Adaptive JUNIOR User manual

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 1

JUNIOR User Guide

Version 1.04

09th Jan 2019

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 2

Contents

1 Hardware 3

1 1 Introduction 3

1 2 Electrical Specification 3

1 3 Board Overview 4

1 4 Electrical Installation 5

1 5 Temperature Sensors 8

1 6 Fan Interface 8

1 7 Alarm Interface 8

1 8 RS232 Interface 8

1 9 BOOT / UPDATE USB Interface 8

1 10 Solid State Relay Driver (SSR) 8

1 11 COM USB Interface 9

1 12 Mechanical Dimensions 9

2 Software 10

2 1 Introduction 10

2 2 Minimum PC System Requirements 10

2 3 Installing the Software 10

2 4 JUNIOR Quick Setup Guide 10

3 Overview of HMI Display 11

4 Using the Software 12

4 1 Starting the Software and Connecting the Controller 12

4 2 Software Flow 12

4 3 Alarm Configuration Pages 13

4 3 1 Temperature Sensor Alarm Configuration Page 13

4 3 2 Fan Alarm Configuration Page 14

4 4 Alarm Status Page 15

4 5 Control Page 16

4 5 1 Manual Control Mode 16

4 5 2 Thermostat Control Mode 17

4 5 3 PID Control Mode 18

4 5 4 PID Auto Tune Mode 18

4 5 5 PID Basics Explained 19

4 6 Plot Window 20

4 7 Fan Configuration Page 22

4 8 Temperature Configuration Page 23

4 8 1 Using NTC Thermistors 23

4 8 2 Using K Type Thermocouples 23

4 8 3 Optional Calibration 24

5 Appendix 1 JUNIOR Communication Interface 25

5 1 Serial Protocol and Settings 25

5 2 Commands, Register Set and Limits 25

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 3

1. Hardware

1.1. Introduction

The Adaptive JUNIOR is a PID capable pulse width modulator intended for thermoelectric cooler or heater

applications requiring either uni- or bi-directional operation The Adaptive JUNIOR thermoelectric controller features

all the hardware and software necessary to complete standalone heating or cooling applications based on

thermoelectric devices (TEG) The board is also capable of driving isolated solid state relays in higher power AC

applications The controller allows users to easily evaluate a thermoelectric set up with the help of the auto tuning

facility and make decisions once the behaviour of the system is known It offers an on-board micro USB and RS232

connection allowing direct interface to a PC for easy programming and evaluation Users can download the latest

version of the Adaptive HMI control software to configure and monitor applications using the JUNIOR board

The board features include:

• RS232 and USB programming interface

• Four thermocouple or NTC sensor inputs

• Two operating mode feedback LEDs

• Manual set temperature

• Three fan driver output

• Alarm output

• Solid state relay (SSR) output

• Thermoelectric driver output

1.2. Electrical Specification

The electrical parameters for the Adaptive JUNIOR board are shown in Table 1 Electrical Specification below

Input voltage range

11

–

48V DC

Maximum Load

15 A

Control temperature

range

-

5

0°C to +

2

50°C

Operating

temperature

-

2

0°C to +

50°C

Compatible fan

2, 3 and 4 wire fans

Fan output voltage range

11

–

48V DC

Compatible sensors

K

-

type, NTC

Communication interface

USB 2 0, RS232

Temperature control accuracy

+/

-

0

1 C°

Table 1. Electrical specification

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 4

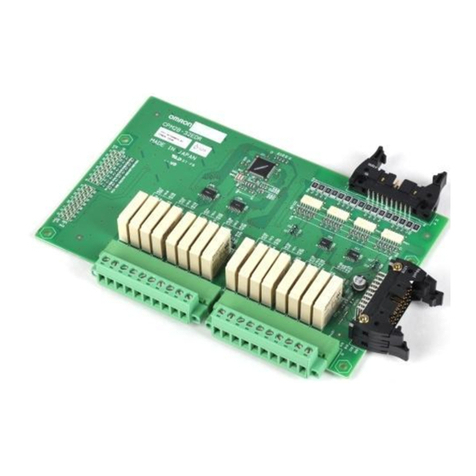

1.3. Board Overview

Figure 1 shows the Adaptive JUNIOR connections details and features, which are further detailed in Table 2

Figure 1. Board Connections and Functions (Top View)

ID

Function

Comment

1

Sensor Input

NTC and K

-

type thermocouples

2

Fan driver interface

Supports generally available fans

3

Power Input

Main power

to the board

4

Power Output

Thermoelectric Module or Assembly PWM power

5

Alarm output

SPDT relay contacts

6

Serial interface

RS232 level interface

7

BOOT

interface

USB 2 0 interface (micro USB connector)

–

Firmware

upgrade only

!

