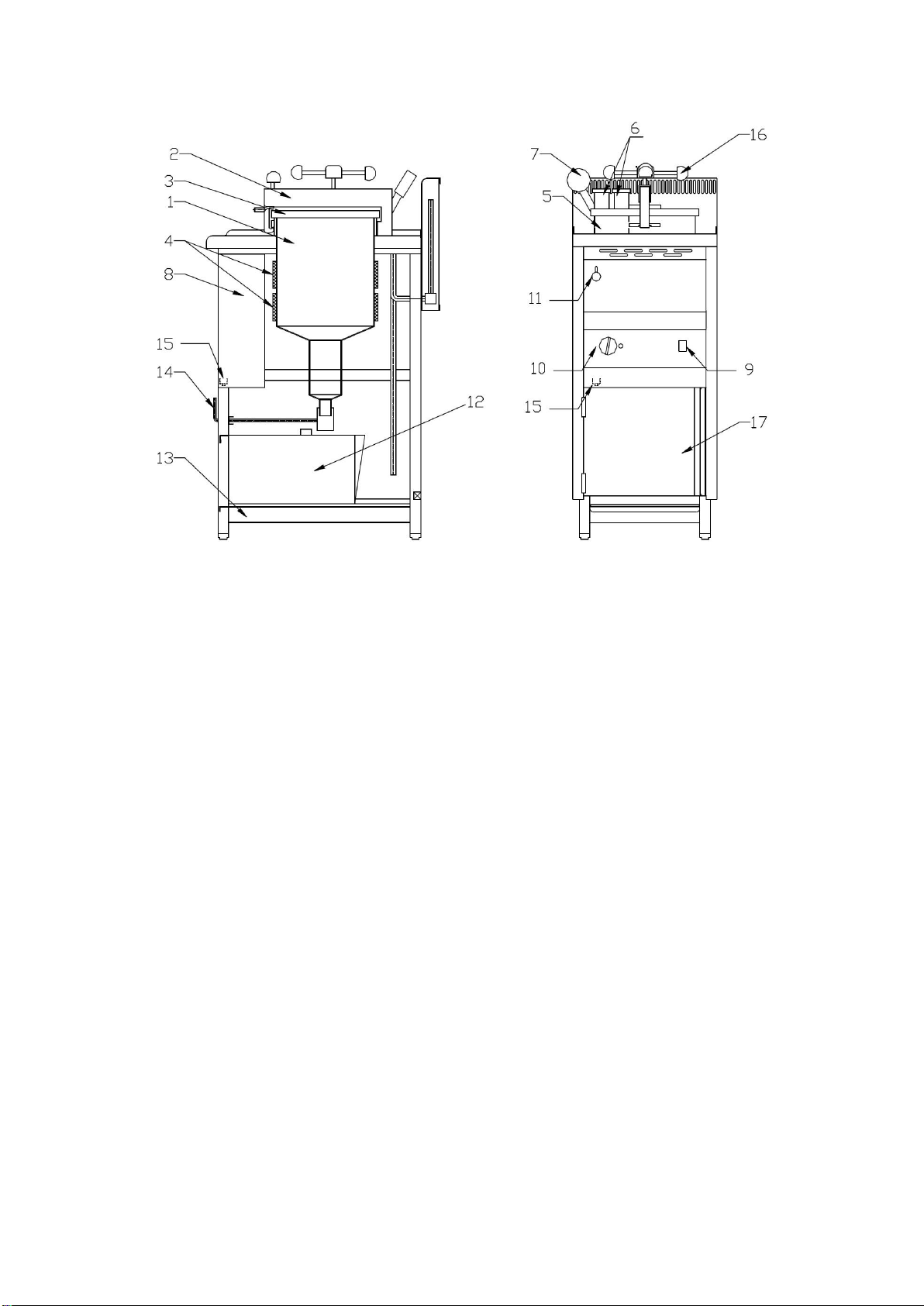

Pic. 3. Construction scheme of electric pressure fryer ADA SCE 12

1. Heating chamber; 2. Holdfast tap; 3. Cover; 4. Heaters; 5. Safety valve;

6. Safety valve weights; 7. Manometer; 8. Control panel; 9. Main switch; 10. Thermostat knob with

control light; 11. Pressure reducing lever; 12. Oil tank; 13. Condensate tank;

