Adam Pumps TECH TANK 210L Guide

cabinets, meter, DC and AC pumps, accessories, repair kit

MANUAL OPERATION AND MAINTENANCE

TECH TANK

210L

440L

NB PERFORMANCE OF UNAUTHORIZED MODIFICATIONS TO

“ADAM PUMPS” AUTOMATICALLY VOID WARRANTY OF ANY AND

ALL RESPONSIBILITY ‘CIVIL AND CRIMINAL CHARGE OF THE

SAME.

GENERAL DESCRIPTION

INSTALLATION & OPERATION

MAINTENANCE & REPAIR

PARTS LIST

Read and understand this Operating Manual before starting

installation, maintenance or repair.

GENERAL DESCRIPTION AND ALLOWED USE

This diesel transfer system is designed for the delivery of diesel fuel

(also for heating fuel and antifreeze) to vehicles and equipment from

an open surface storage tank. The pump is a self priming, positive

displacement, rotary vane machine which operates on 12V DC power

(models for 24V DC power are available), and delivers a flow of

approximately 40 litres per minute. The pump has a built-in bypass

valve that keeps the operating pressure below 1.3 Bar (18 psi). The

motor has a 30 minute duty cycle.

SAFETY PRECAUTIONS AND FORBIDDEN USE

Improper use or installation of this product can

cause serious bodily injury or death!

• Not for use with gasoline, alcohol, or other liquid

with a flash point below 40°C (104°F)

• Not for use in hazardous locations.

• Not for use with fluids thicker than diesel fuel.

• Not for use to transfer fluids into an aircraft.

• Not for use with fluids for human consumption.

• Not for dispensing water.

• Not for continuous duty applications.

EC COMPLIANCE STATEMENT

ADAM PUMPS ITALIA SPA, Via della Resistenza, 46/48,

41011 Campogalliano (Modena) - Italy, states.This system has been

designed for stocking, transport and transfer of diesel fuel for vehicles

or machines (see forbidden use paragraph). The flow comply with

the Directive for Machines 89/392/CEE (91/368/CEE, 93/44/CEE,

93/68/CEE), 89/336/CEE (93/68/CEE), 73/23/CEE, and with stand-

ards EN 60529, EN 60204-1, EN 55081-2. The TECH TANK system

has been designed following total exemption normative 1.1.3.1C

ADR. Declaring that the pump EN 55011C/.A, D.L. 277/91 and

AC Tech 40, conforms to the harmonized EN 60529, EN 60204-1,

EN 50081-2, EN 55011C/.A, DL 277/91. This document has been

signed by:

Mr. Bernard Gilson, Via della Resistenza, 46/48,

41011 Campogalliano (Modena) - Italy, Phone +39 059 528128,

Fax +39 059 528437who has full legal authority to represent the firm

in the European Community. Dated, 1st of February 2008.

Machine Identification - Label (typical example)

This Operating Manual should be considered as part of the

machine. When the machine is sold, it must be transferred

to the new owner.

ADAM PUMPS Italia Spa

Via della Resistenza 48

41011 Campogalliano

Modena Italy

Code : 2108510020802

ELETTR. KPT 12-40 FLT 25 CASS. PL. ROSS

12 Volt - 270 Watt - 18 A - 2800 r.p.m.

30 min. duty cycle Weight Kg.: 4

Manufacturer

Production

date

Product code

Model

Technical

data

2006

NOV

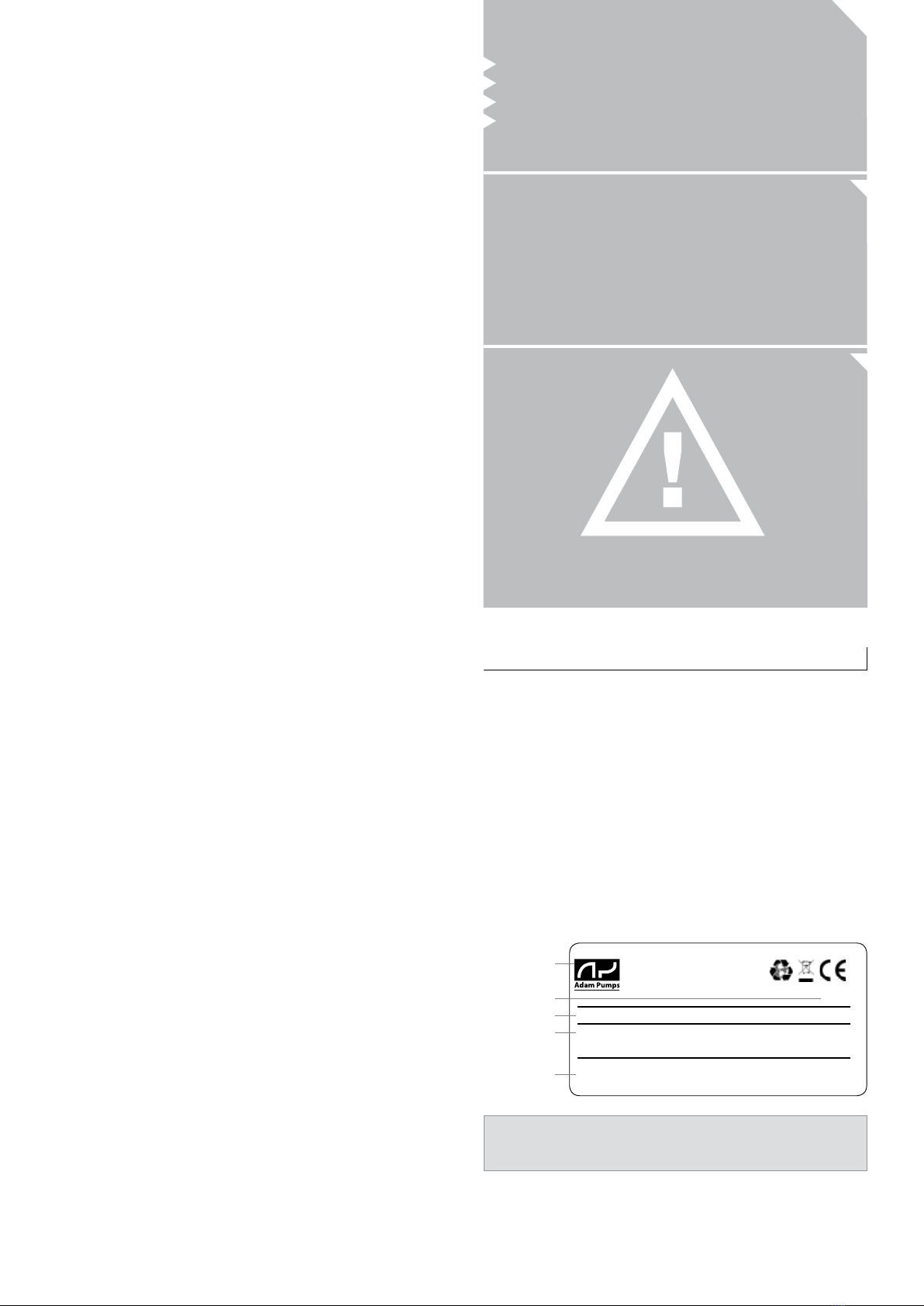

TECH TANK 1

DISCHARGE

HOOSE

C-TECH 40

PUMP

IN-LINE

DIGITAL

FLOWMETER

RELIEF

VALVE

FILLER

PLUG

AUTOMATIC

NOZZLE 60L

CAP 2”

TRANSFER GROUP COMPONENTS

SUCTION

OPENING/CHIUSING

VALVE

b) Position the tank on a secure surface, in a ventilated area, mak-

ing sure that it is securely fastened during transportation. ATTEN-

TION once full with diesel, the sloshing force could provoke tank

movements!

c) Unscrew the filler plug and fill up the tank with diesel after hav-

ing verified that pump is unplugged. For this operation wear ap-

propriate safety clothes and devices like glasses and gloves.

d) One the tank is full, close and secure the filler plug.

e) If part of the kit, calibrate the digital flowmeter Di-Flow In line.

(CALIBRATION paragraph)

ELECTRICAL INSTALLATION 12/24V

1. Connect the battery clips on the motor power cord to a suitable

battery, capable of delivering the necessary voltage and current

(see the Technical Data, back page of this manual)

• The RED clip is attached to the positive (+) battery terminal.