8

SSR driver output

3 3V level PWM output to drive DC/AC solid state relays

9

SD card interface

Log data in offline mode

10

LCD interface

Optional

LCD display to monitor parameters in offline mode

11

Service mode

Special boot mode activated if jumper fitted (eg Firmware upgrade)

12

Fan 1 direct power

Fan 1 directly powered from the power input connector if jumper fitted

13

Fan 2 direct power

Fan

2 directly powered from the power input connector if jumper fitted

14

Fan 3 direct power

Fan 3 directly powered from the power input connector if jumper fitted

15

Display control 1

Various functions

16

Display control 2

Various functions

17

Service mod

e control

Special boot mode trigger (eg Firmware upgrade)

18

Analog control

Manual set temperature control in offline mode

19

Current limit fuse

Auto mini blade fuse (58V DC)

20

Status LEDs

Visua

l feedback Green: normal operation, Alternating: alarm,

Red: shutdown

21

Display control 3

Various functions

22

Serial Interface

USB 2 0 interface (micro USB connector)

–

Standard communication interface

23

Expansion Interface

Reserved for future use

Table 2. Connector pin functions

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 5

1.4. Electrical Installation

Figure 2 shows the required hardware for a thermoelectric control application using Adaptive JUNIOR

Figure 2. Thermoelectric Cooling Heating Application Setup

Figure 3a below, shows the recommended wiring diagram for connecting the components making up a typical

thermoelectric system To keep potential interference problems to a minimum ensure that the wires used for

connecting the power supply to the controller, and especially from the controller to the thermoelectric assembly (‘TE

OUT-‘ and ‘TE OUT+’ ), are sized correctly for the module’s power and kept as short as possible Wire lengths can be

optimised by mounting the JUNIOR controller right at the thermoelectric assembly’s connection output

Figure 3a. Wiring diagram of minimum level installation

Figure 3a shows the JUNIOR controller in a complete system setup

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 6

Figure 3b. Wiring diagram of complete installation

Figure 3c. Wiring diagram for Thermoelectric Assemblies with thermal protection.

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 7

The connectors used for integrating the board into a typical system are shown in the connector layout diagram

below

Figure 4. Connector map (top view)

Connector

ID

Pin

ID

Name

I/O

Type

Voltage

max [V]

Current max.

[A]