14. Oil valve lever; 15. Temperature limiter buton (reset); 16. Cover holdfast;, 17. Doors.

All fryer components are of metal construction, made of stainless and acid-resistant

sheets approved for contact with food. The cover and safety valve elements are made of

aluminum sheet.

The design of the appliance is based on adjustable feet on which the fryer housing

rests. Inside the housing, around the frying chamber are band heaters and electrical

installation. The heaters heat the frying chamber. The thermostat sensor and safety sensor

(temperature limiter) are mounted, which turns off the heaters when the oil reaches a

temperature of 220°C. A basket is placed in the chamber; after the frying process is

finished, the basket is pulled out by the handle.

In order to close the chamber tightly, there is cover with a gasket made of a silicon

rubber which is oil and temperature proof. The cover of the fryer is held by the holdfast

(16.) so that it is closed tightly to form the overpressure. The possible pressure

occurring in the chamber is about 0,04 MPa. After the pressure is exceeded, the safety

valve (5.) opens to reduce the pressure to 0,04 MPa.

Impurities from the coating of products settle in the "cold chamber" at the bottom of

the tank. The cold chamber allows for an extended oil life, because the burnt particles fall to

the bottom of the "pocket" where the temperature is lower than in the frying chamber. Due

6

to this difference, burnt particles are eliminated from the frying process and do not

contaminate the oil in the chamber.

In the final part of frying, steam collected in the chamber (causing overpressure)

should be removed by pulling the pressure reducing lever (11.) and letting the steam

escape from the chamber and condense in the condenser. After that, the steam

accumulates in the form of a condensate in the condensate tank (13.).

Warning!

Each time before opening the cover, release the pressure reduction lever to release the

accumulated steam! Failure to do so may result in severe burns.

After the whole process of frying is done, let the oil out of the chamber using the

chamber emptying valve (14). The used oil should be poured through a linen filter in

order to purify it and separate the remnants of a meal from it. The purified oil should be

placed in the proper tank (12).

The fryer control parts include:

- main switch (9.);

- thermostat knob with control lamp (10.);

- chamber pressure indicator (manometer) (7.);

- pressure reduction lever (11.).

Basic fryer equipment:

- basket (1 pc)

- basket holder (1 pc)

- oil tank (1 pc)

- condensate tray (1 pc)

Additional equipment (optional):

- divided basket (1 pc)

Technical data

ADA SCE 12

Dimensions [mm]

400 x 650 x 1000

Chamber capacity [l]

12

Maximum load [kg]

2,5 - 3,0

Pressure [MPa]

0,04

Working temperature [°C]

150-170

Heating power [kW]

5,8

Voltage [V]

400

Weight [kg]

57

Tab. 1. Basic technical parameters of ADA SCE 12 electric pressure fryers

7

3. TECHNICAL MANUAL FOR THE APPLIANCE INSTALLER

The device may be connected to the electrical installation only by a qualified person.

Parts that have been secured by the manufacturer may not be adjusted by the installer.

The fryer is designed for 400 V AC power supply ant the 32 A amperage.

The fryer's electrical installation includes:

-Electric theromstat (0 –200C)

-Main switch,

-overheating protection (temperature limiter - 220C)

-contactor

-electric cables

-external power cord with plug

-protective grounding clamp

When installing devices, the following legal provisions must be observed:

-Standards, regulations, building and fire regulations.

-Health and safety regulations.

-Standards, regulations, ordinances for the installation of electrical devices

-Normy, przepisy, zarządzenia dotyczące wentylacji.

