Contents

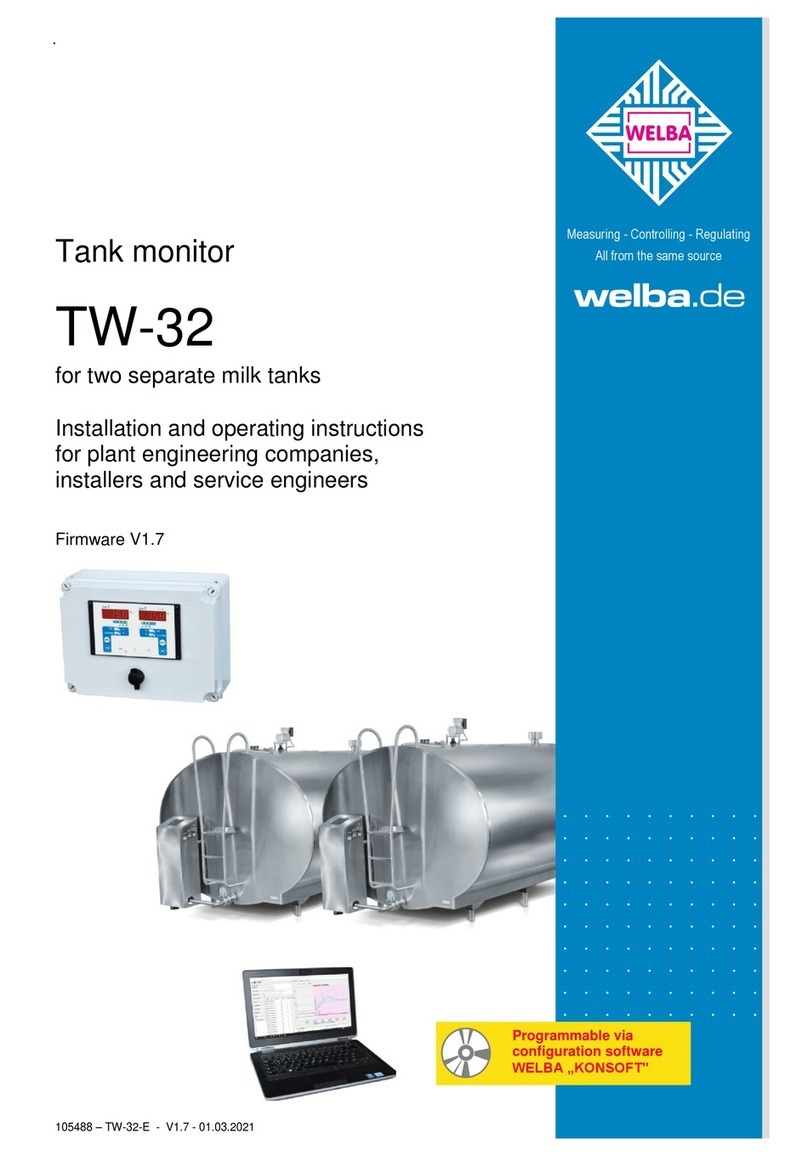

Introduction ...........................................4

Safety ................................................5

- General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

- Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

- Wiring, screening, earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation ............................................8

- Location and climatic conditions . . . . . . . . . . . . . . . . . . . . . . . . 8