• The BLACK clip is attached to the negative (-) battery terminal

or to the vehicle frame.

2. If the power cable provided is not long enough, have it replaced

by an authorized electrician.

Avoid sparks that could cause a fire: Do NOT use a

patch cord to extend the power cables.

ELECTRICAL INSTALLATION 230V

The pump must be provided with a safety device of 30mA mini-

mum Din standard. The plug must be connected to an earthed

SHUKO socket. Do not cut or replace the provided plug.

Avoid sparks that could cause a fire: Do NOT use a

patch cord to extend the power cables.

OPERATIONS

AVOID HAVING PUMP RUNNING DRY FOR MORE THAN 3 MINUTES.

a) Open tank cover.

b) Before using the system, clean nozzle and hose from dirt.

c) Insert the nozzle into that to be filled up.

d) Connect the electrical cable to power supply as explained in para-

graph: ELECTRICAL INSTALLATION after having verified that pump

switch is on OFF(O)

e) Open the valve located at pump inlet.

f) Switch on pump motor.

g) Reset the DI-FLOW flowmeter to 0 by pressing the R button

h) Press nozzle lever to dispense.

i) When desired quantity or when the nozzle has automatically

closed, release the trigger.

j) Switch off pump immediately.

k) Reposition nozzle and hose into their login and rewind power

supply cable.

l) Close pump inlet valve and close tank cover.

MAINTENANCE

1. Inspect and clean the strainer on the inlet hose or pipe monthly.

2. Clean the metal “mouth” portion of the battery clips with steel

wool monthly to maintain good electrical connection to the battery.

3. Hoses should be inspected annually. Replace if cracked or worn.

4. Rotor and vanes will eventually wear, and should be replaced if pump

performance degrades. See the “Operational Problems” section to

determine if replacement is needed.

5. Drain hoses and pump and store in a clean, dry place when not in use.

®Teflon is a registered trademark of E.I. Du Pont De Nemours and Company.

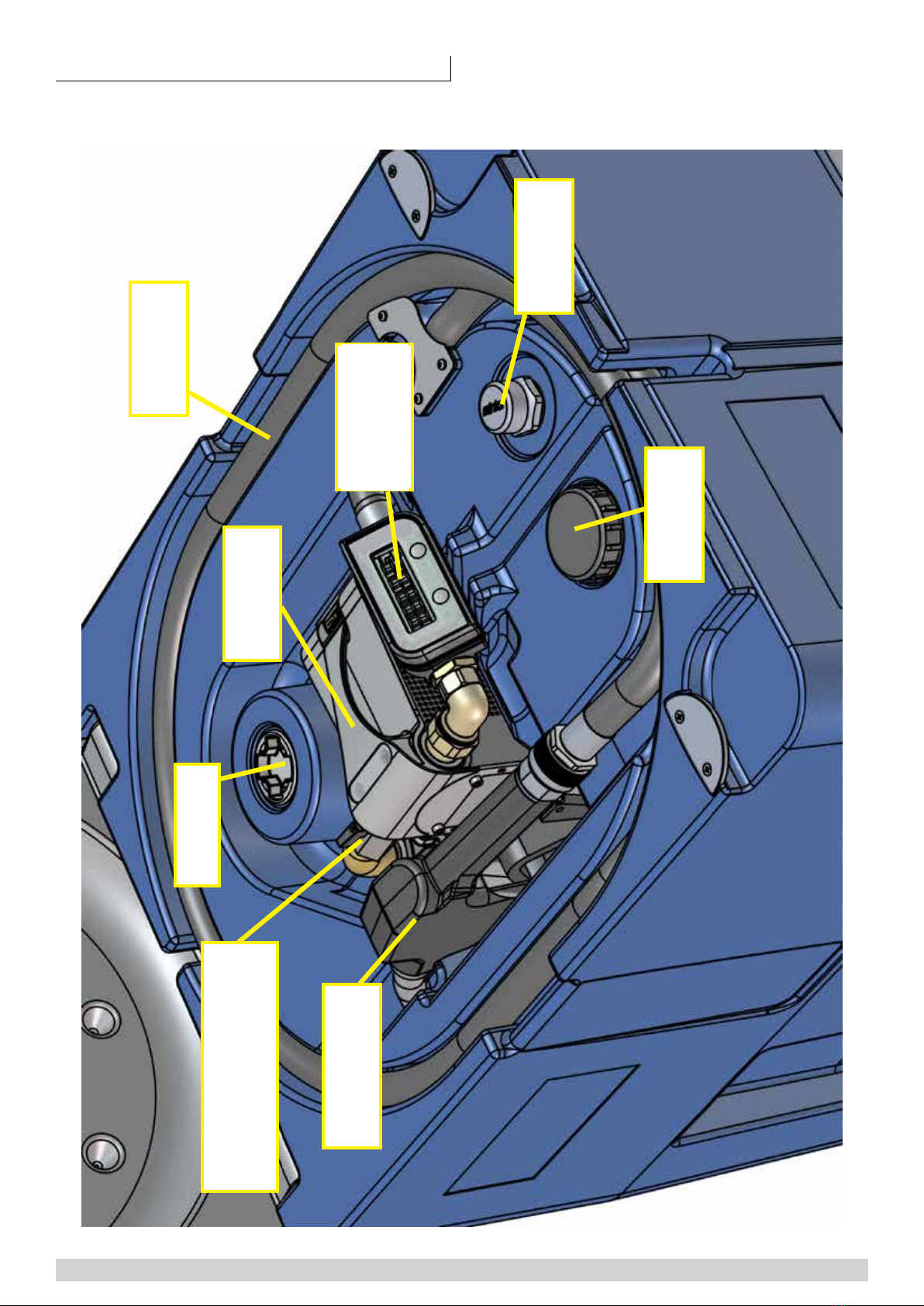

PRELIMINARY OPERATIONS

Before making any type of operation, read atten-

tively this manual..

a) Using the key supplied with the unit, open the tank cover,

make sure that during tran sport thank has not been damaged.

2 TECH TANK •

1. 2.

3.

4.