The appliance installer should:

-Have a qualification certificate

-Read the information on the type plate

-Check the effectiveness of all components of the appliance's functioning.

-Familiarize the user with the operation of the device

3.1. Asembly order

Before starting to assemble the fryer, make sure that all its parts are complete and have

not been damaged in transport.

Determining the location for the fryer is extremely important in terms of operating

range, speed and convenience.

1. Place the appliance in a place that allows easy access from all sides, on a hard and

non-flammable surface. The distance from non-flammable walls should be at least 10

cm. If the walls are not resistant to high temperatures, use appropriate insulation and

keep a minimum distance of 30 cm. Also keep a distance of at least 20 cm from other

devices.

8

2. Level the fryer using the regulated legs.

Pic. 3. . Electrical diagram of the ADA SCE 12 electric pressure fryer

R1, R2 –heater 2,9 kW; W1 –main switch; T1 –temperature regulator; T2 –thermal fuse; K1 –control

lamp

Warning!

Incorrect use of the appliance can cause oil to burn and fry, which can cause severe

burns, injury, as well as fires and equipment damage.

3. Before connecting the appliance to the electrical system, check the information on the

type plate.

4. Before connecting the appliance to the electric installation, it is mandatory to connect a

protective conductor with yellow-green insulation and a cross-section of not less than 2.5 mm

to the housing. The protective terminal is located on the back of the device and is marked with

the symbol

5. The appliance should be connected to the network, and a protective switch in

accordance with standards should be installed. The ground wire must not be connected

to this switch. The electric cable should be positioned so that it does not reach a

temperature 50°C higher than its surroundings at any point.

6. After connecting the AC power cord with the socket, check the correctness of

individual phases.

9

7. It is recommended to install the appliance under an efficient ventilation system (hood).

Warning!

If any electric cable is damaged, do not turn on the appliance to avoid danger. Contact aservice

center and order repair.

After completing the installation of the device, the packaging components must not be

kept within the reach of children, as they may cause hazards. Therefore, they must be

disposed of (also for environmental protection reasons) in accordance with applicable

regulations.

10

4. INSTRUCTIONS FOR USE AND MAINTENANCE

Each appliance has been thoroughly inspected and tested before shipment. However, it is

good practice to check the device before starting it.

4.1. Operation and maintenance

Warning!

Make sure that the cover closes properly and locks. Incorrect closing can result in