- Unpacking and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

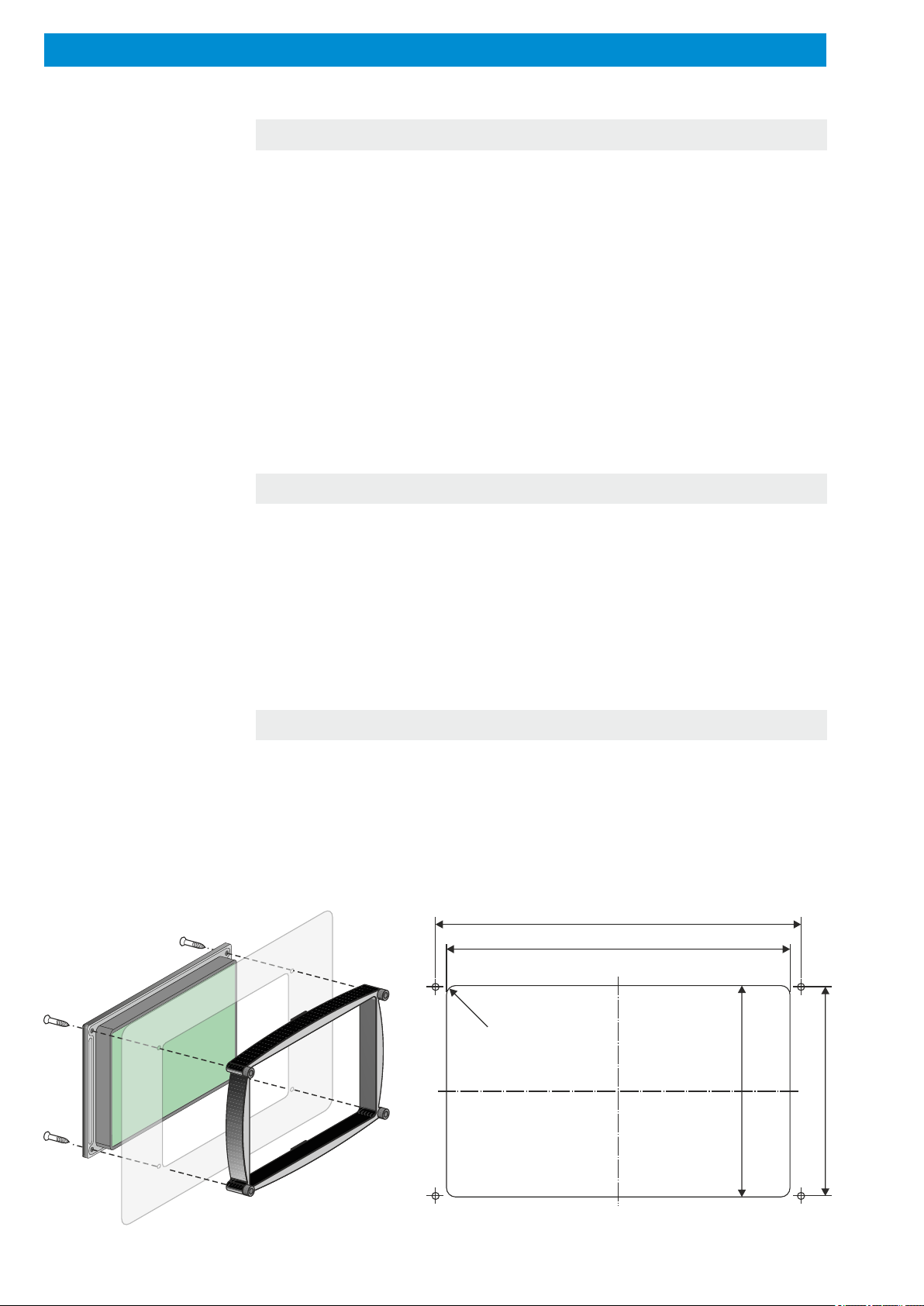

- Installation of housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

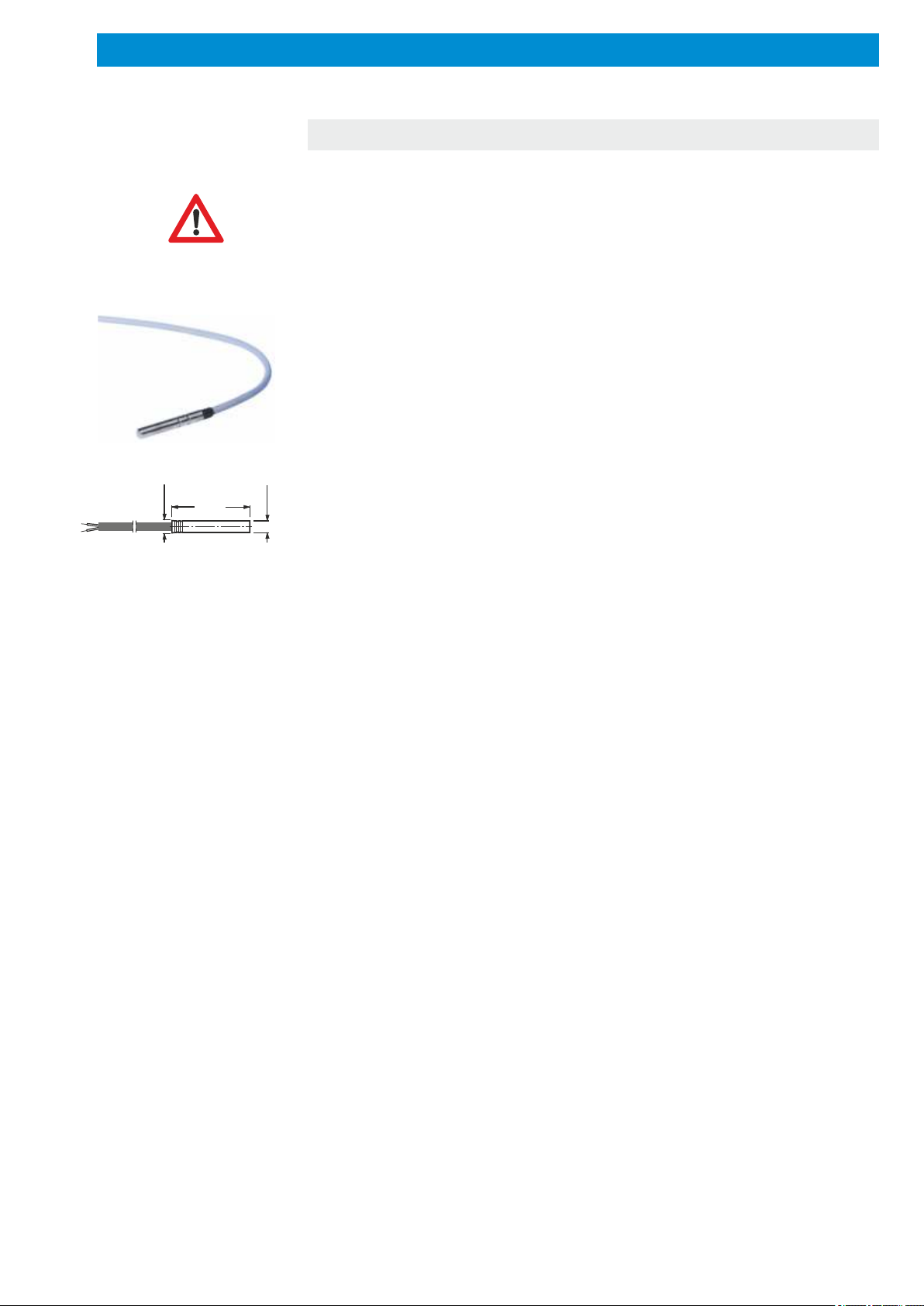

- Fitting the sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

- Safety during installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

- Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

- Connection diagramm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Technical data ........................................12

Function overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Internal data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- EMAIL or SMS- alarm message/remote maintenance/

remote diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

The configuration software "Konsoft" . . . . . . . . . . . . . . . . . . . . 16

Operating levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation of working level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

- Button functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

- Meaning of LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

- Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

- OFF mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

- Cooling mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

- Cleaning mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contents

Cleaning programme description . . . . . . . . . . . . . . . . . . . . . . . . 24

- Cleaning programme diagram. . . . . . . . . . . . . . . . . . . . . . . . . 24

- Cleaning stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

- Cleaning with alkaline or acidic detergent. . . . . . . . . . . . . . . . 31

- Disinfect with "P-acid" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

- Time of dosing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

- Cleaning cycle completed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

- Manual stop of the cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 32

- Stop of the cleaning process due to faults . . . . . . . . . . . . . . . 32