TECH TANK 3

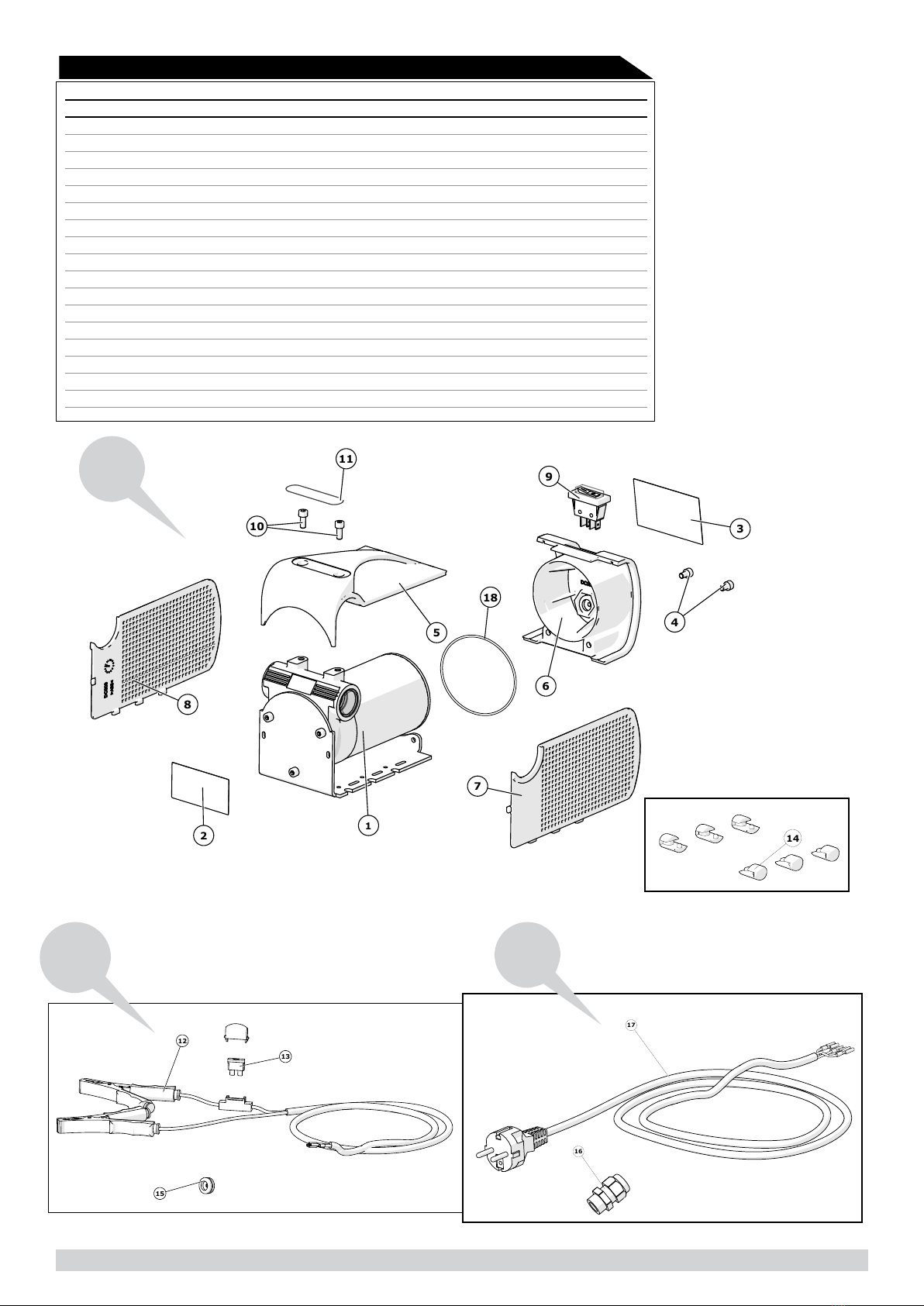

POS REFERENCE DESCRIPTION Q.TY

1 TT010 TANK 1

2 TT04 RELIEF VALVE1” BSP/G 1

3 OR006 O-RING 4112 1

4 121500700000 FILTER FLT 25 1

5 TUB002 BOCCOLA PRESSATUBO Ø 25 2

6 20152500000 TRANSPARENT SPIRALED HOSE Ø25 PVC 1

7 240015025000 HOSE STEM 1X25 O-RING 3118 NBR 1

8 13001015 SCREW TCCE M8X16 ZNB ISO 4762 2

9 INCH0002 TANK ADAPTOR 2” BSP/G 1

10 18001008 O-RING 3118 NBR 1

11 INCH0034 SWIVEL 3/4” BSP/G 1

12 250151500200 BRASS ELBOW 90° 3/4” BSP-G M-F 1

13 TT008 VALVE 3/4” BSP/G M/F 1

14 - PUMP C-TECH 40 1

AC400200 AC - TECH 40 L 230 V -

DC402400 DC - TECH 40L12V -

DC404400 DC - TECH 40L 24 V -

15 250161500200 BRASS CURVED NIPPLE 3 PZ 3/4” BSP-G 1

16 250053254000 BRASS NIPPLE 1’’-3/4’’M 1

17 ILG00D IN-LINE DIGITAL FLOWMETER 1

18 240015020000 HOSE STEM 1”X19 + O-RING 3118 NBR 2

19 TUB001 ALUMINUM BUSHING Ø19 (B28X30) 2

20 201015005000 DISCHARGE HOSE Ø19 X 4M 1

21 2715010000000 AUTOMATIC NOZZLE 60L 1

SPARE PARTS MANUAL

REPAIR KITS

KIT - 40 KIT40

KIT BY PASS 40-45 KITBY40-45

OPERATIONAL PROBLEMS (See Figures 5, 6 & 7)

Relieve pressure by opening the nozzle and draining the hose, and

disconnect power before servicing pump.

PROBLEM POSSIBLE CAUSE SOLUTION

Pump won’t

prime.

1. Suction line problem

2. Outlet is blocked

3. Bypass valve open

4. Vanes are sticking

5. Excessive rotor

and/or vane wear

Check for leaks or obstruction in suc-

tion hose or pipe;

Check to make sure outlet hose

and nozzle are clear and operating

correctly;

Remove and inspect valve; must

move freely & free of debris;

Check vanes and slots for nicks,

burrs and wear;

Replace rotor and vanes;

Pump hums but

won’t dispense

fluid.

1. Dirt or rust in pump

cavity

2. Broken rotor key

3. Motor failure

Clean out pump cavity;

Remove all debris & replace key;

Return to place of purchase;

Low Flow. 1. Excessive dirt in filter

2. Restriction on the

outlet or in the inlet

3. Excessive rotor or

vane wear

4. Low fluid level

Remove and clean or replace filter;

Long and small ID hoses, filters, and

automatic nozzles will reduce the flow

rate. Use higher flow components;

Replace rotor and vanes;

Fill tank;

Pump runs

slowly.

1. Incorrect voltage

2. Vanes sticking

3. Wiring problem

4. Motor problem

Check incoming power;

Check vanes and slots for nicks,

burrs and wear;

Check for loose connections;

Return to place of purchase;

Motor surface

temperature

gets hotter than

100°C (212°F).

1. Fluid is too thick

2. Motor ran more than

30 minutes

3. Excessive dirt in filter

4. Blocked pump rotor

Fluid must not be thicker than diesel

fuel;

Motor is designed for a maximum

“on” time of 30 minutes. Motor must

be allowed to cool down before using

again (except for model PA1 60);

Remove and clean filter;

Clean and check rotor and vanes;

Motor will not

turn on.

1. Battery dead or low

(pump 12-24V)

2. Fuse in power cord

is blown (pump

12-24V)

3. Switch failure

Check battery;

A blown fuse often indicates a prob-

lem with the free rotation of the mo-

tor. Inspect for dirt or debris in pump

cavity. Replace fuse with a standard

automobile fuse with same value;

Replace switch;

Liquid leaks. 1. Bad o-ring gaskets

2. Dirty shaft seal

3. Bad shaft seal

4. Incompatible fluid

5. Loose fasteners

Check all o-ring gaskets;

Clean seal and seal cavity;

Replace seal;

The liquid must be compatible with

HNBR seals and cast iron;

Tighten fasteners;

NOTICE: ANY MODIFICATION PERFORMED ON THE UNITS WITH-

OUT “ADAM PUMPS” WRITTEN PERMISSION WILL AUTOMATI-

CALLY VOID ANY GUARANTEE AND FREE “ADAM PUMPS” FROM

ANY KIND OF RESPONSIBILITY.

5

8

1

18

4

6

19

5

16

7

2

9

8

3

19

11

10

12

13

20

17

21

18

15

14

4 TECH TANK

TECH TANK

TECH TANK 5

TECHNICAL DATA

GENERAL FEATURES 210L

capacity[L]: 210

dimensions [mm; bxhxp]: 800x600x700

material: polyethylene

empty weight [kg]: 26

empty weight with pump [kg]: 35

cover with locking key: yes

GENERAL FEATURES 440L

capacity[L]: 440

dimensions [mm; bxhxp]: 1200x800x700

material: polyethylene

empty weight [kg]: 45

empty weight with pump [kg]: 54

cover with locking key: yes

TANK

IN RELIEF ADR

N°1.1.3.1.C

VERSIONS

TECH TANK STANDARD 12v CC 24v CC 230v CA

Voltage [V]: 12 24 230

Flow [l/min]: 40 40 40

Cable [m]: 4 4 2

Shut-off valve: sì sì sì

Filler plug: 2” 2” 2”

Discharge hose [m, Ø]: 4.5 - Ø 19 4.5 - Ø 19 4.5 - Ø 19

Nozzle: automatic automatic automatic

Meter: no no no

Safety valve / vent: 1” 1” 1”

TECH TANK TOP 12 v CC 24v CC 230v CA

Voltage [V]: 12 24 230

Flow [l/min]: 40 40 40

Cable [m]: 4 4 2

Shut-off valve: sì sì sì

Filler plug: 2” 2” 2”

Discharge hose [m, Ø]: 4.5 - Ø 19 4.5 - Ø 19 4.5 - Ø 19

Nozzle: automatic automatic automatic

Meter: flowmeter In-Line flowmeter In-Line flowmeter In-Line

Safety valve / vent: 1” 1” 1”