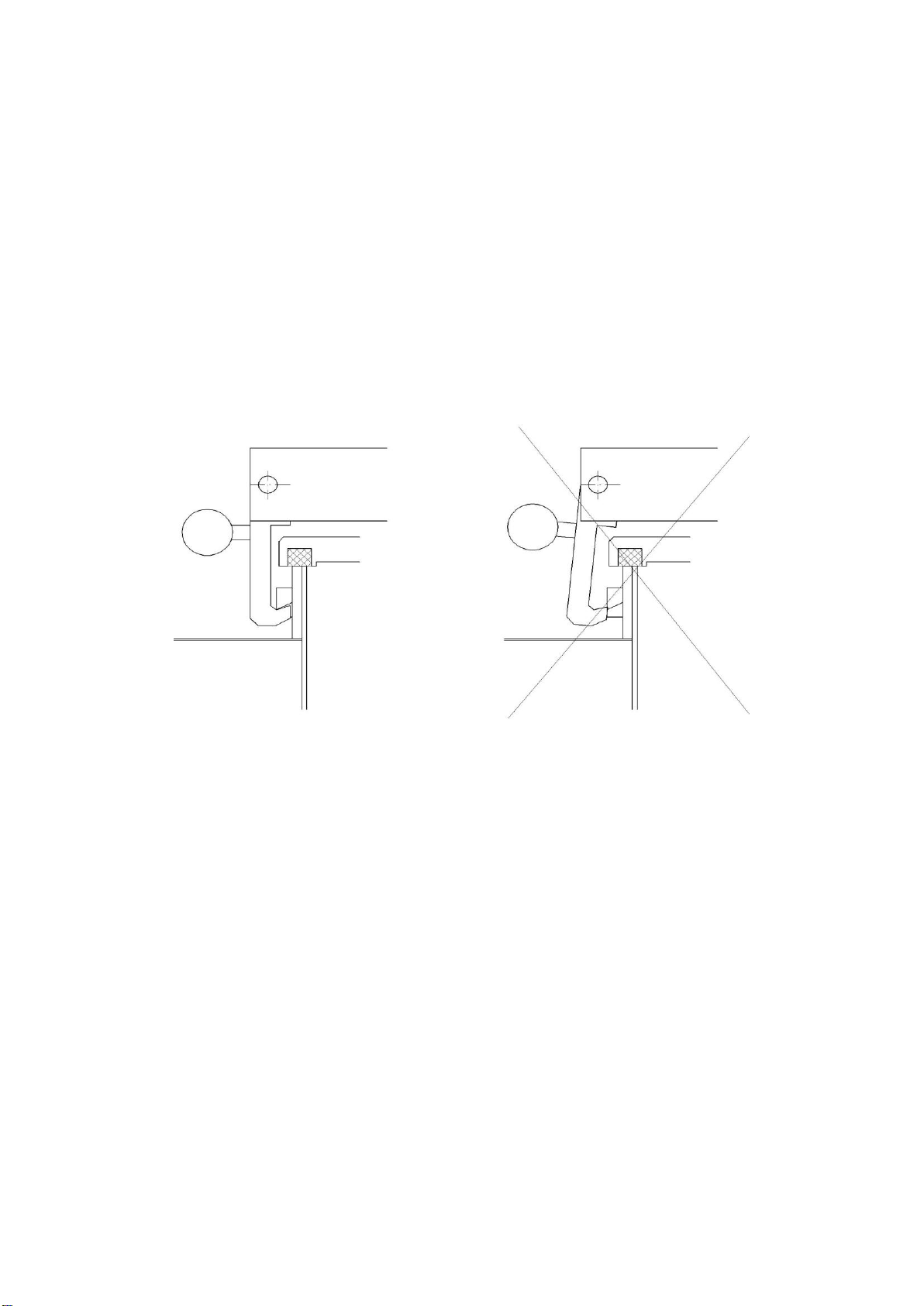

severe burns, injury, as well as fire or material damage. (Pic. 4.)

Pic. 4. Correct closing of the fryer cover (left)

Before starting the first frying process, wash the frying chamber and the rest of the

elements which may contact with food with hot water and suitable detergents.

- Close the chamber drain valve.

- Fill the chamber with water and bring to a boil (it causes cleaning the cover).

Warning!

When heating the oil in the chamber, never close the cover!

- When boiling water, in a closed chamber, do not leave the appliance unattended. When

the water reaches boiling point, release the pressure relief valve every few moments so

that the steam escapes from the chamber.

- Drain the water from the chamber, use a suitable detergent if necessary and rinse.

11

- Fill the chamber with 100 ml of vinegar again to neutralize the alkalis from the cleaning

agents and bring to a boil.

- Empty the chamber andrinse with hot water several times.

- Carefully dry the chamber and additional elements and close the drain valve.

Warning!

The chamber must not be filled with oil until the chamber is thoroughly drained of

water and it is not checked that the drain valve has not retained water. Remember to

place an oil container under the drain valve. If the valve is not closed, oil will flow into

the tank.

Before starting the fryer, turn on the power supply, fill the chamber with oil (the

minimum oil level is the one at which the sensor tube is completely covered with oil). Do

not start the fryer when the chamber is empty.

During the first start, when the device is cold, never turn the thermostat knob to the

maximum position. Choose the minimum value and slowly increase the setting until the

operating temperature is reached. During heating, mix the oil several times to avoid

uneven heating of the oil. This operation should always be carried out when the oil has

cooled to ambient temperature.

Warning!