J1

1

SENS A or 1 + Input Sensor No 1 positive 3 3 0 001

J1

2

SENS A or 1 - Input Sensor No 1 negative 0 0 001

J1

3

SENS or 2 + Input Sensor No 2 positive 3 3 0 001

J1

4

SENS or 2 - Input Sensor No 2 negative 0 0 001

J1

5

SENS C or 3 + Input Sensor No 3 positive 3 3 0 001

J1

6

SENS C or 3 - Input Sensor No 3 negative 0 0 001

J1

7

SENS D or 4 + Input Sensor No 4 positive 3 3 0 001

J1

8

SENS D or 4 - Input Sensor No 4 negative 0 0 001

J2

1

Fan 1 or A GND (-) Output Fan 1 power negative 0 2

J2

2

Fan 1 or A PWR (+) Output Fan 1 power positive 48 2

J2

3

Fan 1 or A TACH Input Fan 1 TACH signal 3 6 0 01

J2

4

Fan 1 or A PWM Output Fan 1 PWM signal 3 6 0 01

J2

5

Fan 2 or GND (-) Output Fan 2 power negative 0 2

J2

6

Fan 2 or PWR (+) Output Fan 2 power positive 48 2

J2

7

Fan 2 or TACH Input Fan 2 TACH signal 3 6 0 01

J2

8

Fan 2 or PWM Output Fan 2 PWM signal 3 6 0 01

J2

9

Fan 3 or C GND (-) Output Fan 3 power negative 0 2

J2

10

Fan 3 or C PWR (+) Output Fan 3 power positive 48 2

J2

11

Fan 3 or C TACH Input Fan 3 TACH signal 3 6 0 01

J2

12

Fan 3 or C PWM Output Fan 3 PWM signal 3 6 0 01

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 8

J3

1

POWER IN + Input Main power positive 48 15

J3

2

POWER IN - Input Main power negative 0 15

J4

1

TE OUT + Output TE Module/Assembly + 48 15

J4

2

TE OUT - Output TE Module/Assembly - 0 15

J5

1

Alarm N O Output Alarm normally open pin 48 2

J5

2

Alarm COM Output Alarm common pin 48 2

J5

3

Alarm N C Output Alarm normally closed pin 48 2

J6

1

RS232 TXD Output Serial transmit signal ±12 0 04

J6

2

RS232 RXD Input Serial receive signal ±12 0 002

J6

3

RS232 GND Output Serial ground 0

J7

-

BOOT

/

UPDATE

USB

- USB 2 0 5 0 1

J8

1

SSR PWM Output Solid state relay PWM 3 3 0 01

J8

2

SSR GND Output Solid state relay GND 0 0 01

J9

-

Standard SD card - - - -

J10

COM USB - USB 2 0 5 0 1

J11

-

EXPANSION - Expansion Interface

(reserved for future use)

- -

Table 4. Connector Pin description and electrical parameters

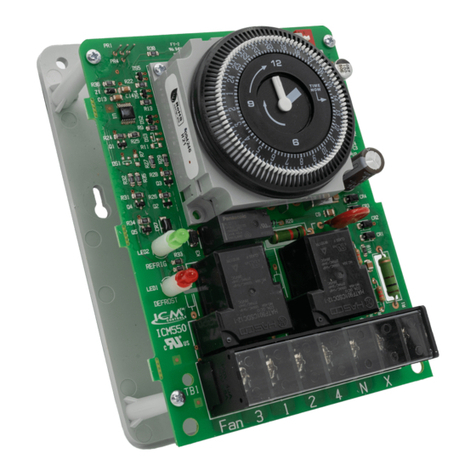

1.5. Te perature Sensors

It is recommended that adequate thermal flow is maintained to the temperature sensor Tight thermal coupling

results better temperature control accuracy The JUNIOR controller is capable to handle K-type thermocouples and

NTC resistor sensors There are four independent sensor channels available for the user

1.6. Fan Interface

There are three independent fan interfaces for the user to access on the board Each channel can be used to drive a

hot or cold side fan on a thermoelectric assembly Speed monitoring or control also supported for three and four

wire fans Signals TACH and PWM are internally pulled up to 3 3V DC and care should be taken selecting a suitable

fan

1.7. Alar Interface

An isolated relay is available for user applications requiring alarm signalling In case of an alarm condition energises

the relay pin 1 and pin 2 will make connection Pin 2 and pin 3 breaks the connection on connector J5

1.8. RS232 Interface

Serial interface is compatible with EIA/TIA-232 and V 28/V 24 specifications

1.9. BOOT / UPDATE USB Interface

The USB 2 0 compatible interface is available through a micro USB connector for future firmware updates This

interface is not intended to be used for communicating with the board It only provides a fail-safe field firmware

update facility

1.10. Solid State Relay Driver (SSR)

For special applications using AC solid state relays the JUNIOR controller provides a PWM output signal Care should

be taken to avoid any high voltage risk to the controller board In SSR control mode the PWM signal is available on

connector J8 and driven by the thermoelectric control parameters In SSR mode the thermoelectric outputs are

disabled Most SSR are suitable to use with the controller however the control voltage should allow for a 3V DC

signal (eg Part number: SSR-40 DA)

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 9

1.11. COM USB Interface

The USB 2 0 compatible interface is available through a micro USB connector providing a serial communication

interface to be used with the Adaptive HMI software or the standard serial protocol detailed within this document

