2FOR SERVICE ASSISTANCE, CALL 800-433-0708 OR VISIT JOHNDOW.COM

WARNING

WARNING

DANGER

Important Safety Information

Read user's manual and this safety information before using this fuel station.

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

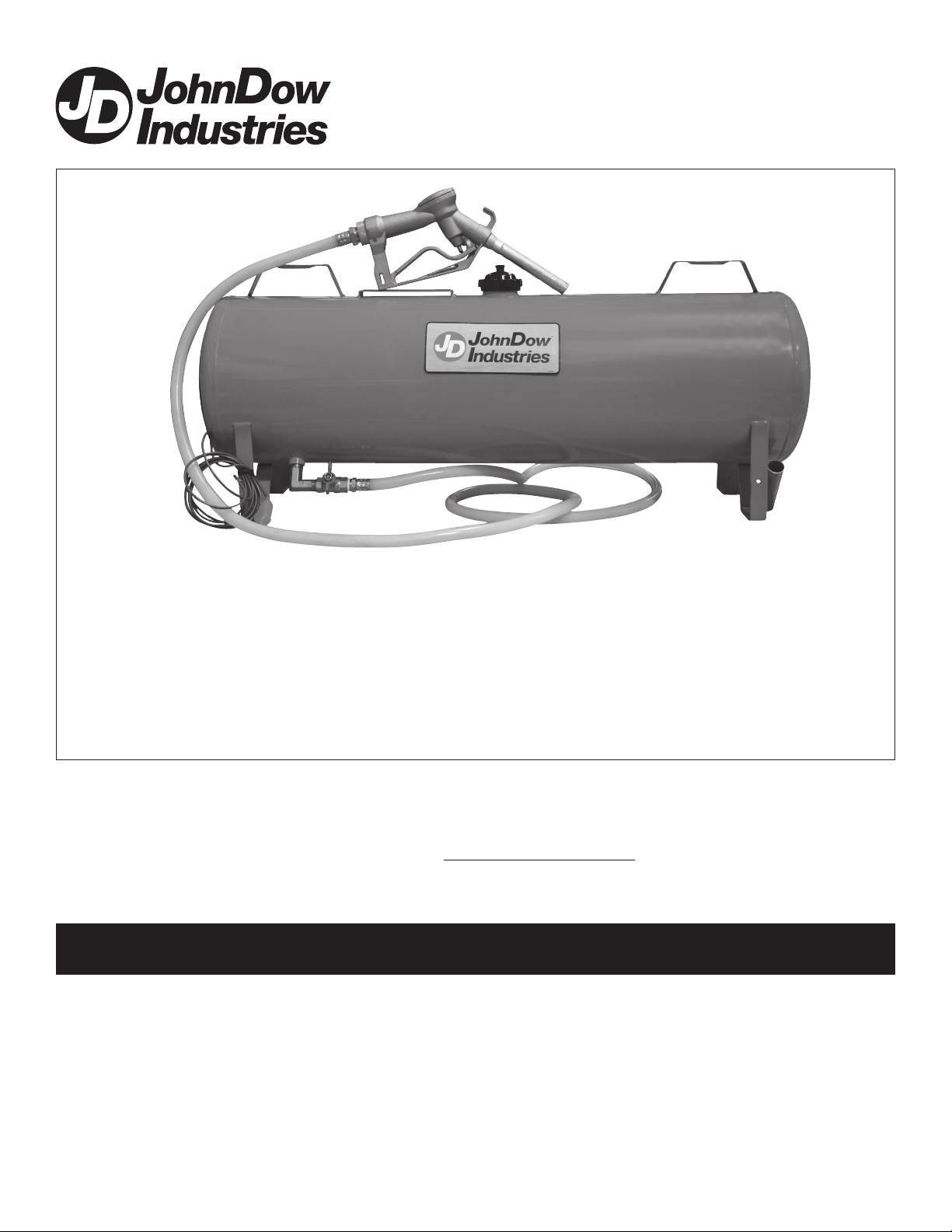

The use of this product includes the

handling of gasoline.

DANGER GASOLINE

EXTREMELY FLAMMABLE

VAPORS CAN EXPLODE

HARMFUL OR FATAL IF SWALLOWED

• Keep container closed.

Static charge and container lling warnings.

• Place container in horizontal position on the ground when

lling.

• Dissipate any static electricity from your body by

touching a metal surface away from the service station

nozzle and prior to removing service station nozzle from

dispensing pump.

• Keep service station nozzle in contact with tank while lling.

• Monitor ow to prevent spills and overlling.

• Fill slowly to prevent buildup of static charge.

Use, transportation, and storage warnings.

• Conrm all users are trained on safe working practices

and comply with any and all regulations for using,

transporting, and storing gasoline.

• Conrm all ttings and connections are tight and leak-free.

• Do not modify this fuel station or its components.

• Perform the entire closure procedure after lling and

before transporting.

• Do not place inside a vehicle trunk or inside passenger

cabin.

• Secure or strap fuel station to a trailer or truck bed.