Under no circumstances should the cover be closed when the oil is warming up. The

cover can only be closed after placing the products in the fryer chamber. Failure to

comply with this rule may result in severe burns, injury, as well as fire and material

damage.

Regularly check the filling level of the chamber.

- Never operate the device with an empty chamber, it may damage the device.

- If the oil level is too low, the machine may overheat and damage.

- Too high oil level may cause leakage and burns.

- Do not add oil to a hot chamber, as this may cause splashing.

After reaching the desired temperature (the thermostat indicator goes off), place the

basket in the working position with the handle removed. We throw into the basket

previously prepared products and close the lid tightly. Be careful to avoid hot fat

splashes when inserting the product. This could cause severe burns. Working

temperature and frying time depend on the type of product and the technology used.

12

Warning!

Do not overfill the basket or introduce products with a very high degree of humidity into

it. Failure to do so may result in fat leaking out of the chamber. This can result in severe

burns or damage to the device.

During frying, we watch the pressure gauge and listen to the work of the fryer. If

there are any leaks tighten the clamping screw harder until the hissing stops. Once the

pressure reaches ~ 0.04 MPa (0.4 atm), the safety valve may be opened. Remember not

to put too much force on tightening the cover. Tighten it enough to seal the chamber.

Tightening the cover 'by force' can damage the cover, pressure arm, and seal.

After finishing the frying cycle, extend the lever of the pressure reducing valve

(Pic. 2. item 11.), reducing the pressure to 'zero' and only then you can open the lid of

the frying chamber. At the end of the cycle, when the pressure gauge reads zero, the

cover should be lifted up quickly and vigorously but avoiding hitting the hinge bumper.

To remove fried products, put a specially prepared handle on the basket. Lift the basket

and hang it on the side on the wall of the chamber to drain. Wait before you throw the

product into the tray.

Warning!

Each time before opening the cover, release the pressure reduction lever to release the

accumulated steam! Never lift the handle or use force to open the lid latch until the

pressure gauge indicates "zero". Failure to comply with this rule may result in serious health

and life risk.

If the oil temperature in the fryer exceeds 220°C, the maximum temperature limiter (15)

will operate, causing the thermostat to switch off automatically. To restart the heaters,

wait until the oil has cooled to around 150°C and then press the "reset" button (Pic. 5.).

This button is located on the lower left side of the control box. Open the appliance door

first.

Pic. 5. Item 15 –temperature limiter button (reset)

13

Products

Time [min]

Fish fillet

5

Chicken legs

9 - 12

Chicken wings

6

Chicken fillets

5

Potatoes

7 - 9

Mushrooms, cauliflower

3

Tab. 2. Frying times of some products

1) To achieve an oil pressure of about 0.04 MPa, it is necessary to place at least 0.8 kg of

raw material in the fryer. A smaller load will not allow enough steam to form.

2) Always remember to place an oil container under the drain valve. If the valve is not

closed, the oil will fall out into the tank.

3) Always before filling the chamber with oil, it is advisable to open the drain valve and

drain the accumulated water, then close the valve.

4) Remember to systematically filter and change the oil.

5) During the first morning warm-up, warm the device up by gradually mixing the oil to

avoid burning it.

6) Remember that every device used in the food industry requires proper care and

maintenance. It must also be periodically subject to mandatory maintenance checks by

persons with the required permissions.

4.2. Use and oil change

Frying breaded products requires oil filtration. Make sure that the fat does not foam

during the frying cycle. If foaming occurs, it must be replaced immediately. The

optimum oil frying temperature is 160–170°C. The oil should be protected against heavy

frying at high temperature.

Warning!

With prolonged use of fat, the flash point is lowered. If excessive smoking or foaming

occurs during frying, it should be poured out. Otherwise, there may be severe burns,

injury, fire or material damage.

14

Warning!

The fryer and basket surfaces are very hot. To avoid burns when working with the

equipment, especially when changing oil, take special care and wear protective gloves.