1.12. Mechanical Di ensions

Figure 5. Mechanical Dimensions

Height and clearance information is shown in Table 5

Component height on the bottom side

3mm

PCB substrate thickness

1 6mm

Component height on the top side

22mm

Total height

26 6mm

Recommended minimum clearance around the board

5mm

SD card protrusion

1 5mm

Micro USB connector protrusion

1 5mm

Table 5 Board height information and Clearance

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 10

2. Software

2.1. Introduction

All Adaptive controllers have a simple text based serial interface available for configuring and setting the various

internal registers used to control the device This is straightforward when the device is simple to configure or needs

only initial setup and occasional monitoring, however for more complicated configurations, monitoring or ease of

use the Adaptive HMI can be used The HMI is compatible with all the Adaptive controller products providing one

common graphical interface that adjusts to the product it is connected to The HMI provides easy setup and

configuration but also basic plotting and data log capabilities This document describes the Adaptive HMI and how it

can be used with the Adaptive JUNIOR

2.2. Mini u PC Syste Require ents

The Adaptive Controller HMI has been designed for use with Microsoft Windows versions 7,8 & 10 It has not been

tested or verified with Windows Vista Windows XP is not supported as XP does not meet the minimum Net

requirements

The application requires Net support and during installation will check and prompt if necessary the installation of

the required Microsoft Net framework (size of the installation is approx 50MB)

Depending on the Adaptive controller product being used the PC will require either 1 free USB or RS232 serial port

Note if the PC does not have a serial port a USB to serial port adapter may be used

2.3. Installing the Software

To install the software you must have admin rights for the user account Locate the installation package, unzip if

necessary to a temporary location and run the setup exe installation file Follow the on-screen instructions provided,

note if the Microsoft Net version needs to be upgraded you will be prompted to download or obtain it before

continuing Once installed a new Adaptive HMI icon will be placed on the desktop and in the All Programs menu

2.4. JUNIOR Quick Setup Guide

The user is encouraged to read this manual fully to familiarise themselves with the operation, however for those

already familiar with the Adaptive HMI and JUNIOR operation this section serves as a quick reminder for setting up a

new JUNIOR controller

1) Wire up the supply and thermistor / thermocouple to the sensor D input on the JUNIOR Connect the USB

cable or RS232 port to the PC, switch on and start the HMI

2) Select the temperature sensor type being used on the Temperature Config page and enter the Steinhart

coefficients if using a thermistor See 4 8 Temperature Configuration Page

3) Connect one or more fans to the board and configure the type and voltage supply using the Fan

Configuration page, see section 4 7 Fan Configuration Page Note: Ensure the jumpers P11, 12 & 13 are fitted

if needed

4) Configure and enable any desired temperature and fan alarms, see sections 4 3 1 Temperature Sensor

Alarm Configuration Pageand 4 3 2 Fan Alarm Configuration Pages

5) Set the Control operating mode to off, see section 4 5 Control Page

6) Switch off the JUNIOR, connect to the Thermoelectric Cooler Module (TEC), the hot and cold side fans,

reapply power and start the HMI

7) Reconnect the HMI to the JUNIOR, verify the temperature sensor and fans are working correctly

8) Set the Control operating mode and setpoint, see section 4 5 Control Page

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 11

3. Overview of HMI Display

The HMI display is split into three main sections as detailed in the table and diagram below;

The live display is visible at all times and shows the important operating variables The menu buttons are used to

swap the configuration area between the various pages that can be used to view alarms, status, allow settings to be

configured or the operating mode to be changed On connection the HMI detects the connected product and

automatically configures the displays and menu options to suit allowing easy connection to different products and

firmware versions

Live Display

This shows the current values of the device such as temperature, drive voltage and

current, mode and status This is typically updated every second

Menu Buttons

These buttons select the various configuration

and alarm pages available for the device

The number and type will vary according to the device that is connected

Configuration

This area shows the available configuration or alarm parameters that can be changed