6 TECH TANK

17

Figura 6

X TECH

12/24 - 40

O TECH CC 40 FIG 6

2

13

4

16

3

7

6

12

1

8

9

10

11

12

5

15

14

4

REPAIR KIT (see picture 6)

POS. DESCRIPTION CODE QTY

KIT 40 LT KIT40

9 O-RING 2212 1

10 PLASTIC KEY 1

12 VANE 5

8 SEALING RING 10 X 19 X 7 HNBR 1

KIT BY PASS 40-45 LT 41071000

7 VALVE 1

5 BY PASS CAP 1

6 BY PASS SPRING 1

POS. DESCRIPTION CODE QTY

12 V 24 V

1 PUMP HOUSING 40L CP001 CP001 1

2 ELECTRIC MOTOR Ø77 231501700000 231501700000 1

3 PLATE AC-DC TECH 40 DC006 DC006 1

4 SAVE CAP THREAD Ø25 163013300000 163013300000 2

5

BY PASS CAP 71000521 71000521 1

6 BY PASS SPRING Ø21, 4X42 71008006 190110000000 2

7 BY PASS VALVE 71000520 71000520 1

8 SEALING RING Ø19 12010031000 12010031000 1

9 O-RING 2212 NBR 18001014 18001014 1

10 PLASTIC KEY 71000517 71000517 1

11 ROTOR Ø45 61000003 61000003 1

12 VANE 71000522 71000522 5

13 TIE M5 X 115 FLANGED 6100481150 6100481150 2

14 SCREW TCCE M5X112 ISO 4762 13001013 13001013 1

15 STICKER “CE” - - 1

16 STICKER “DANGER” 71000653 71000653 1

17 FOOT AC-DC TECH 40 DC005 DC005 6

TECH TANK 7

4

3

6

9

8

1

5

10

18

11

2

7

AC-DC TECH 40 FIG 7

Figura 7

AC -DC TECH 40

12/24 - 230

14

12

13

15

Figura 8

DC TECH

12/24 - 40

17

30

16

Figura 9

AC TECH

230 - 40

POS. DESCRIPTION CODE QTY

12 V 24 V 230V

1 PUMP O-TECH 40 OT40200 OT40400 OT400000 1

2 STICKER “CE” - - - 1

3 STICKER “DANGER” 71000653 71000653 71000653 1

4 SCREW TCCE M5X8 TRILOBATE DIN 7500 E VT002 VT002 VT002 2

5 HANDLE AC-DC TECH 40 DC001 DC001 DC001 1

6 SWITCH HOLDER AC-DC TECH 40 DC002 DC002 DC002 1

7 RIGHT SIDE AC-DC TECH 40 DC004 DC004 DC004 1

8 LEFT SIDE AC-DC TECH 40 DC003 DC003 DC003 1

9 SWITCH ON/OFF 11X30 190050070000 190050070000 190050070000 1

10 SCREW TCCE M5X12 ISO 4762 13001013 13001013 13001013 2

11 FACEPLATE AC-DC TECH 40 MA022 MA022 MA023 1

12 CABLE WITH CLAMP 2M (FIG 8) 17001010 17001010 - 1

13

FUSIBLE 30A (

FIG 8)

190170150000 190170150000 - 1

14 FOOT AC-DC TECH 40 DC005 DC005 DC005 6

15

CABLE GROMMET

(FIG 8) 190100100000 190100100000 - 1

16 CABLE GROMMET (FIG 9) - - AC001 1

17 CABLE WITH SCHUKO PLUG (FIG 9) - - 19000000000 1

18 O-RING 2287 NBR - - OR010 1

8 TECH TANK

5. DI FLOW DIGITAL METER; DI FLOW IN-LINE DIGITAL FLOW METER

3. INSTALLATION AND USE

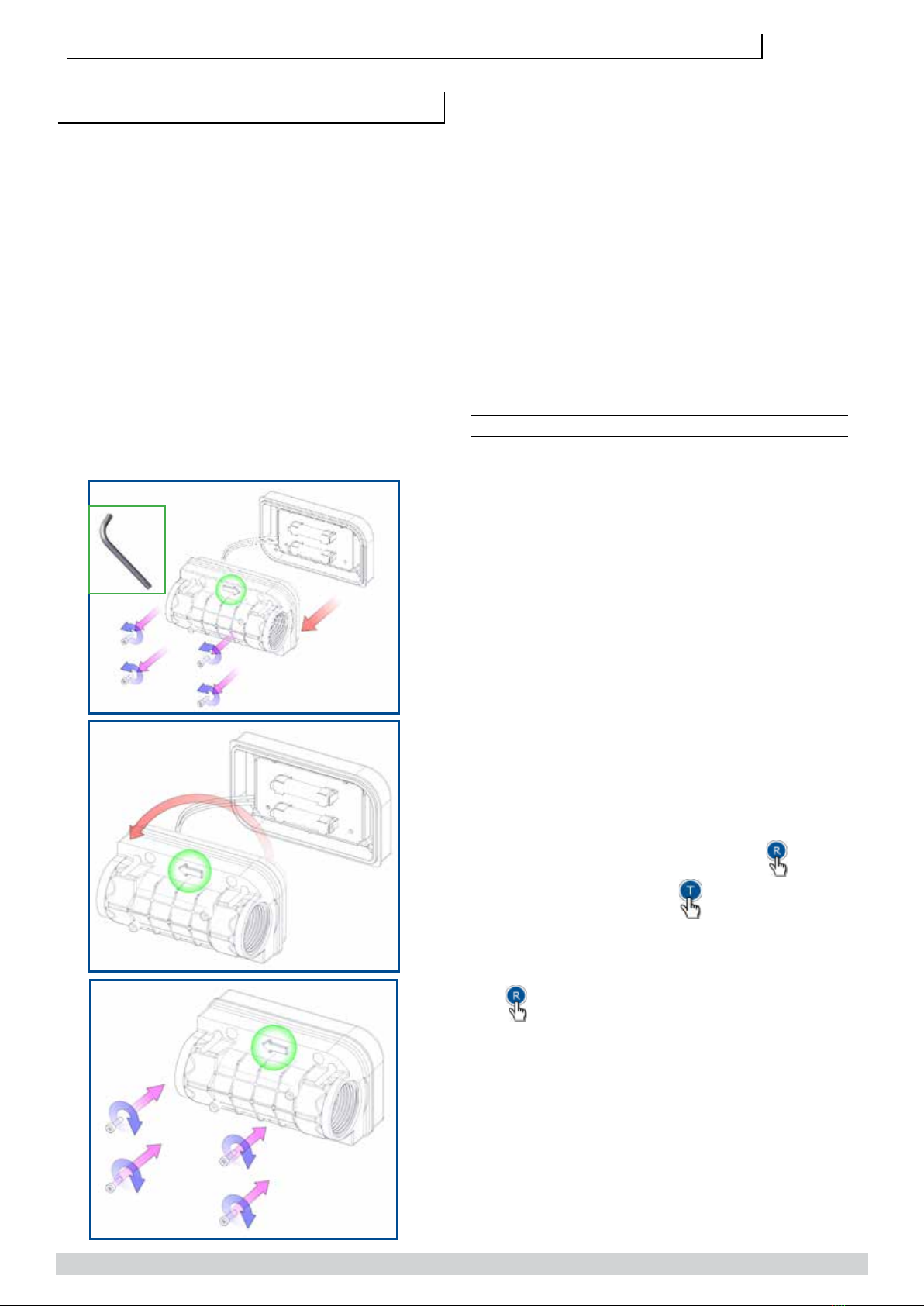

3.1 DISPLAY ORIENTATION

The meter is supplied with a calibration carried

out for liquid diesel at 20 °C. Calibration is

required when metering a different fluid, after

disassembly, at different temperature or after

significant wear. A proving container or a con-

tainer of KNOWN volume will be needed for the

calibration procedure. It is possible to invert the

flow direction using following steps:

1. Remove the 4 screws from the back of the

meter

2. Rotate the meter body by 180°

3. Reposition the body on the cover taking care of

not squeezing wires.

4. Screw the 4 screws to tighten the body to the

cover.

3.2 CONNECTIONS

When adding the flow meter to a existing sys-

tem, connect the flow meter inlet to the outlet

at of the pump, and connect the delivery

hose into the flow meter outlet. It is important

to respect the flow direction looking at the arrows

on the meter body. In case you need the opposite

flow, rotate the meter as described above in para-

graph 3.1.