It is recommended to use high-quality frying fat in the fryer. Some lower quality fats

have a high moisture content, which causes foaming and boiling over.

If you use solid fat, it is recommended to melt it on the external heating device before

placing it in the chamber. The surface of the chamber in electric fryers must be

completely immersed. Otherwise the chamber / device may be damaged.

To change the oil:

1) Turn off the device and disconnect the device from the power supply

2) Make sure that the oil tank is in the right place (under the drain valve)

3) Carefully and very slowly release the trigger lever and drain the oil from the

chamber into the tank so that it does not splash.

4) Leave the oil in the tank designated for this while standing.

5) After draining the fat completely, clean the inside of the chamber thoroughly with

a brush. Carefully remove any accumulated coating particles.

6) Flush the chamber with clean oil.

7) Before the next frying, check if the oil drain valve is closed, set the oil tank and

condensate tray in appropriate positions under the device and fill the chamber with

oil to the appropriate level.

Warning!

Never open the drain valve when the chamber is under pressure. Hot fat can flow out

and cause severe burns.

4.3. Cleaning the appliance

To clean the fryer chamber, follow these steps:

- Turn off the device and disconnect the device from the power supply,

- Place a container under the oil drain valve,

- Carefully and very slowly release the trigger lever and drain the oil from the chamber

into the tank so that it does not splash.

- After complete oil leakage, flush the chamber with clean filtered oil,

- When the chamber is clean, close the drain valve,

Periodically or when the frying chamber and its parts are covered with burnt fat, then

boil the water in the chamber.

15

1) Please pay attention to choosing the right cleaning agent. The cover elements and the

safety valve are made of aluminum. Contact with unsuitable cleaning agents can cause

corrosion.

2) Do not use steel wool or other cleaning tools and cleaning / disinfecting agents

containing chlorine, bromine, iodine or ammonia, as these substances will damage

stainless steel and shorten the life of the fryer.

3) Clean the device only when it is cold - otherwise there is a risk of burns.

Warning!

-The appliance is not designed for direct spraying with a water jet. Do not use a

high-pressure water jet for cleaning the device!

-Remember to wash the inside of the safety valve weight housing and their

threaded ends periodically (even daily - depending on the degree of use). Failure to

do so may result in excessive pressure and could result in serious injury and / or

burns or material damage.

4.4. Additional maintenance performed periodically

Check screw connections as well as tightness of oil and condensate valves and pipelines

on a regular basis.

At least once a month or when the frying chamber and its elements are covered with

burnt fat, boil the water in the chamber according to the instructions in this manual.

Periodically, every few months the interior of the chimney should be washed where the

steam cooler is located. To perform this operation, remove the rear chimney cover.

4.5. Deletion of the disturbance of work

DISTURBANCE

CAUSE

ELIMINATING THE TROUBLES

Pressure is going down

- safety valve is not tight

Clean the seat and the pin of

the weight

- pressure reducing valve is not

tight

It can be caused by dirt in the

valve- it should be cleaned, or

the valve is used- it should be

replaced

-gasket has worn out

If the lid is tightened by too

much pressure, the gasket

should be turned inside out. If

the gasket has been turned

inside out it should be replaced

16

Oil is foaming or boiling over

- water in the oil

It may be caused by lifting the

lid improperly. When the frying

cycle is over the manometer

shows “0”. At that time the lid

should be lifted energeticly and

fast, without hitting the stop of

a hinge. When you lift the lid

like that, water condensated on

it will flow down through the

drain pipe to a container on the

left side of the bowl.

Other reason for that may be a

chocked drain pipe. In such case the

drain pipe should be cleaned

- oil has been used for too long

After some time of use, oil gets

impurities ( water and crumbs).

It is important to replace the oil

regularly, filtrate it and remove

crumbs from the bottom of the

chamber.

4.6. Rules for the safe use of the appliance

The electric pressure fryer ADA SCE 12 has many safety features, however, the only

method to ensure the safe use of the device is to thoroughly understand the principles

of its proper installation, operation and maintenance.