- Power failure during the cleaning process . . . . . . . . . . . . . . . 33

- Quickwash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

- Start options for the cleaning process. . . . . . . . . . . . . . . . . . . 33

- Single step function during cleaning . . . . . . . . . . . . . . . . . . . . 34

Adjustment of parameters in general . . . . . . . . . . . . . . . . . . . . . 35

Operation of 'Cooling parameters 1' level . . . . . . . . . . . . . . . . . 36

Operation of 'Cooling parameters 2' level . . . . . . . . . . . . . . . . . 38

Operation of 'Cleaning parameters 1' level. . . . . . . . . . . . . . . . . 44

Operation of 'Cleaning parameters 2' level. . . . . . . . . . . . . . . . . 46

Operation of 'Hardware Configuratioon' level . . . . . . . . . . . . . . 49

Operation of 'Service parameter' level . . . . . . . . . . . . . . . . . . . . 52

Operation of 'I / O test parameter' level. . . . . . . . . . . . . . . . . . . . 53

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Other information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

- Function "Intermediate stirring" . . . . . . . . . . . . . . . . . . . . . . . . 58

- "Continuous stirring" function . . . . . . . . . . . . . . . . . . . . . . . . . 58

- Setting the actual value correction . . . . . . . . . . . . . . . . . . . . . 59

- Adjustment of level control . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

- Procedure following power failure . . . . . . . . . . . . . . . . . . . . . . 60

- Emergency cooling in the event of a sensor fault . . . . . . . . . . 61

- Anti-Icing protection by means of low pressure monitoring. . . 61

- Different variants for cooling start delay . . . . . . . . . . . . . . . . 62

- Integrated multifunction-time relay . . . . . . . . . . . . . . . . . . . . . 63

- Enter the SIM PIN for the ESGSM-001. . . . . . . . . . . . . . . . . . 65

General measures when using electronic control systems . . . 66

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page 2 Page 3

105871 - WTS-200 31.05.2021105871 - WTS-200 31.05.2021