The meter has a double Reed switch system to

avoid false readings due to vibrations or erroneous

installation and turbine reverse rotation. The meter

is threaded 1” BSP-P female both at inlet and out-

let. Sealing is made using O - ring 30x3 70Sh.

1

2

3

2.5

It is necessary, if not already installed in the

system, to install a filter or screen of at least

40 mesh prior to the flow meter.

3.2.1 ELECTRICAL WIRING FOR PULSER

VERSION

If you bought our pulser model, the flowmeter is

fitted with a 2m cable with 5 internal wirers to be

connected as follows:

1. Yellow wire: power + 12 Vdc

2. Brown wire: power 0 Vdc

3. Green wire: pulser channel 100 imp/unit

4. White and grey wires: Relay contact should you

desire to control the pump with the meter ( max

24Vdc 500mAh)

Once connected to power supply, the meter will

“Beep”, this sound beeps at each button pressure

(this happens only with pulser version).

It is important to know that the system is genera-

ting pulses 0-12Vdc with maximum frequency 2

milliseconds.

Should the meter control the pump, the button

will activate the pump while button stops it.

Two default settings are available and settable in

the system:

1. 60 seconds: to start the transaction after pres-

sing button

2. 20 seconds: seconds without pulse will stop the

transaction.

TECH TANK 9

3.3 KEY DISPLAY

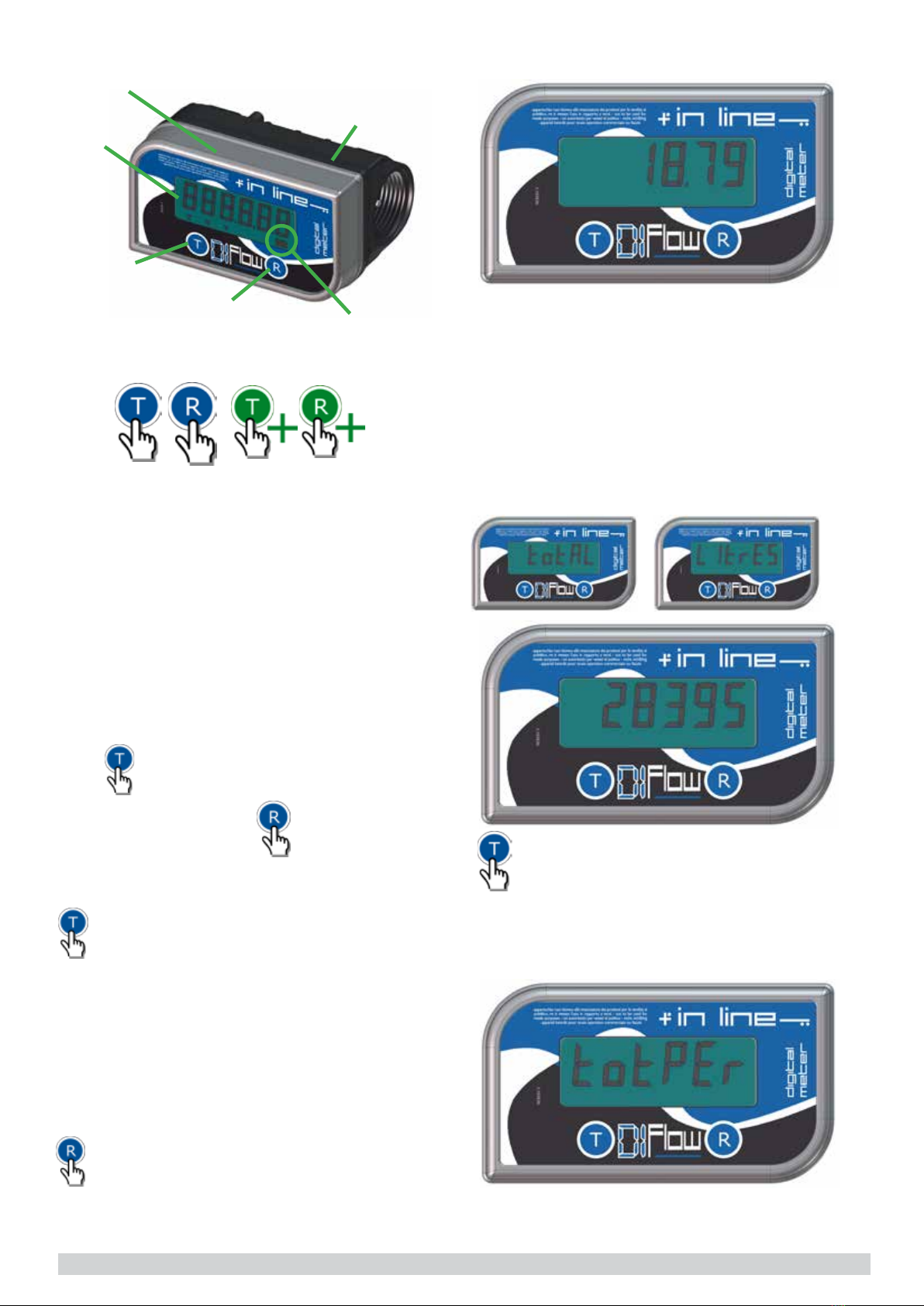

3.4 MAIN FUNCTIONS

The meter switches on automatically when a

transaction starts or when a button is pressed.

The display switches off automatically when no

transaction nor pulse is being detected during 120

seconds. Each time the display switches off, the

“partial” resets to “0”. It is then not necessary to

reset the meter after it has switched off. When the

meter switches o, it will automatically show the

“partial” counter, it will also go back to this screen

if buttons are not pressed during 10 seconds.

There are 5 main screens that can be scrolled

using button, last 5 transaction however

could be visualized using button.

3.3.1 SIMBOLS

simple pressure continued pressure

Starting from the “Partial” screen and at each time

button is pressed, system will scroll between

last 5 transactions. To go back to “partial” screens

wait 10 seconds without pressing buttons.

3.4.0 SCROLLING THROUGH 5 MAIN SCREENS

Starting from the “Partial” screen and at each time

button is pressed, following screens sequence

will be displayed:

1)ToTal, preceded by message “Total Litres”

2)ToTal period, preceded by message “TotPer”

3)Tank STock, preceded by message “Stock”

4)MiniMuM STock alarM, preceded by message

“Alert”

5)parTial

body

cover

“total”

button

display

“reset”

button

battery

alter

simbol

3.4.1 “PARTIAL” SCREEN

3.4.3 “TOTAL PERIOD ”SCREEN WITH

MESSAGE ”TOTPER”

3.4.2 “TOTAL” SCREEN WITH MESSAGE “TO-

TAL LITRES””

Displays 4.2 digits, switches on while pressing a

button or detecting pulses at transaction start. An

active meter will go back to this screens after 10

seconds without activity.

This screen is used as initial condition to

describe other 4 available screens:

, displays 6 digits, no decimal, shows all litres

transferred since first use. Cannot be reset.

10 TECH TANK

displays 5.1 digits, identifica shows all

litres transferred in a defined period of time. This

totalizer can be reset by pressing button.