• If swallowed, do not induce vomiting. Call physician

immediately.

• Do not siphon by mouth.

• Avoid prolonged breathing of vapors.

• Keep out of reach of children.

• Do not store in vehicle or living space.

• Store and use in well-ventilated area.

• Vapors can ignite by a spark or ame source many feet away.

• Keep away from ame, pilot lights, stoves, heaters, electric

motors, and other sources of ignition.

• Do not smoke near or while using this product.

• Do not re-enter vehicle while lling. Re-entry can

cause static buildup on person and create spark.

• Do not use electronics or mobile phones while

using this fuel station.

• Do not use funnels to ll or dispense fuel with this

fuel station.

• If re starts, do not remove service station nozzle.

Back away immediately.

• Use ground wire to equalize static charge potential

between receiving equipment and this tank.

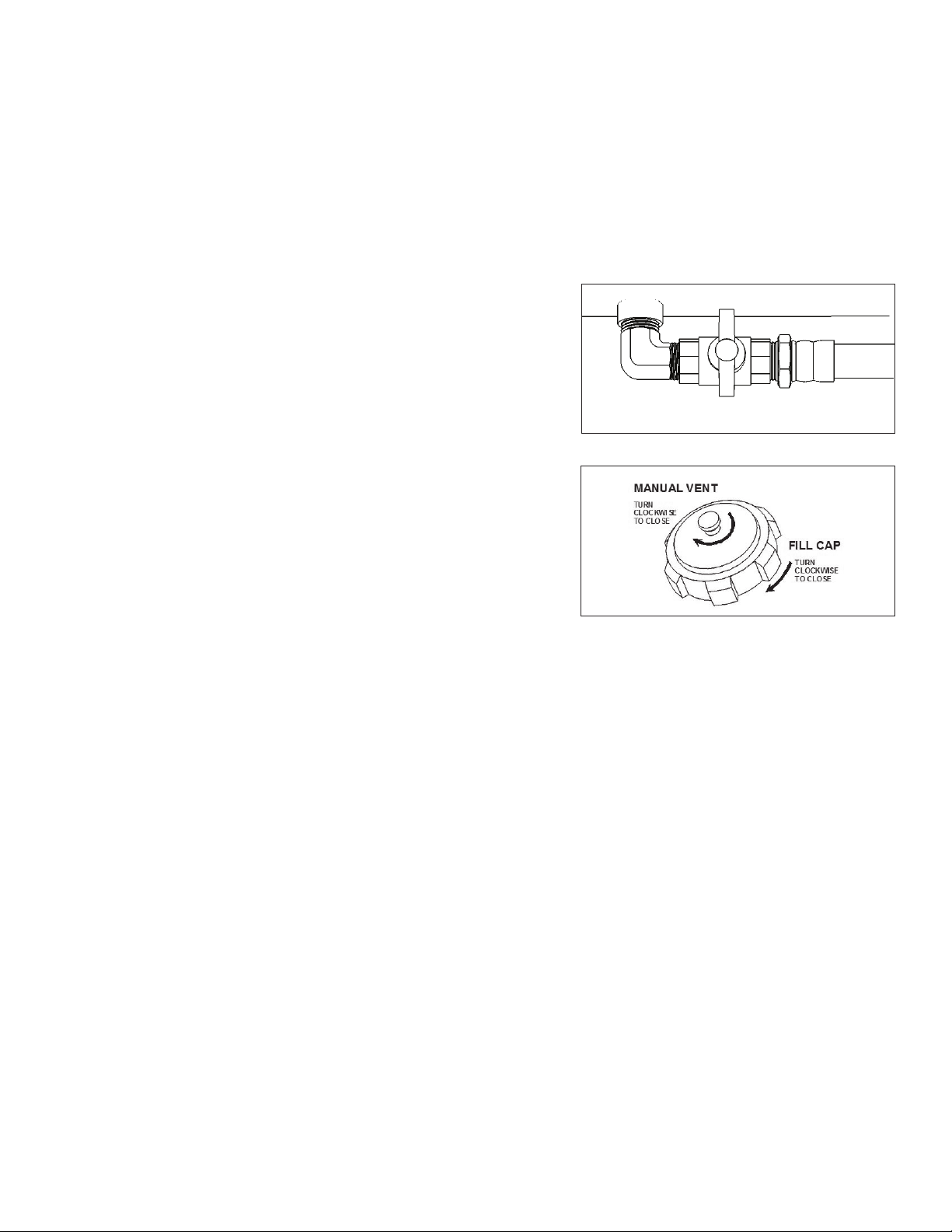

• Open ll cap manual vent screw slowly to release

internal pressure prior to opening valve and nozzle.

• Use care when lifting to prevent loss of control or

injury. Seek assistance to avoid strain or injury.

• State and local regulations vary for the transportation

of gasoline. It is the vehicle operator's responsibility

to review and comply with all federal, state, and local

regulations regarding gasoline transportation.

• Do not store in direct sunlight.

• Do not store in an attached garage connected to a

residence or dwelling.