Figure 6 Exa ple HMI display layout

Whenever an item has been edited or changed on the HMI an ‘Apply’ button appears, click to apply the new values

or flip to a different page and back to ignore and restore the original value If a value is entered that exceeds the

limit for the item in question it will simply revert to the previous value

Figure 7 Apply button appears when settings are changed

Live Display Section

Configuratio

n

Menu Buttons

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 12

4. Using the Software

4.1. Starting the Software and Connecting the Controller

The JUNIOR has RS232 and USB ports, either of which can be used to connect the JUNIOR to a PC for configuration

and control If using the USB serial port, a USB cable must be plugged in and the JUNIOR powered on before the HMI

is started, so that it detects the USB port If using the RS232 serial port simply connect it to the PC If the PC does not

have a free serial port, a USB to serial port adapter can be used instead Whichever port is chosen, if it is not visible

in the drop-down list double check the connection and power, and if using either of the USB types verify that the

correct USB drivers have been loaded

To start the HMI, double click on the Adaptive HMI shortcut icon or select it from the start menu

Adaptive group This will bring up the connection window where the serial port being used can be selected Select

the port from the available port list and click the connect button On successful connection the main display will

appear otherwise a communication error message will be displayed if there are problems talking to the unit If so

double check the connection cable, power and that you have selected the correct port connected to the JUNIOR

Figure 8 HMI connection screen

4.2. Software Flow

The HMI software provides four main options depending on the product that it is connected to; 1 live monitoring of

the variables and alarm status, 2 configuration of the alarm limits and enables, 3 selection of the control mode 4 and

configuration / calibration of the connected temperature sensors and fans1 A plotting page is also provided to view

trends and allow logging to file

The menu section of the display is arranged so that the most frequently used pages are shown at the top and lesser

used below When configuring a device for the first time the menu is normally worked in reverse upwards as the

configuration of the sensors should be completed before attempting to use the device in an operational mode The

menu items vary according to the product connected but the Alarm Status button will always be topmost, see Figure

6Error! Reference source not found. Whenever an active alarm is present in the system and the Alarm Status page

is not on display, its button will flash to indicate the presence of an alarm which the user should investigate

When the HMI successfully connects to a device the Alarm Status page is automatically displayed

1 Options depend on product being used e g Fans available on JUNIOR

Select the port being

used and click connect

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 13

4.3. Alar Configuration Pages

The JUNIOR has configurable alarms for each sensor that can be connected, giving two alarm configuration pages;

the first for the temperature sensors and the second for the fans The specific temperature or fan is selected by

using the selection buttons available

Each alarm has individual trip threshold, Enable, Relay and Shutdown options If the Relay option is selected any

enabled alarm that trips will activate the onboard relay for the duration that the alarm is present This relay can be

used to signal externally connected equipment for example a light stack or sounder When shutdown is enabled for

an alarm, and it trips, the output drive is switched off and remains latched off until the operating mode or power is

cycled

Note: The configurable alarm limits cannot be set beyond the limits as specified in the JUNIOR datasheet

4.3.1. Te perature Sensor Alar Configuration Page

Two configurable alarms are available for each temperature sensor detailed below Up to four sensors can be

connected and the alarms individually configured using the A, B, C or D sensor selection buttons at the top right of

the configuration page – see Figure 9 below

Note: the alarms only operate if a sensor is enabled on its configuration page irrespective of the ‘alarm enables’

configured on this page.

Figure 9 Exa ple JUNIOR Te perature Alar configuration page

Alarm Settings

Alarm Type

Description / Cause

Low Temp

°C

Sets lower temperature limit Alarm trips when the measured temperature falls below this value

High Temp

°C

Sets upper temperature limit

Alarm trips when the measured temperature rises above this value

Alarm Enables

Result on limit exceeded

Enable

Sets the alarm state while limit is exceeded

Relay

Activates the onboard

r

elay for the duration that the alarm is present

Shutdown

Switches output drive off until reset by control mode being switched

to

off or board power

cycled

Alar

m Limits

Alarm Enables

Sensor Selection

Alarm Type

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 14

4.3.2. Fan Alar Configuration Page

Up to four configurable alarms are available for each connected fan as detailed below Fan speed alarms are only

available for 3 & 4 wire fans that have their tacho output connected Up to three fans can be connected and the

alarms individually configured using the A, B or C fan selection buttons at the top right of the configuration page –

see Figure 10 below

Note the alarms only operate if a fan is enabled on its configuration page irrespective of the alarm enables

configured on this page.