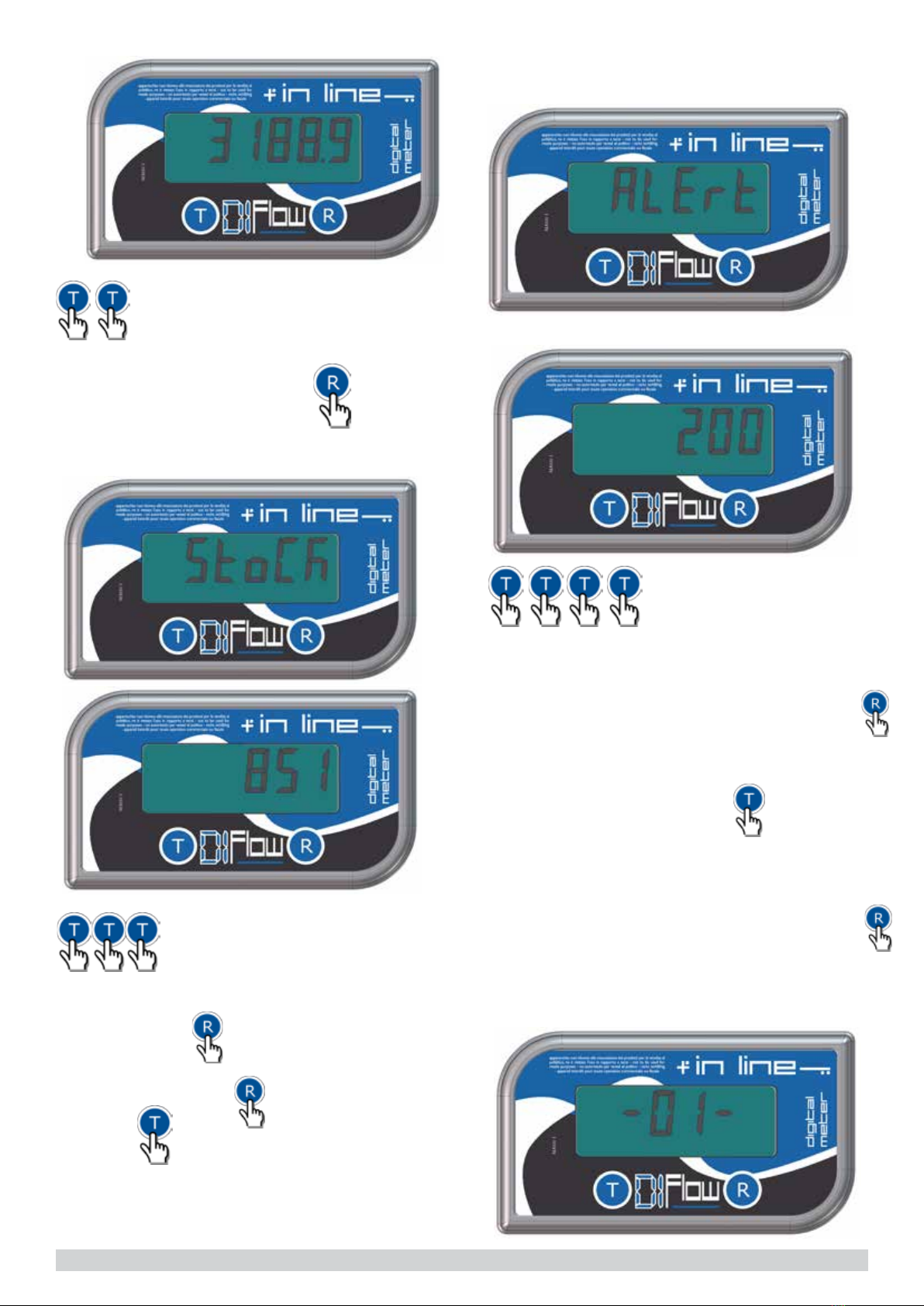

displays 5 digits, no decimal,

shows the calculated available stock. To insert

available stock, it is necessary to go to “Stock”

screen and press button. Value on display will

start blinking and will be then modifiable, increa-

sing the value pressing button or decreasing

it pressing button until you reach the desired

number. Should you maintain the button pressed,

the value will change rapidly. To confirm, wait 10

seconds until the “partial” screen I displayed.

3.4.4 “TANK STOCK” SCREENS WITH

MESSAGE ”STOCK””

displays 5 digits, no decimal

place, settable at maximum 65000 litres. Such

number identifies the minimum stock in the tank

under which the meter will display the alarm. To set

this alarm level, go to “Alert” screens and press

button . Value on display will start blinking and will

be then modifiable, increasing the value pressing

button or decreasing it pressing button until

you reach the desired number. Should you main-

tain the button pressed, the value will change rapi-

dly. To confirm, wait 10 seconds until the “partial”

screen I displayed.

NB. Setting the value “0”, alarm will be de-activa-

ted.

3.4.5 “MINIMUM STOCK ALARM” SCREEN

WITH MESSAGE ”ALERT”

3.4.6 “LAST TRANSACTIONS SCREENS”

Scrolling using but

ton, displays 4.2 digits, allows you to see last 5

transactions. Each time button is pressed,

display shows the transaction number and the

amount transferred. It is possible to sum the last

transactions by pressing button. Total is

made depending off in which screens we currently

are, example if we are currently displaying the four-

th transaction, pressing button will T-04

and the sum of the 4 preceding transactions. It is

possible to do this in any position of the tran-

sactions history.

3.5 SECONDARY FUNCTIONS

The device has some secondary function, neces-

sary to the good operation of the meter which are:

calibration, unit selection and instantaneous flow

rate.

3.5.1 CALIBRATION

The meter is supplied with a pre-calibration car-

ried out for liquid diesel at 20 °C. Calibration is

required when metering a different fluid, after dis-

assembly, at different temperature or after signif-

icant wear. A proving container or a container of

KNOWN volume will be needed for the calibration

procedure. It is recommended that the container

volume be at least 19 liters (5 gallons).

18

16

14

12

16 18,5

ATTENTON: the system does not allow a cali-

bration if quantity transferred is under 5 litres.

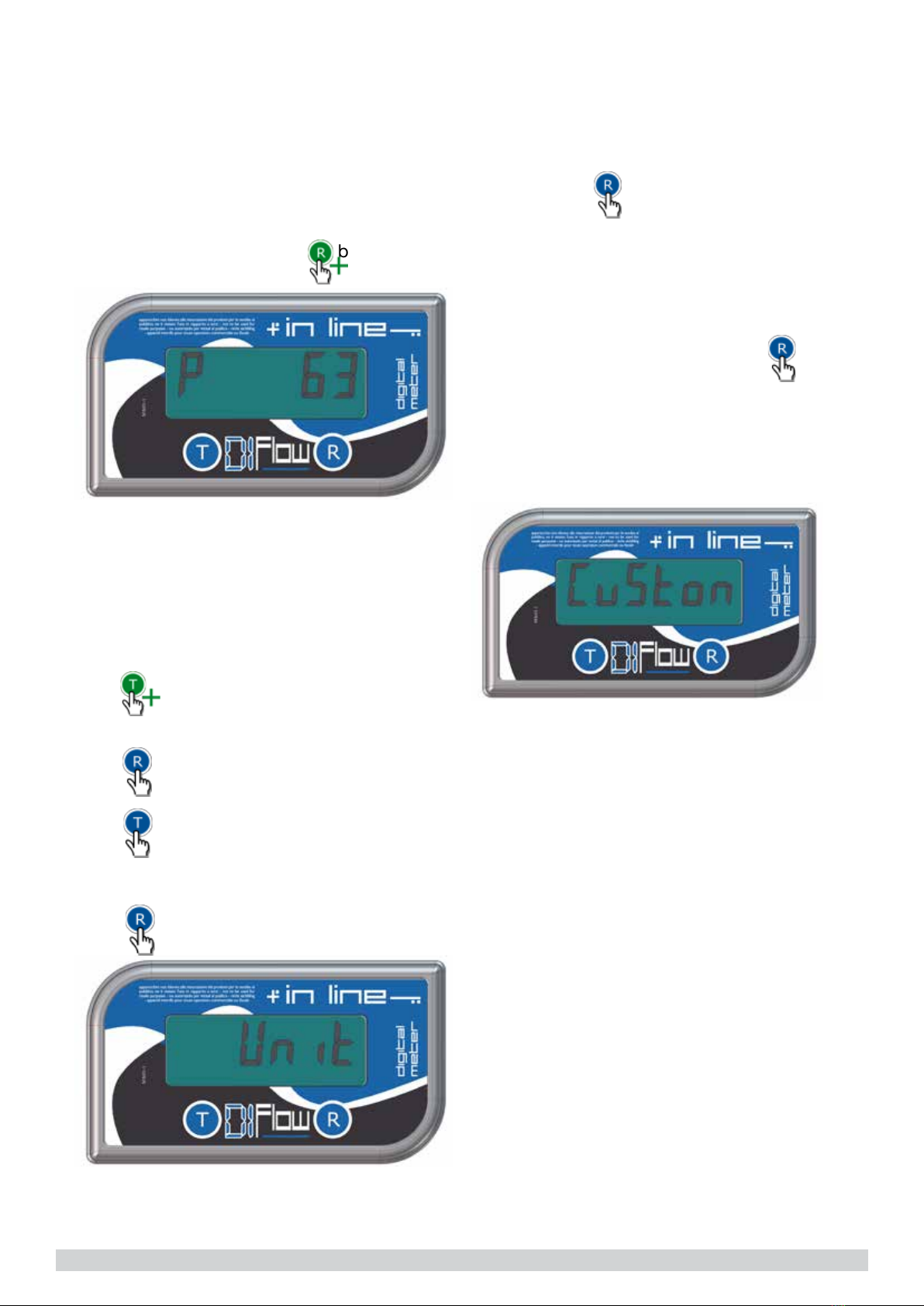

Calibration procedure

1. Starting from “Partial” screen, fill up the calibra-

tion jug to a known volume; it is important to do

this at a flow rate of minimum 10 litres a minute

without topping up else calibration could be inac-

curate. Use the nozzle fully open.

