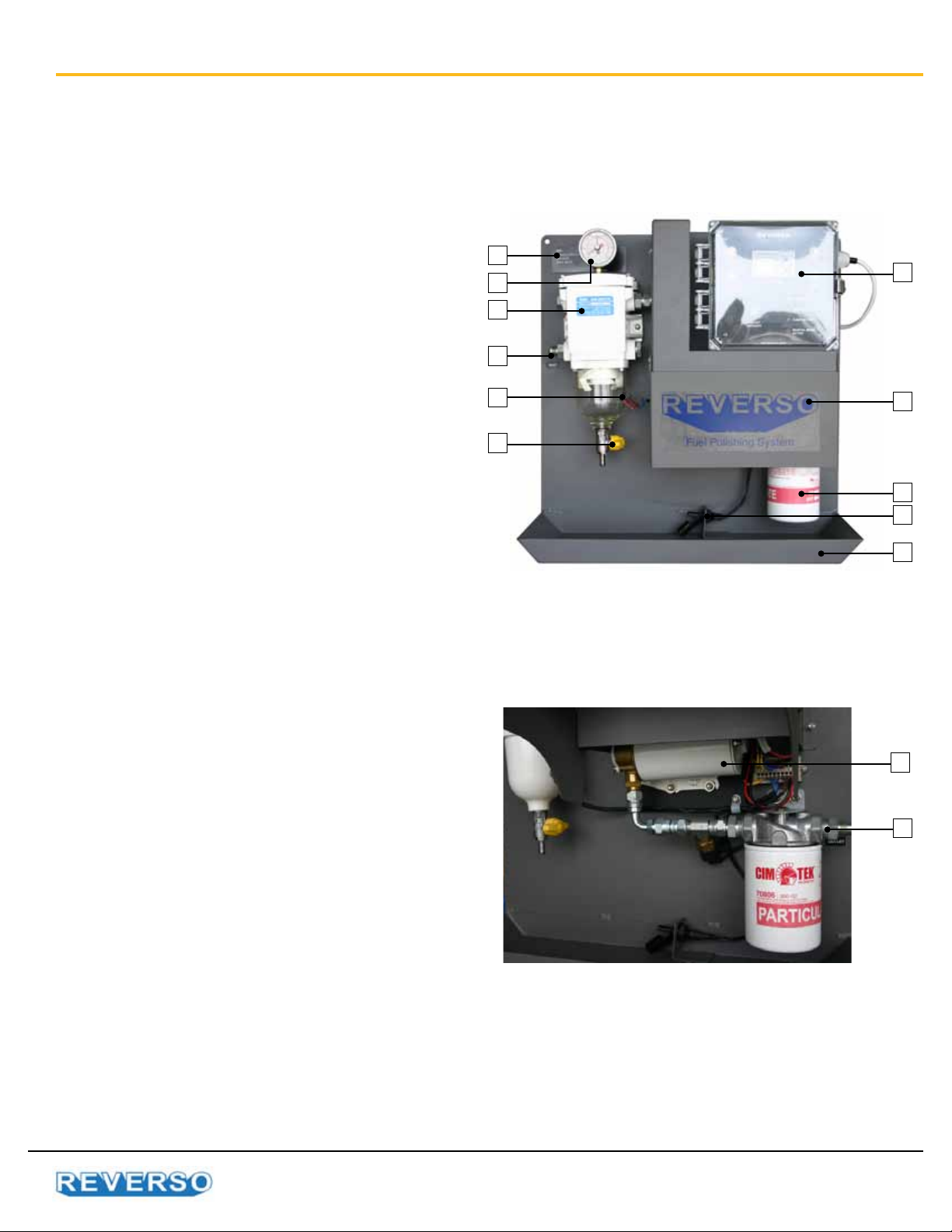

8

Digital Timer Instructions: Set Schedule Timer

ESC OK

MTWTFSS

MTWTFSS

11:00

15:00

ON

OFF

1 2

3 4

5

7