The basic condition for good operation of the device is to keep it properly clean and to

follow the instructions in this instruction manual:

• Before installing and attempting to start the fryer, read the operating instructions

carefully. Incorrect installation, operation, maintenance can damage the device and also

create a security risk.

• The device only works safely when used as intended.

• The fryer can be used in rooms with ventilation that meet the applicable

requirements.

• Pay special attention to the power cables so that they do not touch the device during

operation.

• The fryer may only be operated by adults who have been trained in the use of the

appliance and health and safety regulations.

• Do not leave the device unattended with the heaters on,

• Do not allow children or persons unfamiliar with these instructions to operate the

fryer,

• Connection of the device and all repairs should be carried out by a person with

appropriate permissions.

• Do not make any alterations to the grease spreader by yourself or make changes to

the installation,

17

• Never immerse the device in water or other liquids.

• Do not allow the electrical device connected to the mains to be spilled with liquids or

water jets. It may cause electric shock!

• Do not move or tilt the device during operation.

• Do not hit the knobs and heaters,

• Handle hot fat with particular care.

• When operating the device, remember that the temperature of the device's

components may be high. Particular care should be taken because the top of the

appliance reaches a high temperature, which may result in burns.

• The fryer must not be put into operation after it has been found to be operating

incorrectly.

• Each time after finishing work disconnect the device from the mains.

• Have the technical inspection of the fryer carried out at least once a year. Including

checking the power cords including plug and socket, connection contacts, and grounding

check. This inspection should be carried out at the manufacturer's website or in an

establishment with appropriate qualifications and equipment with the required control

equipment.

4.7. First aid

When providing first aid you should:

- call the appropriate medical services,

- facilitate breathing by removing clothing,

- If necessary, take the injured person into the fresh air,

- cover the injured person with a blanket and prevent them from falling asleep,

- constantly monitor the victim,

- in case the injured person loses consciousness and is not breathing, give artificial

respiration until the arrival of the doctor.

4.8. Warnings

The use of the device for purposes different from or deviating from its normal purpose is

prohibited and considered as improper use.

Any claims against the manufacturer or / and its proxies for damages resulting from the

use of the device contrary to its intended use are excluded.

Liability for damages caused during the use of the device in a manner inconsistent with

its intended use is borne solely by the user.

1. Connection of the fryer to the electrical installation may only be carried out by a

person with appropriate professional preparation (qualifications). The manufacturer is

not responsible for incorrect connection of the device to the installation.

18

2. Under no circumstances should you close the lid while the oil is heating. Never heat

oil alone!

3. Do not fill the chamber with oil until the chamber is thoroughly drained and before

checking that the drain valve has not retained water. Always remember to place an oil

container under the drain valve. If the valve is not closed, the oil will fall out into the

tank.

4. The fryer must not be put into operation after the electric system has been

punctured.

5. Remember to wash the inside of the safety valve weight housing and their threaded

ends daily after finishing frying.

6. Observe the safety rules and basic health and safety regulations.

7. When operating the device, remember that the temperature of the device's

components may be high. Particular care should be taken because the top of the

appliance reaches a high temperature, which may result in burns.

The manufacturer disclaims any liability for any damage that may be caused to persons

or objects as a result of failure to comply with the obligations imposed by safety

regulations and regulations regarding the installation of equipment.

This device is marked in accordance with the European Directive 2012/19 / EU and the Polish Act of 11

September 2015. "On used electronic and electronic equipment" (Journal of Laws of 23.10.2015 item

11688) with a crossed out waste container . Such marking informs that this equipment, after the period

of its use, may not be placed together with other household waste. The user is obliged to give it to the

collectors of used electrical and electronic equipment. Collectors, including local collection points,

shops and communal units, create an appropriate system enabling the delivery of this equipment.

Proper handling of used electronic and electrical equipment contributes to avoiding consequences

harmful to human health and the environment, resulting from the presence of hazardous components

and improper storage and processing of such equipment.