Figure 10 Exa ple JUNIOR Fan Alar configuration page

Alarm Settings

Alarm Type

Description / Cause

Current

(mA)

Sets maximum fan current limit

Alarm trips when the measured

current exceeds t

his value

Voltage

(V)

Sets

maximum fan voltage limit

Alarm tri

ps when the measured voltage exceeds

this value

Speed High

(RPM)

Sets the

upper rotational speed limit Alarm trips if the fan speed rises above this value

2

Speed Low

(RPM)

Sets the lower rotational speed limit Alarm trips if the fan speed drops below this value

2

Alarm Enables

Result

on limit exceeded

Enable

Sets the alarm state while limit is exceeded

Relay

Activates the onboard

r

elay for the duration that the alarm is present

Shutdown

Switches output drive off until reset by control mode being switched

to

off or board power

cycled

2 Only available for 3 and 4 wire fans providing a tacho output signal

Alarm Limits

Alarm Enables

Fan Selection

Alarm Typ

e

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 15

4.4. Alar Status Page

Figure 11 shows a typical alarm page for JUNIOR It displays the current status of the alarms for up to four

temperature sensors and three fans3 When an alarm is active the text indicates the condition, and is highlighted in

red The latched alarms for shutdown and fault are indicated separately A latched fault indicates an internal fault

has occurred and the unit should be power cycled to clear it

The alarms are updated once every second and clear automatically when the alarm condition clears except the

shutdown or fault which have to be cleared either by switching the control mode to off or power cycling the unit

Figure 11 Exa ple JUNIOR Alar status page

Alarm Status

3 Alarms are only valid for the sensors or fans that are connected and enabled

Alarm Type

Alarm Status

Description / Cause

Latched

Alarms

Shutdown Active

At least one alarm with shutd

own option selected has tripped or Internal fault

has occurred

Fault Active Indicates an internal fault has occurred

Temperature

Sensors

Sensor A

Sensor B

Sensor C

Sensor D

Low The measured temperature value has fallen below the Low Temp limit value

High The measured temperature value has risen above the High Temp limit value

Fault The sensor is short circuit, open circuit or not connected

Fans

Speed Low The fan speed has fallen below the Speed Low limit

High The fan speed has gone above the Speed High limit

Current Fault The average bridge current exceeds the Current High limit value

Voltage Fault The maximum bridge voltage exceeds the Voltage High limit value

Latched Alarms

Temperature Alarm

Fan Alarms

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 16

4.5. Control Page

Figure 12 Control screen showing PID settings

The control page provides access to the three Junior operating modes; Manual, Thermostat and PID These are used

with the temperature feedback from sensor D to maintain the temperature of the external device to the required

setpoint The Off mode is provided to switch off the control and output bridge completely An auto-tune option is

provided to aid the automatic configuration of the PID gain settings, depending on the system being controlled it will

generally allow the operator to quickly set an initial PID tuning that can then be fine tuned for performance

The output drive is also flexible, allowing bi-directional output for the TEC which is capable of both heating and

cooling or uni-directional control for single heating or cooling elements A third option is the ability to drive a logic

level TRIAC module via the auxiliary output The output mode is only selectable when the controller is in the Off

mode Care should be taken to ensure that the connected device is compatible with the selected output drive

method

Note: Off mode is also used for clearing shutdown alarms

4.5.1. Manual Control Mode

This is an open loop mode that allows the user to set the drive output at

a fixed value of its maximum The temperature sensor connected to

sensor D is not used as there is no temperature feedback, likewise the

setpoint entered is a percentage of output instead of degrees C

This mode would normally be used to confirm the operation of the

heating, cooling or heating/cooling module that is attached, or for a

system that requires a constant heat input where its effect from its

external environmental is very low

The actual output value is also determined by what output mode has been selected see Table 6 and Figure 14 below

Note the output mode can only be changed when the control mode is set to Off Before changing modes ensure that

the module connected is suitable for the polarity chosen

Required Temperature

Operating Mode

Output Option

Mode

Settings

Figure 13 Manual operating ode

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 17

S

etpoint 0 to 100 % of

f

ull input voltage

Output mode

0%

50%

100%

(TEC)