6

8

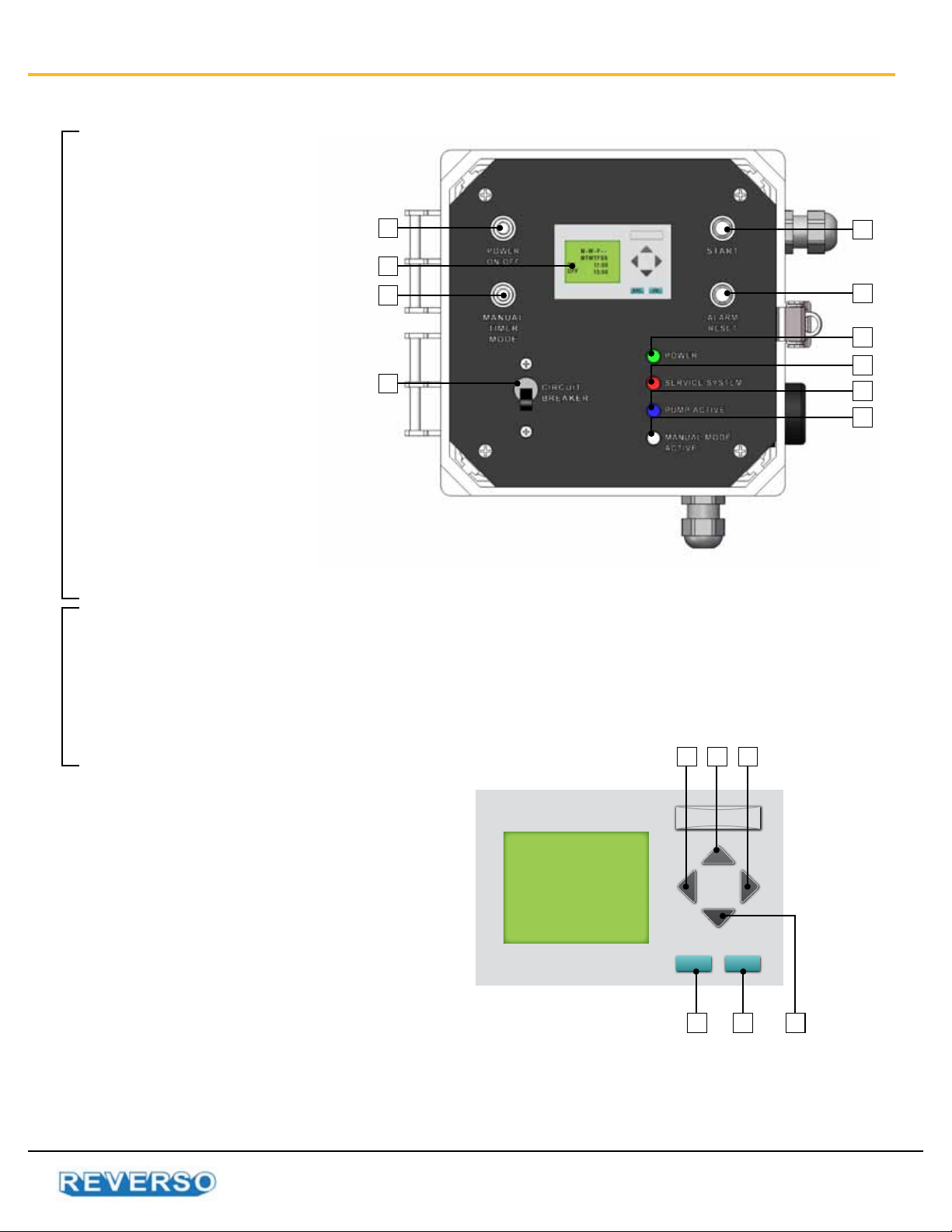

A. Ensure the breaker is ON.

B. Move the red power switch to the ON position and

power indicator light is on.