At the end of the life of the equipment, return the device to the appropriate institution that deals with

the disposal of the devices. On behalf of the manufacturer, the contract regarding the organization and

provision of collection, processing, followed by recovery and recycling and disposal of "Waste

Equipment" shall be completed by:

Elektro-EKO

Electrical and Electronic Equipment Recovery Organization S.A.

ul. Łopuszańska95, Warsaw

ENVIRONMENTAL PROTECTION: Both the packaging of the new device and the old, used devices

contain valuable secondary raw materials and materials for recycling. Please dispose of individual parts

by type of material. Please inform your dealer or local administration about the current disposal

method.

19

5. CONDITIONS OF THE GUARANTEE CERTIFICATE

1. The User of ADA GASTROGAZ appliances is guaranteed by a direct Seller who sets out all the

rules for the warranty he grants through a sales contract concluded with the User.

2. The manufacturer provides warranty for parts for a period of 12 months for the Seller from the

date of sale of the device. The length of the warranty and the conditions for the User are

determined by the Seller upon conclusion of the sales / purchase contract for the device. The

manufacturer recommends carrying out periodic inspection at least once a year to ensure correct

operation of the device.

3. The seller undertakes to repair the device for free during the warranty period. The condition of

the warranty validity is compliance with applicable regulations and standards related to the

installation, use and maintenance of the devices. The faulty parts will be repaired in 14 days from

their record. Buyer has got the right to replace the device with a new one when any repair is

impossible.

4. The warranty does not cover the activities provided for in the operating instructions, which the

User is obliged to carry out on his own and at his own cost, e.g. installation, checking of operation,

cleaning, maintenance of the device and periodic inspections, etc.

The warranty does not apply to parts subject to normal wear and to some parts: in gas appliances

(light bulb, thermocouple, burner protection grid, ceramic plate, glass, gasket), in electrical

equipment (light bulb, glass, gasket).

5. In the event of any faulty operation of the device during the warranty period, immediately

inform the Seller. Complaints should be made in writing (by fax, e-mail or post).

6. Both the manufacturer and the seller shall not be liable for any direct or indirect damage

suffered by the User due to a product defect, in particular loss of profits or income, resulting

downtime, loss or damage of other equipment, costs of replacement goods, etc. Further claims are

also excluded. .

Both the manufacturer and the seller shall not be responsible for connecting the device to an

electric and gas supply inconsistent with the type plate, as well as for faulty assembly and damages

resulting from random events such as: fire, flood or lightning, etc.

7. The basis for accepting a complaint under the warranty is a device purchase document (invoice)

or other document signed by the Seller, containing the terms of the warranty granted. The user is

required to provide a document confirming the right to repair under the warranty. Lack of

document will result in the service being considered for a fee.

8. Unless the contractual terms provide otherwise, the warranty is calculated from the date of

issue of the document confirming the purchase of the device.

9. Compliance with the obligations arising from the guarantee will not extend or restart the

guarantee period.

10. The guarantee do not cover any damages caused in transport.

20

GUARANTEE CERTIFICATE

Appliance: Electric pressure fryer ADA SCE 12

Fabric number:

Manufacturing date:

Manufacturer quality control sign:

Date of sale:

Sign and stamp of seler:

No.

The date of the

declared

complaint

The date of the

repair

The type of the repair

Sign and stamp

Table of contents

Other ADA GASTROGAZ Fryer manuals

Popular Fryer manuals by other brands

Frymaster

Frymaster easyTouch FilterQuick FQG60T Installation, operation and maintenance manual

Metos

Metos 700 Series Installation and operation manual

Cecilware

Cecilware HDEFS15 Operation manual

Smeg

Smeg Built In Fryer SEFR535X Directions for use

METAL SUPREME

METAL SUPREME TFGC-G Series instruction manual

Welbilt

Welbilt Dean Decathlon D Series Installation & operation manual