2. if the displayed quantity is not matching the me-

asured quantity the meter must be calibrated.

3. to enter in calibration mode, display will

show “CAL” blinking

4. to confirm, will display last quantity

transferred blinking in current unit

of measure

5. Increase or decrease that quantity using

or

buttons until correct quantity i displayed.

6. Wait 10 seconds to confirm and save automati-

cally this new calibration.

TECH TANK 11

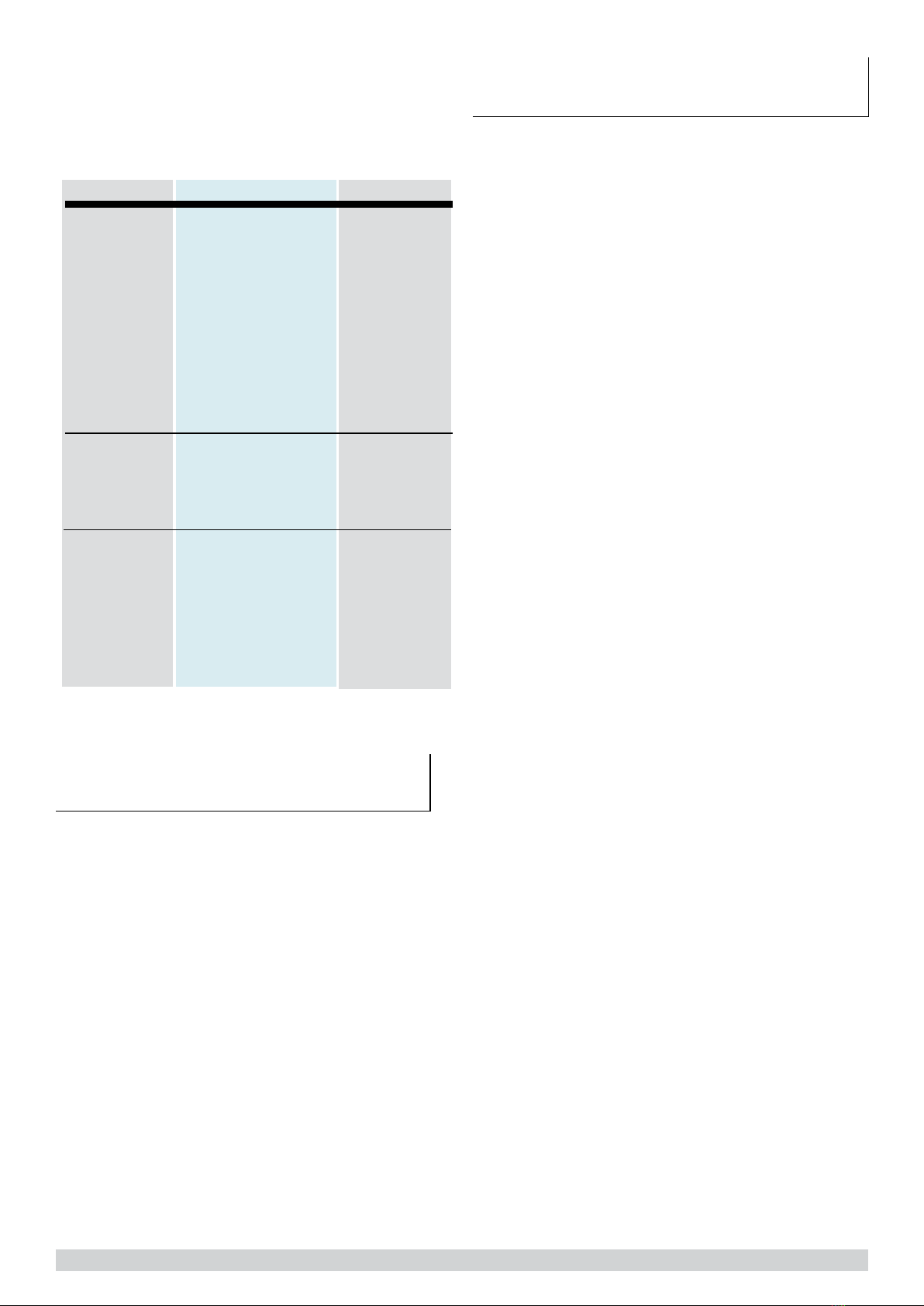

3.5.3 SELECTING UNIT OF MEASURE

The system has 4 standard units of measure (Litre

- US Gallon - Quarts & Pint) plus one “Custom”

unit that can be configured by the user. To select

the unit, do as follows:

1. Start from “Partial” screen, to do this do not

press buttons for 10 seconds.

2. press to enter in “unit of measure” mode,

the message “Unit” will be displayed

3. press to confirm

4. press to scroll between unit:

“litres”- “us-gal” –“quarts” – “pints” – “custom”

5. press to confirm.

3.5.2 INSTANTANEOUS FLOW RATE

The device is capable of showing the instanta-

neous flow rate during a transaction. To visualize

the flow rate press and maintain button during

transaction.

With this new calibration last transaction as well as

last 5 in history will be adapted to new calibration.

TOTAL and TOTAL PERIOD will remain unchan-

ged.

CUSTOM UNIT OF MEASURE

Default factory setting is decalitre (1/10 litre). This

value can be configured as follows:

1.Repeat operations 1 to 5 from paragraph 3.5.3

“Selecting unit of measure”.

2.Once the choice of “custom” has been confir-

med pressing button, the meter will propose

the default value blinking 0.100. To obtain such a

coefficient, it I necessary to simply divide

“custom”/”litre”. Example: if we desire to have a

“custom” unit (1,00) for a 0,33 litre can, we have to

divide 1 / 0,33 = 3,03 and insert the new coeffi-

cient 3.03.

3.Increase or decrease this value with and

button until you reach the desired value taking into

account that reference unit is the litre.

4. Once the correct value is displayed wait 10

seconds, the meter will save the value and return

to “Partial” screen.