C. Ensure timer mode is switched to Schedule Timer.

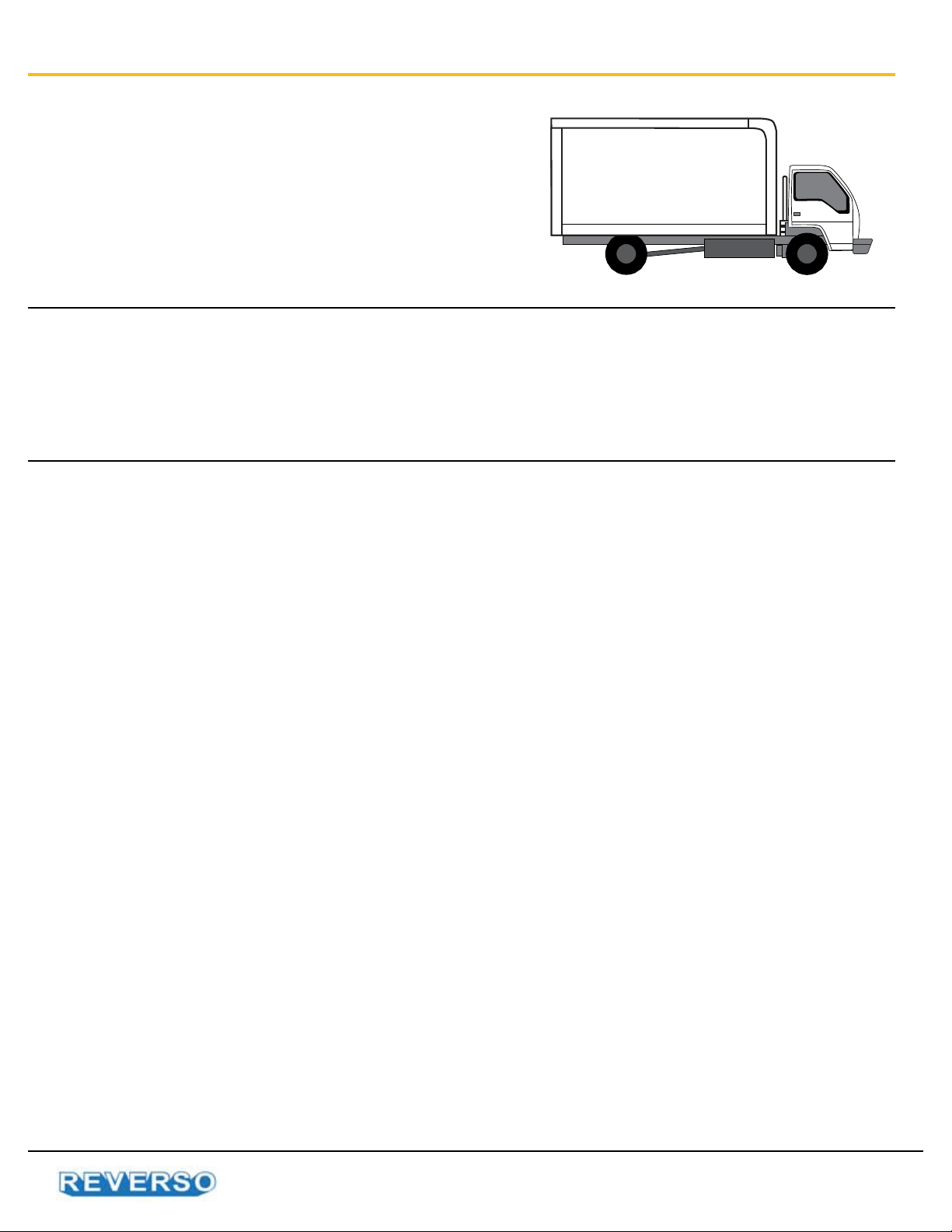

Change the run days

With the ashing underline in the days row, press the

OK key until ashing box appears. Use the LEFT/

RIGHT key to move between days. Use the UP/

DOWN key to program run days. A dash(-) indicates

the system will not run on that day. Press OK key when

nished and the cursor will return to ashing underline.

Press ESC to save. Flashing underline will disappear.

Every 5 seconds, screen will request user to push

Start button to activate pogram.

Hold the ESC key until ashing underline appears

under the rst day of the week. This ashing

underline indicates your selection. Use the LEFT/

RIGHT keys to move between the dates, start time,

and stop time.

When using this method, follow sequence

exactly or damage to program can occur (non-

warrantable situation).

Change the run time

With the ashing underline in the days row, use the

LEFT/RIGHT key to move to start time (ON).Press OK

key until ashing box appears. Use UP/DOWN key

to change time. Press OK key when nished and the

cursor will return to ashing underline. Repeat with

stop time (OFF).

Setting the schedule timer is nished. In this example,

system will run on Monday, Wednesday and Friday.

System will start at 8:00 am and stop at 2:00 pm.

Afterwards, every 5 seconds screen will indicate the

schedule timer is active.