-

ve & +ve

Full negative

output

0v

Full positive output

(Other) +ve only

Zero output

50% of positive

output

100 % of

positive

output

(Other) TRIAC

0% duty cycle

50% duty cycle

100 % duty cycle

Table 6 Output drive polarity based on output ode and drive level

4.5.2. Ther ostat Control Mode

This mode works in the same way that a mechanical thermostat would

except that it has programmable hysteresis and dead band controls It

maintains the temperature measured on sensor D’s input to the setpoint

entered using the values entered for hysteresis and dead band

Hysteresis is used in systems to stop the control from continually

switching back and forth when the temperature is close to the setpoint

In a mechanical system this reduces wear and tear of the parts and also

energy Wear is less of a problem in modern systems but energy and

switching are still important

Dead-band is similar to hysteresis, but where hysteresis is used to prevent the output switching unnecessarily, dead-

band switches off the output completely while the temperature is within its window

The switching on point for the heater is (setpoint – dead-band – hysteresis) and for switching on the cooler (setpoint

+ dead-band + hysteresis) The heater switches off at (setpoint – dead-band) and the cooler switches off at (setpoint

+ dead-band)

Examples of typical output switching for both these modes is shown in the diagram below Note to make the

switching points clearer in the diagram below, the heater will always be on below 23°C and the cooler always on

above 27°C

Figure 16 Exa ple configuration shown hysteresis and dead-band for bidirectional drive

23

25

27

Setpoint

°C

2°C hysteresis without dead

-

band

23

27

25

24

26

Setpoint

°C

1°C hysteresis with 1°C dead

-

band

Heater on

Heater switch on/off

Cooler on

Cooler switch on/off

Figure 15 Ther ostat operating ode

Figure 14 Selecting the output drive ethod when

the control ode is OFF

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 18

4.5.3. PID Control Mode

This mode provides access to Proportional, Integral and Differential

control (PID) In this mode the output is continuously adjusted based

on feedback from temperature sensor D and the P, I & D terms to

maintain the setpoint accurately

The controller can also be used in PI or just P control with lower

accuracy by setting the I or D terms to zero To use this mode simply

enter the P, I and D terms as necessary If you are setting up a new

system it is recommended to use the auto tune mode described below

and then fine tune the values for performance If you are manually

tuning the PID loop then note that the values entered during tuning can often cause the system to oscillate and also

drive the output bridge to either limit very easily, so could easily damage process product

4.5.4. PID Auto Tune Mode

Tuning PID control systems can be a difficult task, taking significant time to produce the best compromise between

speed of response, minimal over shoot, tight control band and stability JUNIOR provides a built-in method to

achieve this for you The auto tune process will drive the output in both directions while measuring the resultant

response of the connected system After a number of cycles, the software will analyse the data and produce P, I and

D terms that will be suitable for most systems These settings will not be as aggressive as they could be so that

JUNIOR can tune the widest range of systems, and provide stable control It is therefore suggested that the auto

tune procedure is performed to quickly provide a usable set that can later be tuned and optimised for the expected

operating conditions

Warning: The auto tune process will provide full positive and negative step outputs, so the connected system must

be able to handle the maximum drive levels safely and without causing damage The time taken to perform the auto

tune varies with each system but is normally 5 to 10 minutes, however it may continue considerably longer if the

output of the system is low or faulty The system should be supervised until the auto tune process has completed.

Tips for the auto tune process

•Before starting the tuning process ensure that you have tested all the sensor inputs and output connections

that will be used and that they are working correctly Note the outputs can be driven fully positive and

negative easily by using the manual control mode to test

•Tune the system when it is at or close to its normal operating conditions

•Use the plot window to observe sensor D output and the bridge current This will give you visual feedback of

the process and see the cyclic steps being produced

To start the auto tune select the control page, press the Auto Tune

button and click apply, see Figure 18 The process will now start and

will complete after a minimum of three cycles have been observed or

stop at ten if the measurements are noisy or uneven4 If ten cycles

pass, it indicates that the auto tune algorithm could not determine the

measurements correctly and the mode will switch to off If this is the

case verify the connections including the polarity of the temperature

sensors and output drive and repeat if necessary

4 Note if the measurements are low or unobservable it may continue indefinitely

Figure 17 PID Operating ode

Figure 18 Start of the Auto Tune process

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 19

When the auto tune completes successfully the P, I and D

gain terms will be automatically updated with the results

and the control mode will swap to PID Figure 19 shows

the plot after tuning, you can see the end of the last tuning

cycle and then the transient to the new setpoint value

The system should now be tested for transient response

and at the expected extremes of the system range to

ensure it remains stable at all times The tuning results can

now be used as a starting point for finer tuning to increase

system performance

Warning: As an algorithm is being used to perform the auto tune and cannot be exposed to all the disturbances or

adjustments possible, it is up to the user to confirm the tuning is suitable Over temperature, under temperature

and over current alarms should always be employed in the system to ensure adequate protection to the user and

equipment from oscillatory or prolonged full-scale outputs.