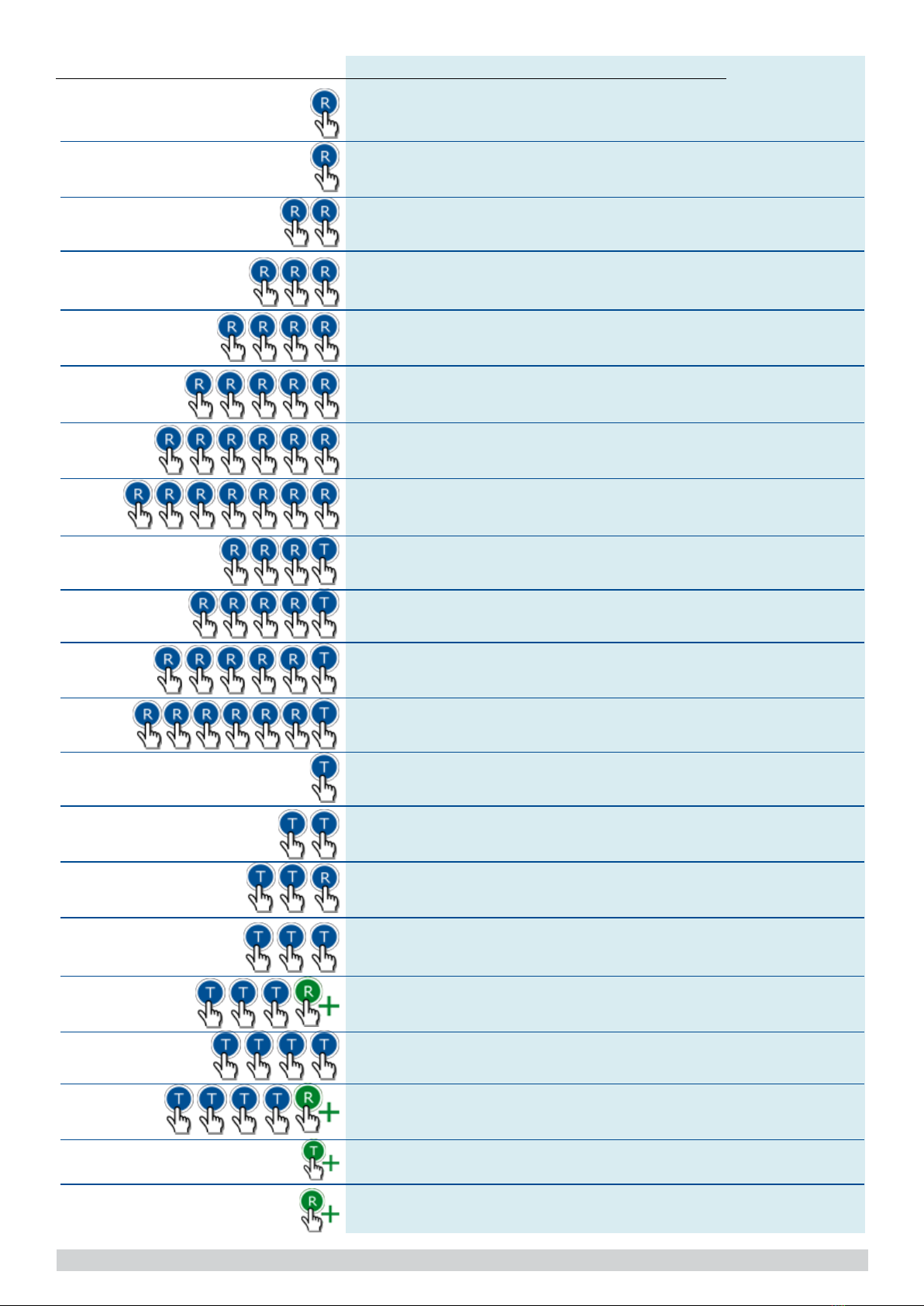

3.5.4 BUTTONS COMBINATIONS:

Starting from “Partial” screen:

(see table page 9)

12 TECH TANK

reset partial screen (only if transaction is not going on

visualize the instantaneous flow rate (only when transaction is ongoing)

visualize first transaction in history

visualize second transaction in history

visualize third transaction in history

visualize fourth transaction in history

visualize fifth transaction in history

visualize first transaction in history

visualize total of first two transactions in history

visualize total of first three transactions in history

visualize total of first four transactions in history

visualize total of all transactions in history

visualize total “Total”

visualize period total “totPer”

reset period total ”totPer”

visualize the ”Stock” situation

modify the value in “Stock”

visualize minimum stock level “Alert”

modify minimum stock level “Alert”

modify “unit of measure”

enter in “calibration mode”

BUTTONS FUNCTION

TECH TANK 13

4. MANUTENTION & STOCK

4.1 TEST LCD & BATTERY CHANGE

While pressing & together for 2 seconds,

the system will run a test one the LCD display

The system will then show following information:

1. Product name: ”DI FLOW”

2. Firmware version: “r1.0”

3. Current unit of measure: “Unit” “Litres”

4. Current calibration factor (imp/l): ”CAL” “40.00”

5. Power supply in Volt: “bat Vol” “2.79” (if value is

< di 2.8V else “FULL”)

6. Percentage of residual battery charge: “bat Per”

“52.95”(displayed only if supply tension is < 2.8

Volt)

When battery power is < 0.9Volt the displays

shows a battery icon (bottom left). When this

happens, display brightness will be low. It will be

necessary to change batteries:

1. Rimove the 4 screws on the back of the meter

2. Exchange the 2 batteries with 2 AAA 1.5V alkali-

ne batteries

3. Reposition the body on the cover taking care of

not squeezing wires.

4. Screw the 4 screws to tighten the body to the

cover.

4.2 CLEANING THE TURBINE

The meter has 2 magnets fitted into the turbine.

This magnets could attract metallic powders (if

present) that could block the turbine into the meter

body. For that reason, it could be necessary to pe-

riodically verify and eventually clean the magnets.

To do this, unscrew the internal shaft and its bolt.

Take care to reassemble the turbine in the correct

mode as illustrated hereafter. .

Be careful when reassembling the turbine in the

correct direction, as in the following figure:

14 TECH TANK

5 .TECHNICAL DATA BATTERY

MODEL

1. Measuring system: Turbine

2. Inlet/Outlet : 1” BSP/G female

3. Measuring range: 5 - 150 lpm

4. Accuracy ± 0.5%

5. Repeatability (typical): ± 0.3%

6. Max Pressure of use: 3,5 bar (50 psi)

7. Temperature of use: -10°C + 60°C

8. Display: 6 digits LCD

9. Power supply: Alkaline batteries 2x1.5V AAA

10. Impermeability rating: IP65

11.Weight: 0.25Kg

4.4 DIAGNOSTIC

PROBLEM

The meter is not

reading

The display is

not switching on

Inaccurate preci-

sion reading

POSSIBLE CAUSE

1. turbine is blocked

2. wrong installation

3. Reed switches are

broken

4. turbine has been

reassembled reverse

1. exhausted batteries

2. bad contact on bat-

teries

1. flow rate too low or

too high

2.wrong calibration

3.air inside system

4. dirty magnets

SOLUTIONS

1. Disassemble &

clean turbine

2.verify thanks

to the arrow on

the meter that it

i correctly fitted

on the line.

3. contact your

supplier to get an

Exchange board

4. rotate the

turbine by 180°

1. change bat-

teries

2. verify batteries

positioning

1. verify technical

data on pump

flow rate

2.calibrate

3. verify that

pump is not

sucking air

4. clean magnets

4.3 STOCK

If the meter has to be positioned in stock for a

while, clean it carefully. This will help to prevent

eventual damages.

5 .TECHNICAL DATA DI-FLOW

12V PULSER MODEL

1. Measuring system: Turbine

2. Inlet/Outlet : 1” BSP/G female

3. Measuring range: 5 - 150 lpm

4. Accuracy ± 0.5%

5. Repeatability (typical): ± 0.3%

6. Max Pressure of use: 3,5 bar (50 psi)

7. Temperature of use: -10°C + 60°C

8. Display: 6 digits LCD

9. Connection cable antiflame: 2m

10. Power supply: 12vDC - 10mAh (yellow +12,

brown 0v)

11. Relay contacts: max.voltage 24vdc 500mAh

(white,grey)

12. Pulser output: 0-12vDC, 100 imp/unit (green)

13. Impermeability rating: IP65

14. Weight: 0.25Kg

TECH TANK 15

03.2014 rev. 0

6 . EXPLODED VIEW & SPARE PARTS

POS. DESCRIPTION REF. Q.TY

1 STICKER WITH BUTTONS MA031 1

2 BOLT M3 81101010000 4

3 METER COVER TF035 1

4 ELECTRONIC PCB TF046 1

5 SCREWS M3 VT010 1

6 BATTERY AAA TF048 2

7 O-RING OR018 1

8 BODY DIFLOW – INLINE TF036 1

BODY DI FLOW - INLINE UREA TF042 -

9 TURBINE SHAFT TF039 1

10 TURBINE HOLDER TF038 2

11 TURBINE TF037 1

12 MAGNET TF040 2

13 SELF BLOCKING BOLT VT009 1

14 SCREW M3 X 12 VT011 1

16 TECH TANK

This manual suits for next models

1

Table of contents

Popular Tank Equipment manuals by other brands

AEROTECNICA COLTRI

AEROTECNICA COLTRI COLTRI SUB Instructions for use

Vmac

Vmac A500245 installation manual

Franklin Fueling Systems

Franklin Fueling Systems UPP PIPING installation guide

JohnDow Industries

JohnDow Industries JDI-FST15 user manual

Reverso

Reverso AFP-150 manual

Armstrong

Armstrong 180-LD instructions