Stop Time

Start Time

Run Days

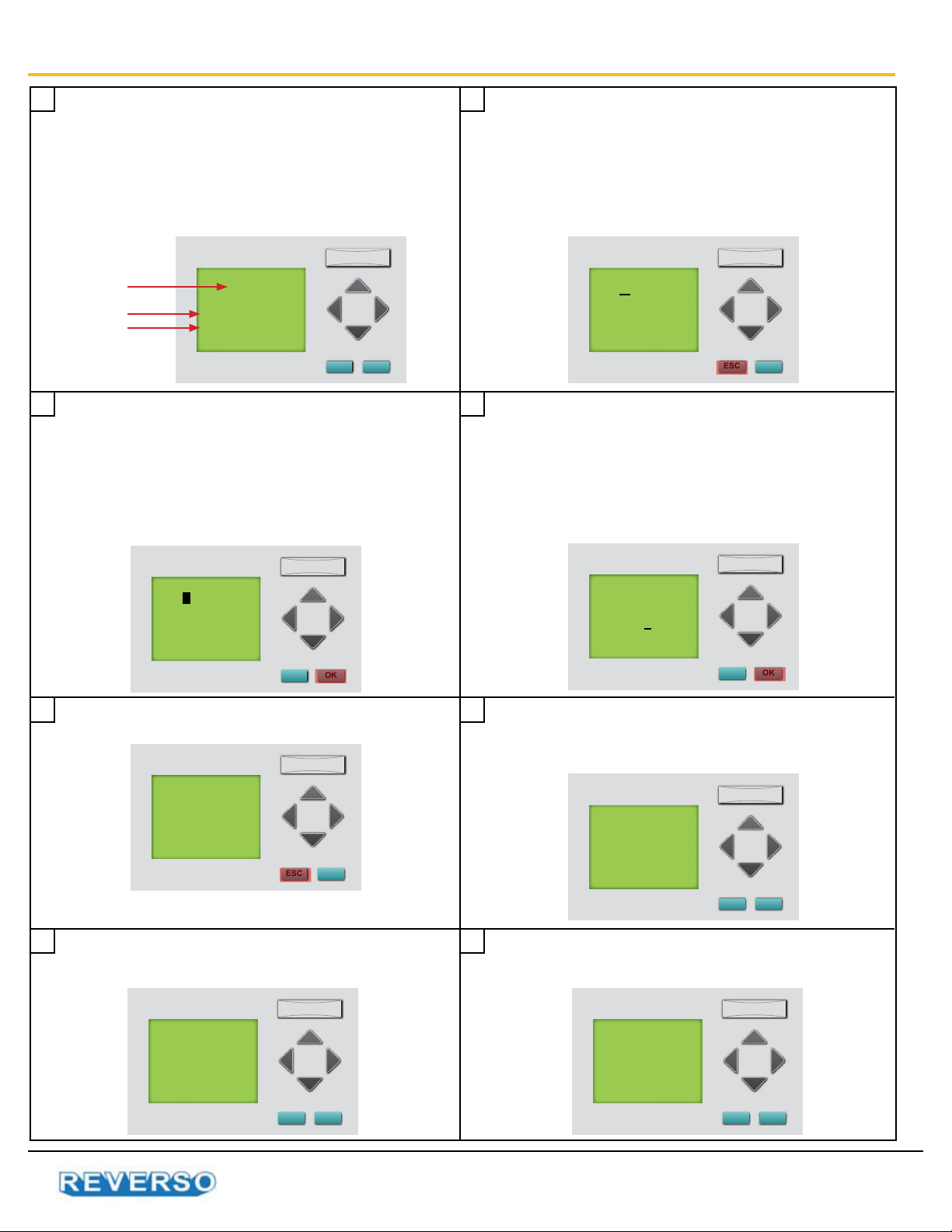

ESC OK

MTWTFSS

MTWTFSS

11:00

15:00

ON

OFF

ESC OK

M- W - F - -

MTWTFSS

11:00

15:00

ON

OFF

ESC OK

M - W - F - -

MTWTFSS

08:00

14:00

ON

OFF

ESC OK

M - W - F - -

MTWTFSS

08:00

14:00

ON

OFF

ESC OK

M - W - F - -

MTWTFSS

08:00

14:00

ON

OFF

ESC OK

Automatic

Timer

Active

ESC OK

To Activate

Push the

Start

Button