4.5.5. PID Basics Explained

The PID control ethod works by first calculating the error between the actual and desired te perature (setpoint –

sensor D feedback). This error is then ultiplied by the P (Proportional) gain value to give an output that is

proportional to the error. This output will reduce the resulting error and so on. However, this has a li itation as there

ust be an error present to produce an output to aintain the te perature. The larger the drive that is required the

larger the error is needed to produce it. The P gain could be increased to reduce the error but repeatedly doing so will

eventually cause the syste to oscillate as the output is driven strongly on the s all errors. Proportional control will

give output that will overshoot the setpoint and always re ain short of the desired te perature. It is not suited to

situations that have large variations in the load.

The I (Integral) ter is used to reduce the re aining error left by the P ter . It does this by accu ulating the error

over ti e (integrating) and adding the result to the output. As the te perature reaches the setpoint and the error

beco es too s all to have any effect on the P ter the I ter beco es do inant and continues to reduce the error

to zero. Although this results in little or no error it co es at the cost of speed as the syste response is reduced.

The final option to control the output is to look at the change of the error over ti e, this is the Differential and it is

adjusted using the D ter . When the error isn’t changing uch the output fro this ter will be low, however if

there is sudden disturbance or the setpoint is adjusted the resulting error will change sharply. This large change over

a short period will provide a strong output to quickly ove the te perature, and as the te perature starts to ove

towards the setpoint the rate of change will start to reduce, reducing the output drive. This has the effect of being

able to quickly respond to changes without overdriving the output as the error reduces.

Tuning a syste is finding the right co bination of PI or PID values that produce the best response. For exa ple, too

uch P will give overshoot, too large I will reduce the response speed and too uch D will a plify any noise present

in the syste . Incorrect values will also lead to instability and oscillation of the te perature around the setpoint.

Figure 19 End of Auto Tune sequence

Adaptive® JUNIOR – Technical and HMI User Guide

REV 1 04 20

4.6. Plot Window

Figure 20 Realti e plotting and logging

The HMI provides basic plotting and logging facilities that can be used to check the operation of the system or

monitor the performance It is not intended for production or extended logging as the log is maintained in one plain

text file with minimum validation

Up to two traces can be selected using the drop-down lists Line 1 & 2 The items are sampled once a second and

added to the trace If logging has been selected they are also recorded to the text file that was selected The items

selected can be changed at any point, but on doing so the trace is cleared before plotting resumes with the new

items If the items are changed whilst logging to a file is in progress the logging simply carries forward with the new

items being logged, causing a discontinuity in the log file

The display options settings affect how the scope data is displayed this no effect on logging

Display Option

Effect

Show

Scope

D

isplays the scope in a window below the main application display

Auto scale

Increases or decreases the Y axis

range so that all the recorded Y values fit within the axis

Clear data

E

rases the current data from the trace, using this when Auto Scale is selected cause

s the axis to

expand the range to fit

Time Span

This c

an be used to adjust the plot

s

X axis from

1 minute to 24 hours, this can be done at any

point and does not cause any loss of data as the data is stored in a rolling 24-hour buffer

Trace

Sele

ction

arm

Display Options

Table of contents

Other Adaptive Controllers manuals

Popular Controllers manuals by other brands

LAE

LAE AR2-27 Instructions for use

Grundfos

Grundfos Alldos Vaccuperm VGB-103 Installation and operating instructions

Faro Barcelona

Faro Barcelona 33974 installation guide

Redarc

Redarc SBI12-LLD manual

artisan

artisan Achronix Bitporter user guide

Minebea Intec

Minebea Intec CSD-918 Series operating instructions